Professional Documents

Culture Documents

Audit Checklist For Construction Hsems (Pt. Matrik Jaya Unggul) - Agustus 2017

Uploaded by

FalistaAnggiStyadhikaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Audit Checklist For Construction Hsems (Pt. Matrik Jaya Unggul) - Agustus 2017

Uploaded by

FalistaAnggiStyadhikaCopyright:

Available Formats

AMMONIA UREA II PROJECT DOC. NO.

: 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 1 / 16

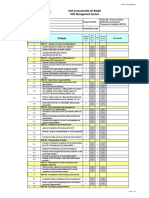

1. AUDIT CHECKLIST FOR CONSTRUCTION HSEMS

Client : PT. ADHI KARYA (PERSERO),TBK Month Of Inspection : NOVEMBER 2017

Project : AMMONIA UREA II Project No. : 201485

Subcontractor : PT. MATRIK JAYA UNGGUL Line Item Rating Evaluation : 1

Cons. Manager : SUJONO 3 - Exceeds Minimum Requirements

Safety Coor. : CLARA 2 - Meets Minimum Requirements

Auditor : FALISTA ANGGI S 1 - Needs Minor Improvement

Date : NOVEMBER 21th, 2017 0 - Totally Unacceptable

NOTE: Use N/A for no entry NOTE: Wt. = 1 to 10 Lo = 1 / IMPACT / 10 = Hi

NO. DESCRIPTION WEIGHT SCORE

1 HSE Policy 20

1.1 s the Subcontractors Corporate HSE Policy be signed by Top

10 10

Management?

1.2 Is the Subcontractor's Corporate HSE Policy posted in prominent

10 10

locations?

2 Safety Management Organization 61

2.1 Is a HSE Organization established? 10 10

2.2 Is a full - time QHSE Mgr./Coordinator assigned? 8 8

2.3 Are the duties and responsibilities of each the following persons clearly

defined? 8 8

* Project Manager

* Construction Manager 8 8

* QHSE Manager/ Field HSE Manager 8 8

* HSE Officer 5 5

* Construction Supervisors 5 5

* Foreman 3 3

* Worker 2 2

2.4 Is the HSE Organization adequately staffed? 4 4

3 HSE Committee 39

3.1 Is a HSE Committee established with adequate representation from

5 5

Subcontractor?

3.2 Are the objectives of the Committee clearly defined? 5 5

3.3 Are the operating rules of the Committee defined? 5 5

3.4 Are the activities of the Committee carried out in accordance with the

5 5

operating rules?

3.5 Are the HSE Committee Meeting conducted regularly and in timely

7 7

manner?

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 2 / 16

NO. DESCRIPTION WEIGHT SCORE

3.6 Are matters decided at the meeting conveyed to all personnel

7 7

concerned?

3.7 Are records of the meetings and the activities of the Committee recorded

5 5

and retained?

4 HSE Administration 48

4.1 Written HSE program plus project rules 5 5

4.2 HSE program enforced by mgmt/Supervisor 10 10

4.3 HSE Coordination Mgr - Authority, Qualified 5 5

4.4 Personnel injury log - accurate, complete 2 2

4.5 Accident investigation/reports 3 3

4.6 Weekly HSE report 3 3

4.7 Loss Prevention inspections performed 5 5

4.8 Hazards anticipated 5 5

4.9 Accident Statistics 10 10

5 Jobsite Information 16

5.1 Posting jobsite warning poster 3 3

5.2 Do you have HSE internal meetings? 5 5

5.3 Are there medical service and first-aid equipment, stretchers and

4 4

emergency vehicles available?

5.4 Is Fire Fighting, Clinic/Hospital/Ambulance phone number being posted? 4 4

6 Work Permitsand JSA 22

6.1 Obtained as required / monitored 5 5

6.2 Smoking controlled 3 3

6.3 Fire extinguisher - as required on permit 2 2

6.4 Personal protective equipment used 2 2

6.5 Supervision present as required 5 5

6.6 Client requirements - HSE precautions / hazards explained to workers 5 5

7 Fire Prevention/Protection 0

7.1 Adequate fire extinguishers for hazard 0 0

7.2 Proper type and location 0 0

7.3 Fire watches trained 0 0

7.4 No smoking signs posted 0 0

7.5 Inspections & maintenance of extinguishers-monthly 0 0

7.6 Fires/Extinguisher use - reported 0 0

7.7 Storage of flammable material - labeled 0 0

7.8 Containers grounded 0 0

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 3 / 16

NO. DESCRIPTION WEIGHT SCORE

7.9 Wooden materials stored properly 0 0

7.10 Flammable Materials stored properly 0 0

7.11 Used metal jerry cans with covers 0 0

7.12 Used metal fuel drums 0 0

7.13 Fuel transfer 0 0

7.14 Muster point free from obstruction 0 0

7.15 Emergency Sirens 0 0

8 Personal Protective Equipment 21

8.1 Head protection - overhead hazards 2 2

8.2 Eye protection - chipping, grinding, etc 2 2

8.3 Foot protection - heavy, sharp object 2 2

8.4 Hearing protection - over 85 dB/8 hours 2 2

8.5 Hand protection - sharp objects, splinters 2 2

8.6 Respiratory protection - hazardous dust, gas etc. 2 2

8.7 Skin protection - acid, caustic, etc 2 2

8.8 Safety hardness (tied off) - over 2 meter high 5 5

8.9 Proper clothing 2 2

9 Safety Schedule Meetings 15

9.1 Are safety and Schedule Meetings carried out periodically with adequate

5 5

representation from subcontractors?

9.2 In addition to topics regarding coordination of the working Schedule and

problems involving conflicts of interest between Subcontractors, are all 5 5

safety topics and problems discussed at the meeting?

9.3 Are matters decided at the meeting conveyed to all personnel

5 5

Concerned?

10 Safety Procedures / Safety Rules 25

10.1 Are the following procedures and regulations prepared and available

* Safety Regulations? 10 10

* Emergency Preparedness? 10 10

* Work Execution Procedures for General work and specific work 5 5

11 Safety Education and Training 52

11.1 Are the procedures and Materials prepared and available for the training? 10 10

11.2 HSE induction for new entrant 5 5

11.3 HSE training for manager and supervisor 5 5

11.4 HSE training for specific hazardous work 5 5

11.5 Refresh Safety education 5 5

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 4 / 16

NO. DESCRIPTION WEIGHT SCORE

11.6 Fire and First Aid Training 5 5

11.7 Is the safety education and training carried out by competent instructors

5 5

in timely manner?

11.8 Are the records of safety education and training retained? 3 3

11.9 Are the workers who received safety education and training and identified

3 3

with distinguishing badge or colors

11.10 Do all workers including supervisors and foreman attend the meeting?

3 3

(e.g. safety talk/tool box meeting)?

11.11 Are the contents of toolbox meeting/safety talk appropriate to ensure safe

3 3

work activities?

12 Construction Tools and Equipment 25

12.1 Are tools and equipment inspected prior to start of the work and then

3 2

periodically by qualified mechanics?

12.2 Are defective tools & equip. immediately repaired or removed from the

2 2

work site?

12.3 Is the power disconnected and any pressure discharged before

3 2

maintenance of power tools and equipment?

12.4 Are abrasive wheels or cutting discs changed by qualified workers, and

2 2

tested a minimum of 3 minutes prior to use?

12.5 Is a cracked or damage abrasive wheel or cutting discs destroyed? 1 1

12.6 Are tools and equipment operated properly in regard to any limiting

3 2

conditions, such as permissible speed, load, etc.?

12.7 Are all electrical or mechanical safe guards for rotating or moving parts in

3 2

use?

12.8 Is proper electric wiring and grounding for power tools and tools used in

3 2

explosion hazardous locations?

12.9 Is proper personal protective equipment (gloves, safety goggles, face

3 2

shield, etc.) used?

12.10 Are workers forbidden to wear loose or frayed clothing and gloves when

handling or operating rotating or moving part tools or equipment, or when 2 2

exposed to contact with moving parts?

13 Heavy Equipment 16

13.1 Operator qualified, licensed 3 3

13.2 Regular inspection and maintenance 3 3

13.3 Wheels chocked when parked on grade 1 1

13.4 Speeding controlled as posted 1 1

13.5 Dump beds chocked up during repairs 1 1

13.6 Backup alarms provided on all equipment 3 2

13.7 Signalmen as needed 1 1

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 5 / 16

NO. DESCRIPTION WEIGHT SCORE

13.8 Fire extinguishers-minimum cover radius at the same floor with type ABC 1 1

13.9 Engine off when re-fuelling 2 2

14 Chemical Handling and Use 0

14.1 Have workers involved in handling chemicals, which are potentially

0 0

hazardous received pre-job training?

14.2 Are procedures for use and handling of the chemicals and emergency

0 0

procedures provided?

14.3 Is personal protective equipment such as safety garment, glove respirator

0 0

etc. and a shower and eye for emergency use is provided?

14.4 Are the chemicals properly stored in a non combustible warehouse with

good ventilation, an impermeable floor washing and drain facilities and air 0 0

conditioning, if required?

14.5 Is the warehouse equipped with warning signs and locked to avoid

0 0

unauthorized entree?

14.6 Are all containers libeled with the chemical's name, ingredient, and

0 0

cautions for storage and handling?

14.7 Are logs of the chemicals (names, Volume and stored, dates) retained? 0 0

15 Safety Inspection/Audit 19

15.1 Are the Safety Inspection procedure and check list Prepared and

5 5

available?

15.2 Are Safety Inspection at the site carried out regularly according to the

2 2

inspection procedures by * Site Manager / Construction Manager

* Site HSE Manager 2 2

* HSE Officer 1 1

15.3 Are the above listed individual authorized to halt operation and use

3 3

facilities in emergency or imminent danger situation?

15.4 Are the results of the safety inspection recorded and corrective actions

3 3

confirmed?

15.6 Is a safety audit by a third party or a safety consultant from

3 3

Subcontractors Home Office periodically carried out?

16 Accident Investigation and Reporting 19

16.1 Are the accident investigation procedures prepared and Available? 5 5

16.2 Is the reporting procedure for an accident established? 5 5

16.3 Is a near-miss (property damage, MVA, fire/explosion) accident log-up-to-

4 4

date, reported and is a report mandatory?

16.4 Is an analysis of cause or causes or an accident carried out and are

5 5

measures to be taken to prevent similar accident reported?

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 6 / 16

NO. DESCRIPTION WEIGHT SCORE

17 Safety Promotion (+Awards) 12

17.1 Is safety bulletin board displaying the safety performance of

3 3

Subcontractor and safety slogan etc.?

17.2 Are the following notices posted in prominent location in the site? 3 3

* Site Office Rules

* Emergency network for fires and accidents with address and telephone

numbers

17.3 Are safety posters posted in appropriate location? 3 3

17.4 Are warning signs, danger signs, caution signs and Instruction sign

3 3

appropriately displayed on the job site?

18 Explosives 0

18.1 Qualified operators and supervision 0 0

18.2 Proper transport vehicles 0 0

18.3 Local laws and regulations observed 0 0

18.4 Storage magazines constructed per regulation or as recommended 0 0

18.5 Experience personnel handling explosive at all times 0 0

18.6 No Smoking sign posted at right places 0 0

18.7 All personnel familiar with signals properly used at all times 0 0

18.8 Inspection after each shot 0 0

18.9 Proper protection and accounting for all explosive at all time 0 0

18.10 Proper Disposition of wrapping, waste and scrap 0 0

18.11 Advise residents nearby of blasting cap danger 0 0

18.12 Check radio frequency hazards 0 0

19 Motor Vehicles 11

19.1 Regular inspection and maintenance (Pre-Trip Inspection for Light

3 3

Vehicle on Daily Basis)

19.2 Lubrication Qualified Operators 1 1

19.3 Local and state vehicle laws and regulations observed 1 1

19.4 Brakes, lights, warning devices in good condition 1 1

19.5 Weight limit and load controlled 1 1

19.6 Personnel carried in a safe manner 1 1

19.7 Is all glass in good condition? 1 1

19.8 Are back-up signals provided? 1 1

19.9 Are fire extinguishers installed where required? 1 1

20 Garages and Repaired Shops 0

20.1 Fire hazard available 0 1

20.2 Dispensing of fuels and lubricants 0 1

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 7 / 16

NO. DESCRIPTION WEIGHT SCORE

20.3 Good house keeping 0 1

20.4 Lighting 0 2

20.5 Carbon Monoxide dangers. 0 1

20.6 Are all fuels and lubrications in proper containers? 0 3

20.7 Proper ventilation 0 1

21 Work Site Documentation 5

21.1 Is the following documentation prepared, updated and Retained? 5 5

*Training and education record

* Safety Inspection and audit record

* Instruction records for corrective action

* Inspection records of equipment and tools

* Equipment Maintenance records

* Hoisting/Lifting apparatus log book

* Electric Equipment log book

* Safety meeting records

* Medical Examination Records

* Accident investigation records

* Work permit records

* Workers and operators licenses log book

* Insurance Certificates

22 Ionizing Radiation 0

22.1 Are procedures for work involving ionizing radiation provided, in

0 0

accordance with statutory and / or company Regulations?

22.2 Is any work involving ionizing radiation devices mainly Executed during

0 0

off-peak hours or night, and obtained the work permit system?

22.3 Is a qualified (licensed) supervisor and experienced workers assigned to

0 0

the work?

22.4 Are all persons involved in radiation activities obliged to carry personal

0 0

radiation mattering devices at all times?

22.5 Are radiation meter evaluation and calibration intervals specified and

0 0

recorded on the site?

22.6 Is the work area protected against unauthorized entry by barricade and

0 0

warning signs?

22.7 Is a safe distance specified? 0 0

22.8 Is the handling and storage of radioactive source and emergency

procedures specified in accordance National (BATAN )or International 0 0

standards?

22.9 Are storage areas for ionizing radiation hazards equipped with relevant

0 0

warning sign and locked to avoid unauthorized entre?

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 8 / 16

NO. DESCRIPTION WEIGHT SCORE

23 Barricades 8

23.1 Floor opening planked over or barricaded 1 1

23.2 Roadways and sidewalk effectively protected 2 2

23.3 Adequate lighting provided 2 2

23.4 Traffic controlled 3 1

24 Transportation 21

24.1 Employee transport adequate seating 5 2

24.2 Seat belt use enforced 5 2

24.3 Tires, lights, etc. maintained 2 1

24.4 No riding back of open trucks without proper seats 2 1

24.5 Traffic regulation enforced 3 1

24.6 Driver qualified/licensed 2 1

25.7 Operational car passed permit 2 1

25 Concrete Construction 20

25.1 Form properly installed and braced? 3 3

25.2 Adequate shoring, plumbed, and cross-braced? 3 3

25.3 Shoring remains in place until strength as attained? 1 2

25.4 Proper curing period and procedure? 2 2

25.5 Check heating devices? 2 2

25.6 Mixing and transport equipment supported and traffic planned and noted? 3 2

25.7 Adequate runways? 2 2

25.8 Protection from cement dust? 2 2

25.9 Is the work place be kept neat and orderly 2 1

26 Steel Erection 0

26.1 Safety nets or planked floors 0 0

26.2 Taglines for tools 0 0

26.3 Fire hazards at rivet forge and welding operations 0 0

26.4 Floor opening covered and barricaded 0 0

26.5 Ladders, stairs, or other access provided 0 0

26.6 Hoisting apparatus checked 0 0

27 Scaffolding 0

27.1 Dismantling/erection supervised 0 0

27.2 Designed properly for height/loading 0 0

27.3 Connections secured 0 0

27.4 Platform and walkway min. width 40 cm 0 0

27.5 Scaffold tied to structure every 20 feet 0 0

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 9 / 16

NO. DESCRIPTION WEIGHT SCORE

27.6 Platform free of debris 0 0

27.7 Base pads used/casters locked 0 0

27.8 Guardrails in good condition no knots, splits 0 0

27.9 Mobile scaffolds use in motion, no riders 0 0

27.10 Ladders access provided/used 0 0

27.11 Suspended scaffolds-hand railed, stable 0 0

27.12 Anchored, safety belts used 0 0

27.13 Qualified Inspector Scaffolding & Qualified Scaffolder 0 0

27.14 Scaffold Tag Displayed 0 0

28 Excavation/Trenching/Shoring 21

28.1 Supervised/inspected daily- competent person 5 5

28.2 Access/egress 1 0

28.3 Shoring/sloping-Adequate for soil type 4 2

28.4 Barrier and warnings 1 1

28.5 Spoil clearance over 2 from edge 2 2

28.6 Adjacent structures shored 2 2

28.7 U/G lines identified and located hand dig 2 2

28.8 Equipment kept clear of excavation edge 2 2

28.9 Checked for flammable/toxic gas 2 2

29 Cranes and Lifting 0

29.1 Current certification 0 0

29.2 Loads/radius indicator as required 0 0

29.3 Safety latches (hooks) 0 0

29.4 Condition of wire ropes, slings, chain 0 0

29.5 Condition of shackles-no makeshift devices 0 0

29.6 Qualified rigger/Signalman 0 0

29.7 Proper use of outriggers/Supports 0 0

29.8 Tag lines used 0 0

29.9 Inspection and maintenance monthly/annual 0 0

29.10 Power lines at safe distance minimum 10 feet 0 0

29.11 Lifting Plan Calculation (Including Crane Layout Position) 0 0

29.12 Operator Lisence (SIO) 0 0

29.13 Anti Two Block System 0 0

30 Electrical System 28

30.1 Service panel: a) Fused 5 5

b) 3-Wire distribution 5 2

c) Grounding 5 5

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 10 / 16

NO. DESCRIPTION WEIGHT SCORE

30.2 Hold tags and lockout used 5 2

30.3 Warning signs posted/enforced 5 1

30.3 U/G electrical protected 3 3

31 Electric Arc Welding 0

31.1 Are all welders qualified? 0 0

31.2 Are welding machine, accessories and tool inspected at carry-in daily? 0 0

31.3 Before start of work and periodically? 0 0

31.4 Is proper insulation electrode holders used? 0 0

31.5 Is an automatic electric shock prevention devices furnished on A.C arc

welding machines? (when the arc is stopped, no load voltage on the 0 0

output becomes 30 volt or less within 5 second, see note below)

31.6 Is personal protective equipment provided for welder? 0 0

31.7 Is a welding booth or shields installed to prevent emission of welding ray,

0 0

and scatter of spark, molten melt, etc.?

31.8 Is ventilation system provided for welding work in confined space and

0 0

poorly ventilated locations?

31.9 Is the electrode disconnected from the holder when the welder leaves? 0 0

31.10 Are fire extinguishers provided near the work place? 0 0

31.11 Prior to welding work, is any combustible material around and / or under

0 0

the work place removed?

Note: Automatic electric shock prevention devices are necessary for

Welding surrounded by electric conductors, such as the inside of vessel,

Pipe, duct etc. and in wet condition.

32 Welding/Cutting 0

32.1 Secured cylinders upright 0 0

32.2 Gauges removed when moved 0 0

32.3 Hoses-condition 0 0

32.4 Fire extinguisher ABC 0 0

32.5 Operators protective equipment used 0 0

32.6 Shields and spark catchers installed 0 0

32.7 Grounding close to work station 0 0

32.8 Cable condition/roll up 0 0

32.9 Permit obtained as required 0 0

32.10 Equipment off when not in use 0 0

33 Abrasive Blasting/Painting 0

33.1 Operator hood/Air supplied 0 0

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 11 / 16

NO. DESCRIPTION WEIGHT SCORE

33.2 Air filter CO monitor, high temperature alarm 0 0

33.3 Operators PPE 0 0

33.4 Painters use of PPE 0 0

34 Health and Welfare 21

34.1 Medical facilities 4 3

34.2 Toilet facilities minimum 1 per 20 3 2

34.3 Washing facilities / sanitary conditions 3 1

34.4 Ambulance/emergency phone number posted 2 1

34.5 Rescue equipment / personnel trained 4 2

34.6 Toxic chemical protection labeled, MSDS 5 4

35 Ladders Ramps and Stairs 0

35.1 Ladders inspected frequently 0 0

35.2 Ladders designed and used for the task 0 0

35.3 Secured at top/base level and on firm footing 0 0

35.4 Side rails extend 3 above top support 0 0

35.5 Rungs not over 12 on center-req. spacing 0 0

35.6 Ramp cleaned 0 0

35.7 Stairways properly build- 0 0

35.8 Guardrails provided 0 0

35.9 Openings covered labeled or railed 0 0

36 Housekeeping/Material Handling 14

36.1 Good site layout 3 1

36.2 Site Access/Dust controlled 2 1

36.3 Trash containers/covers used 1 1

36.4 Material stacked and stable 1 1

36.5 Flammable & Combustible storage/access clear 3 1

36.6 Timber de-nailed/picked up 1 1

36.7 Passageways clear at all times 1 1

36.8 Proper manual material handling 2 1

37 Steel/Pipe Erection 0

37.1 Perimeter guarding 0 0

37.2 Platforms/floors w/in 30 0 0

37.3 Tagline used 0 0

37.4 Floor opening cover/labeled 0 0

37.5 Ladders or stair provided/used 0 0

37.6 2 connecting bolts before releasing beam 0 0

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 12 / 16

NO. DESCRIPTION WEIGHT SCORE

37.7 Erection properly supervised 0 0

37.8 Vertical rebar covered 0 0

37.9 Safety hardness tied off over 6 high 0 0

38 Power Tools 7

38.1 Correct voltage 1 1

38.2 Properly grounded 1 1

38.3 Properly guarded at all times 1 1

38.4 Cable/hose, plug, connectors in good condition 1 1

38.5 Inspection/Maintenance-daily/monthly 2 1

38.6 Correct disk for grinding 1 1

39 Hand Tools 5

39.1 Correct tool for the job 1 1

39.2 Correct use 1 1

39.3 Inspection 2 1

39.4 No makeshift devices 1 1

40 Powder Actuated Tools 0

40.1 Eye protection 0 0

40.2 Ear protection 0 0

40.3 Control of cartridges authorized persons 0 0

40.4 Equipment handling manufacturer recommendation 0 0

40.5 Certified operator 0 0

40.6 Inspection and maintenance 0 0

41 Air Compressors/Generators 5

41.1 Pressure valve/Mufflers 1 1

41.2 Air pressure gauges in working order 1 1

41.3 Hoses and connection/Cords/Grounding 1 1

41.4 General condition 1 1

41.5 Correct coupling/secured 1 1

42 Flammable Cases and Liquids 0

42.1 All containers clearly identified 0 0

42.2 Proper storage practices observed 0 0

42.3 Fire hazard checked 0 0

42.4 Proper storage temperatures and protection 0 0

42.5 Proper types and number of extinguishers nearby 0 0

42.6 Carts for moving cylinders 0 0

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 13 / 16

NO. DESCRIPTION WEIGHT SCORE

43 Shut-Down or Maintenance Work 0

43.1 Are work execution procedures established? 0 0

43.2 Is a work permitting system established? 0 0

43.3 Are roles and responsibilities for work, inspection and subcontractor

0 0

clearly defined?

43.4 Have workers involved in the work received instruction and training for

0 0

the work

43.5 Are sufficient preventive measures for fire and explosion furnished? 0 0

43.6 Is an evacuation system including a warning system such as siren etc.

0 0

established?

43.7 Has any residue and pressure in vessel, tank or pipeline been

0 0

discharged?

43.8 Has the power source been cut off and the power distribution panel

0 0

boards locked?

43.9 Has blind isolation of the pipeline been installed, and confirmed and are

0 0

tags with warning exhibited?

43.10 When gas cutting is used on an existing pipeline or equipment has there

0 0

residue been discharged and gas been purged by inert gas?

43.11 Are proper tools and equipment such as explosion proof or Non-sparking

0 0

one used?

43.12 Is a meeting held daily to coordinate the work schedule and any

0 0

complicated work conditions in a limited or narrow area?

43.13 If nitrogen is used for purging or sealing are proper measures and

0 0

warning to prevent suffocation accidents provided?

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 14 / 16

2. SUMMARY OF SAFETY AUDIT

Project : AMMONIA UREA II PROJECT

Subcontractor Audited : PT. MATRIK JAYA UNGGUL

Date of Audit : AGSUTUS 21th, 2017

Location : UREA, DEMIN AREA, AMMONIA BASSIN

GENERAL :

Kesiapan Bekerja di ketinggian harus selalu diperhatikan (akses, lifeline, pengunaan full body

harness)

II. Value

NO AUDIT CHECKLIST WEIGHT SCORE VALUE

1 Safety Policy 20 20 100,00%

2 Safety Management Organization 61 61 100,00%

3 Safety Committee 39 39 100,00%

4 Safety Administration 48 48 100,00%

5 Jobsite Information 16 16 100,00%

6 Work Permits and JSA 22 22 100,00%

7 Fire Prevention/Protection 0 0 0,00%

8 Personal Protective Equipment 21 21 100,00%

9 Safety Schedule Meetings 15 15 100,00%

10 Safety Procedures / Safety Rules 25 25 100,00%

11 Safety Education and Training 52 52 100,00%

12 Construction Tools and Equipment 25 19 76,00%

13 Heavy Equipment 16 15 93,75%

14 Chemical Handling and Use 0 0 0,00%

15 Safety Inspection/Audit 19 19 100,00%

16 Accident Investigation and Reporting 19 19 100,00%

17 Safety Promotion 12 12 100,00%

18 Explosives 0 0 0,00%

19 Motor Vehicles 11 11 100,00%

20 Garages and Repaired Shops 15 10 66,67%

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 15 / 16

NO AUDIT CHECKLIST WEIGHT SCORE VALUE

21 Work Site Documentation 5 5 100,00%

22 Ionizing Radiation 0 0 0,00%

23 Barricades 8 6 75,00%

24 Transportation 21 9 42,86%

25 Concrete Construction 20 19 95,00%

26 Steel Erection 0 0 0,00%

27 Scaffolding 0 0 0,00%

28 Excavation/Trenching/Shoring 21 18 85,71%

29 Cranes and Lifting 0 0 0,00%

30 Electrical System 28 18 64,29%

31 Electric Arc Welding 0 0 0,00%

32 Welding/Cutting 0 0 0,00%

33 Abrasive Blasting/painting 0 0 0,00%

34 Health and Welfare 21 13 61,90%

35 Ladders Ramps and Stairs 0 0 0,00%

36 Housekeeping/Material Handling 14 8 57,14%

37 Steel/Pipe Erection 0 0 0,00%

38 Power Tools 7 6 85,71%

39 Hand Tools 5 4 80,00%

40 Powder Actuated Tools 0 0 0,00%

41 Air Compressors/Generators 5 5 100,00%

42 Flammable Cases and Liquids 0 0 0,00%

43 Shut-Down or Maintenance Work 0 0 0,00%

Total 586 535 91,30%

PT. ADHI KARYA (PERSERO), TBK

AMMONIA UREA II PROJECT DOC. NO. : 201485 HSE PD 006

PT PETROKIMIA GRESIK

Rev. No. : 1

GRESIK - JAWA TIMUR

HSE AUDIT SYSTEM Page : 16 / 16

Total Value = TOTAL INSPECTION VALUE X 100% = YZ %.

TOTAL INSPECTION VALUE AVAILABLE

Total Value =

535 X 100%

586

Total Value = 91,30 %

PERCENTAGE RANKING

+85% Outstanding Superior Loss Control-All

75 - 85% Good Good Loss Control/Key request

70 - 75% Marginal Needs Some Improvement

60 - 69% Poor Needs Major Improvement

00 - 59% Unacceptable

AUDITORS:

1. Name Falista Anggi Styadhika Sign _______________

2. Name Erdi Wisnu Riftianto Sign _______________

AUDITY:

1. Name Clara Sign _______________

PT. ADHI KARYA (PERSERO), TBK

You might also like

- SHARQ HSE Audit ChecklistDocument10 pagesSHARQ HSE Audit ChecklistDoo PLTGU100% (2)

- Construction HSE ProcedureDocument39 pagesConstruction HSE ProcedureAli Hajirassouliha100% (1)

- Site Safety Audit ReportDocument3 pagesSite Safety Audit Reportasem sawalmehNo ratings yet

- Contractor Health Safety Information BookletDocument14 pagesContractor Health Safety Information BookletDharmendra Khatri100% (1)

- 1 WAH ChecklistDocument2 pages1 WAH Checklistvirendra kumar singhNo ratings yet

- Annual Hse ReportDocument8 pagesAnnual Hse Reportbakari hamisiNo ratings yet

- HSE Staff ResponsibilitiesDocument7 pagesHSE Staff Responsibilitiesakv9005No ratings yet

- Section B: List of Chemicals Hazardous Chemical To HealthDocument4 pagesSection B: List of Chemicals Hazardous Chemical To HealthSzaz Wani100% (1)

- ISBN Sample Site Induction Checklist 2017 06 PDFDocument2 pagesISBN Sample Site Induction Checklist 2017 06 PDFZeljkoNo ratings yet

- Waste Management ProcedureDocument7 pagesWaste Management Procedureaone mothupiNo ratings yet

- ISO 9001 Check List TemplateDocument32 pagesISO 9001 Check List TemplateScribdTranslationsNo ratings yet

- HSE Performance CriteriaDocument3 pagesHSE Performance CriteriaHossamKandilNo ratings yet

- Annex 06 - ODS HSE Plan 0236-22-HRR-K - Mirawa 1 Rev.3 - IGDocument47 pagesAnnex 06 - ODS HSE Plan 0236-22-HRR-K - Mirawa 1 Rev.3 - IGFahmi AbdullahNo ratings yet

- Safety FileDocument1 pageSafety FileSaikat RamNo ratings yet

- OHSAS 18001 2007 Internal Audit ChecklistDocument27 pagesOHSAS 18001 2007 Internal Audit ChecklistNaeem IqbalNo ratings yet

- Health and Safety Quarterly Audit ChecklistDocument73 pagesHealth and Safety Quarterly Audit ChecklistAnonymous sAApMNG9vw0% (1)

- SST ContractorSafetyManualDocument14 pagesSST ContractorSafetyManualTimothy DimaanoNo ratings yet

- Internal OHS Audit Methodology PDFDocument8 pagesInternal OHS Audit Methodology PDFPaul MaposaNo ratings yet

- Working at Heights ChecklistDocument3 pagesWorking at Heights ChecklistCristiane RibeiroNo ratings yet

- Training Matrix SampleDocument4 pagesTraining Matrix SampleMaurice Avicor CoccusNo ratings yet

- HS 060 Evaluation of ComplianceDocument12 pagesHS 060 Evaluation of CompliancegrantNo ratings yet

- Stop Work Authority TBTDocument9 pagesStop Work Authority TBTEeverPaul Casaclang DeLeonNo ratings yet

- Scaffolding Safety Checklist PDF enDocument3 pagesScaffolding Safety Checklist PDF enarya100% (2)

- Improvement of Al Awir Road and International City Accesses PROJECT NO: R1005/1Document10 pagesImprovement of Al Awir Road and International City Accesses PROJECT NO: R1005/1Ravi Shankar TurlapatiNo ratings yet

- f445 Hseq Ims Internal Audit ChecklistDocument14 pagesf445 Hseq Ims Internal Audit ChecklistSrikant Ch100% (1)

- CEMP Audit ChecklistDocument6 pagesCEMP Audit ChecklistNash C. UsopNo ratings yet

- Contract Environmental Management Plan: Generic Shire CouncilDocument46 pagesContract Environmental Management Plan: Generic Shire Councilmjvw100% (1)

- IMS-QHSE ChecklistDocument11 pagesIMS-QHSE ChecklistDerrick AgabaNo ratings yet

- ISO 28000 A Complete Guide - 2019 EditionFrom EverandISO 28000 A Complete Guide - 2019 EditionRating: 4 out of 5 stars4/5 (1)

- Opti Tower Health and Safety File Oct 12Document387 pagesOpti Tower Health and Safety File Oct 12Pieter HerbstNo ratings yet

- Monthly HSE PerformanceReport REV2Document2 pagesMonthly HSE PerformanceReport REV2parthaNo ratings yet

- Construction Safety Check ListDocument6 pagesConstruction Safety Check ListJeya Keeshan J KNo ratings yet

- Ensure sufficient natural and artificial lightingDocument3 pagesEnsure sufficient natural and artificial lightingMohamed MounerNo ratings yet

- Strongly Disagree Disagree Neutral 1,275 1,275 1,275 3,879 6,464 7,757 0 Slightly Agree Moderat Ely Agree Highly Agree Not Applicabl EtomeDocument4 pagesStrongly Disagree Disagree Neutral 1,275 1,275 1,275 3,879 6,464 7,757 0 Slightly Agree Moderat Ely Agree Highly Agree Not Applicabl EtomeRias Sahul0% (1)

- Lead Exposure Control PlanDocument3 pagesLead Exposure Control PlanShahzeb HassanNo ratings yet

- Contractor HSE Questionnaire: 1. GeneralDocument14 pagesContractor HSE Questionnaire: 1. GeneralAsep FirmansyahNo ratings yet

- CCC Hse ManualDocument36 pagesCCC Hse ManualFarrukh JavedNo ratings yet

- 7.2 Ror Rev#4 IsoDocument31 pages7.2 Ror Rev#4 IsoMohamed Thowfeek100% (1)

- Ge700 2020 Ga01Document1 pageGe700 2020 Ga01LucianNo ratings yet

- Excavation Procedure & Permitting GuideDocument4 pagesExcavation Procedure & Permitting GuideTengku & Wan ResourcesNo ratings yet

- Site Visitor Management PlanDocument8 pagesSite Visitor Management Planhanshul sisodiyaNo ratings yet

- HSE Safety AuditsDocument3 pagesHSE Safety Auditsvlad100% (1)

- HSE Legal and Other RequirementsDocument7 pagesHSE Legal and Other RequirementsAjas AjuNo ratings yet

- OH&S Objective Action Taken Resources Responsible Timeline Leading Indicators Lagging IndicatorsDocument1 pageOH&S Objective Action Taken Resources Responsible Timeline Leading Indicators Lagging IndicatorsdnmuleNo ratings yet

- Evolution Business Park Construction Project Safety Audit ReportDocument15 pagesEvolution Business Park Construction Project Safety Audit ReportMohamed Hadjkacem100% (2)

- 33.0 - Working On of Adjacent To A Road v3.0 EnglishDocument20 pages33.0 - Working On of Adjacent To A Road v3.0 EnglishjbdejhiuhwNo ratings yet

- CDMR94 Pre Tender H&S PlanDocument2 pagesCDMR94 Pre Tender H&S PlanVignesh KmNo ratings yet

- HSE SpecificationsDocument88 pagesHSE SpecificationsADS KİMYA Derya DelenNo ratings yet

- P-LUS-OCEMP-000: Overall Construction Environment Management PlanDocument158 pagesP-LUS-OCEMP-000: Overall Construction Environment Management PlanRafzeena100% (1)

- ERP ManualDocument11 pagesERP ManualNOR SYAHIRA SOBBRINo ratings yet

- Checklist PDFDocument6 pagesChecklist PDFVeera RagavanNo ratings yet

- Appointment Letter Temporary WorksDocument3 pagesAppointment Letter Temporary Worksjamie100% (2)

- Hand & Power Tools InspectionDocument4 pagesHand & Power Tools InspectionShashwat PandeyNo ratings yet

- Hse Manual: Date: 27-04-2009 Document : HSE-M-01 Rev : 0 Page 1 of 12Document12 pagesHse Manual: Date: 27-04-2009 Document : HSE-M-01 Rev : 0 Page 1 of 12vladNo ratings yet

- Safety Inspections How To Conduct and Document Safety InspectionsDocument10 pagesSafety Inspections How To Conduct and Document Safety InspectionsNiel Brian VillarazoNo ratings yet

- Occupational Health and Safety PolicyDocument15 pagesOccupational Health and Safety PolicyMaritsa DreyerNo ratings yet

- 704 Area Vehicle Entry ProcedureDocument11 pages704 Area Vehicle Entry ProcedureObominuru Egwonor FestusNo ratings yet

- List of Documents ISO 45001 Premium Documentation Toolkit enDocument3 pagesList of Documents ISO 45001 Premium Documentation Toolkit envirat100% (1)

- HSE Evaluation CriteriaDocument2 pagesHSE Evaluation CriteriaChan RizkyNo ratings yet

- Needed Labor For Pertamina Project RUDocument3 pagesNeeded Labor For Pertamina Project RUBAGUSNo ratings yet

- OPCO Company Profile and Facilities GuideDocument63 pagesOPCO Company Profile and Facilities Guidevangeliskyriakos8998No ratings yet

- 02-012 Working at Heights PolicyDocument7 pages02-012 Working at Heights PolicyJoachimNo ratings yet

- Managing Health and Safety in the WorkplaceDocument12 pagesManaging Health and Safety in the WorkplaceSaqib AbbasiNo ratings yet

- Sanjay Kaushik CVDocument4 pagesSanjay Kaushik CVSANJAY KAUSHIKNo ratings yet

- Joji Resume PDF UpdatedDocument5 pagesJoji Resume PDF Updatedloveson709No ratings yet

- MC-PH01-P04-06A03-SAB-MTS-CIV-000005 Method Statement of Bituminous Paint Rev.01Document16 pagesMC-PH01-P04-06A03-SAB-MTS-CIV-000005 Method Statement of Bituminous Paint Rev.01ehteshamNo ratings yet

- Syed Mazhar CV 250913Document8 pagesSyed Mazhar CV 250913Anwar SultanNo ratings yet

- Part 1Document2 pagesPart 1Mock ProjectNo ratings yet

- Ara 2018 19 PDFDocument124 pagesAra 2018 19 PDFHervian LanangNo ratings yet

- HSE Job DescriptionDocument2 pagesHSE Job Descriptionnabil awadNo ratings yet

- Unit 101-WORKING IN ENGINEERING - Copy (2) - p1-p5Document5 pagesUnit 101-WORKING IN ENGINEERING - Copy (2) - p1-p5yasirNo ratings yet

- HCML Vhse Management System SocializationDocument33 pagesHCML Vhse Management System Socializationnurwinanto01100% (1)

- Iosh and Nebosh Course ContentsDocument8 pagesIosh and Nebosh Course ContentsAJAYNo ratings yet

- UntitledDocument48 pagesUntitledAtif QamarNo ratings yet

- Safety Violation FormDocument12 pagesSafety Violation FormShah MuzzamilNo ratings yet

- Method of Statement For Concrete Surface RepairDocument13 pagesMethod of Statement For Concrete Surface RepairMohd MuksinNo ratings yet

- Curriculum Vitae: Post Applied For: Hsse AdvisorDocument5 pagesCurriculum Vitae: Post Applied For: Hsse AdvisorBalasubramaniamkamarajNo ratings yet

- Willis CNOOC HSE Management Practice-EnDocument54 pagesWillis CNOOC HSE Management Practice-EnTatak Bay Ahmed100% (1)

- CSMS BSP - Azil Revised by HakaDocument5 pagesCSMS BSP - Azil Revised by HakaIr Azil Awaludin MohsNo ratings yet

- Mohammad JavedDocument3 pagesMohammad JavedAdeniran IdrisNo ratings yet

- R-Series Overall Project Execution Plan 10.07Document73 pagesR-Series Overall Project Execution Plan 10.07Đào Văn Hoàng100% (2)

- HSE - EEMUA 160. Safety Related Instrument Systems Forthe Process IndustriesDocument2 pagesHSE - EEMUA 160. Safety Related Instrument Systems Forthe Process IndustriesAndrew BaileyNo ratings yet

- Experienced Safety Officer Seeking New OpportunityDocument3 pagesExperienced Safety Officer Seeking New OpportunitypremNo ratings yet

- Norsok Version 2019Document40 pagesNorsok Version 2019alexander ospina100% (1)

- HSE Plan - PT Anugrah Pacific KencanaDocument15 pagesHSE Plan - PT Anugrah Pacific Kencananew auctionNo ratings yet

- PT SAMPOERNA ALAM SAMUDRA HSE PlanDocument27 pagesPT SAMPOERNA ALAM SAMUDRA HSE PlanYogo Pratisto100% (1)

- Procedure-Communication, Participation & ConsultationDocument5 pagesProcedure-Communication, Participation & Consultationindrasain100% (2)

- EXP PR DI020 en R0 - 3 Operational SafetyDocument143 pagesEXP PR DI020 en R0 - 3 Operational Safetybali100% (1)

- Pre-Spud InspectionDocument6 pagesPre-Spud InspectionHany100% (2)