Professional Documents

Culture Documents

29 61-001-002 AVK015 Eng v1-0

Uploaded by

Anonymous gMgeQl1SndOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

29 61-001-002 AVK015 Eng v1-0

Uploaded by

Anonymous gMgeQl1SndCopyright:

Available Formats

AVK UNDERGROUND FIRE 29/61

HYDRANT, PN16

The Series 29/61 is a Type 1 fire hydrant suitable for use with water and neutral liquids, to a

maximum temperature of 70C. Complies with requirements of BS 750:2006 and BS EN1074-

2:2004 and EN 14339:2005, underground hydrants. Also to BS EN 1074-6 for potable (drinking)

water.

Features: Options:

! Fully maintainable.

! Ductile iron construction. ! Outlet options:

- Stainless steel or Gunmetal to BS

! 2 London round thread outlet to BS 750. 750 round thread

- Instantaneous (Morris)

! Exceeds flow requirements: - Belfast

- Kv = 92 minimum 2000l/min - London V thread

- Kv = 113 maximum 2470l/min - Internal screwed Norwegian

- Bayonet (Dublin)

! Corrosion resistant construction, compliant

with BS EN 1074-6 for disinfection

products.

! Inlet flange drilled BS EN 1092:1997,

PN10/16 Note:

It is recommended that applications in a

! Inlet is of a proprietary type. corrosive atmosphere or sited in exposed

locations use a stainless steel stem 1.4404

! Draining stopper. (316) and all exposed fasteners in A4 stainless

steel.

! Low weight design.

! WRAS approved.

The designs, materials and specifications shown are subject to change without notice due to our continuing programme of

product development.

AVK UK Limited 29/61:V1:6/2009

AVK UNDERGROUND FIRE HYDRANT 29/61

TESTS SERVICE CONDITIONS

Hydraulic test to BS 750 Maximum Working Pressure: 16 Bar.

Seat: 1.1 x PN. Body: 1.5 x PN. Operating torque test. Temperature Range: -10C to +70C.

Insulation essential for

temperatures of 0C and

APPLICABLE STANDARDS below.

Complies with BS 750:2006 Type 1. Screwed -down type

with screwed 2 round thread outlet.

Inlet flange universally drilled to BS EN 1092-2 PN10/16.

Complies with Annex ZA of BS EN 14339 in respect of

Construction Products Directive (CPD) 89/106/EEC.

WRAS approved. MATERIALS OF CONSTRUCTION

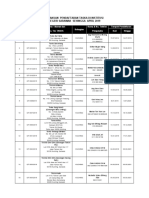

No. DESCRIPTION MATERIAL

1 Body Ductile Iron, BS EN 1563

EN-GJS-500-7.

2 Wedge Ductile Iron, BS EN 1563

EN-GJS-500-7,

GROUND

Encapsulated in EPDM

LEVEL 3 Drain plug Nylon 6.6.

150

22

4 Wedge Nut DZR brass wedge nut to

(integral) BSEN12164 CW602N.

5 Stem Stainless Steel, BS EN

16 10088 No.1.4021. Option for

15

Stainless Steel 1.4404 (316)

14

6 Body/Bonnet Seal EPDM WRAS approved.

300,0

7 Bonnet Ductile Iron, BS EN 1563

13

EN-GJS-500-7.

12

8 O-Rings/Seals NBR WRAS approved.

11 9 Thrust Collars DZR brass, BS EN 12164,

10 CW 602 N.

9

10,11,Gland Flange Ductile iron, BS EN 1563

8

12,13 Assembly EN-GJS-500-7 with bush

14 nylon 6.6 and 3 O Rings

21 7

NBR WRAS approved.

447

20 6

15,16 Stem Cap Ductile Iron, BS EN 1563

19 5 22 Assembly EN-GJS-500-7.Insert PE.

18 4 Cap screw A2 stainless.

17

17 Outlet seal NBR WRAS approved.

18,19 All Fastenings Hex head screws, cap

235,0

screws & washers Stainless

D

Steel grade A2. Option for

Stainless Steel A4.

2

20 Outlet Stainless Steel

3 1

to BS EN 10088 No. 1.4021.

21 Dust Cover Polyethylene.

318

DIMENSIONS & WEIGHTS

Ref No. DN L H2 H3 W5 Weight

With automatic mm mm mm mm Kg

Frost Valve

29-080-61-2141X1 80 318 240 447 150 21

When ordering: x=3 for gunmetal outlet and 4 for stainless steel outlet

Northampton Office Chesterfield Office

8 Rushmills, Northampton, Colliey Close, Ireland Ind. Est., Staveley,

NN 4 7YB England, UK. Chesterfield, S43 3FH England, UK.

Tel.: +44 (0) 1604 601188 Tel.: +44 (0) 1246 479100

AVK UK Limited Fax.: +44 (0) 1604 604818 Fax.: +44 (0) 1246 479200 www.avkuk.co.uk

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Experiment 1 - Moisture Content & AwDocument3 pagesExperiment 1 - Moisture Content & AwAmirah Syakira40% (5)

- D5002 Density and Relative Density of Crude Oils by Digital Density AnalyzerDocument5 pagesD5002 Density and Relative Density of Crude Oils by Digital Density AnalyzerSergey GrigoryevNo ratings yet

- Qatar Gas Painting Procedure PDFDocument99 pagesQatar Gas Painting Procedure PDFBalaji Guru100% (1)

- SPA Circular 2 of 2021Document1 pageSPA Circular 2 of 2021Anonymous gMgeQl1SndNo ratings yet

- Master Taska Di InstitusiDocument4 pagesMaster Taska Di InstitusiAnonymous gMgeQl1SndNo ratings yet

- T U B A (A P - 3 0 0 8 - F H) : Air PurifierDocument1 pageT U B A (A P - 3 0 0 8 - F H) : Air PurifierAnonymous gMgeQl1SndNo ratings yet

- AVK Couplings AdaptorsDocument16 pagesAVK Couplings AdaptorsJaveed KhanNo ratings yet

- Precision 15 7520 Laptop Owner's Manual en UsDocument84 pagesPrecision 15 7520 Laptop Owner's Manual en UsMligo ClemenceNo ratings yet

- Schedule of Rates For Building Works in Sarawak 2018 PDFDocument56 pagesSchedule of Rates For Building Works in Sarawak 2018 PDFHayatoNo ratings yet

- Precision 15 7520 Laptop Owner's Manual en UsDocument84 pagesPrecision 15 7520 Laptop Owner's Manual en UsMligo ClemenceNo ratings yet

- PDF 5dce08d437cf5 PDFDocument14 pagesPDF 5dce08d437cf5 PDFSazali YatimanNo ratings yet

- Precision 15 7520 Laptop Owner's Manual en UsDocument84 pagesPrecision 15 7520 Laptop Owner's Manual en UsMligo ClemenceNo ratings yet

- Precision 15 7520 Laptop Owner's Manual en UsDocument84 pagesPrecision 15 7520 Laptop Owner's Manual en UsMligo ClemenceNo ratings yet

- Lombok 3 Sales HandoutDocument1 pageLombok 3 Sales HandoutAnonymous gMgeQl1SndNo ratings yet

- CAPTAIN (AP-1717A) : Air PurifierDocument1 pageCAPTAIN (AP-1717A) : Air PurifierAnonymous gMgeQl1SndNo ratings yet

- Sharp Inverter Washing Machine BrochureDocument4 pagesSharp Inverter Washing Machine BrochureAnonymous gMgeQl1SndNo ratings yet

- Guide For Better Public ToiletsDocument106 pagesGuide For Better Public ToiletsElisha SorianoNo ratings yet

- Cherry, Almond & Pecan BreadDocument2 pagesCherry, Almond & Pecan BreadAnonymous gMgeQl1SndNo ratings yet

- Egg Enriched White Bread RecipeDocument2 pagesEgg Enriched White Bread RecipeAnonymous gMgeQl1SndNo ratings yet

- Abcd Eÿ GH Ij KLM No Kkÿ Ao Kbpÿ Qked RKDocument2 pagesAbcd Eÿ GH Ij KLM No Kkÿ Ao Kbpÿ Qked RKAnonymous gMgeQl1SndNo ratings yet

- Bure User - Manual EngDocument8 pagesBure User - Manual EngAnonymous gMgeQl1SndNo ratings yet

- ATLAS - Ti 8 Windows Importing and Exporting Code ListsDocument4 pagesATLAS - Ti 8 Windows Importing and Exporting Code ListsAnonymous gMgeQl1SndNo ratings yet

- ATLAS - Ti 8 Windows Importing and Exporting Code ListsDocument4 pagesATLAS - Ti 8 Windows Importing and Exporting Code ListsAnonymous gMgeQl1SndNo ratings yet

- 2020 Budget SnapshotsDocument8 pages2020 Budget SnapshotsAnonymous gMgeQl1SndNo ratings yet

- ATLAS - Ti Project Data Exchange PathsDocument6 pagesATLAS - Ti Project Data Exchange PathsAnonymous gMgeQl1SndNo ratings yet

- TaXavvy Budget 2020 Part 1Document29 pagesTaXavvy Budget 2020 Part 1Anonymous gMgeQl1SndNo ratings yet

- ATLAS - Ti 8 Windows Quick TourDocument66 pagesATLAS - Ti 8 Windows Quick TourAnonymous gMgeQl1SndNo ratings yet

- Bs 2020Document88 pagesBs 2020limmingjunNo ratings yet

- 2018 Hilux MaxcheckDocument10 pages2018 Hilux MaxcheckAnonymous gMgeQl1SndNo ratings yet

- Tropics City BrochureDocument11 pagesTropics City BrochureAnonymous gMgeQl1SndNo ratings yet

- Take5 Budget2020 Malaysia 12oct2019Document15 pagesTake5 Budget2020 Malaysia 12oct2019Anonymous gMgeQl1SndNo ratings yet

- Range RoverDocument96 pagesRange RoverAnonymous gMgeQl1Snd100% (1)

- PFDocument19 pagesPFAnonymous gMgeQl1SndNo ratings yet

- Application of QUAL2K For Water Quality Modeling of River Ghataprabha (India)Document6 pagesApplication of QUAL2K For Water Quality Modeling of River Ghataprabha (India)EnvironmentaldavidNo ratings yet

- Quantitative Determination of Total Hardness in Drinking Water by Complexometric EDTA TitrationDocument14 pagesQuantitative Determination of Total Hardness in Drinking Water by Complexometric EDTA TitrationJoza Juan100% (2)

- Guía de Mantenimiento Motor ContinentalDocument81 pagesGuía de Mantenimiento Motor ContinentalJean MunozNo ratings yet

- Class III WW Review Questions - 1Document8 pagesClass III WW Review Questions - 1Marj MarjNo ratings yet

- 02 05Document9 pages02 05Cecep Permana NingratNo ratings yet

- Physicochemical Analysis of Borewell Water SamplesDocument7 pagesPhysicochemical Analysis of Borewell Water SamplesThirulogachandar AsokanNo ratings yet

- Assessing Your Site for Fruit Tree PlantingDocument29 pagesAssessing Your Site for Fruit Tree PlantingDandee Florence ManggaoNo ratings yet

- Spa Quick Start Guide Balboa VS/GS100 System For VL 200 Topside ControlDocument2 pagesSpa Quick Start Guide Balboa VS/GS100 System For VL 200 Topside Control薛泽绵No ratings yet

- Palm Jumeirah: KSB SolutionsDocument2 pagesPalm Jumeirah: KSB SolutionsBily SunNo ratings yet

- Mass Balance CalculationsDocument3 pagesMass Balance CalculationsSiphoNo ratings yet

- Key Notes: Chapter-10 Human SettlementsDocument4 pagesKey Notes: Chapter-10 Human SettlementsAaqib JavaidNo ratings yet

- Volatile Content of Coatings: Standard Test Method ForDocument3 pagesVolatile Content of Coatings: Standard Test Method ForramakantNo ratings yet

- Dynamic Model of A Scrubber Using Aspen PlusDocument19 pagesDynamic Model of A Scrubber Using Aspen PlusAnonymous mpU5JeNo ratings yet

- Ancient and Modern Water Supply of JerusalemDocument41 pagesAncient and Modern Water Supply of JerusalemCristian PetrescuNo ratings yet

- 6 Installation System RefDocument48 pages6 Installation System Refcengiz kutukcuNo ratings yet

- Goplaganj Khulna BeelDocument11 pagesGoplaganj Khulna Beelrohana rashidNo ratings yet

- National Oilwell: Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake, Model 7838Document51 pagesNational Oilwell: Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake, Model 7838sorangel_123100% (1)

- BAC Product and Application HandbookDocument513 pagesBAC Product and Application HandbookyasserismailNo ratings yet

- UntitledDocument41 pagesUntitledHoussam RachidNo ratings yet

- Business PlanDocument183 pagesBusiness PlanVinoNo ratings yet

- 4600 ManualDocument28 pages4600 ManualAngelo Leonardo Ameri PerezNo ratings yet

- Dr. Md. Mujibur Rahman: Ahsanullah University of Science & Technology (AUST)Document6 pagesDr. Md. Mujibur Rahman: Ahsanullah University of Science & Technology (AUST)Mohaiminur ArponNo ratings yet

- Lost at Sea Exercise-Decision MakingDocument20 pagesLost at Sea Exercise-Decision MakingJohn Lorenz BelanioNo ratings yet

- Rohtas DistrictDocument107 pagesRohtas DistrictUmesh MishraNo ratings yet

- EVS 2016 Question PaperDocument5 pagesEVS 2016 Question Paperfishandrice3003No ratings yet

- Aqueena Water Filter: Group # 5Document15 pagesAqueena Water Filter: Group # 5aigoshaNo ratings yet

- Automatic Softening Plants Series Stfa: A Group of Co-Operating European Water Treatment SpecialistsDocument4 pagesAutomatic Softening Plants Series Stfa: A Group of Co-Operating European Water Treatment Specialistsitsirc67No ratings yet