Professional Documents

Culture Documents

06r Parker

Uploaded by

Anonymous YqkTPzVF0Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06r Parker

Uploaded by

Anonymous YqkTPzVF0Copyright:

Available Formats

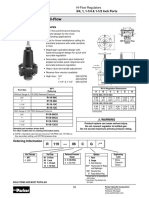

Catalog 0700P-6 Prep-Air II, 06R Series

Compact 06R Series 1/4", 3/8", 1/2" Basic 3/8" Body

06R Regulators Compact

A A

Features

Secondary aspiration plus balanced poppet provides B

PU

quick response and accurate pressure regulation.

CK

H T LO

S

O

Rolling diaphragm for extended life.

Two high flow 1/4" gauge ports can be used as

additional outlets.

Easily serviced. 1/4" NPT

Gauge Ports C

Removable non-rising knob for panel mounting (2)

E

and tamper resistance.

High Flow: 1/4" 53 SCFM

3/8" 60 SCFM

1/2" 75 SCFM D

Port Size NPT 06R Regulator

Without Gauge Dimensions

1/4" 06R113A* A B C

2.81 2.74 4.69

3/8" 06R213A* (71) (70) (119)

1/2" 06R313A* D E

With 160 PSI Gauge 1.39 6.08

(35) (154)

1/4" 06R118A*

Inches (mm)

3/8" 06R218A*

1/2" 06R318A*

Standard part numbers shown bold. For other models refer to

! WARNING

ordering information below. Product rupture can cause serious injury.

NOTE: 2.00 Dia. (51mm) hole required for panel mounting. Do not connect regulator to bottled gas.

SCFM = Standard cubic feet per minute at 100 PSIG inlet, Do not exceed maximum primary pressure rating.

90 PSIG no flow secondary setting and 10 PSIG pressure drop.

Ordering Information

06R 1 13 A * ---

Port Size Pressure Range Relief Engineering Port Type Options Preset /

1 1/4 Inch Without Gauge A Relieving Level Blank NPT Blank No Options Pressure

* Will be 1* BSPP Limited

2 3/8 Inch 11 60 PSIG L Non-Relieving L Preset

3 1/2 Inch 13 125 PSIG H Low Temp. Entered at 2 BSPT Non-Adjustable Blank None

15 250 PSIG Relieving Factory P Preset XXX* Preset

* 1/4 & 3/8 inch

With Gauge** J Low Temp. meet ISO 1179-1 Adjustable Pressure

16 60 PSIG Non-Relieving Standard. R Reverse Flow * Available Preset /

Pressure Limited

18 125 PSIG Inlet Pressure is 100 PSIG. Range, 10 to 90

21 250 PSIG For other pressures, contact PSIG in 5 PSIG

factory. increments. For

** Includes 1-1/2"

Dial Face Gauge higher pressures,

contact factory.

(Example:

065 = 65 PSIG)

Spring Type by Preset / Limited Pressure:

For Preset / Limited Pressure 10 to 25 use 30 PSI Spring

For Preset / Limited Pressure 26 to 50 use 60 PSI Spring

For Preset / Limited Pressure 51 to 90 use 125 PSI Spring BOLD ITEMS ARE MOST POPULAR.

A72 Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-6 Prep-Air II, 06R Series

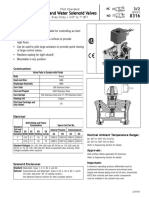

Technical Specifications 06R Air Line Regulators

Technical Information

Relief And Flow Characteristics

06R113A*

Relief And Flow Characteristics

06R213A*

A

100 100

Secondary Pressure - PSIG

Secondary Pressure - PSIG

6 6

Secondary Pressure - bar

Secondary Pressure - bar

80 80

5 5

4 60 4 60

3 3

40 40

2 2

20 20

1 1

1/4 Inch Ports 3/8 Inch Ports

100 PSIG (6.9 bar) Primary Pressure 100 PSIG (6.9 bar) Primary Pressure

0 0 0 0

10 0 10 20 30 40 50 60 70 10 0 10 20 30 40 50 60 70

Rated Flow - SCFM Rated Flow - SCFM

5 0 5 10 15 20 25 30 5 0 5 10 15 20 25 30

3 3

Flow - dm /s Flow - dm /s

n n

Relief And Flow Characteristics

06R313A*

100

CAUTION:

Secondary Pressure - PSIG

6

Secondary Pressure - bar

REGULATOR PRESSURE ADJUSTMENT 80

The working range of knob adjustment is designed 5

to permit outlet pressures within their full range. 4 60

Pressure adjustment beyond this range is also

possible because the knob is not a limiting device. 3

40

This is a common characteristic of most industrial

2

regulators, and limiting devices may be obtained

20

only by special design. 1

1/2 Inch Ports

For best performance, regulated pressure should 100 PSIG (6.9 bar) Primary Pressure

0 0

always be set by increasing the pressure up to the 10 0 10 20 30 40 50 60 70 80 90

desired setting. Rated Flow - SCFM

5 0 5 10 15 20 25 30 35 40

3

Flow - dm /s

n

06R Regulator Kits & Accessories Specifications

Bonnet Assembly Kit .......................................................... PS715P Gauge Ports (2) .................................................................... 1/4 Inch

(Can be used as additional High Flow 1/4 Inch Outlet Ports)

Control Knob ..................................................................... P04069B

Port Threads ..........................................................1/4, 3/8, 1/2 Inch

Gauges 60 PSIG (0 to 4.1 bar) ................................ K4520N14060

Primary Pressure Rating

160 PSIG (0 to 11.0 bar) .............................K4520N14160

Maximum Primary Pressure ........................... 250 PSIG (17.2 bar)

300 PSIG (0 to 20.0 bar) ........................... K4520N14300

Secondary Pressure Ranges

Mounting Bracket Kit (Includes Panel Mount Nut) ............. PS707P Standard Pressure .............................. 2 to 125 PSIG (0 to 8.6 bar)

Panel Mount Nut Plastic .....................................................P04082 Low Pressure ........................................ 1 to 60 PSIG (0 to 4.1 bar)

Metal .................................................... P04079B High Pressure ................................ 5 to 250 PSIG (0.4 to 17.2 bar)

Pressure Sensor MPS-32 .......................... (See pages C32-C38) Temperature Rating ............................. 32F to 175F (0C to 80C)

Reverse Flow Service Conversion Kit Low Temperature .............................-4F to 125F (-20C to 52C)

Relieving ......................................................................... PS708RP Weight ......................................................................... 1.6 lb. (0.7 kg)

Service Kit Relieving (Includes Poppet) ............................ PS708P Materials of Construction

Non-Relieving (Includes Poppet) ................... PS709P Adjusting Stem ......................................................................... Steel

Springs 1-30 PSIG Range .................................................P01698 Body ............................................................................................ Zinc

1-60 PSIG Range .................................................P04062 Bonnet, Piston Stem, Valve Poppet & Cap ........................ Plastic

2-125 PSIG Range ................................................P04063

5-250 PSIG Range ...............................................P04064 Collar, Knob ............................................................................ Plastic

Diaphragm ................................................................................Nitrile

Tamperproof Kit ................................................................... PS737P

Seals .........................................................................................Nitrile

Springs Poppet................................................................ Stainless

Control ...................................................................... Steel

A73 Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

You might also like

- Watts by Dixon R119 06C Specification SheetDocument2 pagesWatts by Dixon R119 06C Specification SheetGIANNo ratings yet

- HDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFDocument1 pageHDL-PSG3442-300 Filtro Solberg - Filtro de Descarga de Equipo PDFYacila AlvaradoNo ratings yet

- 4126 PRDocument6 pages4126 PRkamalNo ratings yet

- Flotect Vane Operated Flow Switches: Field Adjustable - 1 To 6 Inch Pipe, Leak Proof Body, Chemical ResistanceDocument1 pageFlotect Vane Operated Flow Switches: Field Adjustable - 1 To 6 Inch Pipe, Leak Proof Body, Chemical ResistanceMadhan MohanNo ratings yet

- Serie 87Document4 pagesSerie 87afiqaziz86No ratings yet

- B11 Data Sheet - Regulador de PresiónDocument2 pagesB11 Data Sheet - Regulador de PresiónBayronPalacioNo ratings yet

- Check Van - Literature - Hydraulic Controls Europe - HY11-3500UK - PDF - 2013 - C-9C UKDocument2 pagesCheck Van - Literature - Hydraulic Controls Europe - HY11-3500UK - PDF - 2013 - C-9C UKTruong KhacNo ratings yet

- Hydrodynamic Cable Reels - Instruction Manual PDFDocument24 pagesHydrodynamic Cable Reels - Instruction Manual PDFescupabloNo ratings yet

- PFHL - 9 Hi - Lo Gear PumpDocument2 pagesPFHL - 9 Hi - Lo Gear PumpTelassin TauilNo ratings yet

- Series CR: ApplicationsDocument6 pagesSeries CR: ApplicationsRaymond LimNo ratings yet

- Cat Pump Part List 67dx39g1iDocument4 pagesCat Pump Part List 67dx39g1iJorge M M100% (1)

- STS PDFDocument1 pageSTS PDFIman praja firmansyahNo ratings yet

- Fuel Dispensing and Transfer Filtration: Racor Filter Division EuropeDocument16 pagesFuel Dispensing and Transfer Filtration: Racor Filter Division EuropeFERNANDO LARANo ratings yet

- Aqua MagDocument4 pagesAqua MagMahua ChakrabarttyNo ratings yet

- f701 12e7gt m1 Parker Pneumatic Filter DatasheetDocument2 pagesf701 12e7gt m1 Parker Pneumatic Filter DatasheetOkti FirnawatiNo ratings yet

- Nimco Monoblock Control ValvesDocument66 pagesNimco Monoblock Control ValvesHui ChenNo ratings yet

- General Production Hose Crimper: Cc200 / Cc400 Crimpers Operators Manual With Dial Micrometer Style AdjustmentDocument18 pagesGeneral Production Hose Crimper: Cc200 / Cc400 Crimpers Operators Manual With Dial Micrometer Style AdjustmentLoki C GowdaNo ratings yet

- A10VO Regulator Teory PDFDocument45 pagesA10VO Regulator Teory PDFmohammad100% (2)

- Sure Cure Kit: Chrysler 41TE (A604), 42LE (A606)Document10 pagesSure Cure Kit: Chrysler 41TE (A604), 42LE (A606)carloaex23No ratings yet

- Hydraulic Gear Pumps: For Building and Construction Machinery ApplicationsDocument6 pagesHydraulic Gear Pumps: For Building and Construction Machinery Applicationseaglego00No ratings yet

- r119 16j Parker Air Regulator DatasheetDocument2 pagesr119 16j Parker Air Regulator DatasheetGIANNo ratings yet

- Resources Instrumentation Parker Pneumatic Prep Air II RegulatorsDocument29 pagesResources Instrumentation Parker Pneumatic Prep Air II RegulatorsAnonymous C05BLcNo ratings yet

- Despiece EMVAK CAT B3cp1120-40d7-08eDocument4 pagesDespiece EMVAK CAT B3cp1120-40d7-08eRoberto BellasNo ratings yet

- Technical Brochure: Multi-Stage Centrifugal PumpDocument4 pagesTechnical Brochure: Multi-Stage Centrifugal PumpcurlyjockeyNo ratings yet

- Eaton Fuller On Off Highway Transmissions Brochure Trsl0116 en UsDocument2 pagesEaton Fuller On Off Highway Transmissions Brochure Trsl0116 en UsSebastian Olaya0% (1)

- Parker Motor Hidráulico - TE SeriesDocument30 pagesParker Motor Hidráulico - TE SeriesFernando BorgesNo ratings yet

- Industrial Grade Sealed Unit: PVC & CPVC Compact Ball ValvesDocument2 pagesIndustrial Grade Sealed Unit: PVC & CPVC Compact Ball ValvesPoro ChanNo ratings yet

- Bombas DDDDocument3 pagesBombas DDDVladimir E. BalvinNo ratings yet

- C Series Centrifugal Pumps: Technical InformationDocument2 pagesC Series Centrifugal Pumps: Technical InformationAdriana HernandezNo ratings yet

- WJ-Series WJ-Series: Turbine Meter Instructions Turbine Meter InstructionsDocument8 pagesWJ-Series WJ-Series: Turbine Meter Instructions Turbine Meter InstructionsIndra SUdirmanNo ratings yet

- High Pressure UCV Catalog 2020Document10 pagesHigh Pressure UCV Catalog 2020МаксимNo ratings yet

- 141 150t H FrameDocument1 page141 150t H FramejassconsNo ratings yet

- 9074 Fuller Manual 8LLDocument2 pages9074 Fuller Manual 8LLpanchoNo ratings yet

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDocument2 pagesModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNo ratings yet

- Air and Water Solenoid Valves: FeaturesDocument4 pagesAir and Water Solenoid Valves: FeaturesZuñiga AntonioNo ratings yet

- Quick Exhaust Valves T70 Series: " " BSPP, NPTDocument4 pagesQuick Exhaust Valves T70 Series: " " BSPP, NPTAbhayy DevNo ratings yet

- Ecomag: Magnetic Flowmeter Primary Head For Chemicals and Process LiquidsDocument4 pagesEcomag: Magnetic Flowmeter Primary Head For Chemicals and Process Liquidsavikbhai50% (2)

- 69 LwcoDocument1 page69 LwcoAlvaro Yaciel Rodríguez LagunesNo ratings yet

- EHYD6 Hydraulic Valves HY14-2502k001Document9 pagesEHYD6 Hydraulic Valves HY14-2502k001Ahmet SaygılıNo ratings yet

- 09 - Domino Junior Logic (Sept 07)Document6 pages09 - Domino Junior Logic (Sept 07)Peter RhoadsNo ratings yet

- 2-Way Poppet SVP08-NCR: Solenoid Valves Technical InformationDocument2 pages2-Way Poppet SVP08-NCR: Solenoid Valves Technical InformationÂnderson Silva BrasilNo ratings yet

- WheelHorse D-180 Service ManualDocument71 pagesWheelHorse D-180 Service ManualKevins Small Engine and Tractor Service67% (6)

- CCF 015 - Mi4011 FAC Close Coupled 3 5 HP - WEBDocument8 pagesCCF 015 - Mi4011 FAC Close Coupled 3 5 HP - WEBJordany JimenezNo ratings yet

- B C N (None) : C-Spool H-SpoolDocument2 pagesB C N (None) : C-Spool H-SpoolPasqualeNo ratings yet

- Railstar Motor Driven Trolley - CatDocument1 pageRailstar Motor Driven Trolley - CatAde RamdanNo ratings yet

- Common Sucker Rod SpecificationsDocument1 pageCommon Sucker Rod SpecificationsMichelangeloTiberiiNo ratings yet

- Cy3 - Te MeteringDocument22 pagesCy3 - Te MeteringSilpa Asti Nura100% (1)

- FlowMon Catalogue 2 PDFDocument12 pagesFlowMon Catalogue 2 PDFsimbamikeNo ratings yet

- Air Preparation ProductsDocument6 pagesAir Preparation ProductssenamotoNo ratings yet

- Asco 8344 PDFDocument2 pagesAsco 8344 PDFOsman Lopez SalasNo ratings yet

- Air and Water Solenoid Valves: NC NODocument4 pagesAir and Water Solenoid Valves: NC NODevinNo ratings yet

- Pressure Reducing Valve (Inbuilt Strainer)Document1 pagePressure Reducing Valve (Inbuilt Strainer)Sanket SavlaNo ratings yet

- GT03 7296 3Document2 pagesGT03 7296 3Filippo SettimoNo ratings yet

- Argo Hytos-Gp1 PDocument8 pagesArgo Hytos-Gp1 PJoram Marín HernándezNo ratings yet

- Motores de Rotación ParkerDocument26 pagesMotores de Rotación ParkerSam MarmorNo ratings yet

- Feasibility Study of Combining Drilling With Casing and Expandable CasingDocument11 pagesFeasibility Study of Combining Drilling With Casing and Expandable CasingMeli CondoyNo ratings yet

- Parker TC-SeriesDocument18 pagesParker TC-SeriesSam MarmorNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Annisha Jain (Reporting Manager - Rudrakshi Kumar)Document1 pageAnnisha Jain (Reporting Manager - Rudrakshi Kumar)Ruchi AgarwallNo ratings yet

- Standard Cost EstimatesDocument12 pagesStandard Cost EstimatesMasroon ẨśầŕNo ratings yet

- Perpetual InjunctionsDocument28 pagesPerpetual InjunctionsShubh MahalwarNo ratings yet

- List of Light Commercial LED CodesDocument8 pagesList of Light Commercial LED CodesRenan GonzalezNo ratings yet

- Ks 1609Document5 pagesKs 1609krish dabhiNo ratings yet

- Yamaha F200 Maintenance ScheduleDocument2 pagesYamaha F200 Maintenance ScheduleGrady SandersNo ratings yet

- Woodward GCP30 Configuration 37278 - BDocument174 pagesWoodward GCP30 Configuration 37278 - BDave Potter100% (1)

- BSL-3 Training-1Document22 pagesBSL-3 Training-1Dayanandhi ElangovanNo ratings yet

- Gathering Package 2023Document2 pagesGathering Package 2023Sudiantara abasNo ratings yet

- Fin 3 - Exam1Document12 pagesFin 3 - Exam1DONNA MAE FUENTESNo ratings yet

- VB 850Document333 pagesVB 850Laura ValentinaNo ratings yet

- Oops in PythonDocument64 pagesOops in PythonSyed SalmanNo ratings yet

- 19-2 Clericis LaicosDocument3 pages19-2 Clericis LaicosC C Bờm BờmNo ratings yet

- Ap06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónDocument9 pagesAp06 - Ev04 Taller en Idioma Inglés Sobre Sistema de DistribuciónJenny Lozano Charry50% (2)

- SEBI Circular Dated 22.08.2011 (Cirmirsd162011)Document3 pagesSEBI Circular Dated 22.08.2011 (Cirmirsd162011)anantNo ratings yet

- CNS Manual Vol III Version 2.0Document54 pagesCNS Manual Vol III Version 2.0rono9796No ratings yet

- Finaniial AsceptsDocument280 pagesFinaniial AsceptsKshipra PrakashNo ratings yet

- Bondoc Vs PinedaDocument3 pagesBondoc Vs PinedaMa Gabriellen Quijada-TabuñagNo ratings yet

- Double Inlet Airfoil Fans - AtzafDocument52 pagesDouble Inlet Airfoil Fans - AtzafDaniel AlonsoNo ratings yet

- POM 3.2 Marketing Management IIDocument37 pagesPOM 3.2 Marketing Management IIDhiraj SharmaNo ratings yet

- SyllabusDocument9 pagesSyllabusrr_rroyal550No ratings yet

- RFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonDocument8 pagesRFM How To Automatically Segment Customers Using Purchase Data and A Few Lines of PythonSteven MoietNo ratings yet

- CE5215-Theory and Applications of Cement CompositesDocument10 pagesCE5215-Theory and Applications of Cement CompositesSivaramakrishnaNalluriNo ratings yet

- Press Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFDocument6 pagesPress Release - INTRODUCING THE NEW LAND ROVER DEFENDER PDFJay ShahNo ratings yet

- Pharmaceutical Microbiology NewsletterDocument12 pagesPharmaceutical Microbiology NewsletterTim SandleNo ratings yet

- Ahakuelo IndictmentDocument24 pagesAhakuelo IndictmentHNNNo ratings yet

- Bharat Heavy Electricals LimitedDocument483 pagesBharat Heavy Electricals LimitedRahul NagarNo ratings yet

- Criminal Law I Green Notes PDFDocument105 pagesCriminal Law I Green Notes PDFNewCovenantChurchNo ratings yet

- Change Language DynamicallyDocument3 pagesChange Language DynamicallySinan YıldızNo ratings yet

- Chapter 1 Hospital and Clinical Pharmacy Choplete PDF Notes D.Pharma 2nd Notes PDF NoteskartsDocument7 pagesChapter 1 Hospital and Clinical Pharmacy Choplete PDF Notes D.Pharma 2nd Notes PDF NoteskartsDrx Brajendra LodhiNo ratings yet