Professional Documents

Culture Documents

Detect A Fire Installation Manual Vertical

Uploaded by

hcalderonmarin0 ratings0% found this document useful (0 votes)

200 views2 pagesDetector térmico instalación.

Original Title

Detect a Fire Installation Manual Vertical

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDetector térmico instalación.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

200 views2 pagesDetect A Fire Installation Manual Vertical

Uploaded by

hcalderonmarinDetector térmico instalación.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

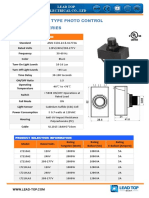

Anderson-Bolds - 216-360-9800

Series 27100, 28000

Vertical DETECT-A-FIRE Units

Installation Instructions

12.01.F

DESCRIPTION Table 2: Model Number 28021

DETECT-A-FIRE thermal detectors are UL Listed, UL of Canada

F F Spacings (in feet) Color

available upon request, and FM Approved detection and release RTI

Setting Tolerance UL ULc FM Coding

devices used in fire detection systems to activate alarms and

actuate extinguishing systems. This Rate Compensated device 140 +7/-8 50 50 30 V-Fast Black

combines the best features of both fixed temperature and

160 +7/-8 25 25 30 V-Fast Black

rate-of-rise detectors.

190 +7/-8 50 50 30 V-Fast White

ELECTRICAL RATING 210 +7/-8 25 50 30 V-Fast White

Contact 225 +7/-8 25 50 30 V-Fast White

Model

Operation on Electrical Rating 275 +10 25 50 30 V-Fast Blue

Number

Temperature Rise (Resistive Only)

325 +10 50 50 30 V-Fast Red

27120 Opens +10

5.0 Amps 125 VAC 360 25 50 30 V-Fast Red

28020 (450F Max)

450 +15 25 50 30 V-Fast Green

27121 5.0 Amps 126 VAC +15

500 50 50 30 V-Fast Orange

0.5 Amps 125 VDC

Closes 600 + 20 N/A 50 30 V-Fast Orange

2.0 Amps 24 VDC

28021 + 20

1.0 Amps 48 VDC 725 N/A 50 30 V-Fast Orange

*Although incandescent lamps are considered resistive, their inrush Note: For clean agents and CO2 supression systems, ceiling spacing

current is 10 -15 times their steady current. Do not exceed ratings. 20ft. apart unless otherwise specified.

Note: 28020 is a 2-wire device and RTI is not applicable.

LOCATION

Fitting Required for

DETECT-A-FIRE detectors are precision temperature sensors. Hazardous Model

UL, ULc Listings

They must be mounted in an area (normally a ceiling) so that: Location Numbers

and FM Approval

1. The detector spacing complies with both system Class 1*, Groups 27120-22

requirements and requirements of the agency having A, B, C, and D; 27121-20 Mount detector to a

Class II, Groups 28020-3 suitably listed fitting in

local jurisdiction.

E, F and G 28021-5 accordance with National

2. The thermal air path to the shell is not obstructed. Electric Code and/or local

Class 1*, Groups

Spacing per UL, FM, and UL of Canada is shown in Table 1 A, B, C, and D; 27120-0 authority having

and 2. Distances given are for between units on smooth Class II, Groups 27121-0 jurisdiction.

E, F and G

ceilings. Distances from partitions or walls are half that shown.

To assure that all spacing requirements are met, consult * Division 1 and 2.

the authority having local jurisdiction.

MOUNTING

Table 1: Model Number 27120*, 27121 DETECT-A-FIRE units are not position sensitive. Horizontal

and vertical detectors refer to the most common mounting

F F Spacings (in feet) Color

Toler- RTI configurations for that unit. However, each type can be

Setting ance UL ULc FM Coding mounted either horizontally or vertically depending on the

140 +7/-8 50 50 25 Fast Black application and installation requirements.

160 +7/-8 25 25 25 Fast Black INSTALLATION

190 +7/-8 50 50 25 Fast White

210 +7/-8 25 50 30 V-Fast White

225 +7/-8 25 50 30 V-Fast White

275 +10 25 50 30 V-Fast Blue

325 +10 50 50 30 V-Fast Red

360 +10 25 50 30 V-Fast Red

450 +15 25 50 30 V-Fast Green

500 +15 50 50 30 V-Fast Orange

600 + 20 N/A 50 30 V-Fast Orange

725 + 20 N/A 50 30 V-Fast Orange

* 27120 is a normally closed device and does not meet the requirements

of NFPA-72 for use as an initiating device.

Page 1 Vertical DETECT-A-FIRE Units 1-800-FENWAL-1 www.fenwalcontrols.com

Anderson-Bolds - 216-360-9800

1. Kidde-Fenwal recommends that standard 4-inch octagonal Table 3

outlet boxes be used to mount detectors.

2. Attach detector to outlet box cover through a 0.875 inch diameter Non-Hazardous Outdoor Locations

hole and using two 1/2-14NPT retainer nuts as indicated.

3. Connect system wiring to detector per Figure 3 and applicable F Fittings Required for

Model

electrical codes. Temperature UL Listings and

Number Settings

4. Ordinary Locations: The DETECT-A-FIRE Units are to be installed in FM Approval

grounded metallic junction boxes only. They are to be secured to the

boxes using two lock nuts, one on either side of the mounting plate. Mount detector to a fitting suitable

27120-0

DETECT-A-FIRE Units are not to be installed in non-metallic junction for outside use, (NEMA Type 3),

27120-22 140, 160,

boxes. in accordance with National Electric

27121-0 190, 225

5. Hazardous Locations: For Class I, Division 1 and 2 locations, install Code and/or local authority having

27121-20

the DETECT-A-FIRE unit in a listed explosion-proof enclosure with jurisdiction.

a minimum thread engagement of five full turns. No non-conductive

material is to be placed on the threaded joint of the DETECT-A-FIRE FM requires the use of a Killark Outlet Box P/N VLJX-1, with P/N

Unit or in the listed explosion-proof enclosure. For Division 2 VJH-1 cover, and P/N VBNB Gasket to satisfy Outdoor NEMA 3

locations assure that a protective ground terminal is provided in the rated installation requirements.

listed explosion-proof enclosure when flexible metal conduit is used.

6. Non Hazardous Outdoor Location: Mount the DETECT-A-FIRE in a FUNCTIONAL TEST

listed NEMA Type 3 outlet box, cover and conduit, with 1/2 - 14 NPT When used with automatic fire extinguishing systems, first

threads and a minimum thread engagement of 5 full turns. Use of disconnect the initiator/solenoid leads from the panel and

pipe plugs with RTV silicone rubber sealant, a rubber gasket and connect a 24 VDC bulb to initiator terminals in the control unit.

self-sealing screws to attach the cover, and PTFE thread seal tape Gently heat the D-A-F units with a heat gun, hairdryer or heat

on the DETECT-A-FIRE threads should be appropriate for outdoor lamp (see WARNING below). When the bulb in the control unit

applicatiions and in accordance with the National Electrical Code changes state, remove heat source and allow D-A-F unit to

and/or local authority have jurisdiction. cool. Reset control unit. Test lamp must change state and

7. Do not exceed a maxium torque without thread lubricant of stay changed after system is reset. Do not reconnect initiator

20 foot-pounds (27.1 Newton Meters). solenoid leads until all D-A-F units have cooled below set point

Series 28000 units are similar to Series 27100 units except they have as indicated by test lamp. When D-A-F units are used in other

two 1/2-14 NPT threads for mounting. types of systems, disconnect them from the system, connect a

The unit may be mounted as described above or may be threaded into 24 VDC lamp and power source in series with the D-A-F units

a 1/2 - 14 NPT tapped hole in the vessel wall or threaded into a coupling and test with heat source as above. Make sure that contacts

brazed or welded to the vessel wall. have reset to normal condition before reconnecting to system

circuit.

Field Wiring Requirement

Field wiring must be capable of withstanding the maximum anticipated WARNINGS

ambient temperature in the application. 1. DO NOT overshoot the setpoint of the unit by more than 100F

(55C). This could result in a shift of the set point temperature.

Figure 3: System Wiring 2. DO NOT contact the sensing shell with a heating device such as a

soldering iron or blowtorch as this will damage the unit and cause

a shift of the set point temperature.

3. In order to function properly, the sensing shell of the unit must

remain free from paint, grease, oil, etc. Should such a build up

occur, DO NOT, under any circumstances, attempt to remove it.

Replace the unit.

4. Detectors mounted in an area subject to physical abuse or damage,

other than above, must be suitably protected without any obstructing

the thermal airpath to the unit.

3. Do not install the unit where the shell would be physically damaged

by sand, grain, rocks, etc.

4. Do not over torque the unit when installing.

5. Any detector that has been involved in a fire, abused or damaged

must be replaced.

6. Consult the factory for special precautions necessary for outdoor

use or moist environments.

ANY OF THE ABOVE COULD CHANGE THE FACTORY

TEMPERATURE SETTING, WHICH MAY RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY OR DEATH.

Figure 4

IT IS POSSIBLE FOR A UNIT TO HAVE BEEN ABUSED OR

DAMAGED AND NOT DISPLAY ANY OUTWARD INDICATION

OF DAMAGE. ALL UNITS SHOULD BE TESTED PERIODICALLY

IN ACCORDANCE WITH NATIONAL FIRE PROTECTION

ASSOCIATION REQUIREMENTS (72E) OR THE AGENY

HAVING LOCAL JURISDICTION.

These instructions do not purport to cover all the details or variations in the equipment described,

400 MAIN STREET, ASHLAND, MA 01721 nor do they provide for every possible contingency to be met in connection with installation,

TEL: (508) 881-2000 FAX: (508) 881-6729 operation and maintenance. All specifications are subject to change without notice. Should further

information be desired or should particular problems arise which are not covered sufficiently for

www.fenwalcontrols.com

the purchasers purposes, the matter should be referred to KIDDE-FENWAL, Inc., Ashland,

Massachusetts.

Fenwal is a registered trademark of Kidde-Fenwal, Inc. 2009 Kidde-Fenwal. All rights reserved. Printed in U.S.A. 06-L04103-001 7/29/2009

Page 2 Vertical DETECT-A-FIRE Units

1-800-FENWAL-1 www.fenwalcontrols.com

You might also like

- Series 27100, 28000: 12.01.F Table 2: Model Number 28021 DescriptionDocument2 pagesSeries 27100, 28000: 12.01.F Table 2: Model Number 28021 DescriptionAli AlSowaidiNo ratings yet

- Evacuate LampDocument2 pagesEvacuate LampYosses Sang NahkodaNo ratings yet

- Series 27100 28000 Vertical Detect A Fire UnitsDocument2 pagesSeries 27100 28000 Vertical Detect A Fire UnitsMarcelo LeguizamonNo ratings yet

- DETECTOR TERMICO Detec-a-FireDocument2 pagesDETECTOR TERMICO Detec-a-FirefranciscoNo ratings yet

- Vertical Detect A Fire & Ultraviolet Fire DetectorDocument10 pagesVertical Detect A Fire & Ultraviolet Fire Detectoryouceflebni26No ratings yet

- Detect-A-Fire: Detection and Release DevicesDocument6 pagesDetect-A-Fire: Detection and Release DevicesGustavo Alejandro Flores GarriNo ratings yet

- Detect-A-Fire Detection and Release DevicesDocument6 pagesDetect-A-Fire Detection and Release DevicesAli HadiNo ratings yet

- Detect-A-Fire: Detection and Release DevicesDocument6 pagesDetect-A-Fire: Detection and Release DevicesFirman TopNo ratings yet

- DS - F-12-0-001 Fenwal Heat DetectorDocument6 pagesDS - F-12-0-001 Fenwal Heat DetectorElia Nugraha AdiNo ratings yet

- Detection and Release Devices: FeaturesDocument6 pagesDetection and Release Devices: FeaturesMarcelo LeguizamonNo ratings yet

- Functional Specification For Three Phase Peak Substation Distribution Transformers 300 12000 Kva Ps202010enDocument13 pagesFunctional Specification For Three Phase Peak Substation Distribution Transformers 300 12000 Kva Ps202010enFrancisco José Murias DominguezNo ratings yet

- % Impedance 75 KVA Etc EatonDocument14 pages% Impedance 75 KVA Etc EatonNOELGREGORIONo ratings yet

- CatalogDocument5 pagesCatalogdevy andiniNo ratings yet

- PricingDocument8 pagesPricingBherllyne JumillaNo ratings yet

- Eaton 269471 Emt6 KDB en GBDocument4 pagesEaton 269471 Emt6 KDB en GBAriel TorresNo ratings yet

- Name of Lab: Electrical Circuits & Simulation: S.No - Name of Equipment Name of Experiments Semes Ter/ye ArDocument3 pagesName of Lab: Electrical Circuits & Simulation: S.No - Name of Equipment Name of Experiments Semes Ter/ye Archolleti sriramNo ratings yet

- 2600 RTDDocument2 pages2600 RTDjtcool74No ratings yet

- Installation Manualime72470v Ds80Document85 pagesInstallation Manualime72470v Ds80ZawYeLinNo ratings yet

- Distribution Transformers PS202003ENDocument15 pagesDistribution Transformers PS202003ENDiana Rose TapelNo ratings yet

- Fenwal Temp.Document2 pagesFenwal Temp.Christian FernandezNo ratings yet

- 15N60Document6 pages15N60Alejandra SeguraNo ratings yet

- Bexs110 & Bexds110 Atex Eex Hazardous Area Alarm SoundersDocument2 pagesBexs110 & Bexds110 Atex Eex Hazardous Area Alarm SoundersBrillyanNo ratings yet

- Cat4101 DDocument9 pagesCat4101 DArdvaakNo ratings yet

- Plexo: Lamp SuppliedDocument1 pagePlexo: Lamp Suppliedayman.duaisNo ratings yet

- Surge Arrester-Class I+ Class II MG25/275-S/PN50: Power Supply SystemDocument2 pagesSurge Arrester-Class I+ Class II MG25/275-S/PN50: Power Supply SystemDuy ChuNo ratings yet

- Fiche Technique Du Luminaire (Non Suspendu)Document1 pageFiche Technique Du Luminaire (Non Suspendu)HoucinNo ratings yet

- Control and Relay PanelDocument104 pagesControl and Relay Panelbakien-can100% (1)

- CATALOGUEDocument27 pagesCATALOGUEparahu ariefNo ratings yet

- Power Supply EmersonDocument20 pagesPower Supply Emersonindra gunawanNo ratings yet

- BESS - Preliminary Equipment Heat DissipationDocument1 pageBESS - Preliminary Equipment Heat DissipationJeniffer Sta. MariaNo ratings yet

- ODLI20161010 - 011 UPD Es - AR EB C 236 TL D Ficha TécnicaDocument2 pagesODLI20161010 - 011 UPD Es - AR EB C 236 TL D Ficha Técnicachus55No ratings yet

- Rele de Control Tarjeta Brazo Reloj de Marcaje Vigilancia Junio 17 Del 2022Document3 pagesRele de Control Tarjeta Brazo Reloj de Marcaje Vigilancia Junio 17 Del 2022HENRY MEZANo ratings yet

- CPM-20 LVD Doc-130108Document62 pagesCPM-20 LVD Doc-130108Oscar Alexander Ojeda AriasNo ratings yet

- Installation Installation Installation Installation InstallationDocument4 pagesInstallation Installation Installation Installation InstallationTow kim boonNo ratings yet

- 1SFL551001R8511-a300-30-11-380-400v-50hz-400-415v-60hz-contactorDocument5 pages1SFL551001R8511-a300-30-11-380-400v-50hz-400-415v-60hz-contactorTrong Hung NguyenNo ratings yet

- Eaton 134917 DS7 340SX055N0 N en - GBDocument5 pagesEaton 134917 DS7 340SX055N0 N en - GBasmoosa_scribdNo ratings yet

- 30n06L InterfaceDocument8 pages30n06L Interfacepre freedaNo ratings yet

- Eols Gu 35XXDocument8 pagesEols Gu 35XXTestgame GameonlyNo ratings yet

- Eaton Transformadores de Dist.Document15 pagesEaton Transformadores de Dist.FlaKo Man La AmeNazaNo ratings yet

- 30N06 DatasheetDocument8 pages30N06 DatasheetSteve AbonyiNo ratings yet

- Automotive Dual-Line TVS in SOT323-3L For CAN Bus: Esdcanxx-2BwyDocument14 pagesAutomotive Dual-Line TVS in SOT323-3L For CAN Bus: Esdcanxx-2BwyЕвгений ИвановNo ratings yet

- Gems LS-270 Series Single-Station Level Switch Instruction BulletinDocument4 pagesGems LS-270 Series Single-Station Level Switch Instruction BulletinTimang LhangNo ratings yet

- 32-00038efsp ADocument16 pages32-00038efsp AlesliehoyNo ratings yet

- REM200 GBDocument4 pagesREM200 GBadeleng2025No ratings yet

- Unisonic Technologies Co., LTD: 80A, 75V N-Channel Power MosfetDocument9 pagesUnisonic Technologies Co., LTD: 80A, 75V N-Channel Power MosfetALI ALhdidiNo ratings yet

- X20at4222-Eng V3.12Document10 pagesX20at4222-Eng V3.12Asif MehmoodNo ratings yet

- DS7 EatonDocument5 pagesDS7 EatonBenício AvellarNo ratings yet

- XRB03340283 InglesDocument1 pageXRB03340283 InglesEbraheem GawadNo ratings yet

- 2N60 600V N Channel Power MOSFET: - FeaturesDocument7 pages2N60 600V N Channel Power MOSFET: - Featuresnivaldo de oliveira OliveiraNo ratings yet

- Unisonic Technologies Co., LTD: 4.0A, 600V N-CHANNEL Power MosfetDocument7 pagesUnisonic Technologies Co., LTD: 4.0A, 600V N-CHANNEL Power MosfetDarush RjNo ratings yet

- FF - FA Works - MS - T2Document27 pagesFF - FA Works - MS - T2Engy AhmedNo ratings yet

- Lt210a SeriesDocument1 pageLt210a SeriesdendiNo ratings yet

- Led Driver 1-Lunatone Led Drivers 86458618 - Dali - PD - en - D0033Document10 pagesLed Driver 1-Lunatone Led Drivers 86458618 - Dali - PD - en - D0033samranNo ratings yet

- 1SBL177001R1110 Af16 30 10 11 24 60v50 60hz 20 60vdc ContactorDocument5 pages1SBL177001R1110 Af16 30 10 11 24 60v50 60hz 20 60vdc ContactorHector SuarezNo ratings yet

- Functional Specification For Single Phase Pad Mounted Type Distribution Transformers 5 167 Kva Ps201002enDocument9 pagesFunctional Specification For Single Phase Pad Mounted Type Distribution Transformers 5 167 Kva Ps201002enRetsel WanNo ratings yet

- TABLE CCLDocument3 pagesTABLE CCLmayurNo ratings yet

- Manual Eaton-134922-DS7-340SX160N0-N-en - GBDocument4 pagesManual Eaton-134922-DS7-340SX160N0-N-en - GBBanning RamonaNo ratings yet

- BIOLUX HCL PL 1200 S 40W TW DALI enDocument8 pagesBIOLUX HCL PL 1200 S 40W TW DALI encentralhidroabanicoNo ratings yet

- ADR280 1.2 V Ultralow Power High PSRR Voltage Reference: ÷HZ TypicalDocument8 pagesADR280 1.2 V Ultralow Power High PSRR Voltage Reference: ÷HZ Typicalgem1144aaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Información KiddeDocument7 pagesInformación KiddehcalderonmarinNo ratings yet

- Pub002 027 00 - 0607Document2 pagesPub002 027 00 - 0607hcalderonmarinNo ratings yet

- KIDDE IND - Dry.chemical - Fire.suppression - SystemDocument2 pagesKIDDE IND - Dry.chemical - Fire.suppression - Systemhcalderonmarin100% (1)

- Series 74 Positioner ManualDocument25 pagesSeries 74 Positioner ManualhcalderonmarinNo ratings yet

- 00215A9B03CC1EE5B5B739E29B10E391Document24 pages00215A9B03CC1EE5B5B739E29B10E391hcalderonmarinNo ratings yet

- 005056B602221EE5889ECD582E8BAE0ADocument12 pages005056B602221EE5889ECD582E8BAE0AhcalderonmarinNo ratings yet

- Certificat Conformitate Panouri FVDocument2 pagesCertificat Conformitate Panouri FVemilNo ratings yet

- CNT-81 & CNT-81R: Timer/Counter/CalibratorsDocument4 pagesCNT-81 & CNT-81R: Timer/Counter/CalibratorsMichael DixonNo ratings yet

- Sika Hydrotite CJ-Type 2012-01-1Document5 pagesSika Hydrotite CJ-Type 2012-01-1pandavision76No ratings yet

- ErC-DU Planning Manual 10aug2009Document45 pagesErC-DU Planning Manual 10aug2009berto_diego100% (14)

- 5s Audit PlanDocument3 pages5s Audit PlansomuanindianNo ratings yet

- Maintenance Management of Electrical Equipment Condition Monitoring Based Part 1Document5 pagesMaintenance Management of Electrical Equipment Condition Monitoring Based Part 1Abdan ShidqiNo ratings yet

- Template - Project Office ChecklistDocument6 pagesTemplate - Project Office ChecklistGryswolfNo ratings yet

- Guia ILAC G24 - Determination of Calibration-Intervals of Measuring Instruments - 2007Document11 pagesGuia ILAC G24 - Determination of Calibration-Intervals of Measuring Instruments - 2007Kelly de Souza SilvaNo ratings yet

- Bowie Dick Testing - Medical Industry - EllabDocument1 pageBowie Dick Testing - Medical Industry - EllabSabinaNo ratings yet

- Banner Mini Screen SystemDocument60 pagesBanner Mini Screen SystemMauricio Sanchez PortillaNo ratings yet

- Iso 11623 - 2015 - PDFDocument36 pagesIso 11623 - 2015 - PDFandres jaramilloNo ratings yet

- Valv Seg Serie 2600 Farris.Document96 pagesValv Seg Serie 2600 Farris.Jose Victor100% (1)

- RWF40 Modulating Feedwater Control Valve Application Guide: RWF40 Compact Universal ControllerDocument24 pagesRWF40 Modulating Feedwater Control Valve Application Guide: RWF40 Compact Universal ControllersakarisoNo ratings yet

- SQL LoaderDocument35 pagesSQL LoaderSharathRajNo ratings yet

- PulsecDocument4 pagesPulsecRocknee1No ratings yet

- iSYS Company Profile QSIDocument9 pagesiSYS Company Profile QSIAshwin0% (1)

- R-SG7 DP-SG7 X-SG7: Instruction ManualDocument56 pagesR-SG7 DP-SG7 X-SG7: Instruction ManualMariq Xristova KonovaNo ratings yet

- Technical SpecificationsDocument8 pagesTechnical SpecificationsSaud PathiranaNo ratings yet

- LightRadio Metro 9764 WCDMA B1 B2 1W en DatasheetDocument2 pagesLightRadio Metro 9764 WCDMA B1 B2 1W en DatasheetmborazNo ratings yet

- ATC-820 User's ManualDocument2 pagesATC-820 User's ManualMaitry Shah50% (2)

- FibracousticDocument2 pagesFibracousticPratik ThakkarNo ratings yet

- How To Configure Site-To-Site IKEv2 IPSec VPN Using Pre-Shared Key AuthenticationDocument14 pagesHow To Configure Site-To-Site IKEv2 IPSec VPN Using Pre-Shared Key AuthenticationCoolzero CoolzeroNo ratings yet

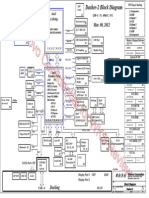

- x230 SchematicsDocument101 pagesx230 Schematicsangga_scribdNo ratings yet

- Iec 62552 2 2015 Amd1 2020Document12 pagesIec 62552 2 2015 Amd1 2020ASSISFERREIRANo ratings yet

- User Guide: TL-SG1005D TL-SG1008D 5/8-Port Gigabit Desktop SwitchDocument12 pagesUser Guide: TL-SG1005D TL-SG1008D 5/8-Port Gigabit Desktop SwitchmonkeyhophopNo ratings yet

- Canon FB1210U Service ManualDocument102 pagesCanon FB1210U Service ManualDuplessisNo ratings yet

- GET6600G Section 10 Guide Form Spec Rev 2Document14 pagesGET6600G Section 10 Guide Form Spec Rev 2NestorNateraNo ratings yet

- Topcon Tools Quick Reference Guide PDFDocument72 pagesTopcon Tools Quick Reference Guide PDFCharlees IvaxNo ratings yet

- Essentials 20101009 175521Document6 pagesEssentials 20101009 175521Amin ThabetNo ratings yet

- Keeline Operation & Maintenance Manual: Safety at The Highest LevelDocument24 pagesKeeline Operation & Maintenance Manual: Safety at The Highest LevelEddy Cuellar MartinezNo ratings yet