Professional Documents

Culture Documents

Precast Concrete Piles Ver5 13th Dec 2014

Uploaded by

zzweirdozzCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Precast Concrete Piles Ver5 13th Dec 2014

Uploaded by

zzweirdozzCopyright:

Available Formats

S21 PRECAST CONCRETE PILES

TABLE OF CONTENTS

S21.1 GENERAL

S21.2 STANDARDS

S21.3 DEFINITIONS

S21.4 TOLERANCES

21.4.1 Setting out

S21.4.2 Position

S21.4.3 Verticality

S21.4.4 Rake

S21.4.5 Forcible Correction

S21.4.6 Pile Out of Alignment or Position

S21.5 PILING METHOD

S21.6 PILING PROGRAMME

S21.7 PILING RECORDS

S21.8 NUISANCE AND DAMAGE

S21.8.1 Noise, vibration and disturbance

S21.8.2 Damage to adjacent structures

S21.8.3 Damage to piles

S21.8.4 Temporary support

S21.9 ORDERING OF PILES

S21.10 CLASSIFICATION

S21.11 MATERIALS

S21.11.1 Cement.

S21.11.2 Steel reinforcement.

S21.11.3 Aggregates

S21.11.4 Water

S21.11.5 Admixtures

S21.11.6 Steel and iron components

S21.11.7 Test certificates

S21.12 MANUFACTURE

S21.12.1 Supervision and manufacturing process

S21.12.2 Concrete mix

S21.12.3 Placing and compacting concrete

S21.12.4 Protecting and curing concrete

S21.12.5 Handling

S21.12.6 Mould

S21.13 PERMISSIBLE TOLERANCES IN PILE DIMENSIONS

S21.14 PILE JOINTS

CTT/ Precast Concrete Piles.Ver.5 1

Date 13th December 2014

S21.15 PILE SHOES

S21.16 PILE HEAD REINFORCEMENT

S21.17 REINFORCEMENTS

S21.18 PRESTRESSING

S21.18.1 General

S21.18.2 Concrete strength

S21.18.3 Records

S21.18.4 Post tensioned piles

S21.18.5 Grouting procedure

S21.18.6 Grout

S21.18.7 Testing works grout

S21.18.8 Batching grout

S21.18.9 Mixing grout

S21.18.10 Transporting grout

S21.19 RECORDS

S21.20 PILE QUALITY

S21.21 MARKING OF PILES

S21.22 BEND TESTS

S21.23 DRIVING PILES

S21.23.1 Strength of piles

S21.23.2 Driving Resistance

S21.23.3 Preliminary test piles

S21.23.4 Depth of Penetration

S21.23.5 Pile Acceptance Criteria

S21.23.6 Leaders and trestles

S21.23.7 Performance of driving equipment

S21.23.8 Driving procedures and redrive checks arising from interruptions to

driving

S21.23.9 Redrive checks on time effects on piles

S21.23.10 Set

S21.23.11 Driving sequence and risen piles

S21.23.12 Preboring

S21.24 REPAIR AND LENGTHENING OF PILES

S21.24.1 Repair of damaged pile heads

S21.24.2 Lengthening of precast reinforced and prestressed concrete and

prestressed spun piles

S21.24.3 Driving repaired or lengthened pile

S21.25 CUTTING OFF PILE HEADS AND REMOVAL OF SURPLUS LENGTH

S21.26 HAMMERS

S21.27 DRIVING PILES ONTO LIMESTONE ROCK

CTT/ Precast Concrete Piles.Ver.5 2

Date 13th December 2014

S21 PRECAST CONCRETE PILES

S21.1 General

The Contractor shall carry out detail design of the piles to the loads, dimensions and

Class specified and / or shown on the drawings and shall manufacture, deliver and

install the piles to set and to such lengths as to comply with the design requirements

and criteria of acceptance, all in accordance with the specifications.

This section contains specifications covering the design, certain materials and

workmanship required for construction and installation of precast reinforced

concrete piles, precast pretensioned concrete piles and precast prestressed spun

concrete piles. The materials and workmanship specified in other sections of the

specifications apply to precast concrete piles except where modified, amended or

excluded herewith.

S21.2 Standards

The whole of the works and materials shall be in accordance with British Standard

Code of Practice BS 5328: 1981, BS 8110: 1985 and BS 8004: 1986; Malaysian

Standard MS 1314: Part 1 : 1993 and MS : 1314 : Part 2 : 1993 and JKR Standard

Specification Specifikasi ILP 1 91 Precast Concrete Piles in Building Projects

(herein referred to as JKR ILP 1-91)and other specifications referred to in the

Specifications unless otherwise stated and except where the requirements of the

British and Malaysian Standards are in conflict with this specifications, the latter

shall take precedence.

S21.3 Definitions

In this section, the terms approved, approval and required shall mean

approved by the Engineer, approval of the Engineer and required by the

Engineer respectively.

S21.4 Tolerances

S21.4.1 Setting out

Setting out shall be carried out from reference lines and points shown on the

Drawings. Immediately before installation of the pile, the pile position shall be

marked with suitable identifiable pins and markers.

S21.4.2 Position

The maximum permitted deviation of the pile center from the center point shown on

the setting out drawing shall be 75 mm in any direction.

S21.4.3 Verticality

The maximum permitted deviation of the installed pile from the vertical shall be 1:

100.

CTT/ Precast Concrete Piles.Ver.5 3

Date 13th December 2014

S21.4.4 Rake

The piling rake shall be set and maintained to attain the required rake. The

maximum permitted deviation of the finished pile from the specified rake is 1 : 25 for

piles raking up to 1 : 6 and 1 in 15 for piles raking more than 1 : 6.

S21.4.5 Forcible Correction

Forcible corrections to concrete piles shall not be made.

S21.4.6 Piles Out of Alignment or Position

For piles out of the permissible alignment or position (or ordered by Engineer) , the

Contractor shall extract and reinstall any pile which has deviated out of position or

alignment by more than the specified limit, or alternatively by adding compensating

piles and/or modifying the substructure to the approval of the Engineer. The

Contractor shall submit to remedial proposal including eccentricity check to Engineer

for review and approval. The cost of such extraction and reinstallation, or

compensating piles, or any extra cost in the design and construction of a modified

foundation shall be borne by the Contractor, if in the opinion of the Engineer such

extra works have been made necessary due to incompetency, error and/or

negligence of the Contractor.

S21.5 Piling Method

The Contractor shall submit for approval all relevant details of the method of piling

and the plant he proposes to use. Any alternative method to that specified shall be in

accordance with the Specifications.

S21.6 Piling Programme

The Contractor shall submit to the Engineer his proposed programme for the

execution of the piling work at least seven days before commencement of work. In

addition, the Contractor shall inform the Engineer each day of the programme of

piling for the following day and shall give adequate notice of his intention to work

outside normal hours and at week ends.

S21.7 Piling Records

Comprehensive records shall be kept. The record shall include the following

information:-

(i) Contract particulars, building number etc

(ii) Reduced level on the pile position;

(iii) Pile reference number;

(iv) Pile type and details of the pile

(v) Nominal cross sectional dimensions or diameter;

CTT/ Precast Concrete Piles.Ver.5 4

Date 13th December 2014

(vi) Length of preformed pile including the lengths of each segment;

(vii) Date and time of driving, re driving or pre boring from start to finish;

(viii) Ground level at pile position at commencement of installation of pile;

(ix) Working level on which the piling machine stands

(x) Pile toe level

(xi) Pile head level at end of installation

(xii) Cut off level

(xiii) Type, weight, drop and mechanical condition of hammer and equivalent

information for other equipment.

(xiv) Number and type of packing used and type and conditions of dolly used

during driving of the piles.

(xv) Set of pile in millimeters per 10 blows or number of blows per 25 mm of

penetration.

(xvi) Temporary compression of pile.

(xvii) Driving resistance taken at 0.25 m intervals.

(xviii) All information regarding obstructions, delays and other interruptions to the

sequence of work.

(xix) Pile installation equipment including rig no.

(xx) For raking piles, the angle of the rake.

(xxi) Weather report.

(xxii) All other information as may be required by the Engineer.

Two duplicate copies certified by the Contractors P.E. and every such log shall be

furnished to the Engineer within 24 hours of the completion of the pile in question.

The signed copies shall form part of the records for the Works.

On completion of piling, the Contractor shall deliver to the Engineer three copies of

as built drawing and its soft copy, certified by the Contractors P.E. recording the

precise positions, recording the final depths of all piles relative to the Ordinance

Datum and any other information as directed by the Engineer

S21.8 Nuisance and Damage

S21.8.1 Noise, vibration and disturbance

The Contractor shall carry out his works in such a manner and at such times as to

minimize noise, vibration and other disturbance in order to comply with current

CTT/ Precast Concrete Piles.Ver.5 5

Date 13th December 2014

statutory requirements and legislations. He shall comply with all the requirements of

all the relevant authorities.

The Contractor shall also comply with the recommendations of noise and vibrations

given in:

BS 5228

Noise control on construction and open sites. Part 4. May 1992. Code of

practice for noise and vibration control applicable to piling operations.

BS 7385

Evaluation and measurement for vibration in buildings.

Part 1: 1990. Guide for measurement of vibration and evaluation of their

effects on buildings.

Part 2: 1993. Guide to damage levels from ground borne vibrations.

BRE Digest

Damage to structures from ground-borne vibration. Digest 403. March 1995.

The Contractor shall carry out measurements of noise and vibrations during the

installation of the preliminary piles and at such times as may be instructed by the

Engineer.

S21.8.2 Damage to adjacent structures

If in the opinion of the Contractor, damage may be caused to other structures or

services by the execution of his works he shall immediately notify the Engineer. The

Contractor shall submit his plans for surveys and monitoring of movements and

vibrations before the commencement of Works.

S21.8.3 Damage to piles

The Contractor shall ensure that during the course of the work, displacement or

damage that would impair either performance or durability does not occur to

completed piles.

The Contractor shall submit to the Engineer his planned sequence and timing for

installing piles having regard to the avoidance of damage to adjacent piles.

S21.8.4 Temporary support

The Contractor shall ensure that where required, any permanently free standing

piles are temporarily braced or stayed immediately after installation to prevent

loosening of the piles in the ground and to ensure no damage resulting from

oscillation, vibration or movement can occur.

S21.9 Ordering Of Piles

The Contractor shall ensure that the piles are available in time for incorporation in

the Works. All piles and production facilities shall be made available for inspection at

any time. Plies shall be examined at the time of delivery and any faulty units

replaced. The records of testing of the steel and concrete used in the piles shall be

submitted.

CTT/ Precast Concrete Piles.Ver.5 6

Date 13th December 2014

S21.10 Classification

The classification of piles shall be as given in Table S21.1. The requirements of the

different classes are given in Table S21.2.

Pile type Classes

Precast reinforced concrete piles Class 1 -

Precast pretensioned concrete piles Class X Class Y

Precase prestressed spun concrete piles Class A Class B

Table S21.1

S21.11 Materials

The materials used for the manufacture of the precast concrete piles shall complying

with the following requirements:

S21.11.1 Cement.

Cement shall be Ordinary Portland cement and shall comply with MS 522. Other

types of cement shall be to the approval of the Engineer.

S21.11.2 Steel reinforcement.

Steel reinforcement shall consist of cores, bars or strands complying with the

following requirements and specifications.

(i) Rolled steel bars and hard drawn steel wire shall comply with MS 144 and MS

146.

(ii) Prestressing steel shall comply with JIS G3109 or BS 4486, BS 5896, or

ASTM A416.

S21.11.3 Aggregates

The coarse and fine aggregates shall be clean, durable and comply with MS 29. The

maximum size of aggregates shall be 20 mm. All batches of aggregates used shall

be tested in accordance with MS 29. Alkali reaction tests shall be carried out on the

different rock types used.

S21.11.4 Water

Water shall be free from harmful amounts of matter injurious to concrete and steel

reinforcements and shall comply with MS 28.

S21.11.5 Admixtures

Admixtures may only be used with the approval of the Engineer. Admixtures, if used,

shall comply with MS 922. Admixtures with calcium chloride shall not be accepted.

CTT/ Precast Concrete Piles.Ver.5 7

Date 13th December 2014

S21.11.6 Steel and iron components

In the manufacture of precast concrete piles and jointed precast concrete segmental

piles, fabricated steel components shall comply with BS 4360 Grades 43A and 50A

or BS EN 10 025 Grades Fe 430A or Fe 510A, cast steel components with BS 3100,

grade A (A1, A2 or A3) and ductile iron components with BS 2789 Grades 420 / 12,

400 / 18 or 350 / 22.

S21.11.7 Test certificates

Test certificates and / or mill certificates for tests on the following shall be made

available to the Engineer:

cement,

steel reinforcements,

admixture (if used) from approved supplier

aggregates;

steel and iron components.

Test results showing failure to comply with the requirements of the Specifications

shall result in rejection of the entire piles produced from that batch of materials.

Records shall also be kept of suppliers, dates of supplies, quantities supplied, pile

referencing to batches of materials used.

The frequency of testing shall be in accordance with MS 1314: Part 1: 1993

Appendix C.

S21.12 Manufacture

S21.12.1 Supervision and manufacturing process

Experienced engineers, concrete technologists shall be employed and shall be

responsible for all tests and inspections specified in MS 1314 : Part : 1 : 1993. All

mixing and measuring equipment shall be maintained and calibrated regularly under

supervision.

Production and transportation of concrete shall be in accordance with MS 523.

The manufacturing process shall comply to the requirements of MS ISO 9002.

S21.12.2 Concrete mix

Concrete shall be sampled and tested in accordance with MS 26. Concrete mixes

shall be designed and verified by trial mixes. The concrete strength shall be

designed for a mean strength greater than the required characteristic strength by a

minimum margin of 1.64 times the standard deviation. In the absence of statistical

data, a standard deviation of 5.5 N / mm2 shall be adopted. The aggregates, cement

and water shall be proportioned and mixed using appropriate batching and mixing

plant to produce a consistent and homogeneous of the specified strength.

S21.12.3 Placing and compacting concrete

CTT/ Precast Concrete Piles.Ver.5 8

Date 13th December 2014

The method of placing and compacting concrete shall be such as to ensure that the

concrete in its final position is dense and homogeneous. The concrete shall be cast

in a continuous operation. The concrete shall be thoroughly compacted against the

mould and around the reinforcement by means of immersed and / or shutter

vibrations or spinning process. Vibrators shall be operated in such a manner that

neither segregation of the concrete mix constituents nor displacement of

reinforcement occurs.

S21.12.4 Protecting and curing concrete

Immediately after completion of placing and compaction, concrete shall be

adequately protected from all harmful effects of weather including wind, rain, high

temperatures and rapid temperature changes and from all detrimental effects such

as vibrations.

The piles shall be cured using any one of the following or a combination of the

following methods:

(a) Accelerated curing with either low pressure steam or radiant heat in a moist

atmosphere.

(b) Water curing by covering the pile with water saturated material for a minimum

period of 3 days.

(c) Membrane curing with a sealing membrane applied to ensure loss of water not

more than 0.055 g / cm2 of surface area over a 72 hour period. The sealing

membrane shall conform to the requirements of ASTM C 309. Other methods of

curing shall be to the approval of the Engineer.

S21.12.5 Handling

Lifting hooks or holes, specific for the purpose, shall be designed for and cast into

each pile. Piles shall not be removed from the moulds or lifted from the casting beds

until the concrete cube strength exceeds:

16 N / mm2.

or until when the compressive stresses from handling (including that from the

pile weight) is less than the 0.33 the strength of the pile at time of handling

whichever the higher.

The method and sequence of handling, transporting and storing of piles shall be

such as to avoid shock loading and to ensure that the piles are not damaged. Only

designed lifting and support points shall be used. During transport and storage, piles

shall be appropriately supported under the marked lifting points or fully supported

along their length. Piles shall be stored only on stiff ground not liable to settlement

under the weight of the stack that will induce bending of the piles.

All piles within a stack shall be in groups of the same length. Packing of uniform

thickness shall be provided between piles at the same lifting points.

A pile shall be rejected when the width of any transverse crack exceeds 0.3 mm.

The measurement shall be made with the pile in its working attitude.

CTT/ Precast Concrete Piles.Ver.5 9

Date 13th December 2014

S21.12.6 Mould

The moulds used in the manufacturing of the piles shall be sufficiently rigid and

accurate to maintain the pile dimensions to within the tolerances stated in Clause

S21.12 of the specifications. All casting surfaces shall be of smooth nonporous

material. Square piles shall have chamfered corners.

The moulds shall be robust, clean and so constructed and maintained as to prevent

loss of grout or aggregate from the wet concrete and to ensure the production of

uniform pile sections, free from defects.

Piles shall be removed from the mould in such a manner as to prevent any damage

to the pile.

S21.13 Permissible Tolerances in pile dimensions

The cross sectional dimensions shall be not less than that specified and shall not

exceed them by more than 6 mm. Each face of the pile shall not deviate by more

than 6 mm from any straight line 3 m long joining two points on the face, nor shall

the center of the pile at any cross section deviate by more than 12 mm from a line

joining the centers of area at the ends of the piles.

Wall thickness of precast prestressed spun concrete piles shall be within 3 mm to

+ 6 mm. Outside diameter of precast prestressed spun concrete piles shall be within

3 mm to + 5 mm for 600 mm diameter and smaller and within 4 mm and + 7 mm

for larger diameters.

The outside diameter shall be defined as the average of two measurements taken

along the axes at right angles to each other on a cross section. The wall thickness

shall be the average of four measurements taken along the axes at right angles to

each other in a cross section.

The head of the pile element shall be square to the pile axis within a tolerance of 1 :

150.

S21.14 Pile joints

The joints shall conform to the requirements of JKR ILP-91.

The joints shall be close-fitting face to face and the locking method shall be such as

to hold the faces in intimate contact. Details of the design, manufacture and tests of

the jointing system shall be submitted and approved by the Engineer prior to the

commencement of the contract.

Joints shall have strengths in compression, bending, tension, shear and torsion

during installation and in service not less than that of a single unjointed pile of the

same cross-sectional dimensions and materials as that of the pile segments joined.

The joints shall also be able to withstand the stresses due to repeated impacts of

driving hammers and heat from welding.

The welding of a joint to main reinforcement in lieu of a lapped connection with

projecting bars affixed to the joint shall not be permitted.

CTT/ Precast Concrete Piles.Ver.5 10

Date 13th December 2014

Each joint shall be square to the axis of the pile within a tolerance of 1 : 150. The

centroid of the pile joint shall lie within 5 mm of the true axis of the pile element. The

minimum thickness of the steel plate shall be 15 mm. The diameter of the centering

bar shall be 32 mm with a minimum anchorage depth of 200 mm and protrusion

length of 100 mm.

The length of anchor / starter bars shall be precast reinforced concrete piles shall be

at least 40 times the reinforcement of the pile segments joined. The cross section of

the anchor / starter bars shall be not less than the reinforcements of the pile

segments joined. A mild steel skirt of at least 1.6 mm thick and 50 mm high shall be

provided around the edges of the pile joint.

The requirements for anchor / starter bars for precast prestressed spun concrete

piles shall be as given in Table 4 of MS 1314: Part 1: 1993.

The contractor shall carry out Bending Strength tests on joints in accordance with

MS 1314: Part 1 : 1993 as instructed by the Engineer.

S21.15 Pile shoes

Pile shoes shall be constructed so as to ensure that damage is not caused to the

pile during installation.

Pile shoes shall be as shown on the drawings and shall comply with the following as

relevant:

(i) Chilled - hardened cast iron shoes as used for making grey iron casting to BS

1452, Grade 10;

(ii) Mild steel to BS 4360, Grade 43A or JIS 3101 Grade SS 41.

S21.16 Pile head reinforcement

Pile heads shall be so reinforced or banded as to prevent bursting of the pile under

driving.

S21.17 Reinforcements

The required steel reinforcements shall be as stated in Table S21.2.

The main longitudinal reinforcing bars in piles not exceeding 12 m in length shall be

in one continuous length. In piles more than 12 m length, joints will be permitted in

main longitudinal bars so that the number of joints is minimized. Joints in

reinforcement shall be such that the full strength of the bar is effective across the

joint, following BS 8110.

Lap and splice joints shall be provided with sufficient link bars to resist eccentric

forces. Reinforcement shall be incorporated for lifting and handling purposes.

Lateral reinforcements in the form of hoops, links or spirals shall be firmly fixed to

the reinforcement bars.

Spacing blocks shall be of mortar concrete or other materials comparable in

durability and strength as the main concrete and which shall not lead to corrosion of

the reinforcement or spalling of the concrete cover. Details of the means by which

CTT/ Precast Concrete Piles.Ver.5 11

Date 13th December 2014

the Contractor plans to ensure the correct cover to and position of the reinforcement

shall be submitted.

If a pile is constructed with a shaped point or shoe, then the end of the pile shall be

symmetrical about the longitudinal axis of the pile. Holes for handling or pitching

shall be lined with steel tubes; alternatively inserts may be cast in.

S21.18 Prestressing

S21.18.1 General

Tensioning shall be carried out only when the Engineer is present, unless otherwise

approved. In cases where piles are manufactured off the site, the Contractor shall

ensure that the Engineer is given adequate notice and every facility for inspecting

the manufacturing process.

Pre stressing operations shall be carried out only under the direction of an

experienced and competent supervisor. All personnel operating the stressing

equipment shall have been trained in its use.

The calculated extensions and total forces, including allowance for losses, shall be

agreed with the Engineer before stressing is commenced.

Stressing of tendons and transfer of prestress shall be carried out at a gradual and

steady rate. The force in the tendons shall be obtained from readings on a recently

calibrated load cell or pressure gauge incorporated in the equipment. The extension

of the tendons under the agreed total forces shall be within 5% of the agreed

calculated extension.

S21.18.2 Concrete strength

The contractor shall cast sufficient cubes, cured in the same manner as the piles, to

be able to demonstrate by testing two cubes at a time, with approved intervals

between pairs of cubes, that the necessary in situ strength of the concrete has been

reached.

Concrete in the piles shall not be stressed until two test cubes attain the necessary

strength.

S21.18.3 Records

The Contractor shall keep detailed records of times of tensioning, measured

extensions, pressure gauge readings or load cell readings and the amount of pull-in

at each anchorage. The Contractor shall also check the cover to reinforcement of

each pile and shall ensure that it is at least that specified. Copies of these records

shall be supplied to the Engineer. within such reasonable time from completion of

each tensioning operation, as may be required, and in any case not later than noon

on the following working day.

S21.18.4 Post tensioned piles

Apart for the requirements for ducts and vents in post tensioned piles to be

grouted after the transfer of pre stress, the requirements for pre-stressed piles apply.

CTT/ Precast Concrete Piles.Ver.5 12

Date 13th December 2014

S21.18.5 Grouting procedure

Grout shall be mixed for a minimum of 2 minutes and until a uniform consistency is

obtained.

Before grouting is started all ducts shall be thoroughly cleaned by means of

compressed air which shall be free of oils.

Grout shall be injected near the lowest point in the duct in one continuous operation

and allowed to flow from the outlet until the consistency is equivalent to that of the

grout being injected.

Vents in ducts shall be provided in accordance with Clause 8.9.2 of BS 8110.

S21.18.6 Grout

Grout for prestress shall have the following properties.

(a) The design and workability of grout to be used in the formation of piles shall

produce a mix which is suitable for pumping.

(b) The grout shall consist only of ordinary Portland cement, water and approved

admixtures; admixtures containing chlorides or nitrates shall not be used;

(c) The grout shall have a water/cement ratio as low as possible consistent with the

necessary workability, and the water/cement ratio shall not exceed 0.40.

(d) The grout shall not bleed in excess of 2% after 3 hours, or in excess of 4%

maximum, when measured at 18oC in a covered glass cylinder approximately

100mm in diameter with a height of grout of approximately 100mm, and the

water shall be re-absorbed after 24 hours.

S21.18.7 Testing works grout

Cube strength testing shall be carried out in accordance with BS 1881. A sample

shall consist of a set of six 100 mm cubes. Three cubes shall be tested at seven

days and the remaining three at 28 days after casting.

S21.18.8 Batching grout

The weighing and water dispensing mechanisms shall be maintained at all times

within the limits of accuracy described in BS 1305.

The weights of each component of the mix shall be within 2 % of the respective

weights per batch.

S21.18.9 Mixing grout

Cement grout shall be mechanically mixed throughout to produce a homogeneous

mix.

The grout shall be mixed on site until a homogeneous grout is obtained and shall be

kept in continuous movement until in used. It shall be used within 30 minutes from

CTT/ Precast Concrete Piles.Ver.5 13

Date 13th December 2014

the start of mixing. Following mixing, the grout shall be passed through a 5 mm

aperture sieve and shall be remixed if lumps are retained.

S21.18.10 Transporting grout

Grout shall be transported from the mixer to the position of the pile in such a manner

that segregation of the mix does not occur.

S21.19 Records

The Contractor shall keep records of grouting, including the date, the proportions of

the grout and any admixtures used, the pressure, details of interruption and topping

up required. Copies of these records shall be submitted within such reasonable time

after completion of each grouting operation, as may be required, and in any case not

later than noon of the following working day.

S21.20 Pile quality

A certificate of quality from the pile manufacturer shall be provided stating that the

requirements of this Specification have been fulfilled during manufacture.

S21.21 Marking of piles

Each pile shall be marked in such a manner that it can be identified with the records

of manufacture which shall state the date of casting, the cement type, the concrete

grade, element length, the prestressing force where appropriate, Manufacturers

name or registered trademark/logo and any other relevant data. On delivery the

piles shall be accompanied by records of manufacture. Lifting positions shall be

marked on each pile in accordance with the requirements of design.

S21.22 Bend Tests

The Contractor shall carry out bend tests on the pile and on the pile joint in

accordance with MS 1314 : Part 1 : 1993 when instructed by the Engineer.

S21.23 Driving piles

S21.23.1 Strength of piles

Piles shall be not be driven until the concrete cubes have achieved the specified

characteristic strength and the pile has attained the strength to resist driving

stresses, whichever is the greater.

S21.23.2 Driving Resistance

Unless otherwise specified in the contract piles shall be driven to achieve an

ultimate static resistance not less than twice the working load shown in the contract.

Before commencement of pile driving the contractor shall submit pile driving

methodology, equipment and details to the Engineer for his approval.

S21.23.3 Preliminary test piles

CTT/ Precast Concrete Piles.Ver.5 14

Date 13th December 2014

The Contractor shall carry out driving and testing of preliminary piles. The number of

preliminary test piles shall be specified or instructed by the Engineer. The Contractor

shall propose a programme for carrying out the preliminary pile tests and shall give

at least 24 hours notice of the commencement of driving and testing of the

preliminary test piles.

The following tests shall be carried out on each preliminary test pile:

a. Dynamic load tests or high strain dynamic pile test in accordance with

ASTM D4945 96 : Standard Method for high Strain Dynamic Testing of Piles

during the entire driving process of the pile or over a length of the pile specified

or directed by the Engineer to measure the dynamic stresses and dynamic

resistance through depth and to evaluate the hammer performance and driving

stresses.

b. Dynamic load tests to evaluate the integrity, pile capacity and load

settlement behavior at 4, 8 and 14 days after completion of driving, if instructed

by Engineer.

c. Maintained static load tests in accordance with the Specifications with the

additional requirement that sufficient reaction shall be provided to enable the pile

to be tested up to three times the working load of the pile or test load specified

whichever higher.

S21.23.4 Depth of Penetration

If the Engineer is not satisfied with the depth of penetration irrespective of the

driving resistance being attained, the Engineer shall specify the penetration and the

contractor shall carry on driving by increasing the driving energy which may include

a change to a heavier hammer. Driving shall be continued until the desired depth of

penetration has been attained.

S21.23.5 Pile Acceptance Criteria

The Engineer or Engineers Representative shall select and instruct the Contractor

on the working piles to be subject to maintained static load tests.

Notwithstanding the Engineers approval and acceptance of the contractors pile

driving equipment or system, driving and work methodology, when maintained static

pile load tests has been carried out as described in the Specifications, the pile so

tested shall be deemed to have failed if:-

EITHER

(i) The residual settlement after removal from working load exceeds 4.0 mm

OR

(ii) The total settlement under the working load exceeds 12.0 mm;

OR

(iii) The total settlement under twice the working load (or test load whichever bigger)

exceeds 30 mm, or 10% of pile diameter/width whichever is the lower value;

CTT/ Precast Concrete Piles.Ver.5 15

Date 13th December 2014

S21.23.6 Leaders and trestles

At all stages during driving and until incorporation into the structure the pile shall be

adequately supported and restrained by means of leaders, trestles, temporary

supports or other guide arrangements to maintain position and alignment and to

prevent significant damage to the pile.

S21.23.7 Performance of driving equipment

The efficiency and the energy of the driving equipment including when followers are

used shall be notified. Dynamic evaluation and analysis shall be carried out to verify

the efficiency and energy.

Where a drop hammer is used, the mass of the hammer shall be at least half that of

the pile. For other types of hammer the energy delivered to the pile per blow shall be

at least equivalent to that of a drop hammer of the stated mass. Drop hammers shall

not be used from floating craft in such a manner as to cause instability of the craft or

significant damage to the pile.

S21.23.8 Driving procedures and redrive checks arising from interruptions to driving

The driving procedure shall be such as to avoid damage to the piles.

The Engineer shall be given 24 hours notice of the commencement of the driving of

the first pile. The Contractor shall give adequate notice and provide all necessary

facilities to enable the Engineer to check driving resistances, sets and temporary

compressions.

The driving of the pile shall be continuous until the depth or set as required has

been reached. In the event of unavoidable interruptions to driving, the pile may be

redriven provided it can subsequently be driven to the desired depth and / or

resistance or set without damage. A follower shall not be used unless the set is

revised where applicable in order to take into account reduction in the effectiveness

of the hammer blow.

Driving records shall be made for every pile. The record shall contain the weight and

fall of the ram and the number of blows for each 0.25 m of penetration.

The Contractor shall inform the Engineer without delay if an unexpected change in

driving characteristics is noted.

S21.23.9 Redrive checks on piles

The Engineer may at any time order re drive on piles already driven to set to check

for farther penetration on re drive. In the event that the re drives show the pile to

penetrate farther, the Contractor shall immediately inform the Engineer and shall

submit for the acceptance of the Engineer:

(a) His proposals for checking the already installed piles.

(b) The revised criteria for terminating the pile including the times for redrives,

the number of redrives on each pile and the minimum pile length.

CTT/ Precast Concrete Piles.Ver.5 16

Date 13th December 2014

(c) His proposals for additional dynamic and static maintained load tests.

S21.23.10 Set

The set and temporary compression shall be measured and recorded for each pile

at the completion of driving. When a set is being measured, the following

requirements shall be met:

(a) The exposed part of the pile shall be in good condition without damage or

distortion.

(b) The helmet, dolly and any packing shall be in sound condition.

(c) The hammer blow shall be in line with the pile axis and the impact surface shall

be flat and at right angles to the pile and hammer axis.

(d) The hammer shall be in good condition, delivering adequate energy per blow,

and operating correctly.

(e) The temporary compression shall be recorded.

The set shall be recorded as the penetration in mm per 10 blows or as the number

of blows required to produce a penetration of 25 mm.

S21.23.11 Driving sequence and risen piles

Piles shall be driven in a sequence to minimize any detrimental effect of heave and

lateral displacement of the ground. The sequence and method of piling including

preboring shall limit uplift and lateral movement so that the final position of each pile

is within the specified tolerances. At all times the deflections of each pile from its

axis as driven shall not be such as to cause damage or impair durability of the piles

or any structure or services.

The maximum permitted uplift of each pile due to any one pile driven within a pile

center to center radius of eight pile diameters is 3 mm unless it can be

demonstrated by static load testing that uplift exceeding the amount does not affect

the ability of the pile to meet the requirement of this Specifications.

Even if during the installation of preliminary piles uplift is shown to be within the

permitted maximum and the preliminary pile tested meet the requirements of the

Specifications, checks of uplift on working piles shall be made by the Contractor at

least once a week and the results reported to the Engineer.

If preliminary piles are not installed the Contractor shall commence installation of

working piles taking measures to reduce or eliminate uplift until it can be established

by site measurements that such measures are no longer necessary. Thereafter

checks on uplift shall be made by the Contractor at least once a week and the

results reported to the Engineer.

If a static load test shows that piles have been laterally displaced so as to be outside

the permitted tolerance, damaged or of impaired durability the measures the

Contractor plans to adopt to enable the piles to comply with the Specification shall

be provided to the Engineer.

CTT/ Precast Concrete Piles.Ver.5 17

Date 13th December 2014

Laterally displaced piles shall not be corrected by forcible correction to the head.

S21.23.12 Preboring

Pre boring shall also be carried out if the pile cannot penetrate through a layer or

layers of stiff to hard materials. The Contractor shall submit his proposals for pre

boring for the agreement of the Engineer.

S21.24 Repair and lengthening of piles

S21.24.1 Repair of damaged pile heads

If it is necessary to repair the head of the pile before it has been driven to its final

level, the Contractor shall carry out such repair in a way that allows the pile driving

to be completed without farther damage. If the driving of the pile has been

completed but the level of sound concrete of the pile is below the required cut off

level, the pile shall be made good to the cut off level, or the pile cap or the

substructure may be locally deepened, so that the completed foundation will safely

withstand the specified working load.

S21.24.2 Lengthening of precast reinforced and prestressed concrete and prestressed spun

piles

Any provision for lengthening piles incorporated at the time of manufacture shall be

designed by the Contractor to resist all stresses to which it may be subjected.

If no provision for lengthening piles was incorporated at the time of manufacture,

any method of lengthening shall be such that the extended pile including joints is

capable of taking safely the stresses during driving and under load.

S21.24.3 Driving repaired or lengthened pile

Repaired or lengthened piles shall not be driven until cubes for the added concrete

have reached the specified characteristic strength of the concrete of the pile.

S21.25 Cutting off pile heads and removal of surplus length

When the driving of the pile has satisfied the Specification requirements the

concrete or the head of the pile shall be cut off to the level specified. Reinforcing

bars projecting above this level shall be as specified.

Care shall be taken to avoid shattering or otherwise damaging the rest of the pile.

Any cracked or defective concrete shall be cut away and the pile repaired to provide

a full sound section to cut off level.

Surplus length cut off shall be removed to the Contractors own disposal areas off

site.

S21.26 Hammers

(1) The Contractor shall adopt only hydraulic hammers or drop hammers for

driving the piles. Other types of hammers including diesel hammers shall not

be permitted.

CTT/ Precast Concrete Piles.Ver.5 18

Date 13th December 2014

(2) The minimum mass of the hammer shall be in accordance with Table S21.3:

Pile type Pile dimensions Minimum hammer

(mm) mass (tons)

200 x 200 3.5

250 x 250 3.5

Precast reinforced

300 x 300 5

concrete piles

350 x 350 7

400 x 400 7

300 diameter 5

350 diameter 5

Precast pretensioned 400 diameter 7

spun concrete piles 450 diameter 7

500 diameter 9

600 diameter 9

Table S21.3

S21.27 Driving piles onto limestone rock

In addition to the preceding clauses of this specification, this clause shall apply to

piles driven onto limestone rock.

(1) The Contractor shall adopt only hydraulic hammers or drop hammers for

driving the piles. Other types of hammers including diesel hammers shall not

be permitted.

(2) The minimum mass of the hammer shall be in accordance with Table S21.4:

Pile type Pile dimensions Minimum hammer

(mm) mass (tons)

200 x 200 5

250 x 250 5

Precast reinforced

300 x 300 7

concrete piles

350 x 350 9

400 x 400 9

300 diameter 7

350 diameter 7

Precast pretensioned 400 diameter 9

spun concrete piles 450 diameter 9

500 diameter 11

600 diameter 11

Table S21.4

(3) During the pile driving, the drop height of the hammer shall be limited to not

more than 500 mm. When the pile is about to set on limestone rock, the

Contractor shall reduce the height of drop of the hammer to not more than

300 mm. The Contractor shall propose to the Engineer the drop height he

intends to adopt from the results of installation and testing of the preliminary

piles but subject to the limits given in this sub clause.

CTT/ Precast Concrete Piles.Ver.5 19

Date 13th December 2014

(4) On completion of driving each segment of pile, the Contractor shall check the

tilt of the pile by placing a bubble level across the top of the driven segment.

After lengthening the pile, he shall measure the tilt of the pile before

commencement of driving. The pile shall be rejected when the tilt exceeds

the specified limits.

(5) The Contractor shall propose the set criteria from the results of driving and

testing of the preliminary piles for the agreement of the Engineer. This

criterion shall then be adopted for all working piles unless the Engineer

agrees to a revised criterion from additional pile tests carried out by the

Contractor. The Contractor shall carry out not less than 3 sets of set

measurements on each pile. Pile driving may be concluded only when three

(3) consecutive set measurements show the set to be within the agreed set

criteria.

CTT/ Precast Concrete Piles.Ver.5 20

Date 13th December 2014

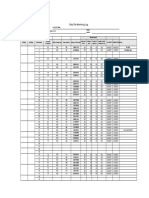

MINIMUM STRUCTURAL REQUIREMENTS FOR PRECAST CONCRETE PILES

Type & Class of Piles Precast reinforced concrete pile Precast pretensioned concrete pile Precast pretensioned spun concrete pile

Requirements Class 1 Class X Class Y Class A Class B

1. Grade of concrete 40 50 55 50 55

2. Minimum cement

content (Kg/m) 400 450 450 450 450

3. Min longitudinal Min 1.2% of cross section or at least 4 bars Min effective stress of Min effective stress of Min effective stress Min effective stress of

reinforcement 5 N/mm 7 N/mm of 5 N/mm 7 N/mm

4. Lateral 1.0% of gross volume over distance of 3 x Min bar size of 6mm diameter at 50mm spacing Spiral hard drawn steel wire shall be not less

reinforcement pile width from each end. over distance of 3 x pile width from each end. than 4mm diameter at a pitch of 50mm over

- at pile/toe 0.4% of gross volume spaced at not more distance of 3 x pile size from each end.

than x pile width.

- at pile body Min bar/wire size is 6mm Spacing gradually increased from pile end to Spacing gradually increased from pile end to

diameter spacing not exceeding pile size less 60mm spacing not exceeding 100mm.

Min spacing 40mm

For pile size exceeding 600mm

diameter, spiral hard drawn steel wire shall

not be less than 6mm

5. Nominal cover 40mm 30mm 30mm 20mm 20mm

6. Minimum thickness 15mm 15mm 15mm

of mild steel plate

for joint (mm)

7. Centering bar 32mm diameter 32mm diameter 32mm diameter

(minimum

anchorage length

200mm and

protruded length of

100mm)

8. Standard sizes Square section of 200mm, 250mm, 300mm, Square section of 200mm, 250mm, 300mm Cylindrical hollow section of external diameter

350mm & 400mm 350mm & 400mm of 250mm, 300mm, 350mm, 400mm, 450mm,

500mm, 600mm, 700mm, 800mm, 900mm,

1000mm & 1200mm.

NOTE 1. Spacing of lateral reinforcement shall be gradually changed from pile head/toe to pile body

NOTE 2. Size of longitudinal reinforcement bars for precast R.C. piles shall not be less than 16mm diameter for casting length of 9m & above

NOTE 3. Sufficient reinforcement must be provided to ensure that the crack width is well within the tolerable limit as specified in Clause 12 of MS 1314: Part 1:

1993 when subject to the cracking bending moment specified in Table 1. Table 2 and Table 3 of MS 1314: Part 1: 1993 as appropriate.

Table S21.2

CTT/ Precast Concrete Piles.Ver.5 21

Date 13th December 2014

You might also like

- SIRIM-Precast Pile 2019 PDFDocument15 pagesSIRIM-Precast Pile 2019 PDFTZeLOonNo ratings yet

- Desing Report - Temporary Sheet PileDocument6 pagesDesing Report - Temporary Sheet PileHafiz KamarudinNo ratings yet

- Gatch Quality TestDocument7 pagesGatch Quality TestMansoor AliNo ratings yet

- Pilescarrying Capacity AnalysisDocument4 pagesPilescarrying Capacity AnalysisBrenda ResurreccionNo ratings yet

- Pile InstallationDocument18 pagesPile InstallationAmal AmranNo ratings yet

- Method Statement of PDA Test For Bored PileDocument12 pagesMethod Statement of PDA Test For Bored PileWee Chek83% (6)

- Sheet Pile Calculation REF Calculations OutputDocument7 pagesSheet Pile Calculation REF Calculations OutputAgboola OluwasolaNo ratings yet

- Proof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan LabuanDocument82 pagesProof Load Test On Jambatan Jalan Kompleks Waterfront FL 745-000-45 Wilayah Persekutuan Labuanfarahazura100% (1)

- Piles IntroductionDocument38 pagesPiles IntroductiondiaidrisNo ratings yet

- Ruukki Splicing of Steel Piles by WeldingDocument8 pagesRuukki Splicing of Steel Piles by Weldingyanickdouce1206100% (1)

- Piled Foundation Design & ConstructionDocument248 pagesPiled Foundation Design & Constructionmarcob74100% (1)

- Differential Settlement Bh7Document9 pagesDifferential Settlement Bh7Zhi Ming CheahNo ratings yet

- Example Mackintosh Probe TestDocument8 pagesExample Mackintosh Probe Testzamzuranee100% (1)

- Pile Capacity Calculation Using SPTDocument12 pagesPile Capacity Calculation Using SPTCharles Ajayi100% (1)

- Shoring SystemDocument3 pagesShoring SystemJason RoyNo ratings yet

- Spun PileDocument7 pagesSpun Pileمحمد فيذول100% (2)

- Method Statement For Construction of Bored Cast In-Situ Piles Using Mechanical Rotary RigDocument5 pagesMethod Statement For Construction of Bored Cast In-Situ Piles Using Mechanical Rotary RigVijay Jamadar100% (2)

- Project: Date: Subject: Done By: Alex: 4/5/2017 4.2m Long Precast Plank RSKU KundangDocument2 pagesProject: Date: Subject: Done By: Alex: 4/5/2017 4.2m Long Precast Plank RSKU KundangalexanderNo ratings yet

- Procedure For Spun Pile at Vac 1 (CH 155.55)Document11 pagesProcedure For Spun Pile at Vac 1 (CH 155.55)Ami ShafiNo ratings yet

- Pile ShoesDocument8 pagesPile ShoesfarahazuraNo ratings yet

- Pile Group:: Piling Works For Bukit Batok N4C18 To C21 468A Pile Ecentricity Calculation G22Document2 pagesPile Group:: Piling Works For Bukit Batok N4C18 To C21 468A Pile Ecentricity Calculation G22lattmdy100% (3)

- Civil Standard & Code No Area Code Standard AstmDocument10 pagesCivil Standard & Code No Area Code Standard AstmTri SeptaNo ratings yet

- 2 Forces On Cofferdams and Their Load CombinationDocument3 pages2 Forces On Cofferdams and Their Load Combinationsyahmi adliNo ratings yet

- MS Plate Bearing Test - PresentationDocument7 pagesMS Plate Bearing Test - PresentationWr Ar100% (1)

- Precast Driven Pile 450x450-350x350Document55 pagesPrecast Driven Pile 450x450-350x350civixxNo ratings yet

- Pile Set CriteriaDocument3 pagesPile Set CriteriaAnonymous O404LiV4CNo ratings yet

- Precast Pile Analysis & Design.400Document4 pagesPrecast Pile Analysis & Design.400civixxNo ratings yet

- Pile Design CalculationDocument69 pagesPile Design Calculationhessian123No ratings yet

- 03 Spun Pile Piling ProcedureDocument8 pages03 Spun Pile Piling ProcedureAhmadRiva'i100% (3)

- Dynamic Load Test MICRO PileDocument16 pagesDynamic Load Test MICRO PileHanafi NidzamNo ratings yet

- Types of PilesDocument40 pagesTypes of PilesMohamad HanifNo ratings yet

- Method Statement For Bored Piling WorksDocument12 pagesMethod Statement For Bored Piling Workstinkerman02No ratings yet

- Pile Design EN1997Document4 pagesPile Design EN1997ikanyu79No ratings yet

- Rebar Join Welding DesignDocument1 pageRebar Join Welding DesignUtaya Kumar Veelmurugan100% (2)

- Rebar Join Welding Design (FW - 6mm)Document2 pagesRebar Join Welding Design (FW - 6mm)Utaya Kumar Veelmurugan100% (2)

- Pile ReportDocument14 pagesPile ReportChen E LikNo ratings yet

- BS Code ListDocument10 pagesBS Code ListUmed ADA-ALSATARNo ratings yet

- Daily Pile Monitoring Log: Pile Grid ID '' ReinforcementDocument2 pagesDaily Pile Monitoring Log: Pile Grid ID '' ReinforcementKarl ToddNo ratings yet

- King PostDocument9 pagesKing PostNyan OoNo ratings yet

- Steel BS Parameter PDFDocument8 pagesSteel BS Parameter PDFdpkNo ratings yet

- SH - Exmp Sheet PileDocument17 pagesSH - Exmp Sheet PileSuntoyo SajaNo ratings yet

- Design of Pad & Chimney FoundationDocument26 pagesDesign of Pad & Chimney FoundationTulsi LakhaniNo ratings yet

- CADS Bearing PileDocument42 pagesCADS Bearing PileDavidNo ratings yet

- Bored Piling Pakubumi 2009 MechanicalDocument19 pagesBored Piling Pakubumi 2009 MechanicaljimdabrondNo ratings yet

- 싱가폴 LTA-Civil Design CriteriaDocument349 pages싱가폴 LTA-Civil Design Criteriacamazie100% (2)

- 300mm Microhtbar RevDocument2 pages300mm Microhtbar RevAlsonChinNo ratings yet

- Diagram Interaksi Spun Pile Dia 450 Kelas A1 R00 F C 52MPa 2014Document11 pagesDiagram Interaksi Spun Pile Dia 450 Kelas A1 R00 F C 52MPa 2014christopherapssNo ratings yet

- TechSpan Brochure PDFDocument6 pagesTechSpan Brochure PDFuet22No ratings yet

- PC Spun Pile Piling Procedure: Table of ContentDocument8 pagesPC Spun Pile Piling Procedure: Table of ContentPUI CHEE KHIANNo ratings yet

- Column Steel DesignDocument37 pagesColumn Steel DesignIlya Joohari100% (1)

- Structural Culvert Design NigeriaDocument54 pagesStructural Culvert Design Nigeriasidiq7100% (2)

- Staad Foundation Pile Calc SheetDocument6 pagesStaad Foundation Pile Calc SheetDeepmalaJayeshNo ratings yet

- GSB-Specs-S21-Precast Concrete Piles-EmployerDocument19 pagesGSB-Specs-S21-Precast Concrete Piles-Employerkiet eelNo ratings yet

- Section 6-Road Works-Part 11-Kerbs, Footways and Paved AreasDocument9 pagesSection 6-Road Works-Part 11-Kerbs, Footways and Paved AreasKashif MalikNo ratings yet

- UntitledDocument47 pagesUntitledbarian karopebokaNo ratings yet

- Acceptance Test of All Concrete Poles PDFDocument24 pagesAcceptance Test of All Concrete Poles PDFIsuru Kasthurirathne100% (1)

- Section 033000 Cast-In-Place Concrete PDFDocument42 pagesSection 033000 Cast-In-Place Concrete PDFTargetRockNo ratings yet

- 1592561914044-1 1996 Reinforced Concrete PolesDocument25 pages1592561914044-1 1996 Reinforced Concrete PolesMahim PritamNo ratings yet

- Structural Steelwork SpecificationDocument14 pagesStructural Steelwork SpecificationruwanpuraNo ratings yet

- Tech Spec 132KV LineDocument285 pagesTech Spec 132KV LineSanjay Rout0% (1)

- SpreadSheet MEYERHOFDocument4 pagesSpreadSheet MEYERHOFzzweirdozzNo ratings yet

- REAM Traffic Signs at JunctionsDocument38 pagesREAM Traffic Signs at JunctionszzweirdozzNo ratings yet

- Construction Standard SpecificationDocument232 pagesConstruction Standard SpecificationzzweirdozzNo ratings yet

- REAM Structural Design of PavementDocument42 pagesREAM Structural Design of PavementzzweirdozzNo ratings yet

- Iwk PDC ChecklistDocument2 pagesIwk PDC Checklistzzweirdozz100% (1)

- 010-05Oct09-COP Demolition Works-Corrected On 30th Sept 2009-1Document148 pages010-05Oct09-COP Demolition Works-Corrected On 30th Sept 2009-1alberttenggarioNo ratings yet

- Iwk Appeal FormDocument2 pagesIwk Appeal Formzzweirdozz50% (2)

- Reinforcement: V, F: Project: Staircase Design - STC 1Document4 pagesReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNo ratings yet

- Iwk SCC ChecklistDocument2 pagesIwk SCC Checklistzzweirdozz100% (1)

- Basics of Rotary Drilling (1) Basics of Rotary DrillingDocument0 pagesBasics of Rotary Drilling (1) Basics of Rotary DrillingmvkellyNo ratings yet

- Nmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)Document8 pagesNmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)parangkilalakitaNo ratings yet

- Fire Tube Boilers PDFDocument16 pagesFire Tube Boilers PDFG.SWAMI67% (3)

- Free LeadingGreen LEED GA Study Guide 3rd Ed PDFDocument46 pagesFree LeadingGreen LEED GA Study Guide 3rd Ed PDFlexsNo ratings yet

- MortarlessDM AS3700 Part1 Section 1 140601Document8 pagesMortarlessDM AS3700 Part1 Section 1 140601jonnypremNo ratings yet

- Avoiding Danger From Overhead Power Lines: Guidance Note GS6 (Fourth Edition)Document12 pagesAvoiding Danger From Overhead Power Lines: Guidance Note GS6 (Fourth Edition)Shahir IbrahimiNo ratings yet

- Metiche AnalDesign FRP Poles PDFDocument26 pagesMetiche AnalDesign FRP Poles PDFMojtaba Mohammad PourNo ratings yet

- Rain Water Harvesting Seminar Report PDFDocument16 pagesRain Water Harvesting Seminar Report PDFHarveen Sai75% (8)

- G M CryocoolerDocument22 pagesG M CryocoolerJaydeep PonkiyaNo ratings yet

- Rolling Bearing Failure V2Document34 pagesRolling Bearing Failure V2dshalev869460% (5)

- Primary SchoolDocument57 pagesPrimary SchoolMUUTHUKRISHNAN100% (1)

- Ssangyong - Compliance Statement-02022017Document11 pagesSsangyong - Compliance Statement-02022017rexNo ratings yet

- Final Bill (Submitted)Document16 pagesFinal Bill (Submitted)Tariq MahmoodNo ratings yet

- TS6 3.5 Tubing 15.8ppfDocument1 pageTS6 3.5 Tubing 15.8ppfKhairilsyam Abdul RashidNo ratings yet

- Foundation For Civil EngineeringDocument2 pagesFoundation For Civil Engineeringmudassir2640No ratings yet

- SamsdataDocument296 pagesSamsdataSamuel AugustineNo ratings yet

- Foundation Engineering-IIDocument24 pagesFoundation Engineering-IIiftikhar AhmadNo ratings yet

- Group 4 Members:: Adjustable Nib Technical PenDocument3 pagesGroup 4 Members:: Adjustable Nib Technical PenLaiRicoNo ratings yet

- Tensile Strength in SoilDocument13 pagesTensile Strength in SoilManash Protim GogoiNo ratings yet

- QBC CRMB TDS Rev 0Document2 pagesQBC CRMB TDS Rev 0nainaNo ratings yet

- Overview of Cross Laminated Timber CLT and Timber Structure Standards Across The WorldDocument13 pagesOverview of Cross Laminated Timber CLT and Timber Structure Standards Across The WorldMarkArchNo ratings yet

- AGI Brochure Chemichal LowRes-24!05!2018Document84 pagesAGI Brochure Chemichal LowRes-24!05!2018Jonathan Ocin JuniorNo ratings yet

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningDocument2 pagesSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezNo ratings yet

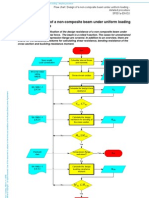

- EC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed ProcedureDocument5 pagesEC3 Flow Chart Design of A Non-Composite Beam Under Uniform Loading - Detailed Procedurejskolmen100% (1)

- Concrete Mix Design As Per Indian Standard CodeDocument4 pagesConcrete Mix Design As Per Indian Standard CodesemakambaNo ratings yet

- L4-Cable Rating-UpdateDocument29 pagesL4-Cable Rating-UpdateboyNo ratings yet

- TT - Revit Structure - Working With Foundation PDFDocument13 pagesTT - Revit Structure - Working With Foundation PDFAshutosh AnandNo ratings yet

- Sydney Opera House: Connection & Collaboration: Lessons From Peter RiceDocument1 pageSydney Opera House: Connection & Collaboration: Lessons From Peter RiceJorge Ariel MamaniNo ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- Thyssen Krupp Synergy-Elevator PDFDocument16 pagesThyssen Krupp Synergy-Elevator PDFAgnelo FernandesNo ratings yet