Professional Documents

Culture Documents

Blind Flange Thickness Calculation

Uploaded by

mamughal123Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blind Flange Thickness Calculation

Uploaded by

mamughal123Copyright:

Available Formats

Blank Thickness calculation

Referring code: ASME-B-31.3

From the clause 304.5.3:

The minimum required thickness of blank.

tm= Dg* 3P +C

16SEW

Where

C = sum of allowances defined

Dg = inside diameter.

E = Quality factor from Table A-1A or A-1B

P = Design gage pressure

S = Stress value for material from Table A-1

W = weld joint strength reduction factor.

S.no Description Unit Converted

1 Design Pressure (P) 63.5 barg 920.75 psi

2 Stress (S) from Table 23.3 ksi 23,300 psi

A-1 for Material

ASTM A105

3 Inside diameter 1131 mm From GASCO

STD 1300-001-034

4 Corrosion allowances 3mm

tm= 1131 3*920.75 +3

16*23300*1*1

tm= 100.35

Mill tolerance= 12.5%

tm= 100.35

.875

tm= 114.68 mm

You might also like

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- Asme Pipe Wall ThicknessDocument3 pagesAsme Pipe Wall ThicknessYoke ShuNo ratings yet

- Flange Rating - Material 1.1Document13 pagesFlange Rating - Material 1.1Clayton KokNo ratings yet

- Pipe SpecificationsDocument5 pagesPipe Specificationsbabar.muetNo ratings yet

- Severin FinalDocument26 pagesSeverin Finalcristasocum_trans1758No ratings yet

- PTC Cacls Asme b31.3Document1 pagePTC Cacls Asme b31.3MamacintNo ratings yet

- Code Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Document4 pagesCode Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Edwardhutauruk100% (1)

- Reflected in WPS If Accepted: FCC BCC HCP FCC Ductile BCC FCC TightDocument3 pagesReflected in WPS If Accepted: FCC BCC HCP FCC Ductile BCC FCC TightAnonymous DMdGdsOENo ratings yet

- PIPE TABLE WIZARD Input Parameters and Component DimensionsDocument2 pagesPIPE TABLE WIZARD Input Parameters and Component DimensionsBangto YibsipNo ratings yet

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

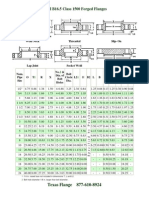

- ANSI B16.5 Class 1500 Forged Flange DimensionsDocument1 pageANSI B16.5 Class 1500 Forged Flange DimensionsMilena Lemus FonsecaNo ratings yet

- ASTM A53 Vs A500 EquivalenceDocument6 pagesASTM A53 Vs A500 Equivalenceemmanuilmoulos6339No ratings yet

- Structural Equivalency SheetDocument73 pagesStructural Equivalency Sheetboim1234No ratings yet

- 3.3development and Scope of Asme CodeDocument1 page3.3development and Scope of Asme CodeArunraj PoikayilNo ratings yet

- 07 Piping BOQDocument54 pages07 Piping BOQHRK65No ratings yet

- ASME B31.3 CalculatorDocument144 pagesASME B31.3 CalculatorLeoNo ratings yet

- Gasket General DimensionDocument20 pagesGasket General DimensionAnonymous uhQ7OyNo ratings yet

- Engineering All in OneDocument245 pagesEngineering All in OneozchrisNo ratings yet

- Boq For AS BoilerDocument1 pageBoq For AS BoilerGayan ChathurangaNo ratings yet

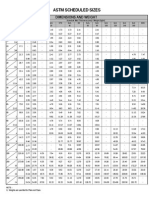

- ASTM PIPE SCHEDULE SIZES AND WEIGHTSDocument1 pageASTM PIPE SCHEDULE SIZES AND WEIGHTSVikasShelkeNo ratings yet

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessNo ratings yet

- PIPE DIMENSIONS AND SPECIFICATIONSDocument13 pagesPIPE DIMENSIONS AND SPECIFICATIONSChristopher Bodys100% (1)

- PipeDocument44 pagesPipesudokuNo ratings yet

- ASME B16.5 Pipe Flanges and Flanged Fittings Published InterpretationsDocument71 pagesASME B16.5 Pipe Flanges and Flanged Fittings Published InterpretationsAymen HileliNo ratings yet

- Davis Controls Ltd. TC Klinger Steam Level GaugesDocument6 pagesDavis Controls Ltd. TC Klinger Steam Level GaugesDavis Controls Ltd.No ratings yet

- Pipeline & Piping ScheduleDocument12 pagesPipeline & Piping SchedulebeyNo ratings yet

- SU Blind Plate ThicknessDocument2 pagesSU Blind Plate Thicknessmanoj19801226100% (1)

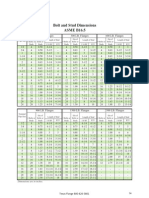

- Bolt and Stud DimentionDocument1 pageBolt and Stud DimentionwhngomjNo ratings yet

- Dimensions for RF Piping ComponentsDocument254 pagesDimensions for RF Piping ComponentsAlpadaniNo ratings yet

- Wrapping Material CalculationDocument1 pageWrapping Material CalculationBiginchNo ratings yet

- 매설배관 건전성평가 PDFDocument169 pages매설배관 건전성평가 PDF이선엽No ratings yet

- Global Marketing For Tube & PipeDocument4 pagesGlobal Marketing For Tube & PipedsyashankaNo ratings yet

- Weight and Size CalculatorDocument4 pagesWeight and Size Calculatorbb84sharmaNo ratings yet

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Document12 pagesInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ibmsherNo ratings yet

- Tank Sizes and Corresponding Nominal CapacitiesDocument1 pageTank Sizes and Corresponding Nominal Capacitieskaito kidNo ratings yet

- V E00B0003B Size-Range MetricDocument1 pageV E00B0003B Size-Range MetricopremapodpritisokNo ratings yet

- Asme Ix - Welder Id Rev.2Document5 pagesAsme Ix - Welder Id Rev.2Joseph Peter100% (1)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

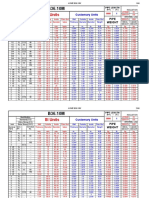

- Asme 16.5Document2 pagesAsme 16.5Norman MoralesNo ratings yet

- Calculator - U Tubes - HSA & QtyDocument4 pagesCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- FittingsDocument50 pagesFittingsashokNo ratings yet

- Bolting Gasket SizingDocument1 pageBolting Gasket SizingKamlesh DalavadiNo ratings yet

- Copia de Unit Converter Ver1Document15 pagesCopia de Unit Converter Ver1Brian TuckerNo ratings yet

- Knife Gate Valve - For Reference OnlyDocument16 pagesKnife Gate Valve - For Reference Onlysj_scribdNo ratings yet

- Studbolt Size ChartDocument3 pagesStudbolt Size ChartRenalyn TorioNo ratings yet

- Technical Data Handbook of Carbon Steel FittingsDocument244 pagesTechnical Data Handbook of Carbon Steel FittingsKrishna KumarNo ratings yet

- Spiral Wound GasketsDocument3 pagesSpiral Wound GasketsHarish GundaNo ratings yet

- Flange Dim EN1092 1 BS4504Document13 pagesFlange Dim EN1092 1 BS4504rcpretoriusNo ratings yet

- Stainless steel pipe dimensions and specifications chartDocument5 pagesStainless steel pipe dimensions and specifications chartNguyễn Duy HưngNo ratings yet

- Heavy Hex NutsDocument3 pagesHeavy Hex NutsAhmadreza AminianNo ratings yet

- ASME B31.3 pressure design thickness calculationDocument1 pageASME B31.3 pressure design thickness calculationsaravoot_jNo ratings yet

- Hydrotest Calculation FormulaDocument1 pageHydrotest Calculation FormulaSandipPatelNo ratings yet

- Types of Flanges-Definition of FlangesDocument4 pagesTypes of Flanges-Definition of FlangesindikumaNo ratings yet

- D - T - D - (Inches) (MM) (MM) (MM) (MM) : Outside Diameter Wall Thickness Inside Diameter Diameter Nominal ScheduleDocument6 pagesD - T - D - (Inches) (MM) (MM) (MM) (MM) : Outside Diameter Wall Thickness Inside Diameter Diameter Nominal ScheduleuzairmetallurgistNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- ASME B31.3 wall thickness calcDocument11 pagesASME B31.3 wall thickness calcAnonymous wIPMQ5rhNo ratings yet

- Rectangular Beam 1VB16-300x800mm - Sagging: InputDocument4 pagesRectangular Beam 1VB16-300x800mm - Sagging: InputSiti Fatimah MokhtarNo ratings yet

- RC Beam DesignDocument1 pageRC Beam DesignshiruhanNo ratings yet

- EPC FOR RUMAITHA NORTH CO2 INJECTION PROJECT-Forecast Schedule (Fabrication)Document3 pagesEPC FOR RUMAITHA NORTH CO2 INJECTION PROJECT-Forecast Schedule (Fabrication)mamughal123No ratings yet

- The PathDocument1 pageThe Pathmamughal123No ratings yet

- Api 5L3-96 PDFDocument16 pagesApi 5L3-96 PDFmamughal123No ratings yet

- Petrol Expanse Claims - 20-02-2019 To 07-03-2019Document1 pagePetrol Expanse Claims - 20-02-2019 To 07-03-2019mamughal123No ratings yet

- Expense Claim - 27-02-2019Document1 pageExpense Claim - 27-02-2019mamughal123No ratings yet

- KBD Vs DBD IDocument1 pageKBD Vs DBD Imamughal123No ratings yet

- Expense Claim - 07-03-2019Document1 pageExpense Claim - 07-03-2019mamughal123No ratings yet

- Typing - PracticeDocument1 pageTyping - Practicemamughal123No ratings yet

- Blind Flange Thickness CalculationDocument1 pageBlind Flange Thickness Calculationmamughal123No ratings yet

- KBD Vs DBD IDocument1 pageKBD Vs DBD Imamughal123No ratings yet

- Packing List DetailsDocument1 pagePacking List Detailsmamughal123No ratings yet

- Sajid Ali QureshiDocument1 pageSajid Ali Qureshimamughal123No ratings yet

- Blind Flange Thickness CalculationDocument1 pageBlind Flange Thickness Calculationmamughal123No ratings yet