Professional Documents

Culture Documents

CB003

Uploaded by

luismdmjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CB003

Uploaded by

luismdmjCopyright:

Available Formats

Publication

CB 003

GB Twin Hydraulic Midi

Booster Assembly

NOTE: This instruction describes the replacement procedures for the Carlisle Twin Hydraulic Midi Booster

Assembly. Information contained in this publication is subject to change without notice or liability.

WARNING: For optimum results and safety, Carlisle recommends that all work should be carried

out by a suitably trained fitter/mechanic. If it is decided to replace used components or

assemblies, always use genuine Carlisle replacement parts. If in doubt seek professional help.

WARNING: Do not attempt to dismantle the hydraulic booster assembly. The Internal

components are not serviceable. Any defective booster assembly must be replaced with a new

genuine Carlisle assembly. Any attempt to remove internal components will void all warranty

terms.

WARNING: This unit contains special synthetic rubber components. Use only Mineral Brake Oil

recommended by the vehicle manufacturer. Failure to use the correct brake oil can lead to

premature failure of components.

CAUTION: Always ensure appropriate safety glasses and gloves are worn when carrying out the

procedures detailed below.

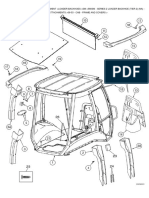

Tank Typical Assembly

Right Hand Brake

Booster

Assembly

Dust Excluder

Left Hand

Brake

Hydraulic Supply

If printed this document is uncontrolled Copyright Carlisle Brake 2011

Park the vehicle on hard ground and chock the wheels. Follow the vehicle manufacturers recommendations to gain

access to the hydraulic booster.

Ensure the parking brake is applied and no hydraulic pressure is held in the system.

Cleaning and Inspection

Clean any dirt or debris from the booster assembly paying particular attention to the areas around the hydraulic

connections.

WARNING: If the areas around the hydraulic connections are not cleaned before the connections

are removed there is a possibility that debris can enter the booster hydraulic ports during the

connection removal process. Any debris entering the hydraulic ports will compromise the

booster function and could lead to premature failure.

Check the rubber dust excluders. They should be soft and flexible and fit tightly in the locating grooves on the

booster and around the push rods.

Dust excluders which show signs of cracking, embrittlememt, swelling or any other damage must be replaced.

Peel back the dust excluders from the location on the booster. If the internal surfaces of the dust excluders contain

brake oil that has emulsified into a grease consistency, this is a normal condition and acceptable.

NOTE: If, when the dust excluders are detached from the booster assembly, brake oil runs from the excluders this

may indicate the failure of the booster's internal sealing arrangement and the booster assembly must be replaced

using a new genuine Carlisle assembly.

Booster Assembly Removal

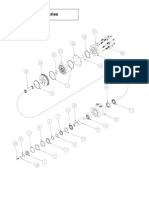

NOTE: The orientation of the brake ports and method of securing the booster unit to the vehicle may vary due to

different vehicle installations. Before removal note the orientation of the booster assembly and position of the

hydraulic pipework connections (Fig. 1) to aid re-assembly.

CAUTION: Ensure any residue brake oil from the disconnected hydraulic pipes or booster

assembly is caught in a suitable container and/or wiped clean with a suitable cloth. Dispose of

any residue brake oil or contaminated cloth in accordance with local environmental regulations.

Drain the braking system of brake oil by attaching a rubber tube to a bleed screw, unscrew the bleed screw half a

turn and pump out the brake oil into a suitable container by operating the foot pedals.

Remove the hydraulic pipe connections from the booster and carefully ease the hydraulic pipes clear of the booster

hydraulic ports.

Disconnect both push rods from the foot pedal linkages.

Remove the nuts, or where applicable bolts, securing the booster assembly to the vehicle bulkhead.

Carefully remove the booster assembly from the vehicle taking care to avoid spillage of any residual brake oil from

the hydraulic supply and tank ports.

Booster Assembly Fitment

Fit the new booster assembly to the vehicle bulkhead, in the correct orientation and secure with the retaining

nuts/bolts.

NOTE: The brake pedals must be in the at rest position, held against the pedal backstop by the pedal return

springs during pushrod connection/adjustment.

Connect the push rods to the brake pedal linkages.

Pushrod adjustment

Adjust the push rods at the pedal linkage until the push rod heads just contact the internal backstops in the booster

assembly. This will automatically set the correct push rod head clearance and enable effective functioning of the

booster assembly.

If printed this document is uncontrolled Copyright Carlisle Brake 2011

NOTE: Ensure the brake pedals remain held against the pedal backstop when pushrod adjustment has been

completed.

Refit the hydraulic pipework connections to the appropriate hydraulic ports on the booster assembly (Fig. 1).

Refer to the note made at booster removal if necessary.

Reference should be made to the following table for the correct tightening torque for each of the various hydraulic

fittings, booster retaining bolts or nuts and push rod connections.

Description Thread Specification Tightening Torque

Booster Retaining Bolt/Nut M8 x 1.25 - 6g/H 22 28 Nm

Pushrod Connection M10 x 1.5 5-6g 22 27 Nm

Right & Left Brake Ports M14 x 1.5 6H 23 27 Nm

Hydraulic Supply Port M14 x 1.5 6H 23 27 Nm

Tank Port M18 x 1.5 6H 70 Nm MAX

When the new booster assembly has been secured to the vehicle and all hydraulic connections made it is

important to remove any air in the hydraulic system. Follow the bleeding procedure details below.

Bleeding Procedure

Turn on the hydraulic supply by starting the engine and latch the brake pedals together.

Attach a rubber tube to one of the bleed screws, unscrew the bleed screw half a turn.

Apply the latched pedals and fully stroke the booster push rods approximately twenty times to expel aerated brake

oil from the booster unit into a suitable container. Tighten the bleedscrew.

Repeat the procedure for the second bleedscrew.

Depending on the type of installation, the bleeding procedure, detailed above, may need to be repeated until all air

has been expelled from the hydraulic system.

CAUTION: Ensure any residue brake oil from the booster assembly is caught in a suitable

container and/or wiped clean with a suitable cloth. Dispose of any residue brake oil or

contaminated cloth in accordance with local environmental regulations.

Check for fluid leaks at all disturbed hydraulic connections and rectify as necessary.

Where applicable, refit the road wheels, remove the axle stands and lower the vehicle to the ground.

Carlisle Brake Products (UK) Ltd.

Omega 500 Unit, Mamhilad Technology Park, Pontypool, Torfaen, NP4 0JJ

Tel: 01495 767300 Fax: 01495 767330 E-Mail: sales@carlislebrake.com

If printed this document is uncontrolled Copyright Carlisle Brake 2011

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- IR SD-100 B 22 15282-B-01xx PDFDocument4 pagesIR SD-100 B 22 15282-B-01xx PDFDiego Alvarez AlvarezNo ratings yet

- Bobcat 753 SpecsDocument2 pagesBobcat 753 SpecsJennifer Williams LawlessNo ratings yet

- Compact SD100DDocument2 pagesCompact SD100DAnonymous QRenwrmJsLNo ratings yet

- B Iny R500lc-7a PDFDocument4 pagesB Iny R500lc-7a PDFluismdmjNo ratings yet

- Ficha Tecnica Vidro Ingersoll - Sd-100dDocument2 pagesFicha Tecnica Vidro Ingersoll - Sd-100dJozé Paxtian100% (1)

- VT Sprinter Truck Market Flyer2Document2 pagesVT Sprinter Truck Market Flyer2luismdmjNo ratings yet

- 520LC 9A Web PDFDocument20 pages520LC 9A Web PDFluismdmjNo ratings yet

- R180LC 9Arev1prnENG Web PDFDocument11 pagesR180LC 9Arev1prnENG Web PDFluismdmjNo ratings yet

- Minicargador Case Kit Alto FlujoDocument9 pagesMinicargador Case Kit Alto FlujoluismdmjNo ratings yet

- Hyundai ExcavatorsDocument12 pagesHyundai Excavatorsluismdmj33% (3)

- BFM 2012 Mobile Machinery enDocument2 pagesBFM 2012 Mobile Machinery enluismdmjNo ratings yet

- Catalog 1Document1 pageCatalog 1luismdmjNo ratings yet

- 125lcr 9a WebDocument4 pages125lcr 9a WebluismdmjNo ratings yet

- 480LC 9A Web PDFDocument20 pages480LC 9A Web PDFluismdmjNo ratings yet

- Quality Replacement Parts CatalogDocument69 pagesQuality Replacement Parts CatalogluismdmjNo ratings yet

- 125LCR 9A Web PDFDocument24 pages125LCR 9A Web PDFluismdmjNo ratings yet

- 125lcr 9a WebDocument4 pages125lcr 9a WebluismdmjNo ratings yet

- FirewallDocument1 pageFirewallluismdmjNo ratings yet

- B Iny R500lc-7aDocument4 pagesB Iny R500lc-7aluismdmjNo ratings yet

- 140LC 9a-Web PDFDocument24 pages140LC 9a-Web PDFluismdmjNo ratings yet

- Case-580SM Series 3Document164 pagesCase-580SM Series 3luismdmj100% (2)

- Catalog 3Document2 pagesCatalog 3luismdmjNo ratings yet

- Catalog 2Document1 pageCatalog 2luismdmjNo ratings yet

- BFM 2012 Mobile Machinery enDocument2 pagesBFM 2012 Mobile Machinery enluismdmjNo ratings yet

- 500 - Parts Motor de HormigoneraDocument2 pages500 - Parts Motor de HormigoneraluismdmjNo ratings yet

- CatalogDocument2 pagesCatalogluismdmjNo ratings yet

- CatalogDocument1 pageCatalogluismdmjNo ratings yet

- Catalo 14Document1 pageCatalo 14luismdmjNo ratings yet

- Engine Thermostat and Thermostat HousingDocument2 pagesEngine Thermostat and Thermostat HousingluismdmjNo ratings yet

- Catalo 15Document1 pageCatalo 15luismdmjNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Noise Performance of A Matched Filter PN Code Synchroniser UDocument5 pagesNoise Performance of A Matched Filter PN Code Synchroniser UOmar HamdiNo ratings yet

- Creation of Customer From Business PartnerDocument9 pagesCreation of Customer From Business PartnerParag SoniNo ratings yet

- Mals-11, Family Readiness Newsletter, July 2011, The Devilfish TidesDocument9 pagesMals-11, Family Readiness Newsletter, July 2011, The Devilfish TidesDevilfish FRONo ratings yet

- Calculating The Pathlength of Liquid Cells by FTIR PIKEDocument1 pageCalculating The Pathlength of Liquid Cells by FTIR PIKEMoises RomeroNo ratings yet

- Chapter 3 Hydro Thermal SchedulingDocument65 pagesChapter 3 Hydro Thermal Schedulingbik_mesiloveNo ratings yet

- 2008 Nissan Teana J32 Service Manual-HacDocument245 pages2008 Nissan Teana J32 Service Manual-HacMrihexNo ratings yet

- University of Wah Wah Engineering College Assignment # 05Document6 pagesUniversity of Wah Wah Engineering College Assignment # 05Ha M ZaNo ratings yet

- Phone Genesys ConfigurationDocument22 pagesPhone Genesys ConfigurationRodolfo TobiasNo ratings yet

- BTD-Final Lesson PlanDocument22 pagesBTD-Final Lesson PlanSunil BajantriNo ratings yet

- Document 1Document14 pagesDocument 1bismarckandresNo ratings yet

- Microsoft Word - Exercise 3 Subsea P&PDocument5 pagesMicrosoft Word - Exercise 3 Subsea P&PKRNo ratings yet

- Ra CocnatsDocument13 pagesRa CocnatsloyioNo ratings yet

- Truck Parking Areas 2009Document147 pagesTruck Parking Areas 2009IRUNo ratings yet

- Koel Engine, Ha Operation and Maintenance Manual (Ha - SR)Document89 pagesKoel Engine, Ha Operation and Maintenance Manual (Ha - SR)Karthik K Raja75% (12)

- LTS 3000 SpecificationDocument4 pagesLTS 3000 SpecificationMuhammad Nabil RoslanNo ratings yet

- D20S-7 Sb1159e01 PDFDocument678 pagesD20S-7 Sb1159e01 PDFGORDNo ratings yet

- Pawan Kumar Dubey: ProfileDocument4 pagesPawan Kumar Dubey: Profilepawandubey9No ratings yet

- 4 10 59 08 Juni 2023Document5 pages4 10 59 08 Juni 2023ihor.vezhninNo ratings yet

- Software: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsDocument8 pagesSoftware: Measurlink Is An Easy-To-Use, Windows-Based Family of Quality Data Management Software ApplicationsBrandi DaleNo ratings yet

- Unitrac 80WDocument1 pageUnitrac 80WprogramacionavanzadaNo ratings yet

- Vatufeku Longman Writing Academic English Xufex PDFDocument4 pagesVatufeku Longman Writing Academic English Xufex PDFNZAR AREFNo ratings yet

- OpenCV 3.0 Computer Vision With Java - Sample ChapterDocument27 pagesOpenCV 3.0 Computer Vision With Java - Sample ChapterPackt PublishingNo ratings yet

- Inlet Modules Model Code: ExampleDocument1 pageInlet Modules Model Code: ExamplemhasansharifiNo ratings yet

- Barrett Light 50Document23 pagesBarrett Light 50Zayd Iskandar Dzolkarnain Al-HadramiNo ratings yet

- Snare Drum: Some Entries From Various Sources (Loosely Cited)Document6 pagesSnare Drum: Some Entries From Various Sources (Loosely Cited)gljebglejebNo ratings yet

- LiquidlevelDocument24 pagesLiquidlevelAnu Raj Anu RajNo ratings yet

- MagnetostictiveDocument17 pagesMagnetostictivekanikasharma22No ratings yet

- PLSQL TutorialspointDocument22 pagesPLSQL TutorialspointSatanu MaityNo ratings yet

- Drilling Data Handbook 9th EditionDocument4 pagesDrilling Data Handbook 9th Editiondedete50% (2)

- HILTI Typical Plumbing ApplicationsDocument140 pagesHILTI Typical Plumbing ApplicationskuraimundNo ratings yet