Professional Documents

Culture Documents

Ge 2

Uploaded by

Anonymous Sy6ss4bpG3Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ge 2

Uploaded by

Anonymous Sy6ss4bpG3Copyright:

Available Formats

Welding Engineer

Global Growth Organization India

GE Global Growth Organization

India

Essential Responsibilities

The position will report to the Manufacturing Manager Fabrication product Line

To lead for the first product manufactured (welding products).

Define process flow and layouts for the serial production.

Define Takt time, no of workstations and cells.

Define resources requirement for specified takt time equipment and machinery list,

manpower calculation with skill and semiskilled bifurcation and no of jigs and fixtures etc.

To read the engineering documents like BOM, TRD, Drawings and make the Work

Instructions, weld maps and other methods documentation for the production department.

After the mock trial and initial few product manufacturing, review the welding drawings and

implementing the changes to smooth the serial production.

To lead the process improvement during serial production.

To provide training to production team at the start of the project.

To support the production department for continuous improvements.

Responsible for the engineering changes to be communicated to local team for implementation.

Conducts Weld-Ergo analysis : Ergo analysis of weld manufacturing process as per inputs

provided.

Good awareness of Welding and its sequencing (ergo-analysis) so that cycle time is optimal.

Has good awareness of loading, unloading of Parts, Assemblies so that cycle time is optimal.

Work with design and manufacturing engineering to resolve materials joining issues before and

during manufacturing and provide technical support to suppliers and customers.

About Us

GE is the world's Digital Industrial Company, transforming industry with software-defined

machines and solutions that are connected, responsive and predictive. Through our people,

leadership development, services, technology and scale, GE delivers better outcomes for global

customers by speaking the language of industry.

Role Summary/Purpose

As part of the GE India Multi-modal Manufacturing team, the Welding Engineer-Heavy

Fabrication is responsible for shop floor management for the fabrication operations including

welding, heat treatment, WPS/PQR, WPQ & fabrication training. The role is to work on the floor

with fitters and welders for the production of heavy fabricated components.

Qualifications/Requirements

1. B.S. Degree in Welding Engineering, Metallurgical, or Materials Science from an accredited

institution with a minimum of five years of related experience in railway bogie or platform

manufacturing is preferred. Equivalent experience may be considered.

2. International Welding Engineer Status from IIW.

3. Weld symbol and fabrication drawing reading skills.

4. Good communication and presentation skills (written and verbal).

5. Proven ability to meet deadlines and multi-task on multiple projects.

6. Be an innovative thinker and present theories/concepts in a professional manner.

7. Knowledge of the following welding codes

- ASME Section V & IX

- AWS D1.1, D1.2, D15.1 & D1.6

- EN Welding & NDT Qualifications

8. Experience in working with carbon, low, high alloy and stainless steels, nickel and copper

based alloys, as well as dissimilar metal welding.

9. Prior experience as a welding, materials or manufacturing engineer.

Desired Characteristics

1. Ability to analyze problems, identify root causes and provide efficient solutions

2. Certified Welding Inspector-AWS

3. Strong organizational skills, MS office skills

4. Ability to handle diverse activities simultaneously and Ability to work in a matrix

organization.

5. Strong interpersonal and leadership skills with good oral and written communication skills

6. Strong project and team leadership

7. Knowledge of Lean and Six Sigma Methodology

8. Fluent in English and Hindi Language (Written and Spoken)

9. Marathi Language Skills (Verbal & Written)

10. Knowledge of AS 9100/ISO and its application in a complex business.

You might also like

- Assignment MEC400Document8 pagesAssignment MEC400Noraisyah ArifinNo ratings yet

- Suggested KeywordsDocument6 pagesSuggested KeywordsHomer Texido FrangioniNo ratings yet

- Design Engineer - Motorcycle Accessories (MC331) Job Description and Person SpecificationDocument2 pagesDesign Engineer - Motorcycle Accessories (MC331) Job Description and Person SpecificationneerajmprakashNo ratings yet

- AB's CVDocument2 pagesAB's CVAnilkumar HatkarNo ratings yet

- March TAIT GigsDocument4 pagesMarch TAIT GigsdboeversNo ratings yet

- Dinesh Kumar Kushwaha: Professional SynopsisDocument4 pagesDinesh Kumar Kushwaha: Professional SynopsisJitendra GondNo ratings yet

- JD Process EngineerDocument2 pagesJD Process EngineerVishwath BhandaryNo ratings yet

- CAD Technician (LSP) Job Order # 017: Main Duties Include But Are Not Limited ToDocument3 pagesCAD Technician (LSP) Job Order # 017: Main Duties Include But Are Not Limited ToismailNo ratings yet

- Application Engineer JDDocument2 pagesApplication Engineer JDJuhaya KojuaNo ratings yet

- Gowthaman Pazhanisamy: Career ObjectiveDocument3 pagesGowthaman Pazhanisamy: Career Objectivegowthaman rajNo ratings yet

- Resume-Chetan-Dhuri-Mechanical Design FEADocument4 pagesResume-Chetan-Dhuri-Mechanical Design FEAChetan DhuriNo ratings yet

- Senior Mechanical EngineerDocument2 pagesSenior Mechanical EngineerJose Gregorio Lira SerranoNo ratings yet

- Key Skills: Profile SummaryDocument5 pagesKey Skills: Profile SummaryKumardasNsNo ratings yet

- Design DutiesDocument5 pagesDesign DutiesKailas NimbalkarNo ratings yet

- Job Description Mechanical Design EngineersDocument1 pageJob Description Mechanical Design Engineersyinkaakins2001No ratings yet

- Job Description Project Engineer - Rocvolt PositionDocument2 pagesJob Description Project Engineer - Rocvolt Positionajaya PAINo ratings yet

- LEAN Green Belt: Ashraf Gerges GadDocument3 pagesLEAN Green Belt: Ashraf Gerges GadBubbleNo ratings yet

- Piping Engineer CVDocument3 pagesPiping Engineer CVArshed Jawad Al-mansori100% (2)

- Vigneshwaran.S: Areas of ExposureDocument2 pagesVigneshwaran.S: Areas of Exposuremamillapalli sri harshaNo ratings yet

- Lokesh Kambar: Career ObjectiveDocument3 pagesLokesh Kambar: Career ObjectiveRanjith LMNo ratings yet

- CV - Rajan Yadav - CleanedDocument2 pagesCV - Rajan Yadav - CleanedzeeshanNo ratings yet

- Robotics Engineering ProfileDocument5 pagesRobotics Engineering ProfileBps PSNo ratings yet

- ORV - ATV - Structures Design EngineerDocument2 pagesORV - ATV - Structures Design EngineerDilipReddiarNo ratings yet

- Kumar N S JULY2019 06Document4 pagesKumar N S JULY2019 06KumardasNsNo ratings yet

- Pratheepraj TDocument3 pagesPratheepraj TvenkyymdNo ratings yet

- (S1) - Project Engineer - Rendra Maha Putra JF - Sriwijaya Univ PDFDocument16 pages(S1) - Project Engineer - Rendra Maha Putra JF - Sriwijaya Univ PDFRendra Maha Putra JfNo ratings yet

- Design Engineer ResumeDocument7 pagesDesign Engineer Resumefzdpofajd100% (2)

- Design Engineer: About CompanyDocument1 pageDesign Engineer: About CompanyshashiNo ratings yet

- G.suresh B.e., M.b.a.Document5 pagesG.suresh B.e., M.b.a.shafeeq ahmedNo ratings yet

- Engineering Technician ResumeDocument6 pagesEngineering Technician Resumezug0badej0n2100% (2)

- Mechanical Engineering CV ExampleDocument2 pagesMechanical Engineering CV Examplemochammad sofiNo ratings yet

- Resume For Welder JobDocument5 pagesResume For Welder Jobbetevopelah3100% (2)

- 114 Mechanical Projects EngineerDocument2 pages114 Mechanical Projects EngineerBasharat AliNo ratings yet

- Well Designer TADocument2 pagesWell Designer TApengepul rosokNo ratings yet

- ShivaRam ResumeDocument4 pagesShivaRam ResumeVishnu TejaNo ratings yet

- JOB DESCRIPTION: Mechanical Design Engineer: OverviewDocument2 pagesJOB DESCRIPTION: Mechanical Design Engineer: OverviewAspire SuccessNo ratings yet

- RambollDocument2 pagesRambollVinoth BalaNo ratings yet

- Aung Myo Min CCB46 Resume SolidworksDocument2 pagesAung Myo Min CCB46 Resume SolidworksAung myo MinNo ratings yet

- JD - EE Hardware Engineer - L5 - 10 YearsDocument3 pagesJD - EE Hardware Engineer - L5 - 10 YearsNitin GhadleNo ratings yet

- Sagar Dhumal-Mechanical Design EngineerDocument2 pagesSagar Dhumal-Mechanical Design Engineerchetan expertgsNo ratings yet

- Job Description Principal Mechanical Engineer - v2.1 Sept23Document1 pageJob Description Principal Mechanical Engineer - v2.1 Sept23srikanth829No ratings yet

- Resume Piping Engineer-Sks01Document4 pagesResume Piping Engineer-Sks01Syed KhalidNo ratings yet

- Construction Project Engineer ResumeDocument6 pagesConstruction Project Engineer Resumezug0badej0n2100% (2)

- Objective:: Name Date of Birth Marital Status AddressDocument5 pagesObjective:: Name Date of Birth Marital Status AddresskspNo ratings yet

- Becoming A Future-Ready R&D Hardware EngineerDocument8 pagesBecoming A Future-Ready R&D Hardware EngineerjackNo ratings yet

- 32 HR Jobprofile DieFollowUp SrEngineer 00 29may13Document2 pages32 HR Jobprofile DieFollowUp SrEngineer 00 29may13Prabhakar KattulaNo ratings yet

- Quality Control - ManufucturingDocument3 pagesQuality Control - ManufucturingShahid KhanNo ratings yet

- Senior Process Engineer PDFDocument2 pagesSenior Process Engineer PDFdelitiberiuskrik24No ratings yet

- Civil Syllabous Online NewDocument12 pagesCivil Syllabous Online NewSyed Arman AlamNo ratings yet

- Position Details: Areas of Accountabilities (List Up To 10 Prime Activities) % of Time SpentDocument3 pagesPosition Details: Areas of Accountabilities (List Up To 10 Prime Activities) % of Time SpentZaidNo ratings yet

- Power Design UpdateDocument7 pagesPower Design UpdateAnonymous ufMAGXcskMNo ratings yet

- Cad Design Engineer Interiors NVH August 2013Document1 pageCad Design Engineer Interiors NVH August 2013Sumit SehgalNo ratings yet

- Personal Details: SkillsDocument5 pagesPersonal Details: Skillsmuthu vNo ratings yet

- Naukri AjayGawai (8y 0m)Document4 pagesNaukri AjayGawai (8y 0m)deepakpushpadNo ratings yet

- Curriculum Vitae: Aamir SuhailDocument3 pagesCurriculum Vitae: Aamir SuhailMrSumitkrgautamNo ratings yet

- May - Job DescriptionDocument28 pagesMay - Job DescriptionSettuNo ratings yet

- Elluri Karthik 11yrs Value EngineeringDocument2 pagesElluri Karthik 11yrs Value EngineeringkarthikNo ratings yet

- Senior Design Engineer - Mechanical Vacancy AdvertDocument1 pageSenior Design Engineer - Mechanical Vacancy AdvertSean Kalu OnuohaNo ratings yet

- Advance Engineered Proposals Team: Melanie Nicholl / Vacancy Tendering EngineersDocument3 pagesAdvance Engineered Proposals Team: Melanie Nicholl / Vacancy Tendering EngineersBayumi Tirta JayaNo ratings yet

- RYLA Handbook 2013Document39 pagesRYLA Handbook 2013katiemc124No ratings yet

- Test Paper (Chegg Essay Evaluation)Document15 pagesTest Paper (Chegg Essay Evaluation)living smart lifestyleNo ratings yet

- Chapter 6 Supply Network DesignDocument22 pagesChapter 6 Supply Network DesignErick Quan LunaNo ratings yet

- Manajemen StratejikDocument6 pagesManajemen StratejikMarysa NovegasariNo ratings yet

- Effective TeamsDocument19 pagesEffective TeamsMuhammad Iqrash Awan50% (2)

- OB Assignment Pratikshya Sewa 3rd Semester (Susan Shrestha Case 1)Document13 pagesOB Assignment Pratikshya Sewa 3rd Semester (Susan Shrestha Case 1)PratikshyaNo ratings yet

- Pinto CRC Final PDFDocument22 pagesPinto CRC Final PDFДр. Цчатерйее50% (2)

- Organizational Behavior of PELDocument57 pagesOrganizational Behavior of PELmalik bhai0% (1)

- HRD Notes DR C V KDocument19 pagesHRD Notes DR C V KKanchana Krishna KaushikNo ratings yet

- WK4Assgn2 - SWOT Analysis II - Baker A v1.1Document8 pagesWK4Assgn2 - SWOT Analysis II - Baker A v1.1avbakerNo ratings yet

- Decision Making Life Skills My Dev Module 3: Leadership and TeamworkDocument6 pagesDecision Making Life Skills My Dev Module 3: Leadership and TeamworkAsh Lee MaNo ratings yet

- Chapter 14 - Engineering Management in The New Millennium: Dr. C. M. ChangDocument52 pagesChapter 14 - Engineering Management in The New Millennium: Dr. C. M. ChangbawardiaNo ratings yet

- Gender Stereotypes Are Alive Well and Busy Producing Workplace DiscriminationDocument6 pagesGender Stereotypes Are Alive Well and Busy Producing Workplace DiscriminationAmanda ViviNo ratings yet

- Leading From The Chair: Executive EducationDocument8 pagesLeading From The Chair: Executive EducationRachit Kumar StudentNo ratings yet

- Cover Letter For MckinseyDocument1 pageCover Letter For MckinseyQueens CommerceNo ratings yet

- Interview Assessment FormDocument1 pageInterview Assessment FormCathleya Marie CoNo ratings yet

- Company and Marketing Strategy Partnering To Build Customer Engagement, Value and RelationshipDocument55 pagesCompany and Marketing Strategy Partnering To Build Customer Engagement, Value and RelationshipHân Nguyễn Thùy DiệuNo ratings yet

- BNS 3rd YEAR 2023 ReviseDocument17 pagesBNS 3rd YEAR 2023 ReviseshadabkhanskNo ratings yet

- Soal Selidik 2Document5 pagesSoal Selidik 2Najibul RahmanNo ratings yet

- Customer Service Management - Turning Customer Loyalty Into Profitability PDFDocument7 pagesCustomer Service Management - Turning Customer Loyalty Into Profitability PDFNur FadhisaNo ratings yet

- A Final Report Submitted by The Effective Utility Management Steering Committee To The Collaborating OrganizationsDocument35 pagesA Final Report Submitted by The Effective Utility Management Steering Committee To The Collaborating OrganizationsRadhakrishna MadabhushiNo ratings yet

- Forrester Service Catalog 2013 PDFDocument23 pagesForrester Service Catalog 2013 PDFenergitixNo ratings yet

- Course: School Leadership (8618) : Assignment No. 1Document13 pagesCourse: School Leadership (8618) : Assignment No. 1Suliman KhiljiNo ratings yet

- ERP ImplementationDocument29 pagesERP ImplementationNaushal Sachaniya100% (2)

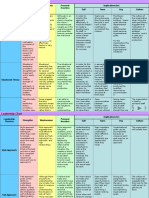

- Leadership Theories Strengths: Weaknesses: Personal Reaction Implications For: Self Team Org CultureDocument2 pagesLeadership Theories Strengths: Weaknesses: Personal Reaction Implications For: Self Team Org CulturedrengerguriNo ratings yet

- LCCI Kidolgozott Szobeli Tetelek 1Document55 pagesLCCI Kidolgozott Szobeli Tetelek 1zsuzsi_harangoz2218100% (2)

- Upload Kaizen Charter - Form 1 PGDocument2 pagesUpload Kaizen Charter - Form 1 PGmanuelNo ratings yet

- Total Quality Management: - Customer Satisfaction - Employee Involvement - Process ApproachDocument22 pagesTotal Quality Management: - Customer Satisfaction - Employee Involvement - Process ApproachgerryztNo ratings yet

- Principles of ManagementDocument19 pagesPrinciples of Managementmehwishali72No ratings yet

- MNO Case 1Document2 pagesMNO Case 1Cee RD75% (4)