Professional Documents

Culture Documents

Double Angle Capacity

Uploaded by

Amey GudigarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Double Angle Capacity

Uploaded by

Amey GudigarCopyright:

Available Formats

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

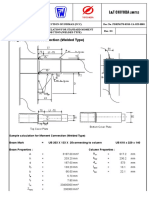

Double Angle Capacity Based on AISC 360-10

INPUT DATA & DESIGN SUMMARY

DOUBLE ANGLE SIZE 2 - L8X6X1

LONG LEGS BACK TO BACK ? Yes (LLBB)

GAP DIMENSION s = 0.375 in

STITCHES SPACING kLz = 4 ft, o.c.

STEEL YIELD STRESS Fy = 36 ksi

AXIAL FORCE (plus sign for compression) P= 80 kips, ASD

STRONG GEOMETRIC AXIS EFFECTIVE LENGTH kLx = 20 ft bf = 12.4 in tf = 1.0 in

WEAK GEOMETRIC AXIS EFFECTIVE LENGTH kLy = 10 ft d= 8.0 in yp = 1.50 in

A= 22.0 in 2 Ix = 162 in4

STRONG GEOMETRIC AXIS BENDING MOMENT 35 Mrx =

ft-kips, ASD, y= 3.14 in Iy = 179 in4

DOUBLE LEGS TENSION ? Yes (back to back legs tension)

STRONG GEOMETRIC AXIS BENDING UNBRACED LENGTH Lbx = 20 ft, (AISC 360-10 F9.2 & F2.2.c)

STRONG DIRECTION SHEAR LOAD, ASD Vstrong = 200 kips

THE DESIGN IS ADEQUATE.

WEAK GEOMETRIC AXIS BENDING MOMENT Mry = 15 ft-kips, ASD

WEAK GEOMETRIC AXIS BENDING UNBRACED LENGTH Lby = 10 ft

WEAK DIRECTION SHEAR LOAD, ASD Vweak = 150 kips

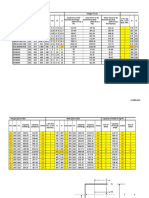

ANALYSIS

CHECK LIMITING WIDTH-THICKNESS RATIOS (AISC 360-10, Table B4.1)

0.5 (bf - s - tw) / tf = 5.00 < 1.0 (E / Fy)0.5 = 28.38 [Satisfactory]

d / tw = 4.00 < 0.75 (E / Fy)0.5 = 21.29 [Satisfactory]

CHECK COMBINED COMPRESSION AND BENDING CAPACITY FOR DOUBLE ANGLES (AISC 360-10, H1)

P 8 M r ,x M r , y Pr

r , for 0.2

Pc 9 M c , x M c, y Pc

0.99 < 1.0 [Satisfactory]

P r M r ,x M r , y Pr

0.2

M c , x M c , y

, for

2 P c P c

Where Pc = Pn / Wc = 270 / 1.67 =

161.41 kips, (AISC 360-10 Chapter E4a or D2)

> Pr = 80.00 kips [Satisfactory]

Mc,x = Mn / Wb = 159.68 / 1.67 = 95.62 ft-kips, (AISC 360-10, F9) > Mr,x [Satisfactory]

Mc,y = Mn / Wb = 129.00 / 1.67 = 77.25 ft-kips, (AISC 360-10, F6) > Mr,y [Satisfactory]

CHECK COMBINED COMPRESSION AND BENDING CAPACITY FOR SINGLE ANGLE BETWEEN STITCHES (AISC 360-10, H1)

P r 8 M r ,max M r ,min Pr

, for 0.2

Pc 9 M c,max M c,min Pc

0.96 < 1.0 [Satisfactory]

P r M r ,max M r ,min

, for P r 0.2

2 P M c,max M c,min Pc

c

Where Pc = Pn / Wc = 256 / 1.67 = 153.09 kips, (AISC 360-10 Chapter E5)

> Pr = 43.50 kips [Satisfactory]

(Conservatively, Pr is single angle possible maximum axial load, which may be non-concurrent with moments.)

Mr,max = 5.30 ft-kips or 5.30 ft-kips ,(major principal axis bending)

Mr,min = 5.30 ft-kips or 5.30 ft-kips ,(minor principal axis bending)

Mc,max = Mn / Wb = 44.40 / 1.67 = 26.58 ft-kips, (smaller equal-leg section used, AISC 360-10 Chapter F10-2)

> Mr,max [Satisfactory]

Mc,min = Mn / Wb = 15.89 / 1.67 = 9.51 ft-kips > Mr,min [Satisfactory]

CHECK SHEAR CAPACITY (AISC 360-10, G2)

Vn,strong / Wv = 345.6 / 1.67 = 206.9 kips > Vstrong = 200.0 kips [Satisfactory]

Vn,weak / Wv = 259.2 / 1.67 = 155.2 kips > Vweak = 150.0 kips [Satisfactory]

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

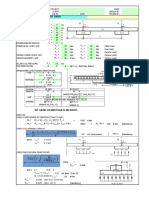

Angle Steel Member Capacity Based on AISC 360-05

INPUT DATA & DESIGN SUMMARY

ANGLE SIZE L8X6X1

STEEL YIELD STRESS Fy = 36 ksi

AXIAL COMPRESSION FORCE P = 43.5013 kips, ASD

STRONG GEOMETRIC AXIS EFFECTIVE LENGTH kLx = 4 ft

WEAK GEOMETRIC AXIS EFFECTIVE LENGTH kLy = 4 ft

STRONG GEOMETRIC AXIS BENDING MOMENT Mrx = ft-kips, ASD

STRONG GEOMETRIC AXIS BENDING UNBRACED LENGTH Lbx = 4 ft, (AISC 360-05 F2.2.c)

STRONG DIRECTION SHEAR LOAD, ASD Vstrong = kips

WEAK GEOMETRIC AXIS BENDING MOMENT Mry = 7.5 ft-kips, ASD

WEAK GEOMETRIC AXIS BENDING UNBRACED LENGTH Lby = 4 ft

WEAK DIRECTION SHEAR LOAD, ASD Vweak = kips

THE DESIGN IS ADEQUATE.

ANALYSIS

CHECK COMBINED COMPRESSION AND BENDING CAPACITY (AISC 360-05, H1)

CHECK SHEAR CAPACITY (AISC 360-05, G2)

Vn,strong / Wv = 172.8 / 1.67 = 103.5 kips > Vstrong = 0.0 kips [Satisfactory]

Vn,weak / Wv = 129.6 / 1.67 = 77.6 kips > Vweak = 0.0 kips [Satisfactory]

You might also like

- A Teaching Guide For Structural Steel ConnectionsDocument85 pagesA Teaching Guide For Structural Steel Connectionsv97% (65)

- F Q GC A: Wind Load On StructuresDocument55 pagesF Q GC A: Wind Load On StructuresAna Bella RosarioNo ratings yet

- Guide To Design Criteria For Bolts and Riveted JointsDocument352 pagesGuide To Design Criteria For Bolts and Riveted JointsHomero Silva96% (24)

- PCA TIME SAVING DESIGN AIDS - WallsDocument5 pagesPCA TIME SAVING DESIGN AIDS - WallsvNo ratings yet

- Ansi Ashrae Acca 183-2007 (Ra 2014)Document10 pagesAnsi Ashrae Acca 183-2007 (Ra 2014)Ahmed Labib100% (3)

- Pca Circular Concrete TanksDocument59 pagesPca Circular Concrete TanksJoaquin Magnet100% (8)

- Design Criteria/Design Check For Star Deck Sheet (44/130)Document2 pagesDesign Criteria/Design Check For Star Deck Sheet (44/130)Advanced Structural EngineeringNo ratings yet

- AISC ASD Base Plate Thickness V2016-2Document9 pagesAISC ASD Base Plate Thickness V2016-2yusuf_jtNo ratings yet

- TATA Structura BrochureDocument20 pagesTATA Structura Brochurecjm100% (2)

- AISC ASD Beam Column CheckDocument9 pagesAISC ASD Beam Column CheckGohar ZamanNo ratings yet

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Water Tank DesignDocument58 pagesWater Tank DesignMoHaMmAd WaHeEd88% (17)

- Double Angle CapacityDocument2 pagesDouble Angle CapacityAlphaNo ratings yet

- BASE (Pin) - R1 For Calculation SheetDocument15 pagesBASE (Pin) - R1 For Calculation SheetSana UllahNo ratings yet

- SP 8004 - Panel FlutterDocument51 pagesSP 8004 - Panel FlutterElumalai SrinivasanNo ratings yet

- StaircaseDocument14 pagesStaircaserameshbabu_1979No ratings yet

- b2b SpliceDocument21 pagesb2b SplicePrasad Dayalamoorthy DNo ratings yet

- Shear Key DesignDocument2 pagesShear Key DesignmaheshbandhamNo ratings yet

- Moment ConnectionDocument39 pagesMoment ConnectionRitwick MishraNo ratings yet

- DoubleAngleCapacityDocument2 pagesDoubleAngleCapacityIsprotec IngenieriaNo ratings yet

- b03 - LRFD - Girt, Purlin - To VendorDocument52 pagesb03 - LRFD - Girt, Purlin - To VendorSaleem KhaderNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- Design of Reinforced Concrete Water TanksDocument71 pagesDesign of Reinforced Concrete Water Tanksace1205100% (3)

- Base Plate - Silo Supporting R1Document10 pagesBase Plate - Silo Supporting R1soumi bhattacharyaNo ratings yet

- Wind Load Calculations As Per ASCE 7-10:: Z Z ZT D 2Document10 pagesWind Load Calculations As Per ASCE 7-10:: Z Z ZT D 2MayurNo ratings yet

- Bracing V1Document6 pagesBracing V1Shawkat Ali KhanNo ratings yet

- Fillet Weld Connection DesignDocument1 pageFillet Weld Connection Designbalaji gmscNo ratings yet

- Four Bolt Moment Connection DesignDocument12 pagesFour Bolt Moment Connection DesignDarshan Panchal0% (1)

- Welded Splice Connection-R2Document16 pagesWelded Splice Connection-R2Nitesh Singh100% (1)

- Batten Plates DesiDocument7 pagesBatten Plates DesiSuhas MangaloreNo ratings yet

- "Bracket13" - Bracket Plate Stress Analysis ProgramDocument7 pages"Bracket13" - Bracket Plate Stress Analysis ProgramFarid TataNo ratings yet

- 00 UEG C 51 301 001 (Rev.X0)Document28 pages00 UEG C 51 301 001 (Rev.X0)Amr AbdeinNo ratings yet

- Daniel Tian Li: Grade Beam Design Based On ACI 318-02Document2 pagesDaniel Tian Li: Grade Beam Design Based On ACI 318-02mdalgamouniNo ratings yet

- Base Plate1Document6 pagesBase Plate1jobees7850No ratings yet

- Base Plate & BoltsDocument3 pagesBase Plate & BoltsarvnndNo ratings yet

- Filled Composite ColumnDocument1 pageFilled Composite ColumnLloyd R. PonceNo ratings yet

- 1893-Part 1-2016Document44 pages1893-Part 1-2016Amey GudigarNo ratings yet

- T-Shape Member Capacity Based on AISC 360-10Document1 pageT-Shape Member Capacity Based on AISC 360-10Amey GudigarNo ratings yet

- LOAD CALCULATIONSDocument19 pagesLOAD CALCULATIONSSudathipTangwongchaiNo ratings yet

- BMREINF13Document50 pagesBMREINF13NEO100% (1)

- LRFD Beam Column DesignDocument242 pagesLRFD Beam Column DesignChristian FTNo ratings yet

- Brace Load CalculationDocument14 pagesBrace Load CalculationmaheshbandhamNo ratings yet

- LRFD Steel BeamDocument30 pagesLRFD Steel Beam정영철No ratings yet

- Styrene Pump FoundationDocument5 pagesStyrene Pump FoundationMUTHUKKUMARAMNo ratings yet

- Base Plate DesignDocument1 pageBase Plate DesignShuvo ShahaNo ratings yet

- Structural Dynamics of A Single Degree of FredomDocument100 pagesStructural Dynamics of A Single Degree of FredomCiprian SteleaNo ratings yet

- 2 Seismic Performance of Adobe BuildingsDocument2 pages2 Seismic Performance of Adobe Buildingsbasabi12No ratings yet

- MOMENT CONNECTION DESIGNDocument232 pagesMOMENT CONNECTION DESIGNklynchelle100% (1)

- Sheet1 A-B Bay CM: Properties of Gantry SectionDocument2 pagesSheet1 A-B Bay CM: Properties of Gantry SectionadihindNo ratings yet

- HSS8X6X1/2: The Column Design Is AdequateDocument24 pagesHSS8X6X1/2: The Column Design Is AdequateSehna SerajNo ratings yet

- Bolted End Plate Connection Design SummaryDocument19 pagesBolted End Plate Connection Design Summarymaheshbandham100% (1)

- TR172 FellDocument279 pagesTR172 FellAmey GudigarNo ratings yet

- HSS WF CapacityDocument7 pagesHSS WF CapacitylucianduNo ratings yet

- 1893-Part 1-2016Document43 pages1893-Part 1-2016Amey Gudigar100% (1)

- M M P P For P M M P M M P P For P M M P: Angle Steel Member Capacity Based On AISC 360-10/16 Input Data & Design SummaryDocument1 pageM M P P For P M M P M M P P For P M M P: Angle Steel Member Capacity Based On AISC 360-10/16 Input Data & Design SummaryAlaaBadwyNo ratings yet

- Supersonic Flow and Shock Waves by Courant & FriedrichsDocument300 pagesSupersonic Flow and Shock Waves by Courant & FriedrichsBrian Pinto100% (3)

- Pipe Concrete Column Design Based On ACI 318-14: Input Data & Design SummaryDocument1 pagePipe Concrete Column Design Based On ACI 318-14: Input Data & Design SummarySilviu DrelciucNo ratings yet

- Simona Onori, Lorenzo Serrao, Giorgio Rizzoni (Auth.) - Hybrid Electric Vehicles - Energy Management Strategies-Springer-Verlag London (2016)Document121 pagesSimona Onori, Lorenzo Serrao, Giorgio Rizzoni (Auth.) - Hybrid Electric Vehicles - Energy Management Strategies-Springer-Verlag London (2016)mpurperNo ratings yet

- Cellular BeamDocument14 pagesCellular BeamAlphaNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Beam GravityDocument11 pagesBeam GravitylucianduNo ratings yet

- Elbow SupportDocument3 pagesElbow SupportНемања КараклајићNo ratings yet

- Shear Wall Design, Using Laminated Bamboo, Based On NDS 2018 Design CriteriaDocument1 pageShear Wall Design, Using Laminated Bamboo, Based On NDS 2018 Design Criteriaridho ziskaNo ratings yet

- Shear Reinforcement of RC BEAM With FRP Plates ACI 440-02: V 29.628 KN V 77.081 KN V 125.000 KNDocument2 pagesShear Reinforcement of RC BEAM With FRP Plates ACI 440-02: V 29.628 KN V 77.081 KN V 125.000 KNBimalBhandariNo ratings yet

- Transformer Diagnostic Testing Response: FrequencyDocument10 pagesTransformer Diagnostic Testing Response: Frequencyosvi009No ratings yet

- Web Tapered Girder Design Based On AISC-ASD 9th, Appendix FDocument4 pagesWeb Tapered Girder Design Based On AISC-ASD 9th, Appendix FLivian TeddyNo ratings yet

- Asce 7 Wind ComparisonsDocument1 pageAsce 7 Wind ComparisonsIrwansyah MuchtarNo ratings yet

- Connections I V2.1.0.a1Document49 pagesConnections I V2.1.0.a1gissel vicencioNo ratings yet

- Zee Purlin Design Sheet AnalysisDocument4 pagesZee Purlin Design Sheet AnalysisShawkat Ali KhanNo ratings yet

- STEEL BEAM WEB STIFFENER ANALYSISDocument7 pagesSTEEL BEAM WEB STIFFENER ANALYSISNEONo ratings yet

- Column Properties:-: Due To UplitDocument2 pagesColumn Properties:-: Due To UplitRohit SinghNo ratings yet

- Consultant Engineering Design of ROUNDED HSS SecDocument2 pagesConsultant Engineering Design of ROUNDED HSS SectamerragaaNo ratings yet

- Design of Base Plate & Anchor Bolt (Crusher House)Document5 pagesDesign of Base Plate & Anchor Bolt (Crusher House)titir bagchiNo ratings yet

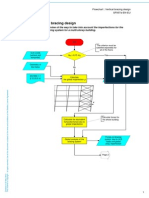

- Flowchart Vertical Bracing DesignDocument3 pagesFlowchart Vertical Bracing DesignAnonymous RrPSDPatRONo ratings yet

- Moment To Column WebDocument905 pagesMoment To Column WebAmanpreet SinghNo ratings yet

- LOAD CALCULATION For PORTAL FRAMED SHED WITH WIND ASCE 7-10Document10 pagesLOAD CALCULATION For PORTAL FRAMED SHED WITH WIND ASCE 7-10Aboalmaail AlaminNo ratings yet

- HSS WF CapacityDocument7 pagesHSS WF CapacityMoe Oo HtunNo ratings yet

- Standard DRG List-1Document1 pageStandard DRG List-1Amey GudigarNo ratings yet

- Standard DRG List-2Document3 pagesStandard DRG List-2Amey GudigarNo ratings yet

- Reinforced Concrete Design (Limit State) - by Varghese P.C.Document564 pagesReinforced Concrete Design (Limit State) - by Varghese P.C.Amey GudigarNo ratings yet

- 1893-Part 1-2016Document42 pages1893-Part 1-2016Amey GudigarNo ratings yet

- 1893-Part 1-2016Document42 pages1893-Part 1-2016Amey GudigarNo ratings yet

- Reinforced Concrete Design (Limit State) - by Varghese P.C.Document565 pagesReinforced Concrete Design (Limit State) - by Varghese P.C.Amey GudigarNo ratings yet

- ASMEpaper DoublecurvaturebendingelasticaDocument9 pagesASMEpaper DoublecurvaturebendingelasticaAmey GudigarNo ratings yet

- FMDocument6 pagesFMRafael Antonio Medina RodriguezNo ratings yet

- TIME SAVING DESIGN AIDS - Concrete WallsDocument6 pagesTIME SAVING DESIGN AIDS - Concrete WallsalshaijiNo ratings yet

- Seismic design loads and combinationsDocument15 pagesSeismic design loads and combinationsAmey Gudigar100% (1)

- PCA TIME SAVING DESIGN AIDS - ColumnsDocument9 pagesPCA TIME SAVING DESIGN AIDS - ColumnsvNo ratings yet

- BeamsDocument6 pagesBeamswarden1921No ratings yet

- 12813Document13 pages12813Ravi BhardwajNo ratings yet

- Is 3070 3 1993 PDFDocument40 pagesIs 3070 3 1993 PDFAmey GudigarNo ratings yet

- Steel-Pipe Rack-Exercise ModelDocument1 pageSteel-Pipe Rack-Exercise ModelAmey GudigarNo ratings yet

- Structural Engineering Handbooks and Codes ListDocument4 pagesStructural Engineering Handbooks and Codes ListAmey GudigarNo ratings yet

- Reference PaperDocument14 pagesReference PaperAmey GudigarNo ratings yet

- Monorails CranesDocument11 pagesMonorails CranesAmey GudigarNo ratings yet

- EC3 GB - WeldingDocument7 pagesEC3 GB - WeldingRancor82No ratings yet

- Moran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Document5 pagesMoran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Marco GassaniNo ratings yet

- Calorimetry and Phase ChangesDocument6 pagesCalorimetry and Phase ChangesVAN STEVEN SANTOSNo ratings yet

- HW 3Document20 pagesHW 3Nadine FrisnediNo ratings yet

- Ahmed HassanDocument4 pagesAhmed Hassanah_hassanNo ratings yet

- Rydberg ConstantDocument16 pagesRydberg ConstantSarla dabasNo ratings yet

- Bowex enDocument32 pagesBowex enTimon2005No ratings yet

- Problemas Del MeriamDocument8 pagesProblemas Del MeriamAnonymous v1O8SPVKB9No ratings yet

- Electromagnetics in Power Engineering SimulationDocument8 pagesElectromagnetics in Power Engineering SimulationSamuel NóbregaNo ratings yet

- JEE Syllabus 2023 Vs 2021 (All Subjects)Document18 pagesJEE Syllabus 2023 Vs 2021 (All Subjects)Harshit SharmaNo ratings yet

- CFD Simulation of A Co-Current Spray Dryer: February 2010Document7 pagesCFD Simulation of A Co-Current Spray Dryer: February 2010muhammad farisNo ratings yet

- Heat TransferDocument14 pagesHeat TransferarunperthNo ratings yet

- MA 201 (2019) - PDE-Lecture-5Document24 pagesMA 201 (2019) - PDE-Lecture-5AditJainNo ratings yet

- PP Elmasonic S15H GBDocument1 pagePP Elmasonic S15H GBliska ramdanawatiNo ratings yet

- Theories of Ion Exchange in SoilsDocument21 pagesTheories of Ion Exchange in SoilsTenkurala srujanaNo ratings yet

- SC 5 P 13 1-ForcesDocument32 pagesSC 5 P 13 1-Forcesapi-263271261100% (1)

- Kausel - Stiffness MatrixDocument19 pagesKausel - Stiffness MatrixkozloNo ratings yet

- Measuring Instruments and UnitsDocument8 pagesMeasuring Instruments and UnitsNarayanaNo ratings yet

- Construction Rules For Shear Force and Bending Moment DiagramsDocument2 pagesConstruction Rules For Shear Force and Bending Moment DiagramsArash KamaliNo ratings yet

- J. Electrochem. Soc.-2017-Monroe-E3547-51Document5 pagesJ. Electrochem. Soc.-2017-Monroe-E3547-51Geovanny JaenzNo ratings yet

- SudaisDocument3 pagesSudaisamirbadshahNo ratings yet

- IB Chemistry - SL Topic 2 Questions 1. Species Number of Protons Number of Neutrons Number of ElectronsDocument19 pagesIB Chemistry - SL Topic 2 Questions 1. Species Number of Protons Number of Neutrons Number of Electronsyasmine hooeyNo ratings yet

- Lab 2Document6 pagesLab 22023498288No ratings yet

- Tension and Compression TestDocument37 pagesTension and Compression TestLydiaNo ratings yet

- 2-1 Solving One-Step Equations - : Christmas Color Match ActivityDocument4 pages2-1 Solving One-Step Equations - : Christmas Color Match ActivityDulce CastroNo ratings yet