Professional Documents

Culture Documents

WPS 136 FW

Uploaded by

socaugustoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS 136 FW

Uploaded by

socaugustoCopyright:

Available Formats

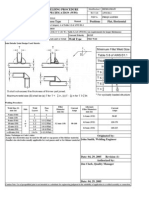

WELDING PROCEDURE WPS No.

: 136-FW-01

SPECIFICATION (WPS) Rev.: 01

Produced by : K&NDT AS Fabricator: Entreprenrservice AS Ref. standard: NS-EN ISO 15614-1

Project: General Ref. spec.:

Location: Rud Ref. WPQ: no: 01 REV 06/09

Welding methods: 1 136 2 3

Shielding gas type: 82% Ar + 18% CO2

Puring gas type NA

Weaving yes/no Yes

Positions PB - PF

Joint type FW

Joint preparation Cutting and grinding

Cleaning method Grinding

Backing NA T T

Single/double NA

Gouging method NA

Flux NA

Flux treatment NA

Tungsten electrode NA

Torch angel 75-90

Stand off distance 15-20

Nozzel diameter 18

Tack weld procedure Tack as weld nr 1

Identification of base material I c max: % 0.13 CE max: % 0,41 PCM max: 0,23 II c max: % 0,13 CE max:%0,41 PCM max: 0,23

Part Name/Grade Standard Group Delivery cond. Thickness range Diameter range

mm mm

NVE36/S355J2 +N 1.2 EN10025-2:2004 -

1 En 10025-2 S355J2+N 10--15

NVE36/S355J2 +N En 10025-2 1.2 EN10025-2:2004 -

2 S355J2+N 10-15

Identification of filler material

Index Brand name Classification Group Filler treatment

Elgacore DWA 50 AWS A5.1.20: E 71T-1M R Ihht Produsent

A

B

Welding parameters Equipment:

Pass Ind Dia. Welding Wire feed Current Volt Polarity W. speed Run out Gas Heatinput

no: ex mm method m/min A V mm/min length mm L/min KJ/mm

PB - -

1 1 1,20 136 13,0-13,5 290-309 27,6-27,7 DC+ 368, - 396 - 13-17

2+n 1 1,20 136 12,5-12,5 306-323 27,4-27,4 DC+ 538-538 - 13-17

PF - -

1 1 1.2 136 13,0-13,5 210-250 24,5-29 A DC+ 368-368 13-17

2+n 1 1.2 136 11,0-12,5 210-250 25,9-29,4 DC+ 500-538 13-17

PWHT min: max: Non-Destructiv Testing: Proposed by :

Soaking : min/mm VE: UT: RT: MT: PT:

Heating rate: Other Information :

Cooling rate: Date: Sign.:

Preheat min: 25 C Approved by :

Interpass max : 55 C

Temp. control: Tempstik Date: Sign.:

You might also like

- Weld Checklist PQRDocument2 pagesWeld Checklist PQRScott Trainor100% (1)

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- Welding procedure specification guideDocument3 pagesWelding procedure specification guideAnilNo ratings yet

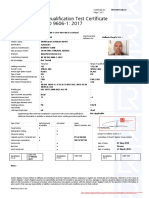

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Document3 pagesWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- WPQR Welding Procedure Qualification RecordsDocument3 pagesWPQR Welding Procedure Qualification Recordsramesh rajaNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Tes-W-109.01-R0-General Welding CriteriaDocument23 pagesTes-W-109.01-R0-General Welding CriteriaUtkucan KILIÇNo ratings yet

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Document2 pagesPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuNo ratings yet

- Procedure for Flame Straightening Structural SteelDocument3 pagesProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- Aluminium WPSDocument2 pagesAluminium WPSAnonymous yCpjZF1rF100% (1)

- Model WopqDocument2 pagesModel WopqAnilkumarGopinathanNairNo ratings yet

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Gmaw Complete Aws d1.6Document1 pageGmaw Complete Aws d1.6Hamza Nouman100% (1)

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- Review of RequirementsDocument1 pageReview of RequirementsSatish KeskarNo ratings yet

- KGP-Flamme Cutting Proce For BEI PDFDocument4 pagesKGP-Flamme Cutting Proce For BEI PDFoomoomNo ratings yet

- Fillet Weid Break and Macroetch Test PlateDocument1 pageFillet Weid Break and Macroetch Test PlatewijiestNo ratings yet

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- WPS Format For ISO 9606-1 WelderDocument2 pagesWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Welder Qualification CertificateDocument2 pagesWelder Qualification CertificatevitharvanNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- WelderDocument1 pageWelderSrikanth Dornalu0% (1)

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Document2 pagesWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNo ratings yet

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- WPS Format For ISO 15614-1 WPSDocument1 pageWPS Format For ISO 15614-1 WPSThe Welding Inspections CommunityNo ratings yet

- Weld Visual Inspection ReportDocument1 pageWeld Visual Inspection ReportfarjadulhaqNo ratings yet

- Transamerican Manufacturing Group: Document Title: Weld Standards, SteelDocument16 pagesTransamerican Manufacturing Group: Document Title: Weld Standards, SteelQuoc VinhNo ratings yet

- DNV Os C401Document44 pagesDNV Os C401Paul Tese AhireNo ratings yet

- Welding Defects Poster 600x900 Lores enDocument1 pageWelding Defects Poster 600x900 Lores enMostafa ZedNo ratings yet

- FCAW Procedure PDFDocument110 pagesFCAW Procedure PDFsolserengsaNo ratings yet

- WPS Welding Procedure SpecificationDocument1 pageWPS Welding Procedure SpecificationburakNo ratings yet

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- Iso 15614-13Document24 pagesIso 15614-13Marija IvanovskaNo ratings yet

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocument3 pagesSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013No ratings yet

- Welding BisplateDocument12 pagesWelding BisplateLim Senglin100% (1)

- Welding Coordination Activities and ResponsibilitiesDocument7 pagesWelding Coordination Activities and ResponsibilitieseliiiiiiNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- Welding VTDocument1 pageWelding VTibrahim hegazyNo ratings yet

- Welding Traceability ANNUAL SHACDOWDocument25 pagesWelding Traceability ANNUAL SHACDOWMonica ManurungNo ratings yet

- Cabeling MEDocument27 pagesCabeling MEarnelectricsolutionsNo ratings yet

- MD (BD) -DWG-SPM-PR-18388 ESD HPU HYDRAULIC SYSTEM REV (0) - 原始文件 PDFDocument1 pageMD (BD) -DWG-SPM-PR-18388 ESD HPU HYDRAULIC SYSTEM REV (0) - 原始文件 PDFKook PengNo ratings yet

- ITP Format - Excel GEP 1120Document22 pagesITP Format - Excel GEP 1120raghuvarma100% (1)

- QS049 P03 AEC CON REP A10016 - Part06 - Compressed - 035 035Document1 pageQS049 P03 AEC CON REP A10016 - Part06 - Compressed - 035 035Alvin JisNo ratings yet

- Crank Rod (G85N - 40017)Document2 pagesCrank Rod (G85N - 40017)SamirNo ratings yet

- Mcore Lab Private Limited: Test Report of Rock CoresDocument1 pageMcore Lab Private Limited: Test Report of Rock Coressivananda reddyNo ratings yet

- Procedure and design instructions for filigree slabs and double wallsDocument16 pagesProcedure and design instructions for filigree slabs and double wallssocaugustoNo ratings yet

- Handling SolutionsDocument41 pagesHandling SolutionssocaugustoNo ratings yet

- Leica iCON Robot 60/ iCON Builder 60: User ManualDocument82 pagesLeica iCON Robot 60/ iCON Builder 60: User ManualsocaugustoNo ratings yet

- Is 7504 1995Document30 pagesIs 7504 1995socaugustoNo ratings yet

- Is 8000 Part 4Document11 pagesIs 8000 Part 4socaugustoNo ratings yet

- 9 Kinroad xt250gk Sahara 250cc Owners ManualDocument48 pages9 Kinroad xt250gk Sahara 250cc Owners ManualPaulo BasayNo ratings yet

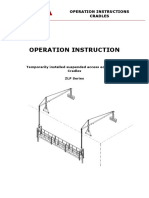

- Cradle Operations ManualDocument33 pagesCradle Operations ManualArul Alvin InfantNo ratings yet

- พอฤทัย วิริยะภาค26 3.5Document2 pagesพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคNo ratings yet

- Flight Instructors Training Procedures Rev 4Document307 pagesFlight Instructors Training Procedures Rev 4Marco Koffeman100% (3)

- Echipament Sudare Sub Strat de Flux Esab Multitrac A2Document2 pagesEchipament Sudare Sub Strat de Flux Esab Multitrac A2Rogo CatalinNo ratings yet

- Chapter 2Document4 pagesChapter 2Manoj SpNo ratings yet

- FAQ Lecture 1Document5 pagesFAQ Lecture 1Richard De Medeiros Castro100% (1)

- BOMBA DAB Divertron Sumergible 1Document2 pagesBOMBA DAB Divertron Sumergible 1Lisi BenassiNo ratings yet

- History of MechatronicsDocument20 pagesHistory of MechatronicsManoj DhageNo ratings yet

- Heavy Vehicle GuideDocument13 pagesHeavy Vehicle Guideanas100% (5)

- Meniu Skoda PDFDocument5 pagesMeniu Skoda PDFCoso MotoNo ratings yet

- Experiment 3: Critical Radius of Insulating MaterialDocument5 pagesExperiment 3: Critical Radius of Insulating Materialmehul deshpande100% (1)

- 6 TransmissionDocument38 pages6 TransmissionKamal Jit DhimanNo ratings yet

- Dynamic Properties of RocksDocument5 pagesDynamic Properties of RocksArnold John Laya100% (3)

- Parts Catalog: Model NB3200AU/A (CE SPEC.) NB3300AU-E (CE SPEC.)Document15 pagesParts Catalog: Model NB3200AU/A (CE SPEC.) NB3300AU-E (CE SPEC.)ManuelSilvaPedrosaNo ratings yet

- CHAPTER 2 Press WorkingDocument29 pagesCHAPTER 2 Press WorkingDen Yogi HardiyantoNo ratings yet

- Tac 07 CsaDocument36 pagesTac 07 CsaWalter TaipeNo ratings yet

- Thermodynamics 1 MEP 261: Dr. M. Ehtisham SiddiquiDocument64 pagesThermodynamics 1 MEP 261: Dr. M. Ehtisham Siddiquiانس الحربيNo ratings yet

- Tutorial 2-Equilibrium 1Document2 pagesTutorial 2-Equilibrium 1Sai KrishnaNo ratings yet

- Kinetic and Potential Energy: VocabularyDocument5 pagesKinetic and Potential Energy: Vocabularykaren cotingjoNo ratings yet

- Track Calc - Staircase - 152X152X23Document13 pagesTrack Calc - Staircase - 152X152X23Ranjit S KashyapNo ratings yet

- AX152886481789en 000712Document120 pagesAX152886481789en 000712Yosmell Fritzan Paz UrbizagasteguiNo ratings yet

- Cummins Big Cam I Big Cam III Shop ManualDocument20 pagesCummins Big Cam I Big Cam III Shop Manualhilda100% (46)

- ETAG 020: Edition March 2006 Amended Version March 2012Document14 pagesETAG 020: Edition March 2006 Amended Version March 2012Raymond ChangNo ratings yet

- Bsen 3310 Flow Meter Discharge Coefficient EstimationDocument7 pagesBsen 3310 Flow Meter Discharge Coefficient Estimationapi-300980681No ratings yet

- Engine 310G 310SGDocument7 pagesEngine 310G 310SGANDRES BAZURTONo ratings yet

- 23 Wind TurbineDocument3 pages23 Wind TurbineHarishNo ratings yet

- Examples: 238 17 PsychrometricsDocument12 pagesExamples: 238 17 PsychrometricsJunior Ferrel AlvarezNo ratings yet

- SBS Fluidized Bath Operating ManualDocument14 pagesSBS Fluidized Bath Operating Manualcraigorio616No ratings yet

- CE GREAT MINDS PREBOARD PRACTICE HYDRAULICS AND GEOTECHNICAL ENGINEERINGDocument7 pagesCE GREAT MINDS PREBOARD PRACTICE HYDRAULICS AND GEOTECHNICAL ENGINEERINGRommel Dave Tejano100% (1)