Professional Documents

Culture Documents

1982 Catalytic Air Oxidation of Propylene To Acrolein

Uploaded by

ChauOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1982 Catalytic Air Oxidation of Propylene To Acrolein

Uploaded by

ChauCopyright:

Available Formats

1

Catalytic Air Oxidation of Propylene to Acrolein:

Modeling Based on Data from an Industrial

Fixed-Bed Reactor

D. ARNTZ, . , and G. PRESCHER

Degussa AG, Hanau, Federal Republic of Germany

G. EMIG and H . H O F M A N N

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

Inst. f. Techn. Chemie I, Universitt Erlangen-Nrnberg, Federal Republic of Germany

From a few w e l l chosen experiments in an i n t e g r a l

r e a c t o r o f t e c h n i c a l dimensions with side-stream

a n a l y s i s both r e a c t i o n schemes and the e f f e c t i v e

heat t r a n s f e r and k i n e t i c parameters o f a r e -

a c t i o n model f o r propylene o x i d a t i o n could be de-

duced, from which v a l u a b l e information f o r both

c a t a l y s t development and o p t i m i z a t i o n o f the r e -

a c t i o n c o n d i t i o n s could be obtained.

The economic s i g n i f i c a n c e (1,2,3) o f the c a t a l y t i c p r o p y l e -

ne o x i d a t i o n n e c e s s i t a t e s a c o n t i n u i n g refinement o f the c a t a -

l y s t . This i n t u r n r e q u i r e s c o n t i n u i n g o p t i m i z a t i o n o f the r e -

a c t i o n c o n d i t i o n s , as these depend upon the c a t a l y s t .

The goal o f t h i s i n v e s t i g a t i o n was the development o f a

s u i t a b l e r e a c t o r model f o r propylene o x i d a t i o n i n an i n d u s t r i a l -

s i z e packed-bed r e a c t o r operated under i n d u s t r i a l l y r e l e v a n t

conditions (4).

From the l i t e r a t u r e i t i s not p o s s i b l e t o deduce a k i n e t i c

scheme s u i t a b l e f o r modeling the r e a c t i o n , s i n c e the majority

of p u b l i c a t i o n s (10-39) do not present an unequivocal p i c t u r e .

Also the fundamental d i f f i c u l t i e s o f e s t i m a t i n g from independent

measurements heat t r a n s f e r parameters f o r a packed-bed r e a c t o r

are w e l l known (5,6,7).

Therefore, an attempt was made t o determine the k i n e t i c

r e a c t i o n scheme and e f f e c t i v e heat t r a n s f e r as w e l l as k i n e t i c

parameters from a l i m i t e d number o f experimental r e s u l t s i n a

s i n g l e - t u b e r e a c t o r o f i n d u s t r i a l dimensions with side-stream

a n a l y s i s . The data e v a l u a t i o n was performed with a pseudohomo-

geneous two-dimensional continuum model without a x i a l d i s p e r s i o n .

The model was t e s t e d f o r i t s s u i t a b i l i t y f o r p r e d i c t i o n .

0097-6156/82/0196-0003$06.00/0

1982 American Chemical Society

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

4 CHEMICAL REACTION ENGINEERING

E x p e r i m e n t a l Set-Up and R e s u l t s

The r e s u l t s w e r e o b t a i n e d i n a c o n t i n u o u s l y o p e r a t e d p o l y t r o p i c p i l o t -

p l a n t r e a c t o r w i t h a f e e d o f a p p r o x i m a t e l y 2-5 m o l e s p r o p y l e n e p e r h o u r . The r e

a c t o r was a s i n g l e t u b e h a v i n g a c a t a l y t i c b e d l e n g t h o f 2.70 m a n d a n i n n e r

d i a m e t e r o f 0 . 0 2 0 5 m. T e m p e r a t u r e was c o n t r o l l e d b y a c i r c u l a t i n g m o l t e n s a l t

b a t h . T h e t e m p e r a t u r e p r o f i l e w i t h i n t h e r e a c t o r was m o n i t o r e d w i t h s i d e - e n t r y

t h e r m o c o u p l e s : e l e v e n i n t h e c e n t e r o f t h e t u b e , t w o i n a n 1/2 r a d i u s p o s i t i o n ,

and t h r e e a t t h e w a l l . F e e d s o f p r o p y l e n e , a i r , i n e r t g a s a n d w a t e r w e r e m o n i t o

red by r o t a m e t e r s and preheated t o s a l t bath temperature. O v e r a l l a c r o l e i n y i e l d s

a v e r a g e d o v e r 48 h o u r s p e r i o d s , were e v a l u a t e d by i s o l a t i n g c r u d e a c r o l e i n by

a b s o r p t i o n with water and subsequent d e s o r p t i o n . Unreacted p r o p y l e n e , c a r b o n o x i -

d e s a n d o x y g e n w e r e m e a s u r e d i n t h e e f f l u e n t g a s ( G . C . ) a n d a c r y l i c a c i d was

a n a l y s e d (G.C.) i n t h e a c r o l e i n - f r e e bottoms. To measure t h e a x i a l c o n c e n t r a t i o n

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

p r o f i l e o f t h e r e a c t o r gaseous samples ( 5 p r o b e s a l o n g t h e r e a c t o r ) were a n a l y s e d

(water scrubber and e f f l u e n t gas a n a l y s i s ) . Minor s i d e products as acetaldehyde

and f o r m a l d e h y d e ( G . C , a n a l y s e d i n c r u d e i s o l a t e d a c r o l e i n ) , a c e t i c a c i d ( G . C ,

analysed b e s i d e s a c r y l i c a c i d ) and p o l y a c r o l e i n ( r e s i d u e o f e v a p o r a t i o n ) always

t o t a l e d l e s s t h a n 4 %, b a s e d o n t h e p r o p y l e n e f e d i n ; t h e c o r r e s p o n d i n g s i d e - r e

a c t i o n s were n e g l e c t e d f o r m o d e l i n g .

The s p h e r i c a l c a t a l y s t , b a s e d o n a m u l t i c o m p o n e n t b i s m u t h m o l y b d a t e was

3 3

p r e p a r e d a c c o r d i n g t o ( 8 ) w i t h d = 5.3 . 1 0 " m , = 0.8 . 1 0 - K J / m . s . K a n d

p

3

P = 1145 kg/m f o r t h e c a t a l y t i c b e d . The range o f v a r i a b l e s s t u d i e d i n t h e

g

packed-bed experiments i s given i n Table I . T y p i c a l d e t a i l e d r e s u l t s f o r an ex

perimental run are given i n Table I I .

Modeling

R e a c t o r Model. The d e s i g n o f an i n d u s t r i a l packed-bed r e a c t o r r e q u i r e s a

r e a c t o r m o d e l a s w e l l a s t h e c h e m i c a l a n d t h e h e a t a n d mass t r a n s f e r p a r a m e t e r s

of the c a t a l y s t bed - gas stream system. Since these parameters are model-speci

f i c , i t seemed a d v i s a b l e t o employ a continuum model f o r t h e r e a c t o r c a l c u l a t i o n .

T h i s i s t h e o n l y model t o date f o r which t h e l i t e r a t u r e c o n t a i n s c o n s i s t e n t

d a t a f o r c a l c u l a t i n g h e a t a n d mass t r a n s f e r p a r a m e t e r s ( 5 , 6 , 7 ) . T h i s m o d e l i n i t s

Table I Experiments - Range o f V a r i a b l e s

Run

No. w max C o m p o s i t i o n o f R e a c t o r F e e d ( M o l e F r a c t i o n ) O v e r a l l

propene

propene propane N 2 0 2 H 0

2

c o n v e r s i o n {%)

1 296 301 0.047i 0.0022 0.595 0.158 0.198 45

2 320 335 0.047 6 0 . 0 0 2 4 0 . 5 9 9 0.159 0.192 72

3 311 325 0.088 2 0.0041 0 . 5 7 0 0.151 0.187 42

4 334 358 0.089! 0 . 0 0 3 8 0.569 0.151 0.187 67

5 377 415 0.089 5 0 . 0 0 4 3 0.567 0.150 0.190 85

T =T(salt bath);

w G - 1.16 0.02 ( k g / m * . s ) ;

= 1.63 0.01 ( b a r ) a t r e a c t o r i n l e t ; p r e s s u r e d r o p : A P = 0 . 0 4 9 g - 0 . 0 0 2 ,

* = remains unreacted under a l l o p e r a t i n g c o n d i t i o n s . (bar/m)

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

1. ARNTZ ET A L . Catalytic Propylene Oxidation

Table I I Run No. 5 - D e t a i l e d I n f o r m a t i o n

bed l e n g t h temperatureQ) m o l e f r a c t i o n x\ ]

p r o p e n e I C 0 , CO a c r o l e i n a c r y l i c

2

acid;

() C

0 377 0.089 5 0 0 0 .

0.15 415

0.30 413 0.071 6 0.003J 0.0162 0.00054 :

0.45 387

0.60 407 0.056 3 0.005 4 0.030 2 0.0010 8 ]

0.80 406 ;

1.00 385 1

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

1.20 397 0.035 2

0.008g 0.049 0 0.00218 1

?

1.40 391

1.70

2.00

390

388 0.021 4 0.013 0 0.059 8 0.0036 6 j

i

2.30 387 t

(

2.60 386

2.70 0.013 6 0.016 2 0.065 3

0.0050 J 0

15 i n c e n t e r o f t u b e , (^ 2 i n 1/2 r p o s i t i o n G = 1.178 ( k g / m * . s )

= 0.051 ( b a r / m )

a r

= 1.633 ( )

two-dimensional form, i n which t h e a x i a l heat c o n d u c t i o n and a x i a l d i s p e r s i o n a r e

n e g l e c t e d , y i e l d s f o r t h e mass b a l a n c e o f t h e c o m p o n e n t s :

3 y

M

j 1 3 , '

3j r~ 3" a ] : V

r ; j=l (1)

3z 1

r ( 2 i e f f

i=l

with t h e boundary conditions:

and f o r t h e e n e r g y b a l a n c e :

3 z=0:yj=yj ; 9=0 (r), 0 0 0*r*l

S-^f k (- H

i

r

) i,eff

3 y

1=1 i 3

O^z^l

3 y

i 3

0 ; B i ( e

0^z="l

^ = 3 T - V

The t r a n s p o r t p a r a m e t e r s i n a j , b j a n d B i a r e e f f e c t i v e p a r a m e t e r s w i t h w h i c h ,

j u s t a s w i t h t h e e f f e c t i v e r a t e r f f , s e v e r a l d i f f e r e n t p h y s i c a l phenomena a r e

e

lumped.

The t w o - d i m e n s i o n a l p s e u d o h o m o g e n o u s r e a c t o r m o d e l ( E q . l ) i s t h e b a s i s f o r

t h e s t a n d a r d i z e d c o m p u t e r p r o g r a m F I B S A S ( 9 ) , w h i c h was u s e d f o r t h e e v a l u a t i o n

and s i m u l a t i o n r e p o r t e d h e r e .

Reaction Schemes and Networks. Within the l a s t few years a

s e r i e s o f review a r t i c l e s have appeared concerning the o x i d a

t i o n o f propylene t o a c r o l e i n (10-16). I t i s g e n e r a l l y assumed

that the f i r s t r e a c t i o n step, the formation o f an adsorbed

a l l y l i c s p e c i e s , i s rate-determining f o r the formation o f aero-

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

6 CHEMICAL REACTION ENGINEERING

l e i n . Side r e a c t i o n s o f t h i s intermediate s p e c i e s as w e l l as d i -

r e c t p a r a l l e l r e a c t i o n s are p o s s i b l e . However, previous mechanistic

i n v e s t i g a t i o n s l e a d n e i t h e r to unequivocal c o n c l u s i o n s over the

r e a c t i o n scheme nor over the r e a c t i o n k i n e t i c s .

A l a r g e number o f i n v e s t i g a t i o n s do not even consider the

formation o f the i n d u s t r i a l l y important a c r y l i c a c i d (Models I -

I I I ) . The most d e t a i l e d Model V, on the other hand, i s too com-

plex f o r a p r a c t i c a l a p p l i c a t i o n . I n v e s t i g a t i o n s o f model s i m p l i -

f i c a t i o n s f o r i n d u s t r i a l l y r e l e v a n t c a t a l y s t s are e i t h e r nonexis-

tent or lead to d i f f e r i n g r e s u l t s (Models I-IV).

A p o i n t common to a l l the models i s that they are based upon

a redox-type mechanism, i n which the r e o x i d a t i o n o f the c a t a l y s t

i s not a l i m i t i n g f a c t o r . Corresponding, none o f them employ the

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

model expression o f Mars and van Krevelen (37). On c o n t r a s t newer

works by Keulks (38,39) assume, a t lower r e a c t i o n temperatures, a

l i m i t i n g e f f e c t from the r e o x i d a t i o n which leads to a dependence

on oxygen p a r t i a l pressure f o r the a c r o l e i n formation and to a two

to t h r e e - f o l d higher a c t i v a t i o n energy compared with the r e a c t i o n

at higher temperatures.

Thus a c o n s i d e r a t i o n o f the l i t e r a t u r e data n e c e s s i t a t e s

e s t a b l i s h i n g a network before determining the e f f e c t i v e k i n e t i c

parameters.

D e r i v a t i o n o f Reaction Schemes Based on Experimental R e s u l t s .

Although numerous methods f o r e v a l u a t i n g r e a c t i o n s schemes have

been developed (40-44), most o f them (40-42) s t a r t with a hypothe-

t i c a l mechanism which i s , by means o f experiments, e i t h e r c o n f i r -

med or r e j e c t e d . A newly developed method f o r the systematic e l u -

c i d a t i o n o f r e a c t i o n schemes o f complex systems r e q u i r e s no chemi-

c a l c o n s i d e r a t i o n s , but concentration-time measurements and sy-

s t e m - a n a l y t i c a l c o n s i d e r a t i o n s (45). The method i s based on the

i n i t i a l slope o f the concentration-time p r o f i l e s and when ne-

cessary the higher d e r i v a t i v e s o f these curves a t t = 0. Reaction

steps i n which products are formed d i r e c t l y from r e a c t a n t s can be

i d e n t i f i e d i n a concentration-time p l o t by a p o s i t i v e g r a d i e n t

dc- a t t = 0 (zero order d e l a y ) .

J

dt

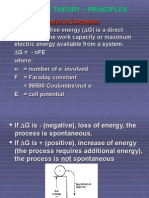

I t can be seen from a t y p i c a l , p r a c t i c a l l y isothermal con-

c e n t r a t i o n p r o f i l e (Figure 1) t h a t a t t = 0 a l l products e x h i b i t

a non-zero s l o p e . This i m p l i e s that a l l o f them must be formed

d i r e c t l y from the r e a c t a n t s propylene and oxygen, which e l i m i n a -

tes the r e a c t i o n schemes I and IV (Table I I I ). Therefore the

f o l l o w i n g s t o i c h i o m e t r i c equations were used i n the a n a l y s i s ;

f o r equation (4) the approximately constant r a t i o o f CO and CO^

which was a c t u a l l y measured was a p p l i e d .

k

i

Pe + 0 2 * > Ac + H 0 2 (2)

Pe + 1.5 0 2 ^> As + H 0 2 (3)

Pe + 4 1/6 0 2 *3 y 2/3 CO + 2 1/3 C0 + 3 H 0

2 2 (4)

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

1. ARNTZ ET A L . Catalytic Propylene Oxidation 7

Table III R e a c t i o n Models

I (17-20) P e Ac > C 0 , C 0 ; 2 I I (21-25)

III (26-30) Pe vC0,C0 ; o I V (31) Pe > co,co 2

Fo,Ad

Ac acrolein

Ad acetaldehyde

V (32-36) Pe - M s C0,C0 2 As acrylic acid

9 Fo formaldehyde

\ y

Fo.Ad Pe propylene

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

Further systematic a p p l i c a t i o n o f the new method l e d t o the con

c l u s i o n that the r e a c t i o n scheme was s t i l l incomplete but that

such r i g o r o u s model b u i l d i n g demands independent v a r i a t i o n s o f

a l l r e a c t a n t c o n c e n t r a t i o n s , which was beyond the scope o f t h i s

investigation.

(5)

The r e a c t i o n scheme was t h e r e f o r e completed using a d d i t i o n a l i n

formation from the concentration-time-diagram. In experiments

with a high degree o f conversion (Table I I ) the y i e l d o f a c r o l e i n

i s obviously l i m i t e d with i n c r e a s i n g residence time. At the same

time the a c r y l i c a c i d c o n c e n t r a t i o n i s s t i l l i n c r e a s i n g a t the

end o f the r e a c t o r , suggesting a concecutive o x i d a t i o n o f a c r o l e i n

to a c r y l i c a c i d as an a d d i t i o n a l r e a c t i o n .

Heat T r a n s f e r Parameters. Attempts i n t h i s i n v e s t i g a t i o n t o

use heat t r a n s f e r parameters ( ^ h ) c a l c u l a t e d from c o r r e l a

t i o n s based on data without r e a c t i o n ,7) l e d t o the r e s u l t t h a t

the energy balance o f the r e a c t o r a t the measured temperatures was

not s a t i s f i e d . On the other hand, the simultaneous e s t i m a t i o n o f

heat t r a n s f e r and k i n e t i c parameters by r e g r e s s i o n a n a l y s i s o f

p o l y t r o p i c measurements allows these parameters t o i n f l u e n c e each

other. I t was observed that the parameters c a l c u l a t e d by these two

methods were q u i t e d i f f e r e n t (5,46). Therefore i n t h i s r e p o r t the

heat t r a n s f e r parameters were determined from experimental r e

s u l t s by a t h i r d method with a minimum o f a d d i t i o n a l assumptions:

The e n e r g y b a l a n c e e q u a t i o n was s o l v e d f o r t h e m o s t e x o t h e r m i c c a s e ( R u n 5 ) ,

( T a b l e s I and I I ) t o g e t h e r w i t h t h e mass b a l a n c e e q u a t i o n ( 1 ) . T h u s , t h e r ^

were d e d u c e d f r o m a w e l l - f i t t e d b u t w i t h r e s p e c t t o t h e k i n e t i c e x p r e s s i o n '

s t i l l a r b i t r a r y d e s c r i p t i o n of the experimental c o n c e n t r a t i o n p r o f i l e along the

r e a c t o r . S i n c e t h e ^ a r e known, i t r e m a i n s t o c h o o s e h and X f f s o t h a t t h e

w e

e x p e r i m e n t a l l y measured temperature g r a d i e n t | i s c o r r e c t l y d e s c r i b e d . For t h i s ,

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

8 CHEMICAL REACTION ENGINEERING

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

mole nj

100 mole Pe

Figure 1. Experimental results from Run 3, Table 1.

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

1. ARNTZ ET A L . Catalytic Propylene Oxidation 9

two a s s u m p t i o n s w e r e made: 1. t h e m o d e l e x p r e s s i o n g i v e n i n ( 7 ) ( w i t h o u t t h e l o n

g i t u d i n a l c o r r e c t i o n ( 9 ) i s c o r r e c t ) ; 2 . B i o t i s c o n s t a n t ( t h e same c o r r e c t i o n

f a c t o r f o r h and * f f )

w e

These heat t r a n s f e r parameters were used f o r a l l experiments

(Table IV); they are d i s t i n c t l y higher than those which can be

c a l c u l a t e d from ( 7 ) f o r the case without r e a c t i o n . T h i s agrees

with i n v e s t i g a t i o n s o f the o x i d a t i o n o f CO ( 5 ) .

Table IV experimentally determined R e f e r e n c e (2)

0

(KJ/m.s.K) 1.25 1 ( H 0.82 10-

err, r

h (KJ/m

w

2

.s . K) 0.412 0.27

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

E f f e c t i v e K i n e t i c Parameters. F o r the r a t e e f f o f the

i t h r e a c t i o n the p o t e n t i a l law '

r. = A. exp(-Ei/RT)T Pj

ij

(6)

was chosen. An i n i t i a l s e t o f parameters ( , E l f n j ) was de

x

termined f o r each t r i a l s e p a r a t e l y (Runs 1 - 5 ) , (Table I ) by

simultaneous f i t t i n g o f measured c o n c e n t r a t i o n and temperature

p r o f i l e s along the r e a c t o r . I n i t i a l gross f i t t i n g was accompli

shed by o p t i c a l o p t i m i z a t i o n ( 4 7 ) t h r o u g h v a r i a t i o n o f A E i , n i j . l f

I t p r o v e d e f f e c t u a l t o s e t s m a l l v a l u e s f o r i{ ( 4 0 - 7 0 x l 0 J / k m o l e )

6

and n i j

( 0 . 3 - 0 . 5 ) a n d a c h i e v e t h e f i r s t f i t b y v a r y i n g A j . A b e t t e r f i t was a c h i e v e d b y

v a r i a t i o n o f E j a n d n j : , w h e r e b y A j was r e c a l c u l a t e d f o r e a c h s u b s e q u e n t com

putation according to ( 7 ) .

The k i n e t i c parameters obtained from t h i s o p t i c a l o p t i m i z a

t i o n are used as s t a r t i n g values f o r the FIBSAS o p t i m i z a t i o n sub

r o u t i n e SIMPLEX. The procedure d e s c r i b e d above was a p p l i e d t o a l l

t r i a l s (Runs 1 - 5 ) , whereby some o f the parameters obtained f o r

the d i f f e r e n t t r i a l runs s t i l l showed s i g n i f i c a n t v a r i a t i o n . A

set o f parameters v a l i d f o r a l l runs was obtained from the l i n e a r

regression ( 8 ) :

I n r . = I n A. - ( E . / R T ) . . I n p . ( 8 )

j 1J j

and p. i n ( 8 ) a r e experimental values; the other parameters

a r i s e from the former f i t t i n g s f o r Runs 1 - 5 . In each step o f

approximation the best f i t i s f i r s t achieved f o r i = l and then,

one a f t e r another, f o r i = 2 - 4 .

The r e s u l t o f t h i s e s t i m a t i o n o f k i n e t i c parameters i s

shown i n Table V and F i g u r e s 2 - 4 .

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

10 CHEMICAL RE ACTION ENGINEERING

Table V Results for Effective Kinetic Parameters

., . _ . _

/ r- / i l 2 3

r A e RT

i , e f f " i * *P<-V > P P e \ P c A

A. E.

1 1 .

i [Z n..) "il n

i2 i3 0

K m o l e / n r . s . P a s c a l J i j J/Kmole

1 16.7 -* 5

47.4 106 0.44 0.93 0

2 1.3 10~ 6

42.8 10 6

0.54 0.54 0

3 1.28x 10" 3

52.8 10 6

0.66 0 0

4 77.1 10~ 3

93.2 10 6

0 0 1

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

Discussion

The model d e s c r i b e s , w i t h i n the l i m i t s o f measuring e r r o r ,

the experimental temperature and c o n c e n t r a t i o n p r o f i l e s q u i t e

w e l l over a wide temperature range (more than 100 C) and propy

lene conversion range (Table I ) , (Figures 2 - 4 ) . But the r e

a c t i o n orders f o r propylene and oxygen have only a l i m i t e d r e

l i a b i l i t y s i n c e e s p e c i a l l y the oxygen c o n c e n t r a t i o n along the

r e a c t o r v a r i e d only w i t h i n narrow l i m i t s . A d d i t i o n a l l y , pressure

and flow r a t e were, f o r the most p a r t , h e l d constant (Table I ) .

The model was then used to p r e d i c t measured r e s u l t s f o r a

wide range o f experimental c o n d i t i o n s (T = 343-360 , ( x ) = p

0.07-0.09, ( x ) = 0.13-0.15 , ( x Q ) = 0 . I 8 5 " 0-003, 5 H 2 0

W

1

G = 1.17 - 1.70 kg.m^s" ) as w e l l as f o r a c a t a l y s t d i f f e r e n t

from t h a t used i n Runs 1-5 . The new c a t a l y s t was based upon

the same chemical system but contained more a c t i v e m a t e r i a l ( 8 ) .

It was s u r p r i s i n g t h a t only the pre-exponential f a c t o r s A^

had to be newly estimated (Table VI) whereby the conversion

f a c t o r s f o r A f o r the three p a r a l l e l r e a c t i o n s s t a r t i n g from

x

propylene ( i = l - 3 , Table VI) proved to be about the same. From

these r e l a t i o n s h i p s u s e f u l i n f o r m a t i o n f o r f u t u r e c a t a l y s t p r e

p a r a t i o n may be drawn ("learning model").

Table VI A . f o r new r u n s (different catalyst)

i n . . A. (5 new r u n s )

1 A. 3

(Kmole/m s . P a s c a l J

) A* ( r u n 1 - 5 )

1 J

1 1

1 j 30.4 " 6

1.8 2

2 2.26 10~ 6

1.7 4

3! 2.03 10" 3

1.5g

4 272.5 10" 3

3.53

The agreement o f the p r e d i c t i v e c a l c u l a t i o n s with the measu

red r e s u l t s i s q u i t e good f o r those new runs ( " p r e d i c t i v e model")

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

1. ARNTZ ET AL. Catalytic Propylene Oxidation 11

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

Figure 2. Experimental results from Run 2, Table L Key: X , temperature mea

sured; > propylene; , acrolein; A * acrylic acid; and , CO and C0 . Z

Figure 3. Experimental results from Run 4, Table I. Symbols are the same as in

Figure 2.

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

1 2

CHEMICAL REACTION ENGINEERING

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

Figure 4. Experimental results from Run 5, Table I. Symbols are the same as in

Figure 2.

Figure 5. Data plotted of a predicted run. Symbols are the same as in Figure 2.

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

1. ARNTZ ET A L . Catalytic Propylene Oxidation 13

as i l l u s t r a t e d i n Figure 5 ( d i f f e r e n t c a t a l y s t ; reduced bed

length; (XQ ) = 0.127; ( X H O ) = 004; G = 1.67 k g . m ^ s " ) .

2 2 0

1

The p r e d i c t i o n o f the new runs succeeded, even though, be

s i d e s the c a t a l y s t , the r e a c t o r feed and flow r a t e were s i g n i f i

c a n t l y d i f f e r e n t from those o f the experimental r e s u l t s (Tables I

and II) from which the model was d e r i v e d .

C l e a r l y , the s i m p l i f i c a t i o n o f the r e a c t i o n scheme t o the

four r e a c t i o n s found i n network (5) i s only v a l i d f o r the tempe

r a t u r e and c o n c e n t r a t i o n range which was i n v e s t i g a t e d . E s p e c i a l l y

at higher temperatures, a d d i t i o n a l secondary r e a c t i o n s , p a r t i c u

l a r l y the o x i d a t i o n o f a c r o l e i n t o CO and CO2, must be e x p l i c i t l y

considered.

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

Legend of Symbols

4.(q /P ).(L/d ).(d /d ).(Pe )-

b 0 t p t Pj,P= p a r t i a l p r e s s u r e ; p r e s s .

m Pascal

L M /G 0 P*m = u . d p / D f f , P e e l e t No. ( m a s s , r a d i a l )

0 r? e

preexponential factor P e - G . C p . d p A f f , P e c l e t No.(heat,radial)

h

r f e

1

4.(L/d ).(d /d ).(Pe )-

t p t h r 2r'/d^, reduced r a d i a l coordinate

b 2 L/(G.c .T ) p 0 r' = radial coordinate m

Bi df h /2V,eff

w B i t number r i f f = e f f . rate of i th reaction

f e

Cp = mass s p e c i f i c h e a t a t c o n s t a n t time s

1

pressure K J k g " "* temperature

CJ = molar c o n c e n t r a t i o n kmole linear velocity ms - 1

dp,d|.= d i a m e t e r ( p a r t i c l e , t u b e ) mole f r a c t i o n

^r,eff effective radial dispersion pseudo-mole f r a c t i o n y j = n j / 5 n j 0

coefficient mV z'/L reduced a x i a l coordinate

E = a c t i v a t i o n energy J mole""* = a x i a l c o o r d i n a t e m

G = mass s p e c i f i c f l o w r a t e k g n r ^ s " * V , e f f e f f e c t i v e r a d i a l t h e r m a l c o n d u c t i

= reaction enthalpy J mole"* v i t y o f t h e c a t a l . b e d K J . n r V .K" 1 1

h

w = wall heat t r a n s f e r stoichiometric coefficient

1

coefficient KJ.nrV ^| Y i j

v o l u m e t r i c mass kg m - 3

ki reaction rate constant o f i th : reduced temperature T / T 0

reaction

L = lenght of reactor superscript:

M = mean m o l a r mass kg k m o l e - 1 i , (i+1) step o f i t e r a t i o n

= amount o f s u b s t a n c e mole

= reaction order

subscripts:

g = gasphase s = s o l i d phase

i = f o r t h e it h r e a c t i o n t = tube

j = f o r t h e jt h s p e c i e s w = wall

= particle 0 = conditions at reactor inlet

Literature Cited

1. Kirk-Othmer "Encyclopedia of Chemical Technology"; Wiley, J., New York,

1978; Vol. 1, p. 288.

2. Weigert,W. "Ullmanns Encyklopdie d. technischen Chemie"; Verlag Chemie,

Weinheim, 1974; Vol. 7, p. 74.

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

14 CHEMICAL REACTION ENGINEERING

3. Weigert, W.M; Maschke, H. Chew. Zeitung, 1974, 98 ( 2 ) , 61

4. Shinnar, R. "ACS-Symposium Series 72", American Chemical Society,

Washington D.C., 1978; p. 1-36

5. Hofmann, H. Chem. Ing. Techn., 1979, 51, 257

6. Schlnder, E.U., "ACS-Symposium Series 72", Chem. React. Eng. Rev.-Houston,

1978, p. 110 - 161

7. "VDI-Wrmeatlas"; VDI-Verlag, Dsseldorf, 1977; p. Gg

8. Degussa, DE-PS 20 49 583, 1970, Degussa, DOS 31 25 061, 1981

9. Hofmann, U., Fortschr.-Ber., VDI-Zeitung. 1977, 3, 49

10. Haber. J., Kin. K a t a l . , 1980. 21, 123 - 135

11. Hucknall, D.J., " S e l e c t i v e Oxidation o f Hydrocarbons",

Academic Press, London 1974

12. V.D.Wiele. K., v.d.Berg, P.J., "Comprehensive Chemical K i n e t i c s " , E l s e v i e r ,

Amsterdam, 1978, V o l . 20, p. 123

13. Krenzke, L.D., Keulks, G.W., Sklyarov, A.V., Firsova,A.A., Kutirev,M.,

Downloaded by UNIV OF WATERLOO on May 6, 2016 | http://pubs.acs.org

Publication Date: September 16, 1982 | doi: 10.1021/bk-1982-0196.ch001

Margolis,L.Y., Krylov,O.V,J.Catal.,1978,52, 418

14. Burlington, J.D., G r a s s e l l i , R.K., J. Catal., 1979, 59, 79

15. G r a s s e l l i , R.K., Burrington, J.D.,Bradzi1, J.D. Faraday Discussion, 1981,

72-72/12

16. Aso, J., Furukawa, S., Yamazone, N., Seiyama, T. J. Catal., 1980, 64, 29

17. Serban, S. Revue Chim. (Bucharest) 1967, 18, 65

18. C a r t l i d g e , J . , Mc Grath, L., Wilson, S.H., Trans. Inst. Chem. Eng.,

1975, 53, 117

19. Kppner, D i s s e r t a t i o n U n i v e r s i t t Erlangen-Nrnberg, 1975

20. Varadarajan, T.K., Visvanathan, ., S a s t r i , M.V.C., Indian J. Chem.,

1977, 15, 452

21. Adams, C.R., Voge, J . J . C a t a l . 1961, 3, 379

22. Peacock, J.M., Parker, A.J., Ashmore,P.G., Hockey, J.A. J. C a t a l . ,

1968, 15, 308

23. Wragg, R.P., Ashmore, P.G., Hockey, J.A., J. C a t a l . , 1973, 31, 293

24. S h i p a i l o , V.Y., Fedevich, E.V., Krivko, V.R., Zhurnal F i z i c h e s k o i Khimii,

1977, 51, 538

25. Lemberanskij, R.A., Azerb. Khim. Zh., 1968, 6, 19

26. Lapidus, V.L., Neftek., 1968, 9, 400

27. Gorshkov, A.P.,Gargarin. S.G., Kolchin, K., Neftek.,1970, 10, 59

28. Crozat, M., Germain, J.E., B u l l . Soc. Chim. F., 1973, 2498

29. Daniel, Ch., Keulks, G., J. Catal., 1973, 29, 475

30. Seinalow, R.J., Rustamow, M.I., Aliew, W.S., Model Khim. Reactorov T r .

Vsos. Konf. Khim. Reactoram, 1968, 3, 41

31. Berty, J.M., Vortrag, U n i v e r s i t t Erlangen-Nrnberg, 1978

32. Moro-Oka, Y., Tan. S., Ozaki, ., J. Catal., 1968, 12, 291

33. T j u r i n , J.N. Andruskewitsch, TW., Neftek., 1977, 17, 744

34. Bednorova, S., Habersberger, K., Chem. Prum., 1978, 28, 182

35. Vinogradova, O.M., Vytnov, G.F., Luiksaar, I.V., K i n . K a t a l . , 1975, 16, 576

36. Sheplew. W.S., Andruskewitsch, T.W., K a t a l l z . i. K a t a l i t . Processy, 1977, 171

37. Mars, P., v.Krevelen, D.W., Spec. Supp. Chem. Eng. S c i . , 1954, 3, 41

38. Krenzke, L.D., Keulks, G.W., J . C a t a l . , 1980, 64, 295

39. Monnier, J.R., Keulks, G.W., J . C a t a l . , 1981, 68, 51

40. Frost, .., Pearson, R.G., " K i n e t i c s and Mechanism.",

John Wiley and Sons, New York, 1961

41. Petersen, E.E., "Chemical Reaction A n a l y s i s " , P r e n t i c e - H a l l , Inc.

Engelwood Cliffs, 1964

42. Wei, J . , Prater, C.D., Adv. Cat., 1962, 13, 203

43. Lee, H.H., AIChE Journal, 1977, 23, 116

44. Akella, L.M., Lee, H.H., Chem. Eng. Jl., 1981, 22, 25 - 41

45. Probst, K., D i s s e r t a t i o n . U n i v e r s i t t Erlangen-Nrnberg, 1981

46. Emig, G., Hofmann. H., F r i e d r i c h , H.,

Proc. 5 th Europ. 2nd Int. Symp. Chem. React. Eng., 1972. 5 - 23

47. Gans, P. Comp. Chem., 1977, 1, 291

RECEIVED April 27, 1982.

Wei and Georgakis; Chemical Reaction EngineeringBoston

ACS Symposium Series; American Chemical Society: Washington, DC, 1982.

You might also like

- Vle of Hcl-WaterDocument6 pagesVle of Hcl-WaterYaqoob Ali0% (1)

- 1180 Exp 04, Density and Specific GravityDocument13 pages1180 Exp 04, Density and Specific GravityShaniCoolestNo ratings yet

- Distillation Experiment Conclusion and RecommendationsDocument2 pagesDistillation Experiment Conclusion and RecommendationsAhmad KhalidNo ratings yet

- Can Bang Long HoiDocument370 pagesCan Bang Long HoiKhanh Nguyen100% (1)

- Fluid Flow Measurement and Analysis ExperimentDocument11 pagesFluid Flow Measurement and Analysis ExperimentJohn TomlinsonNo ratings yet

- Chemical ThermodynamicsDocument33 pagesChemical ThermodynamicsAkash Ghosh0% (1)

- PHE Control Mechanism PDFDocument6 pagesPHE Control Mechanism PDFNaren VmdNo ratings yet

- Fluidized bed reactor design and fabricationDocument11 pagesFluidized bed reactor design and fabricationHarshaNo ratings yet

- Laboratory Scale Water Circuit Including A Photocatalytic ReactorDocument8 pagesLaboratory Scale Water Circuit Including A Photocatalytic ReactorPatrick_NickelsNo ratings yet

- 333 Manual 11 T2 Armfield ManualDocument45 pages333 Manual 11 T2 Armfield ManualSyamim AsyrafNo ratings yet

- Exp-40 Part2Document22 pagesExp-40 Part2Ahmet Samet ÖzdilekNo ratings yet

- Thermo FinalDocument66 pagesThermo Finalsossydj75% (4)

- Drying Sand in a Tray DryerDocument13 pagesDrying Sand in a Tray DryerHaziq AzliNo ratings yet

- ME 495 - Mechanical and Thermal Systems LabDocument12 pagesME 495 - Mechanical and Thermal Systems LabKammy LaiNo ratings yet

- NMR Kinetics: Study of A Reversible Hydrolysis ReactionDocument8 pagesNMR Kinetics: Study of A Reversible Hydrolysis ReactionOldbooklover100% (2)

- VLE of Methanol-Water MixtureDocument14 pagesVLE of Methanol-Water MixtureHafiniHambaliNo ratings yet

- CH312 MASS TRANSFER-I Numerical ProblemsDocument28 pagesCH312 MASS TRANSFER-I Numerical Problemsmayank sinhaNo ratings yet

- Theory of Dropwise Condensation and Effect of Substrate MaterialDocument187 pagesTheory of Dropwise Condensation and Effect of Substrate MaterialJuvy A. BalbaronaNo ratings yet

- J. Chem. Thermodynamics: J. Soujanya, B. Satyavathi, T.E. Vittal PrasadDocument4 pagesJ. Chem. Thermodynamics: J. Soujanya, B. Satyavathi, T.E. Vittal PrasadAngie Paola AcostaNo ratings yet

- P4E2: Kinetics of Homogeneous Reaction in Batch and Continuous Stirred-Tank Reactor at Two Different TemperatureDocument7 pagesP4E2: Kinetics of Homogeneous Reaction in Batch and Continuous Stirred-Tank Reactor at Two Different TemperaturejayaprinaNo ratings yet

- Lab Report R3 Batch ReactorDocument9 pagesLab Report R3 Batch Reactorzy_yf0% (1)

- Isobaric Vapor-Liquid Equilibrium For Binary System of Methanol and AcetonitrileDocument4 pagesIsobaric Vapor-Liquid Equilibrium For Binary System of Methanol and AcetonitrileAlejandra Rodríguez MorenoNo ratings yet

- Liquid-Liquid Extractions Lesson 7Document20 pagesLiquid-Liquid Extractions Lesson 7GATOMICONo ratings yet

- Chem 112.1 - Exer 2 PostlabDocument7 pagesChem 112.1 - Exer 2 PostlabGerry Mark GubantesNo ratings yet

- Residence - Time DistributionDocument9 pagesResidence - Time DistributionNik Nur Izzatul IkmalNo ratings yet

- Reaction CalorimetryDocument12 pagesReaction CalorimetryMajeed KhanNo ratings yet

- Plug Flow Reactor ExperimentDocument16 pagesPlug Flow Reactor ExperimentN Afiqah RazakNo ratings yet

- Measure Gas Diffusion Coefficient Using Winkleman MethodDocument6 pagesMeasure Gas Diffusion Coefficient Using Winkleman MethodMuzammil Iqbal100% (1)

- Process Temperature Control Using PID and LabVIEWDocument17 pagesProcess Temperature Control Using PID and LabVIEWManish SinghNo ratings yet

- Lab Report 1 Diffusion Across Biological Membrances SimulationDocument7 pagesLab Report 1 Diffusion Across Biological Membrances SimulationAmeena Ali50% (2)

- Vapor-Liquid Equilibrium of Systems Containing Alcohols, Water, CarbonDocument8 pagesVapor-Liquid Equilibrium of Systems Containing Alcohols, Water, CarbonJessica CehNo ratings yet

- Energy Transport Notes 2Document102 pagesEnergy Transport Notes 2Faisal MumtazNo ratings yet

- Indus Waste ProblemsDocument3 pagesIndus Waste ProblemsZeus Ian DuarteNo ratings yet

- Lec5 PDFDocument15 pagesLec5 PDFRaviNo ratings yet

- Vapor-Liquid Equilibrium Data For The SystemDocument4 pagesVapor-Liquid Equilibrium Data For The Systemapi-3817782100% (1)

- 124 Melting Point2Document15 pages124 Melting Point2bluestardiverNo ratings yet

- RI Vs Composition Methanol-Water MixtureDocument12 pagesRI Vs Composition Methanol-Water MixtureAnonymous VeJYFSMWLINo ratings yet

- CSTRDocument12 pagesCSTRsamueloNo ratings yet

- Ench 529 Virtual Lab (E5) InstructionsDocument2 pagesEnch 529 Virtual Lab (E5) Instructionsench501No ratings yet

- Measuring Viscosity with an Ostwald ViscometerDocument8 pagesMeasuring Viscosity with an Ostwald ViscometerJohn Andrae MangloNo ratings yet

- Reactor Design Sample ExamDocument7 pagesReactor Design Sample ExamAugustine BrockNo ratings yet

- Saponification Reaction Kinetics in a PFRDocument19 pagesSaponification Reaction Kinetics in a PFRKangae IlhamNo ratings yet

- First Order SystemDocument21 pagesFirst Order SystemNiranjan BeheraNo ratings yet

- Lab Manuals 2CH403 IPC Jan 2020 PDFDocument47 pagesLab Manuals 2CH403 IPC Jan 2020 PDFSamriddha Das GuptaNo ratings yet

- Armfield Ht31 Tubular Heat Exchanger in The Education KeywordsDocument3 pagesArmfield Ht31 Tubular Heat Exchanger in The Education KeywordsCHERUYIOT IAN100% (1)

- Arc Discharge ApplicationDocument15 pagesArc Discharge ApplicationHong Chun LeeNo ratings yet

- Files 2-Experiments Homogenuous Batch ReactorDocument6 pagesFiles 2-Experiments Homogenuous Batch ReactorS M AseemNo ratings yet

- Phase Diagrams in Chemical EngineeringDocument23 pagesPhase Diagrams in Chemical Engineeringchemsac2No ratings yet

- Packed Distillation Column ExperimentDocument20 pagesPacked Distillation Column ExperimentChan Chun ChenNo ratings yet

- Report TemplateDocument9 pagesReport Templatedmscott10No ratings yet

- Chem 155 Lab 3 - ElecetrochemistryDocument9 pagesChem 155 Lab 3 - Elecetrochemistryapi-272555054No ratings yet

- Duhem's theorem determines equilibrium stateDocument1 pageDuhem's theorem determines equilibrium stateZafirahAhmadFauzi100% (1)

- Modern Theory of CorrosionDocument98 pagesModern Theory of CorrosionMujahid HaddadNo ratings yet

- EKC 291 9 Heat ConductionDocument11 pagesEKC 291 9 Heat ConductionLia HolmanNo ratings yet

- AFPT921 Air Flow Pressure Temperature Control TrainingDocument2 pagesAFPT921 Air Flow Pressure Temperature Control TrainingKamalanathen ChlvnNo ratings yet

- EFFECT OF DRIVING SPEED ON REACTION TIME DURING MOTORWAY DRIVING - Tornros 1995Document8 pagesEFFECT OF DRIVING SPEED ON REACTION TIME DURING MOTORWAY DRIVING - Tornros 1995acolpoNo ratings yet

- Camphor BallsDocument8 pagesCamphor BallsGurunath EpiliNo ratings yet

- Enzymes: A Practical Introduction to Structure, Mechanism, and Data AnalysisFrom EverandEnzymes: A Practical Introduction to Structure, Mechanism, and Data AnalysisRating: 4 out of 5 stars4/5 (2)

- Patterns of Three Liquid PhaseDocument8 pagesPatterns of Three Liquid PhaseChauNo ratings yet

- FTIR Reflection TechniquesDocument52 pagesFTIR Reflection Techniquesfrox123No ratings yet

- 2011 Renewable Chemicals Dehydroxylation of Glycer Ol andDocument18 pages2011 Renewable Chemicals Dehydroxylation of Glycer Ol andChauNo ratings yet

- 2014 Conversion of Glycerol Into Allyl Alcohol Over Potassium-Supportedzirconia-Iron Oxide Catalyst PDFDocument7 pages2014 Conversion of Glycerol Into Allyl Alcohol Over Potassium-Supportedzirconia-Iron Oxide Catalyst PDFChauNo ratings yet

- 1 s2.0 S0021951712003132 MainDocument5 pages1 s2.0 S0021951712003132 MainChauNo ratings yet

- Edwards AGC D386!55!880 IssueRDocument74 pagesEdwards AGC D386!55!880 IssueRChauNo ratings yet

- Comparision of The Flow in Co-Rotating and Counter-Rotating TwinscrewDocument11 pagesComparision of The Flow in Co-Rotating and Counter-Rotating TwinscrewChauNo ratings yet

- 2014 From Glycerol To Allyl Alcohol Iron Oxide Catalyzed DehydrationDocument3 pages2014 From Glycerol To Allyl Alcohol Iron Oxide Catalyzed DehydrationChauNo ratings yet

- 1993 Oxidation Reduction and Isomerization of Allyl Alcohol and 1propanol Over CuzO 100Document9 pages1993 Oxidation Reduction and Isomerization of Allyl Alcohol and 1propanol Over CuzO 100ChauNo ratings yet

- Besson IrcelyonDocument2 pagesBesson IrcelyonChauNo ratings yet

- Comparision of The Flow in Co-Rotating and Counter-Rotating Twinscrew PDFDocument5 pagesComparision of The Flow in Co-Rotating and Counter-Rotating Twinscrew PDFChauNo ratings yet

- 1 s2.0 S0021951712003284 MainDocument8 pages1 s2.0 S0021951712003284 MainChauNo ratings yet

- 2012 Aqueous Phase Hydrogenolysis of Glycerol To Bio-Propylene Glycol Over PT SN CatalystsDocument4 pages2012 Aqueous Phase Hydrogenolysis of Glycerol To Bio-Propylene Glycol Over PT SN CatalystsChauNo ratings yet

- Copper Catalysts in The C-O Hydrogenolysis ofDocument128 pagesCopper Catalysts in The C-O Hydrogenolysis ofChauNo ratings yet

- 1 s2.0 S0021951709003017 MainDocument9 pages1 s2.0 S0021951709003017 MainChauNo ratings yet

- 1 s2.0 S0021951709003017 MainDocument9 pages1 s2.0 S0021951709003017 MainChauNo ratings yet

- Opdr-2012-Review Glycerol Carbonate SynthesisDocument11 pagesOpdr-2012-Review Glycerol Carbonate SynthesisSiddhartha MoulikNo ratings yet

- 1993 The Use of Niobia in Oxidation CatalysisDocument9 pages1993 The Use of Niobia in Oxidation CatalysisChauNo ratings yet

- 2004 Active CuZnO and CuZnOAl2O3 Catalysts Prepared by HomogeneousDocument5 pages2004 Active CuZnO and CuZnOAl2O3 Catalysts Prepared by HomogeneousChau MaiNo ratings yet

- 1999 Water-Soluble Colloidal Adams CatalystDocument2 pages1999 Water-Soluble Colloidal Adams CatalystChauNo ratings yet

- 1 s2.0 S1381116909000272 MainDocument7 pages1 s2.0 S1381116909000272 MainChauNo ratings yet

- 14 Production of 1,3-Propanediol by Hydrogenolysis of Glycerol Catalyzed by PtWO3ZrO2Document4 pages14 Production of 1,3-Propanediol by Hydrogenolysis of Glycerol Catalyzed by PtWO3ZrO2ChauNo ratings yet

- 2004 Methanol Steam Reforming Over CuZnOAl2O3 Catalyst Kinetics and Effectiveness FactorDocument11 pages2004 Methanol Steam Reforming Over CuZnOAl2O3 Catalyst Kinetics and Effectiveness FactorChauNo ratings yet

- 20 Cyclopentadienyl and Pentamethylcyclopentadienyl Ruthenium Complexes AsDocument10 pages20 Cyclopentadienyl and Pentamethylcyclopentadienyl Ruthenium Complexes AsChauNo ratings yet

- 2tak Vs 4takDocument3 pages2tak Vs 4takTaufiq AlhakimNo ratings yet

- Dasar Eksitasi Pada GeneratorDocument8 pagesDasar Eksitasi Pada GeneratorTeknisi Abal AbalNo ratings yet

- Service and Repair Instructions: Water & WastewaterDocument72 pagesService and Repair Instructions: Water & WastewaterLa Marina Mantenimiento100% (1)

- Florence Nightingale: The Lady with the LampDocument18 pagesFlorence Nightingale: The Lady with the LampsrinivasanaNo ratings yet

- Ego7 Manual enDocument76 pagesEgo7 Manual ensullivanj69No ratings yet

- Divide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoDocument27 pagesDivide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoAnand KumarNo ratings yet

- Vedic Astrology OverviewDocument1 pageVedic Astrology Overviewhuman999100% (8)

- Etabloc Technical DataDocument108 pagesEtabloc Technical Dataedward ksbNo ratings yet

- JSA .Hendra Pouring Congcrete by Mixer TruckDocument2 pagesJSA .Hendra Pouring Congcrete by Mixer TruckMuhamad Rizki AzisNo ratings yet

- Canadian Wood Council Publications and Tools For Wood Design Robertson RocchiDocument62 pagesCanadian Wood Council Publications and Tools For Wood Design Robertson RocchiDj MacNo ratings yet

- PENERAPAN ARSITEKTUR TROPIS PADA HOTEL RESORT DI PANTAI KRAKALDocument12 pagesPENERAPAN ARSITEKTUR TROPIS PADA HOTEL RESORT DI PANTAI KRAKALleo adoNo ratings yet

- The Hero of the Snore TangoDocument22 pagesThe Hero of the Snore TangoFlora Mae LacostalesNo ratings yet

- General Biology 2: Quarter 3, Module 1 Genetic EngineeringDocument20 pagesGeneral Biology 2: Quarter 3, Module 1 Genetic EngineeringRonalyn AndaganNo ratings yet

- Uv Spectrophotometric Estimation of Carvedilol Hydrochloride by First Order Derivative and Area Under Curve Methods in Bulk and PH PDFDocument7 pagesUv Spectrophotometric Estimation of Carvedilol Hydrochloride by First Order Derivative and Area Under Curve Methods in Bulk and PH PDFMeilia SuhermanNo ratings yet

- Ichroma™ COVID-19 Ab (With Ichroma™ II Reader) Test SystemDocument6 pagesIchroma™ COVID-19 Ab (With Ichroma™ II Reader) Test SystemGopinath AgnihotramNo ratings yet

- Mic ProjectDocument12 pagesMic Projectsarthakjoshi012No ratings yet

- Railway Electrification Projects Budget 2019-20Document9 pagesRailway Electrification Projects Budget 2019-20Muhammad Meraj AlamNo ratings yet

- 25f8e d64fDocument6 pages25f8e d64fapi-233604231No ratings yet

- Everything You Need to Know About Centrifugal FansDocument65 pagesEverything You Need to Know About Centrifugal Fansahmed100% (1)

- A7670 Series Hardware Design v1.03Document69 pagesA7670 Series Hardware Design v1.03Phạm NamNo ratings yet

- Steel 17-4PH MmpdsDocument18 pagesSteel 17-4PH MmpdsManoj ManoharanNo ratings yet

- 43-101 Technical Report Quimsacocha, February 2009Document187 pages43-101 Technical Report Quimsacocha, February 2009Marco Vinicio SotoNo ratings yet

- Lock Out Tag Out ProceduresDocument9 pagesLock Out Tag Out ProceduresyawarhassanNo ratings yet

- Psychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)Document48 pagesPsychopathology: Dr. Shafqat Huma MBBS, FCPS (Psychiatry) Fellowship in Addiction Psychiatry (USA)sfrtr100% (1)

- Weekly Report 52Document196 pagesWeekly Report 52Erceanu DanNo ratings yet

- Evolis User ManualDocument28 pagesEvolis User ManualIonmadalin1000No ratings yet

- Alcon Capacitor AC Mp4aDocument6 pagesAlcon Capacitor AC Mp4aDAC Secretary EENo ratings yet

- General Science EnvironmentDocument28 pagesGeneral Science EnvironmentHamza MujahidNo ratings yet

- Mercy PlansDocument126 pagesMercy Plansdharry8108No ratings yet

- DigiMasterIII Car Model ListDocument72 pagesDigiMasterIII Car Model ListRAGB1989No ratings yet