Professional Documents

Culture Documents

1basic Engine

Uploaded by

AndikaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1basic Engine

Uploaded by

AndikaCopyright:

Available Formats

BASIC KNOWLEDGE

1. DIESEL ENGINE AND GASOLINE ENGINE

A. Diesel Engine B. Gasoline Engine

Advanced Engine Mechanic Development 1

BASIC KNOWLEDGE

DIESEL ENGINE GASOLINE ENGINE

FUEL FUEL LIGHT OIL GASOLINE

FUEL CONSUMPTION RATIO 170 ~ 210 230 ~ 270

FLASHING POINT 50 DEG CELCIUS MORE -25 DEG CELCIUS MORE

COMPRESSION RATIO 14 ~ 30 KG/CM2 5 ~ 10 KG/CM2

IGNITION SELF BURN ELECTRIC SPARK

ATOMIZER METHOD INJECTION PUMP AND NOZZLE CARBURETOR

WEIGT / OUTPUT RATIO KG/HP 3~9 0.5 ~ 3.5

OUTPUT / VOLUME RATIO, HP/LT ~ 20 30 ~ 50

Advanced Engine Mechanic Development 2

BASIC KNOWLEDGE

2. FOUR CYCLE DIESEL ENGINE

Advanced Engine Mechanic Development 3

BASIC KNOWLEDGE

DIRECT COMBUSTION

. High efficiency

. Easily start

. Compatible with big engine

. Low exhaust temperature

. Sensitively with quality of fuel

. Need high pressure injection

. Need multi hole injector

. Low turbulence and difficult for high speed

PRE COMBUSTION CHAMBER

. Widely fuel type used

. Good turbulence

. Easily of fuel pump maintenance

. Low injection pressure

. Compromise with changing of injection timing

. Less of detonation

. Complex construction of cylinder head.

. Low capability of starting engine

. Wasteful of fuel usage

Advanced Engine Mechanic Development 4

BASIC KNOWLEDGE

PRE COMBUSTION CHAMBER

. Good turbulence when compression stroke

. High speed produce

. Less of nozzle trouble

. Compatible for automobile

. Complex construction of cylinder head

. Low efficiency

. Detonation when in low speed..

FIRING ORDER

. Sequence ignition timing for engine more than 1 cylinder.

. Power produce by combustions flat transmitted to crankshaft.

. Reduce vibrations and twisting in the crankshaft.

TABLE SEQUENCE

. Sequence stroke and ignition process in engine 1 cylinder or more.

. For establish mechanism valve setting.

. For determine every cylinder process.

Advanced Engine Mechanic Development 5

BASIC KNOWLEDGE

SEQUENCE TABLE 1 CYLINDER

TDC BDC TDC BDC TDC

INTAKE COMPRESSION POWER EXHAUST

0 180 360 540 720

SEQUENCE TABLE 4 CYLINDER

. FO 1 3 4 2

. Diff stroke every cylinder :

720 / 4 = 180

Advanced Engine Mechanic Development 6

BASIC KNOWLEDGE

SEQUENCE TABLE 4 CYLINDER

SEQUENCE TABLE 6 CYLINDER

FO : 1-5-3-6-4-2

. Diff stroke every cylinder :

720 / 6 = 120

Advanced Engine Mechanic Development 7

BASIC KNOWLEDGE

Advanced Engine Mechanic Development 8

BASIC KNOWLEDGE

VALVE TIMING

. Timing for exhaust valve and

intake valve open and close

EXAMPLE :

. For engine SA12V140

. Intake Stroke = 20+180+30=230

. Compression Stroke = 180-30=150

. Power Stroke = 180-55 = 125

. Exhaust Stroke = 55+180+20 = 255

Total Stroke = 230+150+125+255 = 740

Actually totally 2 times turning

of Crankshaft = 720

. 740-720 = 40

Its mean that 40 is for valve Over lapping

Advanced Engine Mechanic Development 9

BASIC KNOWLEDGE

TABEL SEQUENCE SA12V140

VALVE ADJUSMENT

According to Sequence Table, Valve adjustment can be carry out by knowing about

every process in cylinder from sequence table.

Advanced Engine Mechanic Development 10

BASIC KNOWLEDGE

FUEL COMBUSTION IN DIESEL ENGINE

When Compressed Slowly

. Temperature relatively constant, because the will escape through the wall of cylinder.

. The pressure rises, but the rise is proportional to the extent of volume reduction.

. The manner of compression is called ISOTHERMAL.

When Rapid Compression

. Gives no chance of escape to the heat contained in the trapped and compressed air.

. Will be no exchange of heat between the air being compressed and the outside.

. The manner of compression is called ADIABATIC.

When engine running with a high speed

. Example running at 2000 rpm, each compression is completed in 1,5/1000 second.

. No time for the compressed air to leak out through the valves or the piston rings.

. The heat compression cannot dissipate easily because the engine is generally hot when it is

running fast.

. At high speed running may be regarded as working on ADIABATIC compression.

At the time of starting up a cold engine

. The mode compression is closer to ISOTHERMAL.

Advanced Engine Mechanic Development 11

BASIC KNOWLEDGE

TEMPERATURE AND PRESSURE

. Air is a mixture of molecules oxygen, nitrogen and few others.

. Molecules may be conceived as a ball too small to be seen.

. Billions of these balls are jumping in every which directions, bouncing

against one another in cubic inch of air.

. The velocity with which balls jump about is high when the temperature

is high.

. One way of conceiving heat is to assume each molecular ball to be

vibrating, and emitting and conceiving energy particles.

. When the balls are crowded, the exchange of energy particles goes on

at a higher level. Consequently, each ball becomes more excited,

because of mutual proximity, and jumps faster.

. To heat a given volume of gas is to give it more energy particles than

it gives off to the surrounding object.

. The walls of the vessel containing the gas are constantly bombarded

by billions of tiny balls. The totalized force acting on the unit area of

the wall surface is PRESSURE. The greater velocity with which the balls

impinge on the wall, the higher the pressure.

. If a given volume of gas is compressed, what happens/ This the

question that applies to the air getting compressed in the cylinder

by the piston.

Advanced Engine Mechanic Development 12

BASIC KNOWLEDGE

. The walls of the vessel containing the gas are constantly bombarded

by billions of tiny balls. The totalized force acting on the unit area of

the wall surface is PRESSURE. The greater velocity with which the

balls.

impinge on the wall, the higher the pressure.

. If a given volume of gas is compressed, what happens/ This the

question that applies to the air getting compressed in the cylinder

by the piston.

REQUIREMENT FOR FUEL COMBUSTION

. Fuel oil sprayed into the ordinary atmosphere will not burn.

. Oxygen and high temperature are needed to burn the fuel oil.

. These two requirement are meet by compressing a proper amount

of air within the engine cylinder.

. By burning within the combustion chamber, the fuel oil turns to high

temperature and high pressure.

. The process of burning the fuel may be viewed in three successive

stage. 1) mixture formation (fuel globules vaporize and mix with

the air), 2) ignition, 3) final combustion.

. The very short interval from the moment the fuel oil is injected

until the fuel oil begins to burns is a delay or hesitating period.

. With an easier to burn fuel oil or with finer globules of fuel oil, this

period is shorter.

Advanced Engine Mechanic Development 13

BASIC KNOWLEDGE

FINER THE FUEL PARTICLE, EASIER THE COMBUSTION

. To promote fuel oil vaporization, the totalized surface of a given

portion of fuel must be increased.

. The surface of a droplet can be expanded hundreds of times by

dividing it into the finer particles, this the reason why an injection

nozzle is used to supply fuel into the cylinder.

. If the fuel being injected into the combustion chamber as it happens to

be excessively fine in globule size, vaporization might complete in

an extremely short duration and the entire fuel in mixed state might

burn violently. Such violent combustion is harmful to the cylinder

and piston.

. Large globules of fuel oil will burn slowly.AND WHAT HAPPENS?

. Continuous combustion, as distinguished from violent combustion and

slow combustion results in gradual pressure build up within the

combustion chamber and make greater percentage of mechanical

energy contained in the high pressure gas available for doing

useful work.

. With a given injection nozzle, the higher the injection pressure

(pressure with which the fuel is forced out through the orifice in

the nozzle) the finer are the globules produced by injection.

. With too high injection pressure, the fuel may be spurt out straight

without breaking into finer globules.

. The nozzles are designed to spray at a constant pressure.

Advanced Engine Mechanic Development 14

BASIC KNOWLEDGE

COMPLETE COMBUSTION

. Just before the piston reaches its uppermost position (TDC) some eddying or swirling turbulence is induced

in the combustion chamber. The fuel being injected will thoroughly mix with the compressed air, because

of the turbulence, so that it will burn completely.

. Each diesel engine has its combustion chamber shaped for a certain type of injection nozzle spraying the

fuel in a particular pattern. Too narrow a spraying angle. A crooked spray or cocked spray angle prevents

fuel oil from burning completely and reduce engine horsepower output.

Advanced Engine Mechanic Development 15

BASIC KNOWLEDGE

SOME FUEL OILS ARE HARD TO BURN

. Burning is a chain reaction. A cloud of fuel oil globules catching fire uniformly or simultaneously is

a phenomenon of explosion, not of burning. Ideal combustion means that the first group of globule

introduced into the combustion chamber catch fire or ignite to burn the following groups of globules,

thereby building up pressure rather gradually. With a hard to burn fuel oil, however the first group of

globules hesitate to ignite and the following groups to hesitate for a moment ; then, all of sudden, ignition

occurs here and there almost simultaneously to result in a violent burning, delivering a hammering blow

(knocking) to the walls of the combustion chamber. Such a manner of fuel combustion fails to develop

full power.

CETANE NUMBER

Cetane number represents the ignition quality of a fuel oil. Both ease of starting and combustion roughness

of a diesel engine are influenced by the ignition quality of a fuel oil it uses.

A fuel oil with a higher cetane number burns more easily. The cetane number for a diesel engine is

specified by the engine maker. It is usually the minimum number.

The cetane number of a fuel oil is determined by using the fuel in a special test engine and by comparing

its ignition delay against the ignition delay of the reference fuel (45% cetane 55% alpha-methyl-

naphthaline) whose cetane number is arbitrarily taken 45.

COMPRESSION RATIO

Whycompression ratio diesel engine higher than gasoline engine?

And how about the formula?

Advanced Engine Mechanic Development 16

BASIC KNOWLEDGE

COMPARATION BETWEEN AIR AND FUEL IN DIESEL ENGINE

21% O2

1%

78% N2 Others

A large quantity of air is required for the fuel burn.

Air consist of oxygen (O2) which occupies 20% of air compositions.

Fuel oil consist of many atoms of carbon and hydrogen (HxCx).

Fuel oil burn will produce carbon dioxide gas (CO2), and steam (H2O), if perfect combustion.

In imperfect combustion (lack of oxygen), will produce CO2, CO (carbon monoxide), free carbon and steam.

Carbon monoxide is poisonous and gives no color and smell.

Diesel engine produce less of CO than gasoline engine.

Free carbon consists of carbon grains is not poisonous, and make the exhaust black.

Certain amount of oxygen is indispensable for the complete combustion.

The other words, the air containing such amount of oxygen as above is absolutely necessary.

Required minimum amount is called the theoretical amount of air.

If it is assumed that any amount of fuel oil is made to burn in the theoretical amount of air, so the fuel will

change Carbon dioxide and steam with forming neither carbon monoxide nor free carbon, and oxygen in the air

will be Thoroughly consumed.

Advanced Engine Mechanic Development 17

BASIC KNOWLEDGE

AIR EXCESS RATIO

14,5 gram of air is required for complete combustion of 1 gram of fuel oil, 14,5 gram is theoretical amount of air.

This amount of air corresponds to 12 liters of air in volume at sea level.

In theoretical amount of air can not always be used in combustion effectively, and produce free carbon.

(Thats the reason why, air excess ratio needs for complete combustion).

Air excess air ratio indicates multiplying factor of an excess amount of air against its theoretical amount of air.

For instance in theoretical 1 gram fuel need 14,5 gram air or 12 liters air, for air excess ratio 2, its mean 1 gram

fuel needs 29 gram air or 24 liters air.

As an engine has given size of cylinder, the of air drawn into the cylinder is relatively constant.

Accordingly, the more the amount of fuel is injected, the smaller Air Excess Ratio will be*.

In diesel engine Air Excess Ratio is usually ranged on 1,2 to 1,4 when fuel oil is being fully injected.

When Air Excess Ration comes down, much of fuel oil will burn incompletely and giving the black exhaust.

When Air Excess Ratio goes up, the complete combustion will be recovered, making the exhaust near colorless.

Increasing amount of fuel injection for improve the horsepower but gradually make the black exhaust.

Increasing amount of fuel injection for improve the horsepower, but make combustion gradually incomplete.

At a large Air Excess Ratio, as almost the heat is consumed to raise the temperature of excess air,

and the exhaust gas temperature will kept relatively low. (*Explain contrary condition)

Feeding excessive amount of fuel in order to increase HP, will cause Air Excess Ratio to be lowered extremely.

Lower extremely Air Excess Ratio, result very high temperature of the exhaust, and will cause craks on the piston

and cylinder head.

Advanced Engine Mechanic Development 18

BASIC KNOWLEDGE

EXCESS AIR RATIO

GU / GB

X = Rst

Rst = GU

GB

X = Air Excess Ratio

GU = Weight of air

GB = Weight of fuel

Rst = Air weight theoretical for

Completely burn 1 gram fuel

Rst = 14,5 gram

Advanced Engine Mechanic Development 19

BASIC KNOWLEDGE

SUPERCHARGER

The amount of air to be drawn into the cylinders is dependent on the total displacement and amount of fuel

The amount of air to be drawn into the cylinders is dependent on the total displacement and amount of fuel is limited.

is limited.

When injection of fuel excess, the amount just stated will give black smoke and higher exhaust temperature and fail

When

make theinjection of fuel

increasing excess, the amount just stated will give black smoke and higher exhaust temperature

horsepower.

and fail

Accordingly, the larger the total displacement exists, the more fuel to be injected and more horsepower produced.

In a diesel engine used horsepower.

make the increasing on a construction machine, the horsepower per 1000 cc ranges on 10 17 HP.

Accordingly, the larger

For produced larger horsepowerthe total

in adisplacement exists,

relatively small pistonsthe more fuel toneed

displacement, be supercharging

injected and more horsepower

system.

produced.

Supercharging make forcing when air drawn into the cylinder, and when fuel injected corresponds the amount of

that air to be drawn used

In a diesel engine oncylinder,

into the a construction machine,

the horsepower willthe horsepower

increase per 1000 cc ranges on 10 17 HP.

up to 30%

For produced are

Superchargers larger horsepower

classified in a relatively

into a turbo-type small pistons displacement, need supercharging system.

and rote-type.

Supercharging make forcing when air drawn into the cylinder, and when fuel injected corresponds the

amount of

that air to be drawn into the cylinder, the horsepower will increase up to 30%

Superchargers are classified into a turbo-type and rote-type.

ENGINE AT HIGH ALTITUDES

Higher altitude, is lower atmospheric pressure and thinner the air density.

1 liter air = 1,2 g at sea level and 0,77 g at 3776 m.

In high attitude, the engine operated is same way with lack of air.

Some systems to maintain engine power at high altitude are, Diesel Altitude Control, Air Fuel Control in

Cummins

Automatic Altitude Control in Caterpillar engine.

Advanced Engine Mechanic Development 20

BASIC KNOWLEDGE

THERMAL EFFICIENCY

Thermal efficiency is compare between thermal that convert to effective power in fly wheel with all thermal

that produce by engine in combustion process.

In other words thermal produce by combustion deducted by thermal loosing by cooling, exhaust, and others

mechanical lost.

If thermal produce by combustion = Q1 and Thermal lost = Q2, so thermal efficiency = X 100%

Q1 Q2

THERMAL BALANCE Q1

THERMAL PRODUCE BY COMBUSTION 100% 32% Effective power in flywheel / crank

shaft

31% Thermal lost by temperature of

exhaust gas. Excessive exhaust

temperature, excessive lost power ore

lost thermal.

5% 2%

32% Effective Power 30% Thermal lost by cooling system.

30% Exhaust Lost Lower coolant temperature higher

Cooling Lost thermal lost by water coolant.

Mechanical Lost 5% Thermal lost by mechanical lost (

Pumping Lost instance : Alternator, water pump, oil

31%

pump).

2% Thermal lost by piston movement

when intake, compression and exhaust

process.

Advanced Engine Mechanic Development 21

BASIC KNOWLEDGE

TIMING INJECTION AND PRESSURE IN CYLINDER

Adjustment timing injection is important in engine combustion process, but not so important if :

- Coupling of the injection timing is excessively out of adjustment.

- Advanced timer is defective.

- Improperly assembling timing gear when assembled during overhauling of it.

Some effects when any possible change is made on injection timing.

- Excessive or low pressure in cylinder.

- Knocking, exhaust color, de-rate horsepower etc.

Some effect are varied depending on the following

Circumstances:

- Type or shape of the combustion chamber = Rpm.

- Timing valve = air to fuel mixture rate.

- Type of fuel injection nozzle = Grade of fuel used.

As the effect varies according to each condition under

which the engine operates its very difficult to decide

what will happen when any change is made on the

fuel injection timing. Experience is not enough to

determine the proper injection timing. It is dangerous

to determine the injection timing only by looking at the

exhaust color. It must be adjusted accordance with

instructions of the engine manufacturer.

The proper injection timing of an engine is usually

determined by the manufacturer by taking it into

account to get the most suitable value of the

maximum pressure.

Advanced Engine Mechanic Development 22

BASIC KNOWLEDGE

Injection timing advance maximum pressure in cylinder rise, retard is drops.

Injection timing advance, knocking sound, why?

When the exhaust color is bad, check properly injection-timing tune.

Its important to doubt whether injection timing is correct when a lack of horsepower.

COLOR OF ENGINE DIESEL EXHAUST GASES

Background for analyze exhaust color is cloud or whitish building dont blue sky or trees.

What does black exhaust smokes mean?

- Imperfect combustion excessive fuel or lack of air.

- Un-burnt fuel turns into carbon and mix with exhaust gas.

- Generally exhaust gas gradually become black smoke according to increasing engine loads.

Low air suction efficiency because:

- High attitude

- Air suction resistant increase.

- Supercharges seizes fails to force air to the cylinder.

Leak of the sucked air:

- Air would leak if the cylinder and liner or piston rings wear out and exhaust smoke become bluish.

- Poor contacts or wear out in valve or seat valves.

- Cylinder head not clamped tightly or if gasket breaks.

Fuel is not injected properly into the cylinder:

- Jet pressure is low or a particle of fuel is large.

- Fuel drips from the nozzle at end of injection.

- Nozzle defective, or injector discharge port is clogged.

- Timing injection is out of adjustment.

Excessive amount of fuel is injected into the cylinder:

Advanced Engine Mechanic Development 23

BASIC KNOWLEDGE

- Imperfect combustion, black smoke, piston and cylinder over heat, excessive exhaust temperature.

What does a bluish exhaust smoke mean?

- Indicates engine oil burning with.

- Oil leaks from suction or exhaust valve stem.

- Oil leaks from turbocharger.

What does a whitish exhaust smoke mean?

- There are cases where the color of the exhaust turns white, if the fuel injection timing is out of

Adjustment, the exhaust turns white or this may also happen if water leaks somewhere and

A large amount of vapor mixes with the exhaust, although this happens infrequently.

COMBUSTION PROCESS

a. Period of delayed ignition

b. Period of abrupt combustion

c. Period of normal combustion

d. Period of after burning

(Broken line shows the air expansion)

A. Start of injection

B. Ignition

C. Start of normal combustion

D. End of normal combustion

E. End of after combustion

Advanced Engine Mechanic Development 24

BASIC KNOWLEDGE

KNOCKING

Delay periods too long, causing excessive burning fuel in abrupt periods.

Pressure in cylinder suddenly higher and make knocking sounds.

Knocking preventions:

1. Use fuel with high cetane number.

2. Rise up air temperature in start of injection.

3. Decrease quantity of injection when start of injection

4. Rise up combustion chamber temperature.

Advanced Engine Mechanic Development 25

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Livina AT PDFDocument293 pagesLivina AT PDFAndika100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Diamond DA 42 Systems - V12 - 5clases 19 de JunioDocument402 pagesDiamond DA 42 Systems - V12 - 5clases 19 de JunioLiu Antonio Tang100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Tutorial On Geometric CalculusDocument16 pagesTutorial On Geometric Calculusschlemihl69No ratings yet

- T-CON Schematic PDFDocument138 pagesT-CON Schematic PDFMahmoued Yasin78% (51)

- T-CON Schematic PDFDocument138 pagesT-CON Schematic PDFMahmoued Yasin78% (51)

- Ion Thruster GuideDocument16 pagesIon Thruster GuideMimsisiNo ratings yet

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDocument5 pagesMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrNo ratings yet

- FV 623 CatalogDocument50 pagesFV 623 CatalogOmar Coronado50% (2)

- 1.5 ActuatorsDocument19 pages1.5 ActuatorsAndikaNo ratings yet

- IGCSE Topical Past Papers PhysicsDocument64 pagesIGCSE Topical Past Papers PhysicsHubert DMelloNo ratings yet

- Selden Keel Boat v1 LmarineriggingDocument72 pagesSelden Keel Boat v1 LmarinerigginglmarinegroupNo ratings yet

- 1.6 Hoses, Pipes & FittingsDocument17 pages1.6 Hoses, Pipes & FittingsAndikaNo ratings yet

- 1.6 Hoses, Pipes & FittingsDocument17 pages1.6 Hoses, Pipes & FittingsAndikaNo ratings yet

- POLYTRON BT5 - U-Slim - PS52UV232G - PS52UM70 - HBEE-010A - HBT-01-05 - HBT-05-001 - 7N65 STV9325 MD2009 D313 JF0501-19587 LA44402 PDFDocument4 pagesPOLYTRON BT5 - U-Slim - PS52UV232G - PS52UM70 - HBEE-010A - HBT-01-05 - HBT-05-001 - 7N65 STV9325 MD2009 D313 JF0501-19587 LA44402 PDFAndika100% (6)

- POLYTRON BT5 - U-Slim - PS52UV232G - PS52UM70 - HBEE-010A - HBT-01-05 - HBT-05-001 - 7N65 STV9325 MD2009 D313 JF0501-19587 LA44402 PDFDocument4 pagesPOLYTRON BT5 - U-Slim - PS52UV232G - PS52UM70 - HBEE-010A - HBT-01-05 - HBT-05-001 - 7N65 STV9325 MD2009 D313 JF0501-19587 LA44402 PDFAndika100% (6)

- 4fuel Injection PumpDocument9 pages4fuel Injection PumpAndikaNo ratings yet

- Process Modeling Approach for Evaluating Biodiesel ProductionDocument18 pagesProcess Modeling Approach for Evaluating Biodiesel ProductionSereneTan18_KLNo ratings yet

- BS3974 Pipe SupportsDocument20 pagesBS3974 Pipe SupportsTony100% (1)

- Rcs454: Python Language Programming LAB: Write A Python Program ToDocument39 pagesRcs454: Python Language Programming LAB: Write A Python Program ToShikha AryaNo ratings yet

- Planning - THERM - Timber - H-I - H-V - 2016 (RAICO)Document542 pagesPlanning - THERM - Timber - H-I - H-V - 2016 (RAICO)AnrStukNo ratings yet

- IONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11Document3 pagesIONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11dhiaa mohammedNo ratings yet

- 4E Roadmap for Energy Efficient Electric Motors and Motor SystemsDocument30 pages4E Roadmap for Energy Efficient Electric Motors and Motor SystemsCarlos LopezNo ratings yet

- Data Pin Flyback LengkapDocument49 pagesData Pin Flyback LengkapAhmad Humaidi67% (3)

- Data Pin Flyback LengkapDocument49 pagesData Pin Flyback LengkapAhmad Humaidi67% (3)

- Costiuc Silvia - Culas in Oltenia - CNHC 2011Document25 pagesCostiuc Silvia - Culas in Oltenia - CNHC 2011trancalina100% (1)

- NASKAH PUBLIKASI ARI BAGUS PRATAMA 1310502010.compressedDocument11 pagesNASKAH PUBLIKASI ARI BAGUS PRATAMA 1310502010.compressedAndikaNo ratings yet

- DVR Internet Setting-TronikaDocument8 pagesDVR Internet Setting-TronikaSigit HantoroNo ratings yet

- NASKAH PUBLIKASI ARI BAGUS PRATAMA 1310502010.compressedDocument11 pagesNASKAH PUBLIKASI ARI BAGUS PRATAMA 1310502010.compressedAndikaNo ratings yet

- Si-prog-V2 2 JDM IC PROG Programer-CircuitDocument1 pageSi-prog-V2 2 JDM IC PROG Programer-CircuitAlex Jhon Quispe MesccoNo ratings yet

- TV Service ModeDocument26 pagesTV Service Modevideoson100% (5)

- Illustrated Parts List Y05242 May 2011Document18 pagesIllustrated Parts List Y05242 May 2011AndikaNo ratings yet

- Chip DetailsDocument13 pagesChip DetailsGuto CariocaNo ratings yet

- Alur Pin Protek PD TV SharpDocument7 pagesAlur Pin Protek PD TV SharpAndikaNo ratings yet

- TV Service ModeDocument26 pagesTV Service Modevideoson100% (5)

- 2lube SystemDocument16 pages2lube SystemMaz DhieenNo ratings yet

- 10corossion ResistorDocument8 pages10corossion ResistorAndikaNo ratings yet

- Tvsharp-Wonder Universe Tda9381ps PDFDocument1 pageTvsharp-Wonder Universe Tda9381ps PDFAndikaNo ratings yet

- 1.5 ActuatorsDocument19 pages1.5 ActuatorsAndika100% (1)

- Sekn5016 Dt6 DiyDocument5 pagesSekn5016 Dt6 DiyAndikaNo ratings yet

- Tl494 PWM IcDocument10 pagesTl494 PWM IcSai ChandhraNo ratings yet

- A 6802726Document22 pagesA 6802726AndikaNo ratings yet

- A 6802726Document22 pagesA 6802726AndikaNo ratings yet

- Sistem Kemudi & RemDocument171 pagesSistem Kemudi & RemAndikaNo ratings yet

- Building A Big Data Platform For Smart Cities: Experience and Lessons From SantanderDocument8 pagesBuilding A Big Data Platform For Smart Cities: Experience and Lessons From SantanderDylan GuedesNo ratings yet

- DrillingMotors MKT 001 01Document10 pagesDrillingMotors MKT 001 01Aman Aayra SrivastavaNo ratings yet

- Mine Design and SchedulingDocument10 pagesMine Design and SchedulingLeandro FagundesNo ratings yet

- RtosDocument78 pagesRtossekinNo ratings yet

- Fluid Mechanics Subjective QuestionsDocument3 pagesFluid Mechanics Subjective QuestionsCrewdex ProNo ratings yet

- Nexans - MPRX (2002)Document63 pagesNexans - MPRX (2002)Dan Ghimbasanu0% (1)

- HOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsDocument12 pagesHOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsJo PatrickNo ratings yet

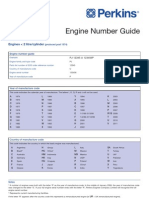

- Perkins Engine Number Guide PP827Document6 pagesPerkins Engine Number Guide PP827Muthu Manikandan100% (1)

- Squashing Commits with RebaseDocument4 pagesSquashing Commits with RebaseDavid BeaulieuNo ratings yet

- Commissioning Report Generator - SAMPLEDocument5 pagesCommissioning Report Generator - SAMPLEMax JohnNo ratings yet

- Home water pressure booster pumpDocument3 pagesHome water pressure booster pumpbadaasaabNo ratings yet

- 7 New Management ToolsDocument6 pages7 New Management ToolsKarthik SivaNo ratings yet

- TBR Wipro LeanDocument8 pagesTBR Wipro LeanAnonymous fVnV07HNo ratings yet

- Physics 110A: Electromagnetism: 1 Introduction and OverviewDocument4 pagesPhysics 110A: Electromagnetism: 1 Introduction and OverviewJoshua LinNo ratings yet

- Everyday Vocabulary Telephone TestDocument3 pagesEveryday Vocabulary Telephone TestzdravkamajkicNo ratings yet