Professional Documents

Culture Documents

Costo LPG PDF

Uploaded by

Gabriel ManavellaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Costo LPG PDF

Uploaded by

Gabriel ManavellaCopyright:

Available Formats

Natural Resources, 2012, 3, 164-169

http://dx.doi.org/10.4236/nr.2012.33021 Published Online September 2012 (http://www.SciRP.org/journal/nr)

Cost Optimal Selection of Storage Tanks in LPG

Vaporization Station

Guohua Shi

Energy and Power Engineering Department, North China Electric Power University, Baoding, China.

Email: lucksgh@126.com

Received May 4th, 2010; revised June 3rd, 2011; accepted June 17th, 2011

ABSTRACT

Liquefied petroleum gas (LPG) is an important urban gas source in China. Before supplied to customers by pipeline

supply systems, LPG is stored in tanks in LPG vaporization stations. Designers usually decide the number and the size

of storage tanks by their experience during constructions of vaporization stations. These decisions are usually not best

and most economical. To solve the problem, a compact mixed integer nonlinear programming model has been de-

veloped in this paper. The objective is to minimize annual storage cost of the vaporization station. The model has been

transformed into a general nonlinear programming model by transforming integer variables and 0 - 1 variables into con-

tinuous variables. One LPG vaporization station was taken as an example to illustrate the usage of the model. The

results show that the optimal storage scheme can be determined accurately and quickly by the model and about 15% of

storage cost can be saved every year after optimization.

Keywords: Liquefied Petroleum Gas; Storage Tank; Cost Optimization; Mixed Integer Nonlinear Programming

1. Introduction gas distribution network.

Obviously, storage tanks ensuring reliable gas supply

There were several hundred millions of people using solid

are key equipments of an LPG vaporization station. Dur-

fuels (biomass and coal) partially or exclusively for cook-

ing constructions of LPG vaporization stations, designers

ing and heating in China, most of these in rural areas, in

usually decide the number and the size of storage tanks

2007 [1]. The long-term and mass combustion of solid

by their experience. Due to various sizes of LPG storage

fuels makes the country suffer serious air pollution. Cook-

tanks, however, there are several selection schemes with

ing with liquid or gas fuels is a strategic choice to reduce

different costs to meet the same storage requirement. The

the level of atmospheric pollution, as well as to improve

cost-optimal selection scheme is very important to in-

peoples living standard. Therefore, the Chinese govern-

crease the profitability of the LPG pipeline supply mode.

ment has been taking firm steps to develop its urban gas

At present, lack of a tool to evaluate the decision on the

industry [2-4].

selection of storage tanks is a big barrier to build LPG

With some advantages, such as convenient transporta-

vaporization stations in China.

tion, easy operation, high energy density, and low pollu-

In this paper, a mixed integer nonlinear programming

tion, liquefied petroleum gas (LPG) is a principal resi-

(MINLP) model is developed. The model minimizes the

dential fuel for a lot of Chinese people not served by

annual storage cost of a LPG vaporization station in con-

natural gas infrastructure [5]. In 2007, LPG was available

sideration of guaranteeing its normal and safe operation.

in more than 90% of total cities and 7.3 million tons of

To solute this model conveniently, integer variables and

LPG was consumed for households in China [6].

0-1 variables are transformed to some continuous vari-

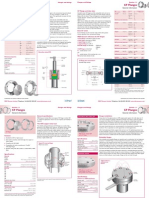

In China, a considerable portion of LPG is supplied to

ables. In order to illustrate the mathematical model, the

customers by a LPG pipeline supply mode (see Figure 1).

economically optimal selection of storage tanks is done

LPG is firstly delivered from LPG import terminals or

for a LPG vaporization station in Guangdong, using a

LPG plants to a vaporization station by tank trucks, and

mathematical software package LINGO [7], and results

then unloaded and stored in cylindrical shaped LPG

are analyzed.

storage tanks. LPG in storage tanks is pumped into

heated vaporizers and converted into gaseous LPG. After

2. Methods

gas-liquid separation, the gas is regulated to a required

pressure, and then transported to customers via a local The objective of the model is to improve the aforemen-

Copyright 2012 SciRes. NR

Cost Optimal Selection of Storage Tanks in LPG Vaporization Station 165

tioned supply modes profitability by minimizing the used or not in the LPG vaporization station:

annual storage cost of the vaporization station. The stor-

1, used

age cost minimization is accomplished by determining a xs

combination scheme of storage tanks. For solving this 0, not used

problem, the following steps are required [8,9]:

defining the appropriate objective function, 2.3. Objective Function

determining the related constraints. The objective function minimizes the annual storage cost

Section 2.1 and Section 2.2 show parameters and deci- of the LPG vaporization station.

sion variables that are used in the MINLP model, respec- In this paper, it is supposed that no funds are borrowed

tively. to buy and install LPG storage tanks. Therefore, for each

LPG vaporization station, its annual storage cost consists

2.1. Parameters of fixed costs (i.e. annual depreciation charge of storage

S The number of sizes of LPG storage tanks tanks) and variable costs which include annual mainte-

which can be used in the vaporization station, nance cost of tanks and annual management cost of tanks.

where s is the index for sizes, such that s = For convenience, annual maintenance cost of storage tanks

1, , S. is calculated by multiplying their annual depreciation

Cs Initial cost of a sth LPG storage tank. charge by a ratio, while their annual management cost is

Vs Volume of a sth LPG storage tank. expressed by a proportion of their initial cost.

i Market discount rate. We assume that there are S possible sizes of LPG

r Residual value rate of LPG storage tanks. storage tanks and the residual value rate and the depre-

D Depreciable life of LPG storage tanks. ciable life are same for each tank.

Kmi Ratio of annual management cost of storage Considering the time value of money, the annual depre-

tanks to initial cost of storage tanks. ciation charge of storage tanks is given by the following

Kmd Ratio of annual maintenance cost of storage equation:

tanks to annual depreciation charge of storage i 1 i D S

tanks. 1 r x C N (1)

Gd Average daily gas consumption in the design 1 i D 1 s s s

s 1

month (i.e. month of maximum average daily The objective function is then formulated as follows:

gas consumption).

s Maximum filling ratio of a sth storage tank at i 1 i D S

Min K mi 1 K md 1 r x C N (2)

its maximum operating temperature. 1 i D 1 s 1 s s s

2.2. Decision Variables 2.4. Constraints

Ns The number of sth LPG storage tanks in the va- Bad weather, such as flood, rain, fog and snow, may

porization station. prevent LPG tank trucks from transporting LPG to va-

The following notation shows that a sth storage tank is porization stations timely. In consideration of adverse

Users

Liquid-phase tube

Gaseous tube

Drain line Drain line

Check valve Stop valve Thermometer Manometer Liquidometer Relief valve

1LPG storage tank; 2Vaporizer; 3Gas-liquid separator; 4Gas pressure regulator; 5LPG tank truck; 6Compressor.

Figure 1. Schematic diagram of the LPG pipeline supply mode.

Copyright 2012 SciRes. NR

166 Cost Optimal Selection of Storage Tanks in LPG Vaporization Station

weather factors, therefore, keeping a safety reserve in S

each vaporization station should be considered sufficient 1 xs 2 (6)

s 1

to guarantee the stations ability to supply stable and

enough LPG to consumers. In addition, the safety reserve Equations (7) and (8) are the non-negativity and inte-

is also used for meeting peak loads. ger requirements for decision variables (xs, Ns). Note that

Reference [10] specifies the LPG storage capacity in the model can set Ns = 0 if the size sth LPG storage tank

one vaporization station, which is described as follows: is not used in the vaporization station.

If the LPG is supplied by LPG plants, the storage xs 0,1 s 1, , S (7)

volume of LPG should be determined based on some

factors, such as the gas supply scale of the vaporiza- Ns 0 if xs 0

s 1, , S (8)

tion station, the production situation of plants, the N s positive integer if xs 1

distance from plants to the station, etc.

If the LPG is supplied by LPG import terminals, the Furthermore, the following equation holds according

storage volume of LPG should be triple of average to (3) and (4):

daily gas consumption in the design month. N s 15Gd Vss s 1, , S (9)

It is clear that the storage capacity of storage tanks in

the station must be no less than the required safety reserve. Here denotes up-rounding (the next higher inte-

According to the investigation, a storage volume of ger). Equation (9) can limit the value range of Ns, which

fifteen times average daily LPG consumption is regarded contributes to cutting the solution time of the model.

as reasonable for a vaporization station which LPG is The optimization problem is to select the values of de-

supplied by LPG plants [11]. Therefore, if LPG plants cision variables xs , N s s 1, , S that minimize the

are suppliers, the storage capacity restriction is shown in annual storage cost subject to (3)-(9). xs s 1, , S

(3): are pure 0-1 variables, while Ns s 1,, S are bounded

S

integer variables.

xsVs N s s 15Gd (3)

s 1 2.5. Conversion of the Model

If LPG import terminals are suppliers, the storage ca- The developed model is a mixed integer nonlinear pro-

pacity restriction is as follows: gramming model. Because the value areas of variables

S

are finite sets of discrete points, the solutions of MINLP

xsVs N s s 3Gd (4) problems are complicated and time-consuming [12,13].

s 1 However, there are many fast solution algorithms for

where is the density of liquid LPG at the maximum general nonlinear programming (NLP) problems, such as

operation temperature of storage tanks. In China, LPG variable metric algorithm, penalty function algorithm,

trust-region algorithm, etc. [14]. For more convenience,

storage tanks are generally equipped with fixed spray

we transform integer variables and binary variables to

cooling devices, so that their maximum operation tem-

continuous variables using approaches suggested in [15]

perature is 40C.

and [16]. Then, the proposed model is converted into a

Reference [10] also requires that the number of storage

general nonlinear programming form.

tanks should not be less than two in each station. Install-

Every binary variable with values in {0,1}, xs, can be

ing two or more tanks in a station has two reasons. The

rewritten equivalently as the following quadratic equal-

first is that gas supply will not be interrupted when one

ity:

tank is maintained. The other is that the LPG in a storage

tank can be transported to other tanks when it has a dan- xs2 xs 0 s 1, , S (10)

gerous fire and explosion risk. The constraint of the Therefore, (7) can be substituted by (10).

number of tanks is shown in (5): It is clear that each Ns in the model is a bounded inte-

S ger variable. Without loss of generality, we write Ns in

xs N s 2 (5) binary form, introducing new 0-1 variables ysj.

s 1

N s j 0 2

log Ls

The corresponding management cost will rise with the 2 j ysj (11)

sizes of storage tanks applied in the station. Additionally, where Ls is the upper bound of Ns.

using more sizes of tanks will make the management

more difficult. Thus, we assume that one station has no Ls 15Gd Vs s (12)

more than two sizes of storage tanks at best. The con- Each new 0-1 variable, ysj, can also be rewritten

straint can be described in the following equation: equivalently as follows:

Copyright 2012 SciRes. NR

Cost Optimal Selection of Storage Tanks in LPG Vaporization Station 167

ysj2 ysj 0 s 1, , S ; j 1, , Ls (13) as follows. It is a LPG vaporization station in Guangdong

province of southern China, vaporizing the LPG from an

Then, we can substitute (9) by (11)-(13). import terminal and supplying gas at 0.14 MPa to ten

After the above transformations, all integer variables thousands of households and hundreds of ceramic enter-

and binary variables in the model are transformed to con- prises via local gas distribution pipelines.

tinuous variables.

3.1. Values of Parameters

2.6. Model

The station supplies 179,320 kg LPG daily and the local

Considering the above sections, the whole mathematical maximum uneven factor of monthly gas consumption is

model is as follows:

1.2. The product of the two data is the average daily gas

i 1 i D S consumption in the design month [17], i.e. Gd is 215,184

Min K mi 1 K md 1 r x C N

1 i D 1 s 1 s s s kg/d.

The physical parameters of the LPG are summarized

Subject to in Table 1.

S S

xsVs N s s 15Gd or xsVs N s s 3Gd In China, the design pressure of tanks for LPG is 1.8

s 1 s 1 MPa and horizontal cylindrical storage tanks are generally

S S used in LPG vaporization stations. Hence, LPG storage

xs N s 2 1 xs 2 tanks just fall into several sizes by volumetric capacity in

s 1 s 1

the example. All sizes of horizontal cylindrical storage

x xs 0 s 1, , S

2

s

tanks for LPG and their parameters are shown in Table

2.

N s j 0 2

log Ls

2 j ysj s 1, , S From Tables 1 and 2, the values of some parameters

used in the model can be obtained, such as , S, Vs, s and

Ls 15Gd Vs s Cs (s = 1, , S). Based on some researches on cylindri-

ysj2 ysj 0 s 1, , S ; j 0, , Ls cal LPG storage tanks on the market, the depreciable life

of storage tanks is taken as 20 years and the residual

The above model is in the general nonlinear program- value rate is 4%. In this paper, market discount rate, i, is

ming form. expected to be 3.87%.

According to experience gained from the construction

3. Results and Discussion and operation of domestic LPG vaporization stations, Kmi

An illustrative example of the model usage is conducted and Kmd are 5% and 30%, respectively.

Table 1. Physical parameters of LPG.

Components Volume Percentage, % Mass Percentage, % Density, kg/m3 Caloric Value of Liquid LPG, MJ/kg

Propane 30 24.2

533a 44

Butane 70 75.8

a

Its the density of liquid LPG at 40C.

Table 2. Summary of LPG storage tanks in China.

Volumetric Capacity (Vs), m3 Design Temperature, C Maximum Filling Ratio (s), % Initial Cost (Cs), Yuanb

5 45,000

10 58,000

20 68,000

25 75,000

32 85,000

50 110,000

20C ~ 50C 90

60 120,000

80 150,000

100 175,000

150 250,000

200 380,000

400 700,000

b

1 Yuan = 0.1543 US$.

Copyright 2012 SciRes. NR

168 Cost Optimal Selection of Storage Tanks in LPG Vaporization Station

Table 3. Values of some variables.

s L x N

1 1346 0 0

2 673 0 0

3 337 0 0

4 270 0 0

5 211 0 0

6 135 0 0

7 113 0 0

8 85 0 0

9 68 0 0

10 45 1 9

11 34 0 0

12 17 0 0

Table 4. Optimization results and comparison.

Items Optimization Scheme Actual Scheme

Number and Size(s) of 9 storage tanks, each with a 7 storage tanks, each with a

Storage Tanks volumetric capacity of 150 m3 volumetric capacity of 200 m3

Annual Storage Cost, Yuan/year 226,665 267,969

3.2. Solution and Results conclusions can be obtained:

Each LPG vaporization station has its optimal selec-

To solve the optimal selection problem of storage tanks,

tion scheme of storage tanks considering of the

the mathematical model were coded using LINGO 8.0.

minimum annual storage cost.

After importing the above values of parameters to

Using the mathematical model, the optimal storage

LINGO, the values of variables were output by running

scheme can be determined accurately and quickly.

the coded model (Table 3). The minimum annual storage

Furthermore, minimizing annual storage cost can cut

cost and the optimal selection scheme of storage tanks

for the vaporization station are presented in Table 4. The the LPG price for users under other same conditions.

actual storage scheme of the station and its correspond- This will reduce the subsidy on residential LPG from the

ing storage cost are also listed in the table. central government and contribute to extending the mar-

From Table 4, it can be noted that using nine storage ket for household LPG use in poorer areas in China.

tanks with a total volumetric capacity of 1,350 m3 is the

economic optimal storage scheme for the LPG vaporiza- 5. Acknowledgements

tion station. After optimization, the annual storage cost is This research was supported by the Fundamental Re-

226,665 Yuan/year which is about 85% of that of the search Funds for the Central Universities (No. 11MG45).

actual storage scheme. It is also concluded that the opti-

mization scheme can make more full use of storage tanks

than the actual scheme, because the latter has a higher

REFERENCES

total volumetric capacity of tanks. [1] National Bureau of Statistics, China Statistical Yearbook

(2008), China Statistics Press, Beijing, 2008.

4. Conclusions [2] L. W. Jiang and B. C. ONeill, The Energy Transition in

Rural China, International Journal of Global Energy Is-

In this study, a mathematical model has been developed sues, Vol. 21, No. 1-2, 2004, pp. 2-26.

to help LPG vaporization stations select optimal mix of [3] Q. Y. Zhang, Residential Energy Consumption in China

storage tanks. It minimizes the annual storage cost, guaran- and Its Comparison with Japan, Canada, and USA, En-

teeing the normal and safe operation of stations. For ergy and Buildings, Vol. 36, No. 12, 2004, pp. 1217-1225.

convenience in solving the MINLP model, it is trans- doi:10.1016/j.enbuild.2003.08.002

formed to be in the general nonlinear programming form. [4] J. W. K. Wong, City-Gas Development in ChinaAn

According to the analysis in this study, the following NG Perspective, Energy Policy, Vol. 38, No. 5, 2009, pp.

Copyright 2012 SciRes. NR

Cost Optimal Selection of Storage Tanks in LPG Vaporization Station 169

2107-2109. doi:10.1016/j.enpol.2009.06.001 [12] K. Aardal, R. Weismantel and L. A. Wolsey, Non-

[5] J. F. Zhu and C. G. Duan, Application of Solar Energy Standard Approaches to Integer Programming, Discrete

to LPG Vaporizer, Gas and Heat, Vol. 25, No. 10, 2005, Applied Mathematics, Vol. 123, No. 1-3, 2002, pp. 5-74.

pp. 13-15. doi:10.1016/S0166-218X(01)00337-7

[6] Ministry of Housing and Urban-Rural Development of [13] Q. L. Wu and N. R. Xie, A New Method for Solving a

the PRC, Chinas Urban Construction Statistical Bulletin Class of Nonlinear Integer Programming Problems, Con-

(2007), China Architecture & Building Press, Beijing, trol and Decision, Vol. 12, No. 2, 1997, pp. 97-108.

2008. [14] G. H. Xu and Y. Liu, Handbook of Operations Research

[7] LINGO Systems Inc., Lingo Users Guide, Chicago, Fundamentals, Science Press, Beijing, 1999.

2000. [15] D. Bertsimas, G. Perakis and S. Tayur, A New Algebraic

[8] S. S. Rao, Optimization: Theory and Applications, 2nd Geometry Algorithm for Integer Programming, Man-

Edition, John Wiley, New York, 1984. agement Science, Vol. 46, No. 7, 2000, pp. 999-1008.

doi:10.1287/mnsc.46.7.999.12033

[9] G. Y. Shi and J. L. Dong, Optimization Methods, High

Education Press, Beijing, 1999. [16] Z. Q. Meng, Q. Y. Hu and X. Q. Yang, A Method of

Non-Linear Penalty Function for Solving Integer Pro-

[10] Ministry of Housing and Urban-Rural Development of gramming and Mixed Integer Programming, Control and

the PRC, Code for Design of City Gas Engineering, Decision, Vol. 17, No. 3, 2002, pp. 310-314.

China Architecture & Building Press, Beijing, 2006.

[17] C. G. Duan, Transportation and Distribution of Gas,

[11] G. H. Shi, Study on Non-Pipeline Gas Supply for Mid- China Architecture & Building Press, Beijing, 2001.

dle-Small Town, M.S. Thesis, North China Electric

Power University, Baoding, 2005.

Copyright 2012 SciRes. NR

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Aspen-Hysys Simulation of Sulfuric Acid PlantDocument3 pagesAspen-Hysys Simulation of Sulfuric Acid PlantacckypenrynNo ratings yet

- HP4Document88 pagesHP4Alexander Neyra100% (4)

- ATM SecurityDocument87 pagesATM SecurityHristo Dokov100% (1)

- Bucher LRV Hydraulic ValveDocument90 pagesBucher LRV Hydraulic Valvedean_lockey0% (1)

- 2014 - Solved Problems in Facility PlanningDocument135 pages2014 - Solved Problems in Facility Planninghshshdhd86% (7)

- Understanding IBR 1950Document7 pagesUnderstanding IBR 1950sammar_10No ratings yet

- Kern Method Heat ExchangerDocument30 pagesKern Method Heat ExchangerCS100% (3)

- Kern Method Heat ExchangerDocument30 pagesKern Method Heat ExchangerCS100% (3)

- Platts 2 Us MktscanDocument19 pagesPlatts 2 Us MktscanGabriel ManavellaNo ratings yet

- Platts 2 Us MktscanDocument19 pagesPlatts 2 Us MktscanGabriel ManavellaNo ratings yet

- Info - Iec61340-5-1 (Ed2 0 RLV) enDocument23 pagesInfo - Iec61340-5-1 (Ed2 0 RLV) enArhamNo ratings yet

- Introduction To Sulfuric Acid Alkylation Unit Process DesignDocument31 pagesIntroduction To Sulfuric Acid Alkylation Unit Process DesignalbertozapalloNo ratings yet

- Refinery Design PDFDocument108 pagesRefinery Design PDFGabriel ManavellaNo ratings yet

- Refining Processes 2011Document0 pagesRefining Processes 2011mukthiyars100% (3)

- Software Engineering EconomicsDocument4 pagesSoftware Engineering Economicsazam_rasheed50% (2)

- Alkylation Technology StudyDocument41 pagesAlkylation Technology StudyGabriel ManavellaNo ratings yet

- Flow SheetDocument1 pageFlow SheetGabriel ManavellaNo ratings yet

- N0s-2a-75 HM 2010 GaDocument1 pageN0s-2a-75 HM 2010 GaGabriel ManavellaNo ratings yet

- Alkyl at I On ManualDocument251 pagesAlkyl at I On ManualTeka KamNo ratings yet

- Maximizando Beneficios AlkylationDocument5 pagesMaximizando Beneficios AlkylationGabriel ManavellaNo ratings yet

- Chapter 1 Vapor Power Cycles - CompleteDocument97 pagesChapter 1 Vapor Power Cycles - CompleteAdnan NimachwalaNo ratings yet

- Makalah Program PDFDocument10 pagesMakalah Program PDFIvanFolkNo ratings yet

- Digital Joints Solutions - Sep-2016-CatalogueDocument102 pagesDigital Joints Solutions - Sep-2016-CatalogueiamlpNo ratings yet

- Series 3501 & 3503Document4 pagesSeries 3501 & 3503Tim Stubbs100% (2)

- Thermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsDocument39 pagesThermodynamics: ENG 214 Chapter 3 - Heat & Work in Open Systems Chapter 4 - The First Law of ThermodynamicsGregory MacLeodNo ratings yet

- Denmark Bye LawsDocument10 pagesDenmark Bye LawshimaniwatalNo ratings yet

- 122Document10 pages122Bayangan HatiNo ratings yet

- 06668967Document10 pages06668967PECMURUGANNo ratings yet

- Databook Continental Agri 2006 PDFDocument0 pagesDatabook Continental Agri 2006 PDFdanilo3073No ratings yet

- Vanguardia, Robert John T - Amte 125L - 1X - Aircraft Fuel Lines (Research)Document5 pagesVanguardia, Robert John T - Amte 125L - 1X - Aircraft Fuel Lines (Research)Robert VanguardiaNo ratings yet

- Relationship of EN 954-1 and IEC 61508 Standards PDFDocument2 pagesRelationship of EN 954-1 and IEC 61508 Standards PDFfitasmounirNo ratings yet

- Copperacetate Ammonium Nitrate Oxidation of Benzoin To BenzilDocument12 pagesCopperacetate Ammonium Nitrate Oxidation of Benzoin To BenzilDillon TrinhNo ratings yet

- Sec1 1 1Document2 pagesSec1 1 1rajfmc100% (1)

- Free Gear Calculator - KHK GearsDocument5 pagesFree Gear Calculator - KHK GearslawlawNo ratings yet

- FC-M6100 SM-BB52: DEORE CranksetDocument1 pageFC-M6100 SM-BB52: DEORE CranksetDon JonesNo ratings yet

- Iso 5294 1989Document9 pagesIso 5294 1989a.mursadinNo ratings yet

- KP Sharma Estimate PDFDocument3 pagesKP Sharma Estimate PDFSudip GhimireNo ratings yet

- New V70 XC70 Owners Manual MY05 en Tp7551Document226 pagesNew V70 XC70 Owners Manual MY05 en Tp7551dynax4No ratings yet

- 82 To 88 CompleteDocument6 pages82 To 88 CompleteUmer KhanNo ratings yet

- Actividad 1 Lorena GuerreroDocument4 pagesActividad 1 Lorena GuerreroAlfonso GutierrezNo ratings yet

- Random PDFDocument15 pagesRandom PDFgreeblemeebleNo ratings yet

- Free and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongDocument18 pagesFree and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongRajesh KachrooNo ratings yet

- ISTJ PersonalityDocument2 pagesISTJ PersonalityMonalisa ChatterjeeNo ratings yet