Professional Documents

Culture Documents

CFM

Uploaded by

umang bhatiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CFM

Uploaded by

umang bhatiaCopyright:

Available Formats

TCDS No.: E.

110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

TYPE-CERTIFICATE

DATA SHEET

No. E.110

for Engine

LEAP-1A & LEAP-1C series engines

Type Certificate Holder

CFM International SA

CFM International SA

2, boulevard du Gnral Martial Valin

75015 Paris

France

For Models:

LEAP-1A23 LEAP-1C28

LEAP-1A24 LEAP-1C30

LEAP-1A24E1 LEAP-1C30B1

LEAP-1A26

LEAP-1A26E1

LEAP-1A30

LEAP-1A32

LEAP-1A33

LEAP-1A33B2

LEAP-1A35A

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 1 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

Intentionally left blank

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 2 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

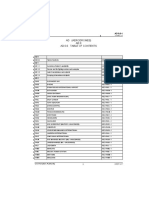

TABLE OF CONTENTS

I. General ...........................................................................................................................................4

1. Type / Models ............................................................................................................................4

2. Type Certificate Holder ..............................................................................................................4

3. Manufacturers ...........................................................................................................................4

4. Date of Application ....................................................................................................................4

5. EASA Type Certification Date .....................................................................................................4

II. Certification Basis...........................................................................................................................4

1. Reference Date for determining the applicable airworthiness requirements: ...........................4

2. EASA Certification Basis .............................................................................................................5

2.1. Airworthiness Standards .........................................................................................................5

2.2. Special Conditions (SC) ............................................................................................................5

2.3. Equivalent Safety Findings (ESF) ..............................................................................................5

2.4. Deviations ...............................................................................................................................5

2.5. Environmental Protection .......................................................................................................5

III. Technical Characteristics ...............................................................................................................5

1. Type Design Definition ...............................................................................................................5

2. Description .................................................................................................................................6

3. Equipment..................................................................................................................................6

4. Dimensions (mm) .......................................................................................................................6

5. Weight (kg).................................................................................................................................6

6. Ratings .......................................................................................................................................7

7. Control System ...........................................................................................................................8

8. Fluids (Fuel, Oil, Coolant, Additives)...........................................................................................8

9. Aircraft Accessory Drives............................................................................................................8

10. Maximum Permissible Air Bleed Extraction .............................................................................9

IV. Operating Limitations ...................................................................................................................9

1. Temperature Limits ....................................................................................................................9

1.1. Exhaust Gas Temperature (C):................................................................................................9

1.2. Oil Temperature (C) ...............................................................................................................9

1.3. Fuel Inlet Temperature (C) .....................................................................................................9

1.4. Engine Equipment Temperatures: ...........................................................................................9

2. Speed Limits .............................................................................................................................10

2.1. Maximum Rotational Speeds (rpm=revolutions per minute): ...............................................10

3. Pressure Limits .........................................................................................................................10

3.1. Fuel Pressure: ........................................................................................................................10

3.2. Oil Pressure: ..........................................................................................................................10

4. Time Limited Dispatch (TLD) ....................................................................................................10

5. ETOPS Capability ......................................................................................................................10

V. Operating and Service Instructions ..............................................................................................11

VI. Notes ..........................................................................................................................................12

SECTION: ADMINISTRATIVE .............................................................................................................13

I. Acronyms and Abbreviations ....................................................................................................13

II. Type Certificate Holder Record ................................................................................................13

III. Change Record ........................................................................................................................13

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 3 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

I. General

1. Type / Models

LEAP-1A23, LEAP-1A24, LEAP-1A24E1, LEAP-1A26, LEAP-1A26E1,

LEAP-1A & LEAP-1C LEAP-1A30, LEAP-1A32, LEAP-1A33, LEAP-1A33B2, LEAP-1A35A

LEAP-1C28, LEAP-1C30, LEAP-1C30B1

2. Type Certificate Holder

CFM International SA

2, boulevard du Gnral Martial Valin

75015 Paris

France

Design Organisation Approval No.: EASA.21J.086

3. Manufacturers

Safran Aircraft Engines GE

Production Organisation Approval FR.21G.0007 Production Certification No. 108

10 alle du Brvent - CE 1420 - Courcouronnes One Neumann Way

91019 Evry Cedex Cincinnati - Ohio 45215

France United States of America

(See note 4)

4. Date of Application

LEAP-1A35A 06 February 2012

LEAP-1A23, LEAP-1A24, LEAP-1A24E1, LEAP-1A26, LEAP-1A26E1,

24 November 2015

LEAP-1A30, LEAP-1A32, LEAP-1A33, LEAP-1A33B2

LEAP-1C28, LEAP-1C30, LEAP-1C30B1 01 December 2015

5. EASA Type Certification Date

LEAP-1A35A 20 November 2015

LEAP-1A23, LEAP-1A24, LEAP-1A24E1, LEAP-1A26, LEAP-1A26E1,

11 March 2016

LEAP-1A30, LEAP-1A32, LEAP-1A33, LEAP-1A33B2

LEAP-1C28, LEAP-1C30, LEAP-1C30B1 21 December 2016

II. Certification Basis

1. Reference Date for determining the applicable airworthiness requirements:

20 November 2012 (3 years prior to initial Type Certification date according to Part 21.A.17)

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 4 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

2. EASA Certification Basis

2.1. Airworthiness Standards

CS-E amendment 3 (23 December 2010)

2.2. Special Conditions (SC)

SC1: Fan Blade Containment - Woven Composite Fan Blade

SC2: 30 Seconds Transient Over-Temperature Approval

2.3. Equivalent Safety Findings (ESF)

ESF1: CS-E 740 Endurance Tests Alternative Schedule

ESF2: CS-E 840 Rotor Integrity High Pressure Turbine Stage 2 Rotor Compliance

2.4. Deviations

None

2.5. Environmental Protection

ICAO Annex 16 Volume II, third edition, July 2008,

including Amendment 7, 18/08/11, as applicable

LEAP-1A35A

to turbofan engines. NOx standards in accordance

with Chapter 3, 2.3.2e (CAEP/8)

LEAP-1A23, LEAP-1A24, LEAP-1A24E1, ICAO Annex 16 Volume II, third edition, July 2008,

LEAP-1A26, LEAP-1A26E1, LEAP-1A30, including Amendment 8, 14/7/14, as applicable to

LEAP-1A32, LEAP-1A33, LEAP-1A33B2 turbofan engines. NOx standards in accordance

LEAP-1C28, LEAP-1C30, LEAP-1C30B1 with Chapter 3, 2.3.2e (CAEP/8)

III. Technical Characteristics

1. Type Design Definition

Engine type is identified by an engine model list including an identification plug reference:

LEAP-1A Engine model list

LEAP-1A23, LEAP-1A24, LEAP-1A24E1,

LEAP-1A..G01*, LEAP-1A..G02*, LEAP-1A..G03*

LEAP-1A26, LEAP-1A26E1, LEAP-1A30,

LEAP-1A..G04*, LEAP-1A..G05*

LEAP-1A32, LEAP-1A33, LEAP-1A33B2,

*.. denotes model rating

LEAP-1A35A

(See note 6)

Engine identification Engine identification

LEAP-1A LEAP-1A

plug reference plug reference

LEAP-1A23 2531M61P54 LEAP-1A30 2531M61P06

LEAP-1A24 2531M61P62 LEAP-1A32 2531M61P14

LEAP-1A24E1 2531M61P58 LEAP-1A33 2531M61P22

LEAP-1A26 2531M61P34 LEAP-1A33B2 2531M61P24

LEAP-1A26E1 2531M61P30 LEAP-1A35A 2531M61P02

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 5 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

LEAP-1C Engine model list

LEAP-1C..G01*

LEAP-1C28, LEAP-1C30, LEAP-1C30B1 LEAP-1C..G02*

*.. denotes model rating

(See note 6)

Engine identification Engine identification

LEAP-1C LEAP-1C

plug reference plug reference

LEAP-1C28 2531M61P30 LEAP-1C30B1 2531M61P23

LEAP-1C30 2531M61P22 - -

2. Description

Dual rotor, axial flow, high bypass ratio turbofan engine:

single stage fan, 3-stage low pressure compressor (LPC), 10-stage high pressure compressor

(HPC)

annular combustion chamber

2-stage high pressure turbine (HPT), 7-stage low pressure turbine (LPT)

dual channel full authority digital engine control (FADEC)

The LEAP-1C engine Type Certificate includes the thrust reverser. This thrust reverser is actuated by an

Electrical Trust Reverser Actuation System (ETRAS) including a digital Thrust Reverser Control Unit

(TRCU). The left-hand engine thrust reverser includes a translating O-duct P/N 95000/BCL0005-06-0

and the right-hand one a translating O-duct P/N 95000/BCL0006-06-0.

3. Equipment

The engine starter is part of the engine type design. Refer to the engine model list for details.

4. Dimensions (mm)

LEAP-1A..G02, G03,

LEAP-1A..G01 LEAP-1C..G01, G02

G04, G05

Length (fan case forward flange

3328 3328 -

to turbine rear frame aft flange)

Length (fan cowl hinge beam

- - 4505

front to centre vent tube end)

Width (maximum envelope) 2543 2533 2659

Height (maximum envelope) 2368 2362 2714

5. Weight (kg)

Weight of the basic engine, including basic engine equipment, as given in the applicable engine

Installation Manual document:

LEAP-1A..G02,

LEAP-1A..G01 LEAP-1C..G01 LEAP-1C..G02

G03, G04, G05

With fluids (oil, fuel) 2990 3008 - -

Without fluids (oil, fuel) - - 3935 3929

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 6 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

6. Ratings

LEAP-1A - Take-Off Thrust

LEAP-1A30

LEAP-1A32

LEAP-1A24 LEAP-1A26

LEAP-1A23 LEAP-1A33

LEAP-1A24E1 LEAP-1A26E1

LEAP-1A33B2

LEAP-1A35A

10680 daN 10680 daN 12064 daN 14305 daN

LEAP-1A - Maximum Continuous Thrust

LEAP-1A30

LEAP-1A32

LEAP-1A24 LEAP-1A26

LEAP-1A23 LEAP-1A33

LEAP-1A24E1 LEAP-1A26E1

LEAP-1A33B2

LEAP-1A35A

10458 daN 10676 daN 11868 daN 14096 daN

LEAP-1C - Take-Off Thrust

LEAP-1C30

LEAP-1C28 - -

LEAP-1C30B1

12998 daN 13714 daN - -

LEAP-1C - Maximum Continuous Thrust

LEAP-1C30

LEAP-1C28 - -

LEAP-1C30B1

12793 daN 13322 daN - -

(See notes 2 and 3)

Engine models which have the same approved ratings in standard static conditions will provide

different level of thrust at altitude and/or high temperature conditions. This is controlled by the engine

identification plug.

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 7 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

7. Control System

The software is part of the engine Type Design At initial certification:

LEAP-1A23, -1A24,

-1A24E1, -1A26, LEAP-1C28, -1C30,

LEAP-1A35A

-1A26E1, -1A30, -1A32, -1C30B1

-1A33, -1A33B2

Factory Loadable Software 2500M35P03

2500M34P03 2500M34P03

P/N 2500M35P04

Application Software P/N 2590M00P02 2590M00P03 2590M02P01

Health Monitoring

2590M01P01 2590M01P01 2590M03P01

Software P/N

Pressure Sub Systems

2474M65P05 2474M65P05 2474M65P05

(PSS) Software P/N

TRCU Operating Software According to SCI

n/a n/a

P/N SK-0000492539-16

TRCU Application

n/a n/a 262074891-0230

Software P/N

8. Fluids (Fuel, Oil, Coolant, Additives)

Fuel and fuel additives: Refer to the latest revision of CFM Service Bulletin LEAP-1A S/B 73-0001 and

CFM Service Bulletin LEAP-1C S/B 73-0001.

Oil: Refer to the latest revision of CFM Service Bulletin LEAP-1A S/B 79-0001 and CFM Service Bulletin

LEAP-1C S/B 79-0001.

9. Aircraft Accessory Drives

LEAP-1A

Max.

Speed Max. power Max. shear Max. weight

Rotation overhung

Component ratio / HP or max. torque (wet)

direction moment

rotor torque (m.daN) (kg)

(m.daN)

Electrical generator CCW 0.462 129 kW 106.2 65 11.3

Hydraulic pump CCW 0.211 14.7 m.daN 48 17.5 2.3

LEAP-1C

Max.

Speed Max. power Max. shear Max. weight

Rotation overhung

Component ratio / HP or max. torque (wet)

direction moment

rotor torque (m.daN) (kg)

(m.daN)

Electrical generator CCW 1.066 151 kW 86.6 65.2 13.9

Hydraulic pump CW 0.203 14 m.daN 40.7 15.4 1.98

CW = clockwise when facing the gearbox drive pad

CCW = counter-clockwise when facing the gearbox drive pad

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 8 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

10. Maximum Permissible Air Bleed Extraction

LEAP-1A and LEAP-1C

Bleed location LP rotor speed Airflow limit

Bypass duct Above minimum idle 2 % of secondary airflow

th

HPC 4 stage Above minimum idle 9.97% of primary airflow*

Below 2314 rpm N1K** 2.9% of primary airflow

HPC 7th stage

Above 2314 rpm N1K** 2.45% of primary airflow

th

HPC 10 stage Above minimum idle 15% of primary airflow

*Absolute maximum. Refer to the LEAP-1A Installation Manual for detailed HPC 4th stage bleed

schedule.

**N1K = Temperature corrected fan rotor speed.

It is not allowed to extract air from 4th and 10th stages simultaneously.

IV. Operating Limitations

1. Temperature Limits

1.1. Exhaust Gas Temperature (C):

The Exhaust Gas Temperature (EGT=T48) is measured at the low pressure turbine inlet.

Maximum Exhaust Gas Temperature (Indicated):

Take-Off: 1060

Maximum Continuous: 1025

Ground Start: 750

Inflight Start: 875

All models are certified for a transitory exhaust gas temperature (EGT) exceedance at take-off of

5C, during 30 seconds maximum. Refer to the applicable "Specific Operating Instructions"

document.

1.2. Oil Temperature (C)

Minimum for starting: minus29 (LEAP-1A engines not compliant

with LEAP-1A S/B 72-0034, S/B 72-0035, S/B 72-0036 and LEAP-1C..G01)

Minimum for starting: minus40 (LEAP-1A engines compliant with

LEAP-1A S/B 72-0034, S/B 72-0035, S/B 72-0036 and LEAP-1C..G02)

Minimum for acceleration to take-off power: 19

Maximum steady state: 140

Maximum transient (15 minutes): 155

1.3. Fuel Inlet Temperature (C)

Maximum steady state: 55

1.4. Engine Equipment Temperatures:

Refer to the applicable engine Installation Manual document for engine equipment steady state

and transient skin temperature limits.

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 9 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

2. Speed Limits

2.1. Maximum Rotational Speeds (rpm=revolutions per minute):

Low pressure rotor (N1): 3894 (101 % - 100 % N1 is defined as 3856 rpm)

High pressure rotor (N2): 19391 (116.5 % - 100 % N2 is defined as 16645 rpm)

3. Pressure Limits

3.1. Fuel Pressure:

Minimum: 345 hPa (differential pressure)

Maximum (LEAP-1A): 4137 hPa (differential pressure)

Maximum (LEAP-1C): 3800 hPa (differential pressure)

When the engine is running, the fuel pressure at the engine pump inlet must be kept 345 hPa

above the true vapour pressure of the fuel with a zero vapour/liquid ratio under normal operating

conditions.

3.2. Oil Pressure:

Minimum at Idle conditions: 1200 hPa (differential pressure)

Minimum at Maximum Continuous conditions: 2000 hPa (differential pressure)

When the engine is running, the oil pressure varies with the rotational speed of the HP rotor (Refer

to the applicable engine "Installation Manual" document). Deliberate operation of the engine with

oil pressure below minimum is prohibited. However, aircraft "negative g" manoeuvres may cause

temporary oil supply interruption. Under "negative g" operating conditions only, it is permissible

to operate the engine below the minimum oil pressure for a maximum of 14 seconds before engine

shutdown is required.

4. Time Limited Dispatch (TLD)

The engine is approved for Time Limited Dispatch in accordance with CS-E 1030. The maximum

rectification period for each dispatchable state is specified in the applicable Engine Shop Manual

document, chapter 5 Airworthiness Limitations.

5. ETOPS Capability

When compliant with CFM service bulletin LEAP-1A-71-00-0006, the LEAP-1A engine is approved for

ETOPS capability in accordance with CS-E 1040 amendment 3 by EASA Certificate 10062224 dated 16

June 2017 for a Maximum Approved Diversion Time of 180 minutes at maximum continuous thrust

plus 15 minutes at hold thrust. ETOPS does not require any special engine limitation, marking, placard,

or configuration other than as instructed by the service bulletin. This approval does not constitute an

approval to conduct ETOPS operations.

The LEAP-1C engine is not approved for ETOPS capability in accordance with CS-E 1040.

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 10 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

V. Operating and Service Instructions

Manuals - LEAP-1A

Turbofan Engine Installation LEAP-1A..G01: CRL-2106a Issue 1 (IM.20)

Manual (EIM) LEAP-1A..G02, G03, G04, G05: CRL-2106a_3 Issue 03

LEAP-1A..G01: CRL-2107a

LEAP-1A..G02: CRL-2107a_1

Installation Drawing LEAP-1A..G03: CRL-2107a_2

LEAP-1A..G04: CRL-2107a_3 Issue 00

LEAP-1A..G05: CRL-2107a_4 Issue 00

Specific Operating Instructions

CRL-2105a Revision 5 (GEK 131717)

(SOI)

Or later approved Issues or Revisions

Manuals - LEAP-1C

Turbofan Engine Installation LEAP-1C..G01: CRL-2106c Issue 0 (IM.22)

Manual (EIM) LEAP-1C..G02: CRL-2106c_1 Issue 0 (IM.22.1)

LEAP-1C..G01: CRL-2107c Issue 1

Installation Drawing

LEAP-1C..G02: CRL-2107c_1 Issue 1

Specific Operating Instructions

CRL-2105c Revision 1 (GEK 131718)

(SOI)

Or later approved Issues or Revisions

Instructions for Continued

LEAP-1A LEAP-1C

Airworthiness (ICA)

See Aircraft Maintenance See Aircraft Maintenance

Maintenance Manual

Manual (AMM) Manual (AMM)

See Aircraft Fault Isolation See Aircraft Fault Isolation

Fault Isolation Manual

Manual (FIM) Manual (FIM)

Engine Shop Manual (ESM) SM.20 SM.22

Standard Practices Manual

SPM.25 SPM.25

(SPM)

Consumable Product Manual

CPM.25 CPM.25

(CPM)

Non Destructive Test Manual

NDTM.25 NDTM.25

(NDTM)

Components Maintenance

As published by CFM As published by CFM

Manuals (CMM)

Service Bulletins (SB) As published by CFM As published by CFM

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 11 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

VI. Notes

1. The EASA approved Airworthiness Limitations Section of the Instructions for Continued

Airworthiness is published in the applicable "Engine Shop Manual" document, chapter 5

"Airworthiness Limitations".

2. Engine ratings are based on calibrated test stand performance, and performance calculations are

based on accepted parameter correction methods documented in the Production Test Requirements

document. These calculations assume the following conditions:

Sea level corner point conditions as defined in the Production Test Requirements;

No aircraft accessory loads or air extraction;

No anti-icing; no inlet distortion; no inlet screen losses; and 100% ram recovery;

Production engine inlet and production exhaust system.

3. The take-off thrust, with the associated limits, shall not be used continuously more than 5 minutes.

The duration may be extended to 10 minutes in case of engine failure in multi-engine aircraft. If the

duration exceeds 5 minutes, this shall be recorded in the engine log book.

4. The type certificate holder, CFM International, is a company jointly owned by Safran Aircraft Engines

(France) and GE (USA). CFM International is responsible for the certification program, the sale and the

customer support activities. With respect to the benefits of type certification for production of certified

engines, Safran Aircraft Engines and GE act as licensees of CFM International. The engine final assembly

location is recorded on the engine identification plate. Engines produced by GE (USA) are identical to,

and fully interchangeable with, engines produced by Safran Aircraft Engines (France).

5. The LEAP-1A engine is approved for use with Aircelle thrust reverser system P/N BDL0011-12-0 for

the left hand thrust reverser half and P/N BDL0051-12-0 for the right hand thrust reverser half. The

LEAP-1C engine Type Certificate includes the thrust reverser.

6. The engine model list contains a configuration group number to differentiate between the following

engine configurations:

Configuration

LEAP-1A - Description

Group

G01 Initial release configuration with aluminium Fan Frame Shroud (FFS)

G02 Initial release configuration with titanium FFS

Titanium FFS, increased FADEC electrical fan fire protection, and software version

G03

L1A0250

Titanium FFS, single Modulated Turbine Cooling (MTC) valve, and software version

G04

L1A0310

G05 Titanium FFS, new Low Pressure Compressor (LPC), and software version L1A0310

Configuration

LEAP-1C - Description

Group

G01 Initial release configuration with aluminium Fan Frame Shroud (FFS)

G02 Initial release configuration with titanium FFS

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 12 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

TCDS No.: E.110 CFM International

Issue: 05 LEAP-1A & LEAP-1C series engines Date: 16 June 2017

SECTION: ADMINISTRATIVE

I. Acronyms and Abbreviations

n/a

II. Type Certificate Holder Record

n/a

III. Change Record

TCDS Issue Date Changes TC issue date

Issue 01 20 November 2015 Initial issue with LEAP-1A35A model Initial Issue,

20 November 2015

Issue 02 11 March 2016 Addition of LEAP-1A23, LEAP-1A24, LEAP- Amended,

1A24E1, LEAP-1A26, LEAP-1A26E1, LEAP-1A30, 11 March 2016

LEAP-1A32, LEAP-1A33, LEAP-1A33B2 models

Issue 03 11 July 2016 Following approval of SOI CRL-2105a/Rev. 2 11 March 2016

and EIM CRL-2106a_1 Issue 2/Rev.1 (certificate

10058275), correction of LEAP-1A LEAP-

1A..G02 engine weight, amendment of

minimum oil temperature for starting and for

acceleration to take-off power, correction of

note 5. Introduction of model list LEAP-1A..G03

(certificate 10058742). Snecma becomes Safran

Aircraft Engines.

Issue 04 21 December 2016 Addition of LEAP-1C28, LEAP-1C30, LEAP- Amended,

1C30B1 models. Amendment of minimum oil 21 December 2016

temperature for starting and for acceleration to

take-off power (certificate 10059856).

Issue 05 16 June 2017 Introduction of model list LEAP-1A..G04 21 December 2016

(certificate 10061124) and model list LEAP-

1A..G05 (certificate 10061530). LEAP-1A engine

ETOPS capability approval (certificate

10062224). Amendment of note 4. Addition of

note 6.

-END-

TE.CERT.00052-001 European Aviation Safety Agency, 2017. All rights reserved. ISO9001 Certified. Page 13 of 13

Proprietary document. Copies are not controlled. Confirm revision status through the EASA-Internet/Intranet.

An agency of the European Union

You might also like

- Trent XWB Type CertificationDocument16 pagesTrent XWB Type CertificationCamilo MartinezNo ratings yet

- Borescope Inspection Report PK-TWXDocument8 pagesBorescope Inspection Report PK-TWXGranita pru24No ratings yet

- 51-49-00 - Description - Standard Torque ValuesDocument14 pages51-49-00 - Description - Standard Torque ValuesMarijaNo ratings yet

- 71-0008 Issue 002Document9 pages71-0008 Issue 002Panneer Selvam0% (1)

- F Maintenance Program Planning ServicesDocument272 pagesF Maintenance Program Planning ServicesFaisNo ratings yet

- Fan Lub CFM56-7Document89 pagesFan Lub CFM56-7ANDRA100% (1)

- DFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015Document20 pagesDFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015KamalVirkNo ratings yet

- Aircraft APU Emissions at Zurich AirportDocument18 pagesAircraft APU Emissions at Zurich AirportAnonymous TDyZWu22S3No ratings yet

- Borescope Training For The WebDocument1 pageBorescope Training For The WebJose RattiaNo ratings yet

- 19790011945Document227 pages19790011945Gabriel GiorgisNo ratings yet

- Multi Purpose Computer PresentationDocument13 pagesMulti Purpose Computer PresentationAminur PahlawanNo ratings yet

- CorrosionDocument6 pagesCorrosiondonjon ellenNo ratings yet

- Training Manual: EASA Part-66 72 Level 3Document16 pagesTraining Manual: EASA Part-66 72 Level 3Luis Enrique La Font FrancoNo ratings yet

- ATA 76 PW1100 - Rev. 0 (16-12-19)Document38 pagesATA 76 PW1100 - Rev. 0 (16-12-19)JOSE SANDOVALNo ratings yet

- Catalogue Nacelle Tooling A320neoDocument31 pagesCatalogue Nacelle Tooling A320neoPablo RestrepoNo ratings yet

- 2c-Check Inspection ScheduleDocument24 pages2c-Check Inspection ScheduleJeffrey DavisNo ratings yet

- All Tool ListsDocument367 pagesAll Tool ListsArabyAbdel Hamed Sadek0% (1)

- LBM Day8Document9 pagesLBM Day8Genaro RodriguezNo ratings yet

- Trent 700 Infographic 1 PDFDocument1 pageTrent 700 Infographic 1 PDFmuhammad syahmi amir hamzahNo ratings yet

- A123281 Aircraft Random Vibration Test CriteriaDocument13 pagesA123281 Aircraft Random Vibration Test CriteriarobNo ratings yet

- W E L C O M E: Dave SlaybaughDocument44 pagesW E L C O M E: Dave SlaybaughCFIRN100% (1)

- Quick Engine Change and CowlsDocument4 pagesQuick Engine Change and CowlsLahu KureNo ratings yet

- Genx Turbofan Engine: The Next Generation TurbofanDocument2 pagesGenx Turbofan Engine: The Next Generation Turbofankdastro009No ratings yet

- CAR2023 EngDocument195 pagesCAR2023 EngRian AulianzaNo ratings yet

- AIRBUS A320 Operations Circular No. DT / A320 / 816 C. T.E., Hyd Era BadDocument2 pagesAIRBUS A320 Operations Circular No. DT / A320 / 816 C. T.E., Hyd Era BadYogish Katagihallimath100% (2)

- Sil IndexDocument162 pagesSil IndexBenjamin Strickland100% (1)

- 6-Evolution of Technical Publications FulsungeDocument23 pages6-Evolution of Technical Publications FulsungeYeshwanth Kumar100% (1)

- TP-5804 SLO Spec & CriteriaDocument2 pagesTP-5804 SLO Spec & CriteriaCARLOS OLIVEROSNo ratings yet

- A320 NLG Family TreeDocument13 pagesA320 NLG Family TreeJindarat KasemsooksakulNo ratings yet

- StandardAero - PW100 EngineDocument2 pagesStandardAero - PW100 EnginechanduNo ratings yet

- CFM56 5B SB Rev 72-1094 TSN.00 N 20201216Document42 pagesCFM56 5B SB Rev 72-1094 TSN.00 N 20201216Irfan05100% (1)

- AD 2010 List PDFDocument63 pagesAD 2010 List PDFEstevam Gomes de AzevedoNo ratings yet

- Mini Pack PDFDocument29 pagesMini Pack PDFSujoy GhoshNo ratings yet

- Airbus: AdvanceDocument29 pagesAirbus: AdvanceLeonid Gurulev100% (1)

- 32-41!11!400-801-A - Installation of The MLG WheelDocument10 pages32-41!11!400-801-A - Installation of The MLG Wheelrüşdi işlerNo ratings yet

- Level III Ata 52 DoorsDocument72 pagesLevel III Ata 52 DoorsGuyNo ratings yet

- CFM56-7B26 Mini Pack No 2 PDFDocument2 pagesCFM56-7B26 Mini Pack No 2 PDFAHAMEDNo ratings yet

- Cf34-8e 72-A0221Document8 pagesCf34-8e 72-A0221Stephen Hyde100% (1)

- Air Ion Counter PDFDocument4 pagesAir Ion Counter PDFRombang Rizky SihombingNo ratings yet

- MLG RemovalDocument14 pagesMLG Removalbilly100% (1)

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekNo ratings yet

- Alerts July06Document192 pagesAlerts July06Allyamacita NaibahoNo ratings yet

- Airbus T1+T2 CFM56 Tech Doc M8 - PP1Document226 pagesAirbus T1+T2 CFM56 Tech Doc M8 - PP1doga dumanNo ratings yet

- 10 J Friedel Moteur LeapDocument20 pages10 J Friedel Moteur LeaplooserlooserNo ratings yet

- VBV System,: Regreasing ProcedureDocument9 pagesVBV System,: Regreasing ProcedurekienNo ratings yet

- ATA 24 Electrical Power R04Document121 pagesATA 24 Electrical Power R04srtrtyrtNo ratings yet

- CF34-3 Engine Notes Chapter 72 Course NotesDocument30 pagesCF34-3 Engine Notes Chapter 72 Course NotesinternetsurfingNo ratings yet

- B737 Ch70 STD PracticesDocument21 pagesB737 Ch70 STD PracticesAhmed Abdoul ZaherNo ratings yet

- Q0 ZNNTYuc GRMDocument4 pagesQ0 ZNNTYuc GRMmenosoftNo ratings yet

- FE-V2500-1IA - Glossary of TermsDocument19 pagesFE-V2500-1IA - Glossary of TermsnegrotettNo ratings yet

- On A/C MSN All: ATR-A-00-65-XX-10000-021A-DDocument13 pagesOn A/C MSN All: ATR-A-00-65-XX-10000-021A-DDVSNo ratings yet

- Rmoval of NLGDocument6 pagesRmoval of NLGje_carD23100% (1)

- 32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelDocument40 pages32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelalfonsofelipesaraviaNo ratings yet

- Mmel Atr 72Document83 pagesMmel Atr 72neonimNo ratings yet

- Bonding, Grounding or EarthingDocument9 pagesBonding, Grounding or EarthingpannNo ratings yet

- A320Document2,908 pagesA320ranjit100% (1)

- Airbus FAST Magazine 44 p8 p16Document9 pagesAirbus FAST Magazine 44 p8 p16Subha SahaNo ratings yet

- E110 TCDS Issue 11 LEAP-1A-1C - 20221205 - 0Document16 pagesE110 TCDS Issue 11 LEAP-1A-1C - 20221205 - 0FFDSNo ratings yet

- EASA E115 TCDS Issue 7 LEAP-1BDocument13 pagesEASA E115 TCDS Issue 7 LEAP-1BliuhkNo ratings yet

- E110 TCDS Issue 12 LEAP-1A-1C 20231124Document16 pagesE110 TCDS Issue 12 LEAP-1A-1C 20231124ewiontkoNo ratings yet

- Working of Fingerprint ScannerDocument5 pagesWorking of Fingerprint ScannerSahana BalasubramanianNo ratings yet

- Power Profile - Armor Powers PDFDocument6 pagesPower Profile - Armor Powers PDFlolo1972100% (2)

- Ladle Cleaning Machine Risk Assessment2Document6 pagesLadle Cleaning Machine Risk Assessment2Edgar PenicelaNo ratings yet

- A4000 Installation ManualDocument10 pagesA4000 Installation ManualMuti FutiNo ratings yet

- FDP ECE BrochureDocument3 pagesFDP ECE BrochureBalasanthosh SountharajanNo ratings yet

- GrabBee HD ManualDocument9 pagesGrabBee HD ManualAndrea Lissette Perez FuentesNo ratings yet

- Aerodromes PDFDocument522 pagesAerodromes PDFaditya100% (1)

- Chemical EarthingDocument18 pagesChemical EarthingDivay ChadhaNo ratings yet

- Women in LeadershipDocument17 pagesWomen in LeadershipSodfa EttafakshiNo ratings yet

- CG FlexconnectDocument32 pagesCG FlexconnectSantanuMannaNo ratings yet

- Development Processes and OrganizationsDocument41 pagesDevelopment Processes and OrganizationsPuneet GoelNo ratings yet

- Roadworthiness Requirements: Vehicle Standards InformationDocument10 pagesRoadworthiness Requirements: Vehicle Standards Informationstallie001No ratings yet

- Operation & Maintenance Manual d260 S3a-En Okt. 2014Document166 pagesOperation & Maintenance Manual d260 S3a-En Okt. 2014DrBollapu Sudarshan50% (2)

- TqemDocument3 pagesTqemJudith D'SouzaNo ratings yet

- 2014 BayHelix Annual Conference Program v2Document19 pages2014 BayHelix Annual Conference Program v2Ulfa Yasmin ShahabNo ratings yet

- sw70x1 Service ManualDocument35 pagessw70x1 Service ManualGitmel GutierrezNo ratings yet

- Compair Fluid Force 4000 IndonesiaDocument3 pagesCompair Fluid Force 4000 Indonesiaindolube75% (4)

- Stm32 Mcu FamilyDocument12 pagesStm32 Mcu FamilyriverajluizNo ratings yet

- Snort ProjectDocument12 pagesSnort Projectsubhendu0% (1)

- Drishtee DevelopmentDocument34 pagesDrishtee Developmenttannu_11No ratings yet

- Experimental Study On Partial Replacement of Sand With Sugarcane Bagasse Ash in ConcreteDocument3 pagesExperimental Study On Partial Replacement of Sand With Sugarcane Bagasse Ash in ConcreteRadix CitizenNo ratings yet

- Ticketswap-Betonhofi-Slaybania-Ticket-20808722 2Document1 pageTicketswap-Betonhofi-Slaybania-Ticket-20808722 2Anderlik-Makkai GergelyNo ratings yet

- 4037 PDFDocument10 pages4037 PDFasfaruk2556No ratings yet

- International StrategyDocument34 pagesInternational StrategymanicatewatiaNo ratings yet

- Fibac 2017 ReportDocument68 pagesFibac 2017 ReportNitin KumarNo ratings yet

- Sci20 Unitb 1 8Document8 pagesSci20 Unitb 1 8api-207957230No ratings yet

- Amca - 201 Fans and SystemsDocument80 pagesAmca - 201 Fans and SystemsenricoNo ratings yet

- Fluorescence Activated Cell SortingDocument6 pagesFluorescence Activated Cell SortingAjit YadavNo ratings yet

- Comp Reflection Short 1Document10 pagesComp Reflection Short 1api-295784162No ratings yet

- GE Custom 8000 Horizontal Induction Motor - GEEP-124-I (1998)Document41 pagesGE Custom 8000 Horizontal Induction Motor - GEEP-124-I (1998)Edson França Rodrigues100% (1)