Professional Documents

Culture Documents

Safegard

Uploaded by

Nikita KadamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safegard

Uploaded by

Nikita KadamCopyright:

Available Formats

Septic Tanks

... An advance solution for safe sanitation

The Supreme Industries Ltd., is an acknowledged leader of India's Features and Benefits

plastic industry. The innovative product portfolio offered by the

Rotationally Molded, One -Piece

company is extensive in range and application and comprises a

Construction

variety of pipes and a vast spectrum of fittings totaling around

7000 diverse products. Together these constitute the most Complete Pre-plumbed set- Available in

comprehensive range in the industry that caters almost every ready to use form.

conceivable need and application. Company has been a torch Unique Design- Unique single piece two

bearer in transition from conventional products to advance chamber patented design.

plastics piping products in the country and has been termed as

"Trend Setters of Plastic Piping Products". Simple and Quick Installation

Supreme Safegard Septic Tanks are designed to provide a better Hygienic and Safe

substitute to existing conventional brick and mortar septic tanks or Great Strength- Robustly designed with

tanks made out of Hume pipes. Conventional septic tanks are unique rib structure.

associated with multiple problems of concrete corrosion and

leakages thereby creating pollution of soil and ground water. Excellent Chemical Resistance- Unaffected

Besides cumbersome and time consuming construction and by soil chemicals and gases, absolutely free

repeated maintenance requirement, the life span of these tanks is from ill effect of hydrogen sulphide (H2S).

short and uncertain. On the other hand Supreme Safegard septic Minimal Maintenance requirements

tanks are free from above problems and has many outstanding

Long Life

features.

Design

Registered

Jeevan bhar ka saath...

Septic Tanks

Available Range

We offer septic tanks in different sizes from 1000 to 29500 liters capacity. Septic tanks up to 3000 liters are made available in vertical

design having two separate integral compartment for proper settlement and decomposition of solid waste whereas the septic tanks

above 5500 liters sizes have modular horizontal design. Different modular units can be connected with each other for increased

capacity up to 29500 liters. The dimensions and product details are given in the following table.

Product Details of Vertical Septic Tanks Product Details of Modular Septic Tanks

Capacity Diameter Height Recommended Capacity Combinations Inlet/Outlet Length Recommended

(Liters) (m) (m) Users (Liters) Sizes (m) Users

1000 1.2 1.039 4 - 5 People 5500 Stand alone 160 2.4 20 - 30 People

9500 2 domed ends coupled 160 3.8 30 - 50 People

1500 1.2 1.410 5 - 8 People

13500 2 domed ends + 1 Intermediate section 160 5.2 50 - 70 People

1800 1.2 1.770 8 - 9 People 17500 2 domed ends + 2 Intermediate sections 160 6.6 70 - 90 People

21500 2 domed ends + 3 Intermediate sections 160 8.0 90 - 100 People

2000 1.7 1.019 9 - 10 People

25500 2 domed ends + 4 Intermediate sections 200 9.4 100 - 130 People

3000 1.7 1.466 12 - 15 People 29500 2 domed ends + 5 Intermediate sections 200 10.8 130 - 150 People

Includes lid, 110 mm inlet and 50 or 110 mm outlet provisions Note- Specified users are based on flow rates of 80 to 120 liter/person/day and 4 -5 years cleaning frequency.

and can be made available with and without lid extension piece. Modular units are supplied with connecting pipes and rubber seals.

Fields of Application:

Primary treatment of sewage in residential, commercial buildings where municipal sewage system is not available.

Installation Procedure

1. Excavate a pit approximately 600 mm larger than the 300 mm (12) around the tank. Excavated soil can be used if it

diameter of the tank. is silt, sand or soft murum but in case of black cotton, loomy or

2. Prepare a 150 mm (6) thick bed of granular material and marshy soil only selected inert granular material i.e. sand/

compact it properly. Ensure that the base of the pit is smooth, stone dust /gravels (max. size 10 mm) should be used as

flat and sufficiently hard to form a solid foundation for the backfill material. It is particularly important to note that

septic tank and no sharp object/stone etc. should protrude excavated material consisting of rock, peat or clay is not used

which can puncture the tank. as backfill material.

3. Lower the tank into position in the pit ensuring that it is 5. When the level of the backfill reaches the underside of the

vertical, centrally positioned, correctly aligned and leveled outlet pipe invert, inlet and outlet connections should be

using spirit level and the outlet pipe faces the soak pit and made. It is recommended to maintain 1:40 to 1:60 fall

inlet pipe swivels, ensuring a straight connection. between drain head and inlet of the septic tank.

rd

4. Fill the tank with a tap water up to / capacity using tap. Start Venting : Connect vent pipe of 50 mm diameter on the vent

the backfilling. Backfilling and water filling should be carried outlet provided on the tank.

out simultaneously ensuring that the backfilling level never 6. Select the appropriate cover as per the site loading conditions

exceeds the rising level of water within the tank until the and place it on the top of tank, in case of rotationally moulded

water overflows through the outlet pipe, thus indicating the light weight cover it should be filled with concrete. For traffic

tank is full. The width of the backfilling should be minimum condition GRP covers of required load class should be used.

Note: Where abnormal soil conditions occur such as vehicular traffic, rock, black cotton soil or high water table is anticipated or when the backfill

above the lid exceeds 1000 mm, detailed guidelines should be referred and the final design rests with the engineer or architect on the project. The

installation principle and procedure for modular septic tank remains same but we advice to follow the detailed procedure as given in the user guide.

All the dimensions unless otherwise specified are in mm All information contained in this literature is given in good faith and believed to be accurate and reliable. But because of many factors which are outside our

knowledge and control and affect the use of product, no warranty is given or is to be implied with respect to such information, nor we offer any warranty of immunity against patent infringement. No responsibility

can be accepted for any error, omissions or incorrect assumptions. Any specifications can change without prior notice.

The Supreme Industries Ltd. (Plastic Piping Division)

1161/1162, Solitair Corporate Park, Building No. 11,167, Andheri Ghatkopar Link Road, Andheri (East) Mumbai - 400 093. India

Tel: 91-22-6771 0000, 4043 0000 Fax: 6771 0099 / 4043 0099. E-mail pvc-pipes@supreme.co.in Website www.supreme.co.in

Overseas Office : Sharjah, U.A.E. Tel # + 971 6 557 4484; Fax # + 97165574485

I & T SIL Gadegaon, Dist-Jalgaon=PC/SGST-SP/MKG/86=REV.02-12/2016

www.supreme.co.in

You might also like

- Ajmera - Treon - FF - R4 - 13-11-17 FinalDocument45 pagesAjmera - Treon - FF - R4 - 13-11-17 FinalNikita KadamNo ratings yet

- Subject - Offer For Supreme Flameguard CPVC Pipes and Fittings For Your ProjectDocument2 pagesSubject - Offer For Supreme Flameguard CPVC Pipes and Fittings For Your ProjectNikita KadamNo ratings yet

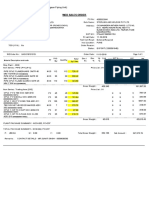

- 515 - ADD ORDER FOR PANJRAPOLE 12 02 18Document1 page515 - ADD ORDER FOR PANJRAPOLE 12 02 18Nikita KadamNo ratings yet

- Hilti 2016 price list with 40% discount on toolsDocument89 pagesHilti 2016 price list with 40% discount on toolsMYGMINo ratings yet

- Sr. No Item Unit Lobby Flat 1 (2 BHK) Flat 2 (2 BHK) Flat 3 (3 BHK)Document2 pagesSr. No Item Unit Lobby Flat 1 (2 BHK) Flat 2 (2 BHK) Flat 3 (3 BHK)Nikita KadamNo ratings yet

- Sr. No. Item Size Rate Per MTR (RS)Document1 pageSr. No. Item Size Rate Per MTR (RS)Nikita KadamNo ratings yet

- Measurement Sample FlatDocument5 pagesMeasurement Sample FlatNikita KadamNo ratings yet

- Flameguard Item Qty. Unit ERP Code Item Code RateDocument1 pageFlameguard Item Qty. Unit ERP Code Item Code RateNikita KadamNo ratings yet

- Web Sales Order: The Supreme Industries Limited (Gadegaon Piping Unit)Document1 pageWeb Sales Order: The Supreme Industries Limited (Gadegaon Piping Unit)Nikita KadamNo ratings yet

- Directorate of Maharashtra Fire Services: List of 588 Approved Licensed Agencies As 31.10.2017Document77 pagesDirectorate of Maharashtra Fire Services: List of 588 Approved Licensed Agencies As 31.10.2017Nikita KadamNo ratings yet

- Mahindra Order 4200323341Document1 pageMahindra Order 4200323341Nikita KadamNo ratings yet

- Hiranandani Castle RockDocument1 pageHiranandani Castle RockNikita KadamNo ratings yet

- Web Sales Order: The Supreme Industries Limited (Gadegaon Piping Unit)Document1 pageWeb Sales Order: The Supreme Industries Limited (Gadegaon Piping Unit)Nikita KadamNo ratings yet

- Mahindra Order 4200323341Document1 pageMahindra Order 4200323341Nikita KadamNo ratings yet

- VS Price ListDocument2 pagesVS Price ListNikita KadamNo ratings yet

- How To Read The Metric Vernier CaliperDocument2 pagesHow To Read The Metric Vernier CaliperNikita KadamNo ratings yet

- Fire Prevention Checklist For Storage WarehouseDocument2 pagesFire Prevention Checklist For Storage WarehouseNikita KadamNo ratings yet

- Pump Test RequirementsDocument1 pagePump Test RequirementsNikita KadamNo ratings yet

- Mahindra Order 4200323341Document1 pageMahindra Order 4200323341Nikita KadamNo ratings yet

- Supreme Industries Piping Unit Sales Order for CPVC PipesDocument1 pageSupreme Industries Piping Unit Sales Order for CPVC PipesNikita KadamNo ratings yet

- FLS - Fire Flow CalculationsDocument4 pagesFLS - Fire Flow CalculationsNikita KadamNo ratings yet

- NFPA 25 - ITM-TaggingDocument10 pagesNFPA 25 - ITM-TaggingMEHBOOB SHAIKHNo ratings yet

- Fire Hydrant Flow Test - NFPA 291 & AWWA M17Document21 pagesFire Hydrant Flow Test - NFPA 291 & AWWA M17Nikita KadamNo ratings yet

- Tabela - CPVC Chemical Compatibility Resistance ChartDocument11 pagesTabela - CPVC Chemical Compatibility Resistance ChartHimozaesNo ratings yet

- Geberit Pluvia BrochureDocument20 pagesGeberit Pluvia BrochureNikita KadamNo ratings yet

- Fire Hydrants - Loop TestingDocument9 pagesFire Hydrants - Loop TestingNikita KadamNo ratings yet

- Convective HT For SprinklerDocument4 pagesConvective HT For SprinklerShabin ShabiNo ratings yet

- Welding Document & WPQDocument1 pageWelding Document & WPQNikita KadamNo ratings yet

- Spacing and Location - Part ADocument23 pagesSpacing and Location - Part ANikita KadamNo ratings yet

- Point of Use Accessories: Turnkey Solutions For End-To-End EfficiencyDocument4 pagesPoint of Use Accessories: Turnkey Solutions For End-To-End EfficiencyNikita KadamNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Contractor Environmental, Health and Safety Evaluation FormDocument13 pagesContractor Environmental, Health and Safety Evaluation Formsainukala100% (2)

- Sukarno by Cindy Adam Bhs - IndonesiaDocument8 pagesSukarno by Cindy Adam Bhs - IndonesiaEncep BuhoriNo ratings yet

- EC Safety Data Sheet: Armaflex 520Document11 pagesEC Safety Data Sheet: Armaflex 520Ferencz ZsoltNo ratings yet

- Lesson PlanDocument5 pagesLesson Planapi-270170633No ratings yet

- Community and Environmental HealthDocument23 pagesCommunity and Environmental HealthEmmei Vincent DiongcoNo ratings yet

- Biodiversity OverviewDocument6 pagesBiodiversity OverviewArifah AdzmiNo ratings yet

- Sustainable Resource Use & Development ContradictionDocument22 pagesSustainable Resource Use & Development ContradictionhumayriNo ratings yet

- 22nd Annual Meeting of The Lees Pond AssociationDocument4 pages22nd Annual Meeting of The Lees Pond Associationapi-225724317No ratings yet

- Modern Landfill Design, Single-Use Plastic Bans, Waste CategoriesDocument3 pagesModern Landfill Design, Single-Use Plastic Bans, Waste Categoriesjenna meadowsNo ratings yet

- Planning Panvel's Sewerage and Sewage Treatment for 2051Document21 pagesPlanning Panvel's Sewerage and Sewage Treatment for 2051Dhruv MudgalNo ratings yet

- Ultra Intensive Aquaculture PaperDocument6 pagesUltra Intensive Aquaculture PaperPradeep SinghNo ratings yet

- Factors Affecting ClimateDocument3 pagesFactors Affecting Climaterose ann tuburanNo ratings yet

- EPA Hydraulic Fracturing Study Technical WorkshopDocument49 pagesEPA Hydraulic Fracturing Study Technical WorkshopHugo WizenbergNo ratings yet

- DENR Eco-Tour Educates Students on MSPLDocument3 pagesDENR Eco-Tour Educates Students on MSPLDivine JoNo ratings yet

- DM (Manual) PDFDocument4 pagesDM (Manual) PDFSubhabrata MabhaiNo ratings yet

- App 5 Concept Design Report 2009 PDFDocument90 pagesApp 5 Concept Design Report 2009 PDFsybaritz100% (1)

- Algal Diversity With Reference To Heavy Metals in Tapi River FromDocument4 pagesAlgal Diversity With Reference To Heavy Metals in Tapi River FromJournal of Environment and Bio-SciencesNo ratings yet

- NESREA Presentation NIMSA SummitDocument100 pagesNESREA Presentation NIMSA SummitHamzy Lawal100% (2)

- (Balkema - Proceedings and Monographs in Engineering, Water and Earth Sciences) Peter P Rogers_ Manuel Ramón Llamas_ Luis Martínez-Cortina_ Fundación Marcelino Botín - Water crisis _ myth or reali.pdfDocument323 pages(Balkema - Proceedings and Monographs in Engineering, Water and Earth Sciences) Peter P Rogers_ Manuel Ramón Llamas_ Luis Martínez-Cortina_ Fundación Marcelino Botín - Water crisis _ myth or reali.pdfCarlos Edd de FreitasNo ratings yet

- Backward Unit Design PlanDocument27 pagesBackward Unit Design Planapi-375517051No ratings yet

- Karen Alleyne PLAS-CRETE Manufacture of Construction Blocks With Shredded PET and HDPEDocument9 pagesKaren Alleyne PLAS-CRETE Manufacture of Construction Blocks With Shredded PET and HDPEAdor Palanca AlledaNo ratings yet

- C4 ClimateAndClimateChangeDocument72 pagesC4 ClimateAndClimateChangeKajemm InfoNo ratings yet

- Chryso MSDSDocument5 pagesChryso MSDSDileepa DissanayakeNo ratings yet

- Design of A Biological Slaughterhouse Wastewater Treatment System (Using An Anaerobic Baffle Reactor - Constructed Wetland System)Document22 pagesDesign of A Biological Slaughterhouse Wastewater Treatment System (Using An Anaerobic Baffle Reactor - Constructed Wetland System)ZuberYousufNo ratings yet

- Mini Project 1 Eia CumeneDocument14 pagesMini Project 1 Eia CumenefazliNo ratings yet

- ICE Annex A Methodologies For RecyclingDocument17 pagesICE Annex A Methodologies For RecyclingChai Lin NyokNo ratings yet

- World Population DayDocument5 pagesWorld Population DayAsim Khan100% (1)

- Innovative Strategies for Sustainable Urban DevelopmentDocument2 pagesInnovative Strategies for Sustainable Urban DevelopmentPola OrregoNo ratings yet

- Rhetorical AnalysisDocument5 pagesRhetorical Analysisapi-3565651850% (2)

- Jurnal 1Document22 pagesJurnal 1Muhammad Barin ElyasaNo ratings yet