Professional Documents

Culture Documents

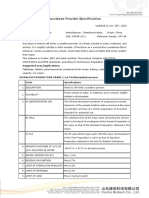

Specifications Sugarbeet Molasses

Uploaded by

Arrianne Jaye Mata0 ratings0% found this document useful (0 votes)

151 views3 pagesThis document contains product specifications for two types of molasses - for distilleries and for animal feed. It describes the basic input materials as sugar beet and water, and the technological process of separating sugar from sugar beet. It provides details on sensory requirements, declared properties, packaging, storage conditions, and minimum durability. The specifications comply with Czech and EU standards for molasses intended for distilleries and animal feed.

Original Description:

Specifications1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains product specifications for two types of molasses - for distilleries and for animal feed. It describes the basic input materials as sugar beet and water, and the technological process of separating sugar from sugar beet. It provides details on sensory requirements, declared properties, packaging, storage conditions, and minimum durability. The specifications comply with Czech and EU standards for molasses intended for distilleries and animal feed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

151 views3 pagesSpecifications Sugarbeet Molasses

Uploaded by

Arrianne Jaye MataThis document contains product specifications for two types of molasses - for distilleries and for animal feed. It describes the basic input materials as sugar beet and water, and the technological process of separating sugar from sugar beet. It provides details on sensory requirements, declared properties, packaging, storage conditions, and minimum durability. The specifications comply with Czech and EU standards for molasses intended for distilleries and animal feed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Sugarbeet molasses for distilleries product specifications

Name of the product Molasses for distilleries

Beet sugar production by-product containing remnants of syrups from

Product characteristics

the sugar refining processes

Applications For distilleries

Basic input materials Sugarbeet, water

Sugar-sucrose is industrially separated from the basic raw material,

sugarbeet, in the following technological processes:

1. Cleaning and chopping the sugarbeet

2. Extracting raw juice

Basic characteristics of the

3. Purifying and filtering the sugar juice

technological process

4. Evaporating

5. Crystallisation

6. Centrifuging

Colour, appearance dark brown to black;

Taste distinguished bitter-sweet;

Sensory requirements Odour typical, without strange odours;

Consistency viscid syrup fluid, may contain small crystals of sucrose;

Frothed, caramelised, infected or contaminated (by solid particles)

product cannot be delivered for fermentation processing.

Dry mass (refractometer): min. 75%

Saccharose (polarometer): min. 43%

(for alcohol and yeast production: min.46 %)

Invert sugar: max. 2.5%

(for alcohol and yeast production: max. 1 %)

Declared properties in

Conductometric ashes: min. 9%

compliance with

Sulphites and sulphur dioxide: max. 0,1 %

SN 56 5840

pH: 7,1 to 8,8

(for alcohol and yeast production: 7,1 to 8,5)

Nitrites: negative

Calcic and magnesium salts : max. 1,0 %

Volatile acids, such as acetic acid: max. 0,8 %

Microbiological

Number of microorganisms in 1g of mass: maximum 10 000

requirements

Packaging The product is filled into road or railway tankers, barrels or other

(including specifications of suitable containers. All of them must be in a good condition, clean and

the applied containers) microbiologically approved.

Product distribution Molasses is distributed in barrels or tankers.

The allowed means of transport must comply with the hygiene

requirements on food transportation as stipulated in the Act No.110/97

Coll. as amended, and the requirements of the Gov. Regulation 38/2001

Coll., as amended, - On materials in contact with loose foodstuffs.

The product is stored in clean, microbiologically suitable and closed

molasses tanks, steel containers or barrels. It is not allowed to apply any

Storing conditions admixtures before dispatch.

Storing temperature limit is max. 35oC; pH value of the stored product

must be at least 8; diluting with water is not allowed.

2 months under stipulated storing conditions

Minimal durability

Molasses (treacle) animal feed product specifications

Molasses animal feed product of the industrial processing of sugar

Name of the product

beet

Producers Register No. 10541

File number 10541-1

Beet sugar production by-product containing remnants of syrups from

the sugar refining processes.

Product characteristics

Animal feed is a product of the vegetable or animal origin providing

nutrition for animals.

Applications Animal feed

The product can be fed directly or used as an ingredient of the fodder

Usage guideline

mixtures for domestic animals and livestock.

Basic input materials Sugar beet, water

Sugar-sucrose is industrially separated from the basic raw material,

sugarbeet, in the following technological processes:

1. Cleaning and chopping the sugarbeet

Basic characteristics of the 2. Extracting raw juice

technological process 3. Purifying and filtering the juice

4. Evaporating

5. Crystallisation

6. Centrifuging

All sugar declared as saccharose

Declared properties

Water content: if above 28 %

required by EU 767/2009

Insoluble ashes fraction in HCl, if above 3.5 % in dry mass

Unwanted elements and Max. rate mg/kg (ppm) of mass

substances with water content 12 %

Arsenic 2

Lead 10

Fluorine 150

Mercury 0.1

Cadmium 1

Aflatoxin B1 0.02

Hydrocyanic acid 50

Aldrine 0.01

Chlordane 0.02

Chemical requirements

DDT 0.05

Endosulfan 0.1

Endrine 0.01

Heptachlorine 0.01

Hexachlorbenzene HCB 0.01

Hexachlorcyclohexan HCH

alfa isomers 0.02

beta isomers 0.01

gama isomers 0.2

Dioxin 0.75 ng WHO-PCDD/F TEQ /kg

Sum of dioxins and PCB with 1.25 ng WHO-PCDD/F-PCB-TEQ/kg

dioxin effects

Packaging The product is filled into road or railway tankers, barrels or other

suitable containers. All of them must be in a good condition, clean and

(including specifications of

microbiologically approved.

the applied containers)

Product is distributed in barrels or tankers. The means of transportation

Product distribution

must comply with hygiene requirements for the animal feed transport.

The product is stored in clean, microbiologically suitable and closed

molasses tanks, steel containers or barrels. It is not allowed to apply any

Storing conditions admixtures before dispatch.

Storing temperature limit is max. 35oC; pH value of the stored product

must be at least 8; diluting with water is not allowed.

2 months under stipulated storing conditions

Minimal durability

You might also like

- Blueprint 7 Student Book Teachers GuideDocument128 pagesBlueprint 7 Student Book Teachers GuideYo Rk87% (38)

- Problems in Biochemical EngineeringDocument22 pagesProblems in Biochemical EngineeringArrianne Jaye Mata50% (4)

- University of Leicester - Involving Your AudienceDocument4 pagesUniversity of Leicester - Involving Your Audiencevalentina zabalaNo ratings yet

- Gso 149 Unbottled Drinking WaterDocument12 pagesGso 149 Unbottled Drinking Waternizar.e keloth kandi100% (3)

- Refined Sunflower Oil Nutrition Facts & AnalysisDocument2 pagesRefined Sunflower Oil Nutrition Facts & Analysisİ. Ethem BuyukkoseNo ratings yet

- Formulating at Low PHDocument42 pagesFormulating at Low PHPeter100% (1)

- Assignment SolutionsDocument10 pagesAssignment SolutionsArrianne Jaye MataNo ratings yet

- Installing OpenSceneGraphDocument9 pagesInstalling OpenSceneGraphfer89chopNo ratings yet

- Renato Cristin Heiddegger and LeibnizDocument10 pagesRenato Cristin Heiddegger and Leibnizaida100% (1)

- Food StandardsDocument36 pagesFood StandardsSamyukta .SNo ratings yet

- Pectina de Manzana APA102 (HM-RS) - FT - APDocument1 pagePectina de Manzana APA102 (HM-RS) - FT - APhannalupeNo ratings yet

- Becarbonate of SodaDocument2 pagesBecarbonate of SodaStory FunnyNo ratings yet

- Salicylic Acid Purified Grade: DentificationDocument2 pagesSalicylic Acid Purified Grade: DentificationMenoddin shaikhNo ratings yet

- Process ProductionDocument10 pagesProcess ProductionULFA ISLAMIANo ratings yet

- Sweet Cherry Powder Spray Dried Fruit Concentrate of Sweet Cherry - 70320010Document3 pagesSweet Cherry Powder Spray Dried Fruit Concentrate of Sweet Cherry - 70320010sasha yablochkovNo ratings yet

- Application NoteDocument7 pagesApplication NoteIngrid Eliana Fernandez CampoNo ratings yet

- Ethanol Laboratory ManualDocument129 pagesEthanol Laboratory ManualYoni LoveNo ratings yet

- NG D NG C A Enzyme Vào Quá Trình Lên Men BiaDocument28 pagesNG D NG C A Enzyme Vào Quá Trình Lên Men BiaVũ HằngNo ratings yet

- CLEANER PRODUCTION GUIDELINES FOR CAUSTIC SODA AND CHLOR-ALKALI INDUSTRIESDocument13 pagesCLEANER PRODUCTION GUIDELINES FOR CAUSTIC SODA AND CHLOR-ALKALI INDUSTRIESphat nguyenNo ratings yet

- Honey Specification - CapilanoDocument2 pagesHoney Specification - CapilanoHuu Thien NguyenNo ratings yet

- MS PT101Document2 pagesMS PT101Pandiya RajanNo ratings yet

- Application A1047 Sodium Carboxymethylcellulose As A Food Additive in Wine Risk and Technical Assessment ReportDocument8 pagesApplication A1047 Sodium Carboxymethylcellulose As A Food Additive in Wine Risk and Technical Assessment ReportSyarifatul IzzaNo ratings yet

- Additives in FoodDocument552 pagesAdditives in FoodPrincess Reannabel BravoNo ratings yet

- Eldercraft® 14% European Black Elderberry Extract - B0120203Document5 pagesEldercraft® 14% European Black Elderberry Extract - B0120203truongmon_20051302No ratings yet

- Alcohol Industry.1Document3 pagesAlcohol Industry.1AQUA ROBOTXNo ratings yet

- Instant Cherry Powder SpecificationDocument3 pagesInstant Cherry Powder Specificationsasha yablochkovNo ratings yet

- Crude Soybean Oil ProductDocument2 pagesCrude Soybean Oil ProductChandan JstNo ratings yet

- Crude Soya OilDocument2 pagesCrude Soya OilFantania BerryNo ratings yet

- Instant Powder Taste Pineapple - 70010042Document3 pagesInstant Powder Taste Pineapple - 70010042sasha yablochkovNo ratings yet

- M643ADocument2 pagesM643AReza FebryantaraNo ratings yet

- Analysis AllDocument8 pagesAnalysis AllDerrick Scott FullerNo ratings yet

- CALLIANDRA - Andy Chahyadi PDFDocument13 pagesCALLIANDRA - Andy Chahyadi PDFrnd talasiNo ratings yet

- Sorbic Acid and Potassium SorbateDocument18 pagesSorbic Acid and Potassium SorbatekobkunkarbNo ratings yet

- Pineapple Powder Spray Dried Fruit Concentrate of Pineapple - 70010029Document3 pagesPineapple Powder Spray Dried Fruit Concentrate of Pineapple - 70010029sasha yablochkovNo ratings yet

- Corn Starch - Food GradeDocument2 pagesCorn Starch - Food GradeMohanad TofahNo ratings yet

- WUT-Biogas 01Document33 pagesWUT-Biogas 01RangaNo ratings yet

- Distillery Industry 7Document15 pagesDistillery Industry 7gundreddy greeshmaNo ratings yet

- Producer: Description:: Citrus Pectin HMC-SSB 1Document2 pagesProducer: Description:: Citrus Pectin HMC-SSB 1Ankit RanaNo ratings yet

- DTPMP Acid Properties and UsageThis concise title highlights the key aspects covered in the document - the properties and usage of DTPMP Acid. It is less than 40 characters as requestedDocument10 pagesDTPMP Acid Properties and UsageThis concise title highlights the key aspects covered in the document - the properties and usage of DTPMP Acid. It is less than 40 characters as requestedJose TerrazasNo ratings yet

- Glycerin IpDocument1 pageGlycerin IpHector Santiago Lopez AcostaNo ratings yet

- IWPC, Dairy and Oil RefineryDocument24 pagesIWPC, Dairy and Oil RefinerySravan JanardhananNo ratings yet

- Notes-Food Proximate AnalysisDocument23 pagesNotes-Food Proximate AnalysisMuhammad Raza UllahNo ratings yet

- Pure Water SpecDocument2 pagesPure Water SpecRisma Berliana PanjaitanNo ratings yet

- FT Shandong Luwei Pharmaceutical Rev 120421Document1 pageFT Shandong Luwei Pharmaceutical Rev 120421Control calidadNo ratings yet

- Soft CandyDocument7 pagesSoft CandybarkahNo ratings yet

- Booklet transparency A5_LOWDocument16 pagesBooklet transparency A5_LOWIssame BoulafalNo ratings yet

- 2-Analysis For Food AdditivesDocument141 pages2-Analysis For Food AdditivesRuben Santiago-Adame50% (2)

- Manual of Methods OF Analysis of Foods: Food AdditivesDocument141 pagesManual of Methods OF Analysis of Foods: Food AdditivesLilis TuslinahNo ratings yet

- ST Eng Sodium Metabisulphite HP 1Document1 pageST Eng Sodium Metabisulphite HP 1Андрій ОлександровичNo ratings yet

- Formulaciones Nourishing Chocolate Milk BodyDocument1 pageFormulaciones Nourishing Chocolate Milk Bodyandres david jimenez acostaNo ratings yet

- Technical Report of Formic Acid PlantDocument6 pagesTechnical Report of Formic Acid PlantMuzzamilNo ratings yet

- Preliminary Phytochemical Screening and Adaptogenic Activity of Chlorophytum Borivillianum RootsDocument12 pagesPreliminary Phytochemical Screening and Adaptogenic Activity of Chlorophytum Borivillianum RootsS Bharadwaj ReddyNo ratings yet

- Sucralose Powder Specs - HarmonyDocument2 pagesSucralose Powder Specs - HarmonyLourdes LandoniNo ratings yet

- Fermentation Technology For ProductionDocument218 pagesFermentation Technology For Productionsb.21p20133No ratings yet

- Formic Acid Plant: A Brief OverviewDocument17 pagesFormic Acid Plant: A Brief OverviewMuzzamilNo ratings yet

- Fichas Tecnicas - Derivados Del CacaoDocument4 pagesFichas Tecnicas - Derivados Del CacaoGabrielaNo ratings yet

- L (+) Lactic Acid Fermentation and Its Product PolymerizationDocument10 pagesL (+) Lactic Acid Fermentation and Its Product PolymerizationRyan MichaelNo ratings yet

- Sugar Research & Innovation, Queensland University of Technology, AustraliaDocument10 pagesSugar Research & Innovation, Queensland University of Technology, AustraliaTeena AlawadNo ratings yet

- Preparación de medio Verduyn para cultivo de microorganismosDocument3 pagesPreparación de medio Verduyn para cultivo de microorganismosLaura ParraNo ratings yet

- Specification Tartrazine (Powder) : DescriptionDocument1 pageSpecification Tartrazine (Powder) : DescriptionShiraz KhanNo ratings yet

- Handbook of Enology, Volume 2: The Chemistry of Wine - Stabilization and TreatmentsFrom EverandHandbook of Enology, Volume 2: The Chemistry of Wine - Stabilization and TreatmentsPascal Ribéreau-GayonNo ratings yet

- Carbonated Soft Drinks: Formulation and ManufactureFrom EverandCarbonated Soft Drinks: Formulation and ManufactureDr. David SteenNo ratings yet

- Atmospheric Chemical Compounds: Sources, Occurrence and BioassayFrom EverandAtmospheric Chemical Compounds: Sources, Occurrence and BioassayNo ratings yet

- Eng Econ SlidesDocument34 pagesEng Econ Slidesاحمد عمر حديدNo ratings yet

- Taxonomy, Physiology and Growth of Lactococcus Lactis: A ReviewDocument14 pagesTaxonomy, Physiology and Growth of Lactococcus Lactis: A ReviewKaycelyn BacayNo ratings yet

- Patel2004 PDFDocument4 pagesPatel2004 PDFArrianne Jaye MataNo ratings yet

- Lactic AcidDocument7 pagesLactic AcidIranna UdachanNo ratings yet

- Lactic Acid Production by Lactobacillus Delbrueckii in A Dual Reactor System Using Packed Bed Biofilm ReactorDocument6 pagesLactic Acid Production by Lactobacillus Delbrueckii in A Dual Reactor System Using Packed Bed Biofilm ReactorArrianne Jaye MataNo ratings yet

- Fundamentals of ElectrochemistryDocument30 pagesFundamentals of ElectrochemistryArrianne Jaye MataNo ratings yet

- Second Law of ThermodynamicsDocument9 pagesSecond Law of ThermodynamicsArrianne Jaye MataNo ratings yet

- Rotary FilterDocument18 pagesRotary FilterArrianne Jaye MataNo ratings yet

- Characterization of Lactic Acid Bacteria Isolated From Poultry FarmsDocument7 pagesCharacterization of Lactic Acid Bacteria Isolated From Poultry FarmsArrianne Jaye MataNo ratings yet

- Ammonium Sulfate Preci P TableDocument1 pageAmmonium Sulfate Preci P TablerkuspriyadaniNo ratings yet

- F SDocument5 pagesF SArrianne Jaye MataNo ratings yet

- Week 5 Air conditioning processes and refrigeration cyclesDocument41 pagesWeek 5 Air conditioning processes and refrigeration cyclesArrianne Jaye MataNo ratings yet

- The A of of Is Is To And, of The Is Is A A A: Fermentation BrothDocument2 pagesThe A of of Is Is To And, of The Is Is A A A: Fermentation BrothArrianne Jaye MataNo ratings yet

- Computer Application in Chemical EngineeringDocument5 pagesComputer Application in Chemical EngineeringArrianne Jaye MataNo ratings yet

- Unitops - ch8 ProblemsDocument7 pagesUnitops - ch8 ProblemsAimee Layson PolancoNo ratings yet

- Introduction For Ch.8 v.2Document3 pagesIntroduction For Ch.8 v.2Arrianne Jaye MataNo ratings yet

- Computer Application in ChEDocument5 pagesComputer Application in ChEArrianne Jaye MataNo ratings yet

- Solutions: Wine ClarificationDocument4 pagesSolutions: Wine ClarificationArrianne Jaye MataNo ratings yet

- Problem Set ThermodynamicsDocument7 pagesProblem Set ThermodynamicsjasonkkzNo ratings yet

- Arrianne Jaye MataDocument3 pagesArrianne Jaye MataArrianne Jaye MataNo ratings yet

- Degree OrderDocument1 pageDegree OrderAadil ShNo ratings yet

- X-FLOW R-100: Microfiltration MembraneDocument2 pagesX-FLOW R-100: Microfiltration MembraneArrianne Jaye MataNo ratings yet

- A 3 ReferencesDocument1 pageA 3 ReferencesArrianne Jaye MataNo ratings yet

- Number 4 MethodologyDocument3 pagesNumber 4 MethodologyArrianne Jaye MataNo ratings yet

- Heat Transfer Problems PDFDocument16 pagesHeat Transfer Problems PDFTareq DahbNo ratings yet

- Bible TriviasDocument7 pagesBible TriviasArrianne Jaye MataNo ratings yet

- PD Chapter 1Document31 pagesPD Chapter 1Arrianne Jaye MataNo ratings yet

- Bible VersesDocument3 pagesBible VersesArrianne Jaye MataNo ratings yet

- English Language and Applied Linguistics Textbooks Lo Res USDDocument61 pagesEnglish Language and Applied Linguistics Textbooks Lo Res USDJames Blackburn Quéré Cutbirth100% (2)

- MemoDocument2 pagesMemoapi-310037519No ratings yet

- Impact of Social Media in Tourism MarketingDocument16 pagesImpact of Social Media in Tourism MarketingvidhyabalajiNo ratings yet

- Soft Start - Altistart 48 - VX4G481Document2 pagesSoft Start - Altistart 48 - VX4G481the hawakNo ratings yet

- Managing Change Leading TransitionsDocument42 pagesManaging Change Leading TransitionsSecrets26No ratings yet

- CHRM - A01.QXD - Unknown - 3071 PDFDocument545 pagesCHRM - A01.QXD - Unknown - 3071 PDFbeaudecoupe100% (2)

- The Benefits of Radio Broadcasting As Perceived by The People in Rural AreasDocument10 pagesThe Benefits of Radio Broadcasting As Perceived by The People in Rural AreasMaeNo ratings yet

- Digital Citizenship RubricDocument1 pageDigital Citizenship Rubricapi-300964436No ratings yet

- Quality Policy Nestle PDFDocument6 pagesQuality Policy Nestle PDFJonathan KacouNo ratings yet

- Struts HTML Checkbox enDocument4 pagesStruts HTML Checkbox enjudesahayarajNo ratings yet

- Inami, Problem Other MindsDocument19 pagesInami, Problem Other MindsfortyrrNo ratings yet

- Devki N Bhatt01240739754Document10 pagesDevki N Bhatt01240739754menuselectNo ratings yet

- 373 07 2Document143 pages373 07 2fpttmmNo ratings yet

- 11 - Chapter 5 PDFDocument35 pages11 - Chapter 5 PDFlouisNo ratings yet

- Week3 Communication Skill Part 1 Student GuideDocument10 pagesWeek3 Communication Skill Part 1 Student GuideZoe FormosoNo ratings yet

- Natural ApproachDocument3 pagesNatural ApproachNovita SariNo ratings yet

- Fox Hunting - The Art of Dating and SeductionDocument93 pagesFox Hunting - The Art of Dating and SeductionEdward Ashley Latimore100% (1)

- Fractions, Decimals and Percent Conversion GuideDocument84 pagesFractions, Decimals and Percent Conversion GuideSassie LadyNo ratings yet

- District Plan of ActivitiesDocument8 pagesDistrict Plan of ActivitiesBrian Jessen DignosNo ratings yet

- Oracle® Database: Administrator's Reference 11g Release 1 (11.1) For Linux and UNIX-Based Operating Sys-TemsDocument174 pagesOracle® Database: Administrator's Reference 11g Release 1 (11.1) For Linux and UNIX-Based Operating Sys-TemsPrakash MohantyNo ratings yet

- The STP Guide To Graduate Student Training in The Teaching of PsychologyDocument101 pagesThe STP Guide To Graduate Student Training in The Teaching of PsychologyNeilermindNo ratings yet

- AufEx4 02 02Document28 pagesAufEx4 02 02BSED SCIENCE 1ANo ratings yet

- Audit of Organizational Communication NetworksDocument17 pagesAudit of Organizational Communication NetworksLissette ObleaNo ratings yet

- Peak Performance Cricket ExtractDocument5 pagesPeak Performance Cricket ExtractRui CunhaNo ratings yet

- Journal of Statistical Planning and Inference: Akanksha S. KashikarDocument12 pagesJournal of Statistical Planning and Inference: Akanksha S. KashikarAkanksha KashikarNo ratings yet

- Implementing IPC Java User Exit To Enable Calculation of EMIDocument27 pagesImplementing IPC Java User Exit To Enable Calculation of EMIArun SinghNo ratings yet