Professional Documents

Culture Documents

Gtaw WPQ

Uploaded by

MuhammadShabbirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gtaw WPQ

Uploaded by

MuhammadShabbirCopyright:

Available Formats

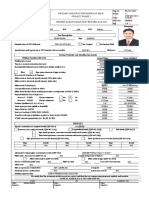

F O R M

WELDER / WELDING OPERATOR PERFORMANCE

Doc. Level: V

QUALIFICATION (WPQ) Doc. Version: 01

Doc. No.: QAQC-FRM-12 w.e.f.: 01-01-2013

Welder's Name Ihsan-Ullah S/O Bashir Ahmad Stamp No 3

Identification of WPS followed AJC - WPS- 01 Test Coupon Production Weld

Specification & type/grade or UNS Number of Base Material(s) SA-516 Gr. 70 Thickness 16 mm

Testing Conditions and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Welding Process (es) SMAW SMAW

Type (i.e.: Manual, Semi Automatic) used Manual Manual

Backing (with/without) With With

Plate Pipe (enter diameter if pipe or tube Plate 16 mm *

Base Metal P- or S-Number to P- or S-Number P No.1 P No.1 ~ 15F

Filler Metal or Electrode Specification(s) (SFA) (info. only)

Filler Metal or Electrode Classification(s) (info. only) E7018

Filler Metal F-Number(s) 4 4,3.2.1

Consumable insert (GTAW or PAW) - -

Filler Metal Product Form (Solid/metal or Flux cored/powder) (GTAW or PAW) - -

Deposit thickness for each process - -

Process 1 SMAW 3 Layers minimum Yes No 16 mm Unlimited

Process 2 3 Layers minimum Yes No

Position Qualified (2G, 6G, 3F etc.) 3G *

Vertical Progression (uphill / downhill) Uphill Uphill

Type of Fuel Gas for OFW - -

Inert Gas Backing (GTAW, PAW, GMAW) - -

Transfer Mode (Spray/Globular or Pulse to Short Circuit-GMAW) - -

GTAW Current type /polarity (AC, DCEP, DCEN) - -

* Plate and Pipe over 610 mm OD (F.V) , 73 mm OD Pipe 610 mm OD (F) , Fillet for Pipe and Plate (F,H,V)

Results

Visual Examination of completed weld (QW-302.4) -

Transverse face and root bends (QW-462.3(a)) Longitudinal bends (QW-462.3(b)) Side bends (QW-462.2)

Pipe bend specimen, corrosion-resistant weld metal overlay (QW-462.5(c))

Plate bend specimen, corrosion-resistant weld metal overlay (QW-462.5(d))

Pipe specimen, macro test for fusion (QW-462.5(b)) Plate specimen, macro test for fusion (QW-462.5(e))

Type Result Type Result Type Result

Alternative Radiographic Examination Results (QW-191) Radiography Test (Report No.1)

Fillet Weld - Fracture Test (QW-181.2) - Length & Percent of Defects -

Fillet Welds in Plate (QW-462.4(b)) Fillet Welds in Pipe (QW-462.4(c))

Macro Examination (QW-184) - Fillet Size(in) - x - Concavity/Convexity (in.) -

Other Tests

Film or specimens evaluated by Muhammad Azhar Company Inspectest (Pvt.) Ltd.

Mechanical Tests Conducted by Laboratory Test No.

Welding Supervised by

We certify that the statements in this record are correct and that the test coupons were prepared welded and tested in accordance with the

requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Manufacturer or Contractor

Prepared By: Approved By: By: . Syed Salman Ali

Approved

Designation: Welding Engineer Designation: Incharge QA/QC

Signature: Signature:

NTROLLED, ONFIDENTIAL @ AJC Engineering (Pvt) Ltd. Page 1 Of 1

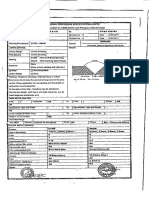

F O R M

WELDER / WELDING OPERATOR PERFORMANCE

Doc. Level: V

QUALIFICATION (WPQ) Doc. Version: 01

Doc. No.: QAQC-FRM-12 w.e.f.: 01-01-2013

Welder's Name Muhammad Aslam S/O Ghulam Moheu Din Stamp No 1

Identification of WPS followed AJC - WPS- 01 Test Coupon Production Weld

Specification & type/grade or UNS Number of Base Material(s) SA 106 B Thickness 5.54 mm

Testing Conditions and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Welding Process (es) GTAW GTAW

Type (i.e.: Manual, Semi Automatic) used Manual Manual

Backing (with/without) Without With and Without

Plate Pipe (enter diameter if pipe or tube DN 50 25 mm to Unlimited

Base Metal P- or S-Number to P- or S-Number P No.1 P No.1 ~ 15F

Filler Metal or Electrode Specification(s) (SFA) (info. only) 5.18

Filler Metal or Electrode Classification(s) (info. only) ER 70-S3

Filler Metal F-Number(s) 6 All F No.6

Consumable insert (GTAW or PAW) Without Without

Filler Metal Product Form (Solid/metal or Flux cored/powder) (GTAW or PAW) Solid (Bare) Wire Solid (Bare) Wire

Deposit thickness for each process

Process 1 GTAW 3 Layers minimum Yes No 5.54 mm 11 mm

Process 2 3 Layers minimum Yes No

Position Qualified (2G, 6G, 3F etc.) 6G All

Vertical Progression (uphill / downhill) Uphill Uphill

Type of Fuel Gas for OFW - -

Inert Gas Backing (GTAW, PAW, GMAW) - -

Transfer Mode (Spray/Globular or Pulse to Short Circuit-GMAW) - -

GTAW Current type /polarity (AC, DCEP, DCEN) DCEN DCEN

Results

Visual Examination of completed weld (QW-302.4) -

Transverse face and root bends (QW-462.3(a)) Longitudinal bends (QW-462.3(b)) Side bends (QW-462.2)

Pipe bend specimen, corrosion-resistant weld metal overlay (QW-462.5(c))

Plate bend specimen, corrosion-resistant weld metal overlay (QW-462.5(d))

Pipe specimen, macro test for fusion (QW-462.5(b)) Plate specimen, macro test for fusion (QW-462.5(e))

Type Result Type Result Type Result

Alternative Radiographic Examination Results (QW-191) Radiography Test (Report No. 02)

Fillet Weld - Fracture Test (QW-181.2) - Length & Percent of Defects -

Fillet Welds in Plate (QW-462.4(b)) Fillet Welds in Pipe (QW-462.4(c))

Macro Examination (QW-184) - Fillet Size(in) - x - Concavity/Convexity (in.) -

Other Tests

Film or specimens evaluated by Muhammad Azhar Company Inspectest (Pvt.) Ltd.

Mechanical Tests Conducted by PCSIR Laboratory Test No.

Welding Supervised by

We certify that the statements in this record are correct and that the test coupons were prepared welded and tested in accordance with the

requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Manufacturer or Contractor

Prepared By: Approved By: By: . Syed Salman Ali

Approved

Designation: Welding Engineer Designation: Incharge QA/QC

Signature: Signature:

NTROLLED, ONFIDENTIAL @ AJC Engineering (Pvt) Ltd. Page 1 Of 1

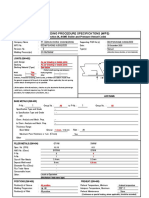

F O R M

WELDER / WELDING OPERATOR PERFORMANCE

Doc. Level: V

QUALIFICATION (WPQ) Doc. Version: 01

Doc. No.: QAQC-FRM-12 w.e.f.: 01-01-2013

Welder's Name Imran Ali S/O Abdul Rasheed Stamp No 1

Identification of WPS followed AJC - WPS- 01 Test Coupon Production Weld

Specification & type/grade or UNS Number of Base Material(s) SA-516 Gr. 70 Thickness 16 mm

Testing Conditions and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Welding Process (es) GTAW + SMAW GTAW + SMAW

Type (i.e.: Manual, Semi Automatic) used Manual Manual

Backing (with/without) Without With With and without With

Plate Pipe (enter diameter if pipe or tube Plate 16 mm *

Base Metal P- or S-Number to P- or S-Number P No.1 P No.1 ~ 15F

Filler Metal or Electrode Specification(s) (SFA) (info. only)

Filler Metal or Electrode Classification(s) (info. only) ER 70S-3 E7018

Filler Metal F-Number(s) 6 4 All F No.6 4,3.2.1

Consumable insert (GTAW or PAW) Without Without

Filler Metal Product Form (Solid/metal or Flux cored/powder) (GTAW or PAW) Solid (Bare) Wire Solid (Bare) Wire

Deposit thickness for each process

Process 1 GTAW 3 Layers minimum Yes No 5 mm 10 mm

Process 2 SMAW 3 Layers minimum Yes No 11 mm 22 mm

Position Qualified (2G, 6G, 3F etc.) 3G *

Vertical Progression (uphill / downhill) Uphill Uphill

Type of Fuel Gas for OFW - -

Inert Gas Backing (GTAW, PAW, GMAW) - -

Transfer Mode (Spray/Globular or Pulse to Short Circuit-GMAW) - -

GTAW Current type /polarity (AC, DCEP, DCEN) DCEN DCEN

* Plate and Pipe over 610 mm OD (F.V) , 73 mm OD Pipe 610 mm OD (F) , Fillet for Pipe and Plate (F,H,V)

Results

Visual Examination of completed weld (QW-302.4) -

Transverse face and root bends (QW-462.3(a)) Longitudinal bends (QW-462.3(b)) Side bends (QW-462.2)

Pipe bend specimen, corrosion-resistant weld metal overlay (QW-462.5(c))

Plate bend specimen, corrosion-resistant weld metal overlay (QW-462.5(d))

Pipe specimen, macro test for fusion (QW-462.5(b)) Plate specimen, macro test for fusion (QW-462.5(e))

Type Result Type Result Type Result

Tensile Test Satisfactory Side Bends OK

Alternative Radiographic Examination Results (QW-191) Radiography Test (Report No. AJC01)

Fillet Weld - Fracture Test (QW-181.2) - Length & Percent of Defects -

Fillet Welds in Plate (QW-462.4(b)) Fillet Welds in Pipe (QW-462.4(c))

Macro Examination (QW-184) - Fillet Size(in) - x - Concavity/Convexity (in.) -

Other Tests

Film or specimens evaluated by Company Jiacco Pakistan

Mechanical Tests Conducted by PCSIR Laboratory Test No. PITMAEN/SA/11379~84-02/13

Welding Supervised by

We certify that the statements in this record are correct and that the test coupons were prepared welded and tested in accordance with the

requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Manufacturer or Contractor

Prepared By: Approved By: By: . Syed Salman Ali

Approved

Designation: Welding Engineer Designation: Incharge QA/QC

Signature: Signature:

NTROLLED, ONFIDENTIAL @ AJC Engineering (Pvt) Ltd. Page 1 Of 1

You might also like

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- Toshiba Brazing Procedure SpecificationDocument3 pagesToshiba Brazing Procedure Specificationsheikmoin100% (1)

- WQT Record for Pipeline Welder QualificationDocument99 pagesWQT Record for Pipeline Welder QualificationVivek Jadhav100% (1)

- PT. VISTA BANGUN UTAMA Welder QualificationDocument1 pagePT. VISTA BANGUN UTAMA Welder QualificationHaryanto RNo ratings yet

- PT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTDocument4 pagesPT. ZUG INDUSTRY WELDING QUALIFICATION DOCUMENTMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Welder Qualification Test Certificate for Mohan ReddyDocument2 pagesWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- WPS - 024Document4 pagesWPS - 024MAT-LIONNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 pagesWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Document2 pagesWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS MS 01C Rev. 0Document1 pageWPS MS 01C Rev. 0alinor_tnNo ratings yet

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocument3 pagesSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013No ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- PQR Is7307Document1 pagePQR Is7307Tridib Dey100% (1)

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 pageWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Welder Performance Qualification (WPQ) According To ASME IX Hassan HussienDocument1 pageWelder Performance Qualification (WPQ) According To ASME IX Hassan HussienMahmoud shawkyNo ratings yet

- Lethal Service Quick GuideDocument5 pagesLethal Service Quick GuideMuhammadShabbirNo ratings yet

- Introduction To Shell and Tube Heat Exchangers PDFDocument33 pagesIntroduction To Shell and Tube Heat Exchangers PDFJoeJeanNo ratings yet

- EU Directive on Transportable Pressure EquipmentDocument18 pagesEU Directive on Transportable Pressure EquipmentliaraaNo ratings yet

- Regulation (Ec) No 765-2008 of The European Parliament and of The CouncilDocument18 pagesRegulation (Ec) No 765-2008 of The European Parliament and of The CouncilAli ÖzgençNo ratings yet

- Checklist For Welding and NDE SectionDocument2 pagesChecklist For Welding and NDE SectionMuhammadShabbirNo ratings yet

- Interpretation Detail: Consent of ASMEDocument1 pageInterpretation Detail: Consent of ASMEMuhammadShabbirNo ratings yet

- Hydrostatic Test ReportDocument1 pageHydrostatic Test ReportMuhammadShabbirNo ratings yet

- Shell-And-Tube Heat Exchangers: Standard Series and Customer Oriented SolutionsDocument24 pagesShell-And-Tube Heat Exchangers: Standard Series and Customer Oriented SolutionsZewdu TsegayeNo ratings yet

- RT Film IntepretationDocument44 pagesRT Film Intepretationawong_911374100% (3)

- List of NOBODocument232 pagesList of NOBOMuhammadShabbirNo ratings yet

- Types of Mill Test CertificateDocument2 pagesTypes of Mill Test CertificateMuhammadShabbirNo ratings yet

- Oj C 2016 272 Full en TXTDocument156 pagesOj C 2016 272 Full en TXTpluto14No ratings yet

- Interpretation Detail: Consent of ASMEDocument1 pageInterpretation Detail: Consent of ASMEMuhammadShabbirNo ratings yet

- Guidelines for Applying Pressure Equipment DirectiveDocument263 pagesGuidelines for Applying Pressure Equipment DirectiveAdrian CeplinschiNo ratings yet

- Form R-2 Report of Alteration: in Accordance With Provisions of The National Board Inspection CodeDocument2 pagesForm R-2 Report of Alteration: in Accordance With Provisions of The National Board Inspection CodeMuhammadShabbirNo ratings yet

- Repair Before Signing MDR PDFDocument1 pageRepair Before Signing MDR PDFMuhammadShabbirNo ratings yet

- R 1form - NB 66Document2 pagesR 1form - NB 66MuhammadShabbirNo ratings yet

- Repair of Boiler Before Final StampingDocument1 pageRepair of Boiler Before Final StampingMuhammadShabbirNo ratings yet

- MANUFACTURER DATA REPORT REGISTRATION CHECKLISTDocument1 pageMANUFACTURER DATA REPORT REGISTRATION CHECKLISTMuhammadShabbirNo ratings yet

- Floating Tubesheet U-2 (G) CalculationsDocument1 pageFloating Tubesheet U-2 (G) CalculationsMuhammadShabbirNo ratings yet

- LED module declaration of conformityDocument3 pagesLED module declaration of conformityMuhammadShabbirNo ratings yet

- Government of Azad State of Jammu & KashmirDocument10 pagesGovernment of Azad State of Jammu & KashmirtrixcompNo ratings yet

- AS/A Level Mathematics The Equation of A Circle: Mathsgenie - Co.ukDocument3 pagesAS/A Level Mathematics The Equation of A Circle: Mathsgenie - Co.ukMuhammadShabbirNo ratings yet

- Hydrogen SulfideDocument4 pagesHydrogen Sulfideابومحمد نايفNo ratings yet

- A Case Study of A 193 Grade b7 Used As A Teaching Tool 01Document5 pagesA Case Study of A 193 Grade b7 Used As A Teaching Tool 01MuhammadShabbirNo ratings yet

- Pair of Lines & CirclesDocument5 pagesPair of Lines & CirclesMuhammadShabbirNo ratings yet

- 17915Document11 pages17915chowhkNo ratings yet

- Circles - Past Edexcel Exam Questions: C Studywell Publications Ltd. 2015Document12 pagesCircles - Past Edexcel Exam Questions: C Studywell Publications Ltd. 2015Chai Min HiungNo ratings yet

- Math CirclesDocument12 pagesMath CirclesAlbert ArominNo ratings yet

- Probs11 2ansDocument3 pagesProbs11 2ansMaydenNo ratings yet

- ALGINATE ProductionDocument14 pagesALGINATE ProductionMarnel Roy MayorNo ratings yet

- Toyo CatalogDocument196 pagesToyo CatalogAnand SinghNo ratings yet

- Precast Guide SpecDocument25 pagesPrecast Guide SpecpabulumzengNo ratings yet

- Bagging ScaleDocument2 pagesBagging ScaleAli HusseiniNo ratings yet

- Ge Inlet Air CoolingDocument4 pagesGe Inlet Air Coolinggeorge gabriel100% (1)

- Turbomachinery For Ammonia Plants: Man TurboDocument20 pagesTurbomachinery For Ammonia Plants: Man TurboavwnashNo ratings yet

- AgailDocument34 pagesAgailnarasakuru79No ratings yet

- Configure MSS (WDA) Settings in SAP NetWeaver BCDocument6 pagesConfigure MSS (WDA) Settings in SAP NetWeaver BCThandile FikeniNo ratings yet

- VOITH MultiformvDocument3 pagesVOITH MultiformvKristina ivanovicNo ratings yet

- Licence Fees For Satellite Services, Networks and Terminals in The Cept October 2001Document64 pagesLicence Fees For Satellite Services, Networks and Terminals in The Cept October 2001Anonymous 3Vgw3v2ZcHNo ratings yet

- Brochure - FTTH Drop Cabinet For 48f & 96f Customer ConnectionsDocument8 pagesBrochure - FTTH Drop Cabinet For 48f & 96f Customer ConnectionskmalNo ratings yet

- My Updated CVDocument5 pagesMy Updated CVSaleem UddinNo ratings yet

- CAT992Document24 pagesCAT992Miriam Ruiz Cabellos100% (1)

- Renewable and Sustainable Energy Reviews: Thomas Poulsen, Rasmus LemaDocument14 pagesRenewable and Sustainable Energy Reviews: Thomas Poulsen, Rasmus LemaRosHan AwanNo ratings yet

- Gyrolok CatalogDocument58 pagesGyrolok CatalogmartinvandoornNo ratings yet

- DB Cylinder Pressure Sensor enDocument2 pagesDB Cylinder Pressure Sensor enjulien17No ratings yet

- METHOD STATEMENT PRESSURE SWITCH UAE Univ.Document2 pagesMETHOD STATEMENT PRESSURE SWITCH UAE Univ.Muhamed RasheedNo ratings yet

- KrisEnergy LTD - Appendix D - Volume2Document194 pagesKrisEnergy LTD - Appendix D - Volume2Invest StockNo ratings yet

- Flipkart's Big Billion Day Sale IT FailuresDocument21 pagesFlipkart's Big Billion Day Sale IT FailuresManisha KumariNo ratings yet

- ATFMDocument4 pagesATFMYuranan LimpananvadeeNo ratings yet

- DrivenDocument20 pagesDrivenAlexandre BanquetNo ratings yet

- 1 Databases and Database Management SystemsDocument83 pages1 Databases and Database Management SystemsUday KumarNo ratings yet

- BrochureDocument7 pagesBrochureapi-239505062No ratings yet

- SMART BRO Data Pro Plans App FormDocument2 pagesSMART BRO Data Pro Plans App FormCatherine TominNo ratings yet

- Formulation ERS 1011 040114 PomadeDocument2 pagesFormulation ERS 1011 040114 PomadeAndina NataliaNo ratings yet

- International GTA220Document1 pageInternational GTA220Anwar MdNo ratings yet

- FlowVision English BRochureDocument2 pagesFlowVision English BRochureSanthosh LingappaNo ratings yet

- How Cathay Pacific Leveraged IT to Support Business GrowthDocument2 pagesHow Cathay Pacific Leveraged IT to Support Business Growthranjeeeth8569100% (1)

- Remedial Examination in EmtechDocument2 pagesRemedial Examination in EmtechJessuel Larn-epsNo ratings yet

- RISK ASESSMENT For SKYLIGHTDocument23 pagesRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)