Professional Documents

Culture Documents

Construction Tool Safety Checklist Rev

Uploaded by

east75%(4)75% found this document useful (4 votes)

3K views2 pagesCTSC

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCTSC

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

75%(4)75% found this document useful (4 votes)

3K views2 pagesConstruction Tool Safety Checklist Rev

Uploaded by

eastCTSC

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

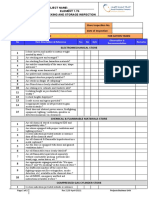

Construction Tool and Equipment Safety Checklist

Job Name __________________________________ Job Number _____________

1. Inspection Items: Material Handling and Storage Yes No N/A

1. Manual material handling Equipment in good condition?

2. Powered material handling Equipment in good condition?

3. Wheel chocks and restraint devices available and functioning properly for

Vehicles?

2. Inspection Items: Hand and Portable Tools General Yes No N/A

4. Proper tools or equipment used for the job, clean and in good condition?

5. Employees trained in tool use, how to inspect and when to remove from use?

6. All tools checked daily and damaged or unsafe tool removed from service?

3. Inspection Items: Hand Tools Yes No N/A

7. Correct tools provided and in use, for each operation?

8. Hand tools in good condition?

9. Tool handles in good condition, no splits or cracks and wedged tight to tool?

10. No mushroomed heads on impact tools, hammers or chisels?

11. Tools stored in dry, secure place to avoid damage and tampering?

4. Inspection Items: Power Actuated Tools (PATs) Yes No N/A

12. PATs in good condition?

13. PAT inspected and cleaned as required? Tool always attended?

14. PAT used by trained and valid operator card users?

15. PAT containers lockable, labeled, with manual, load chart and service

record?

16. PAT loaded only when ready for use and unloaded when work interrupted?

17. PAT operating requirements known and followed by workers? Signs posted?

5. Inspection Items: Portable Electric Tools Yes No N/A

18. Correct tools provided and in use, for each operation?

19. Power tools in good condition?

20. Operational switches functioning properly?

21. Constant contact switches on drills, sanders, grinders, saws, etc. as required?

22. Warning labels or markings showing hazardous areas intact?

23. Power tools double insulated or properly grounded?

24. GFCI or assured grounding program in place when using temporary power?

25. Electrical cords in good condition, no cuts, no tape and ground pin in place?

26. Power tools kept away from wet locations?

27. Power tools not lifted or lowered by electrical cord?

28. Tools stored in dry, secure place to avoid damage and tampering?

29. Circular saws guarded and no tie back or wedging open of the guard?

30. Blades and cutting edges sharp to prevent binding or skipping?

6. Inspection Items: Portable Equipment Yes No N/A

31. Portable Equipment is in safe operating condition?

Reprinted with Permission of Industrial Productions and Safety Solutions+ (Bob Nolan)

2009,

32. Operational switches functioning properly?

33. Guards are in place, properly adjusted and in good condition for all moving

parts and drives?

34. Operators properly attired (no loose clothing or jewelry)?

35. Point of operation safeguarding provided and functioning properly?

36. Portable equipment in good condition?

37. Jackhammer operator wearing foot, eye and hearing protection?

38. Laser equipment used by qualified person with eye protection/warning signs?

39. Are welding and cutting equipment used by qualified person with welding

personal protective equipment and warning signs?

40. Pneumatic nailers/staplers equipped with muzzle safety and securing die

clips?

41. Air supply disconnected when tool not in use?

42. Portable Equipment stored in dry, secure place to avoid damage and

tampering?

6. Inspection Items: Maintenance Yes No N/A

43. Proper tools provided for cleanup and adjustments?

44. Tools unplugged prior to adjustment, tool changes, and maintenance?

45. All machinery on a scheduled maintenance program (lubrication, belts,

servicing, etc.) and records are kept.?

7. Inspection Items: Personal Protective Equipment (PPE) Yes No N/A

46. Safety glasses/face shields used when grinding, chipping, sawing, etc.?

47. Gloves worn as needed to prevent vibration and lacerations using tools?

48. Hearing protectors worn when using noisy tools?

49. Respiratory protection worn to protect against airborne hazards?

50. Appropriate footwear used?

51. PPE stored in dry, secure place to avoid damage and tampering?

Item # Corrective Action Date Comp.

Inspected by_________________________________________ Date __________________

For a more complete set of requirements for Tools used in Construction related-businesses, consult

the Pocket Guide for the Construction Industry at

www.dir.ca.gov/dosh/dosh_publications/htmlconst/Tools.htm.

And for a more complete listing of Tools used in Fixed Location and Construction related-

businesses, consult the Workplace Injury and Illness Prevention Model for High Hazard

Employers at www.dir.ca.gov/dosh/dosh_publications/iiphihzemp.pdf, pgs. 7-23

Reprinted with Permission of Industrial Productions and Safety Solutions+ (Bob Nolan)

2009,

You might also like

- Hand and Power Tools ChecklistDocument2 pagesHand and Power Tools Checklistmonica zetrocNo ratings yet

- Field Services Jobsite Safety ChecklistDocument4 pagesField Services Jobsite Safety ChecklistAdhyartha Keraf100% (1)

- Safety checklist for power toolsDocument5 pagesSafety checklist for power toolsLouieGonzales100% (1)

- Scaffolding safety checklistDocument2 pagesScaffolding safety checklistpalanitharan100% (1)

- Ladder Inspection ChecklistDocument1 pageLadder Inspection Checklistnib100% (1)

- Check List (Pre Entry) For Portable Grinding MachineDocument4 pagesCheck List (Pre Entry) For Portable Grinding Machinealvhyan anandolaki100% (1)

- Rammer/ Jumping Jack Compactor Inspection Checklist: Parameters Acceptable Yes/No RemarksDocument1 pageRammer/ Jumping Jack Compactor Inspection Checklist: Parameters Acceptable Yes/No RemarksJohn75% (4)

- 04 HSE Inspection ChecklistDocument2 pages04 HSE Inspection ChecklistAjay Hazarika100% (2)

- Safety Inspection Checklist Hand Tools PDFDocument1 pageSafety Inspection Checklist Hand Tools PDFHtun Soe100% (5)

- Inspection Checklist For Lifting Tools & TacklesDocument2 pagesInspection Checklist For Lifting Tools & Tacklesnil thaeu100% (1)

- Checklist For Scaffolding: Project: SL# Description Observation Yes/No/ NA Remarks & RecommendationsDocument4 pagesChecklist For Scaffolding: Project: SL# Description Observation Yes/No/ NA Remarks & RecommendationsDeshbandhu Aman PandeyNo ratings yet

- Portable Power Tools Inspection ChecklistDocument2 pagesPortable Power Tools Inspection ChecklistSreekumar88% (24)

- Construction Housekeeping Checklist v1Document1 pageConstruction Housekeeping Checklist v1Jhon Paul Gervacio100% (1)

- FNPDC Project, Yanbu, KSA Daily HSE Preparedness Checklist: Coverage Area: Date: Brief Description of ActivitiesDocument2 pagesFNPDC Project, Yanbu, KSA Daily HSE Preparedness Checklist: Coverage Area: Date: Brief Description of ActivitiesAhmad BilalNo ratings yet

- 022 - HSSE - Full Body Harness Inspection ChecklistDocument1 page022 - HSSE - Full Body Harness Inspection ChecklistShashwat PandeyNo ratings yet

- 8.11. CR 29.H. Firefighting Equipment InspectorDocument3 pages8.11. CR 29.H. Firefighting Equipment InspectorGasa Security100% (2)

- Risk Assessment For Weigh Bridge.Document1 pageRisk Assessment For Weigh Bridge.erkarthik8550% (4)

- Excavation PermitDocument2 pagesExcavation PermitRajesh Kumar SinghNo ratings yet

- Checklist For Safety Harness InspectionDocument1 pageChecklist For Safety Harness InspectionBenny de SouzaNo ratings yet

- Scaffold Inspection ChecklistDocument1 pageScaffold Inspection ChecklistAlves Edattukaran100% (4)

- Hand Tool Ergonomic ChecklistDocument1 pageHand Tool Ergonomic Checklistsivasri999No ratings yet

- GC 3 Oberservation SheetDocument4 pagesGC 3 Oberservation SheetIrshad Ali Solangi33% (3)

- Checklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleDocument1 pageChecklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleMarisabel Maidana100% (2)

- Electrical Hazards Inspection ChecklistDocument1 pageElectrical Hazards Inspection ChecklistMuhammad Ali Raza100% (1)

- JSA of Drill Machine UseDocument1 pageJSA of Drill Machine UseSumair Khalid100% (1)

- Bar Cutting Machine HSE ChecklistDocument2 pagesBar Cutting Machine HSE ChecklistMD Abdullah100% (1)

- Checklist For Equipment Inspection EARTH COMPACTOR (ROLLER)Document1 pageChecklist For Equipment Inspection EARTH COMPACTOR (ROLLER)kami abdul0% (2)

- L6.17 Mobile Welding Machine Inspection ChecklistDocument2 pagesL6.17 Mobile Welding Machine Inspection Checklistom prakash100% (4)

- Weekly Safety Report (15-19 Aug)Document6 pagesWeekly Safety Report (15-19 Aug)Mohd Zulhafizi100% (1)

- Roller Compactor Monthly ChecklistDocument2 pagesRoller Compactor Monthly ChecklistDAOUMY YOUNESSNo ratings yet

- Safety Violation Form PDFDocument1 pageSafety Violation Form PDFmool raj0% (1)

- Job Safety InstallationDocument3 pagesJob Safety InstallationSawLaiBoyanNo ratings yet

- Safety Harness Inspection ChecklistDocument1 pageSafety Harness Inspection Checklistshaheer100% (7)

- Trowel Concrete Machine Pre-Use Inspection Checklist: ProjectDocument2 pagesTrowel Concrete Machine Pre-Use Inspection Checklist: ProjectImam Ali100% (1)

- Check List For Asphalt CutterDocument1 pageCheck List For Asphalt Cutterchassas100% (2)

- Old Cables, Conduits and Cable Trays Dismantling - JSEA FormDocument40 pagesOld Cables, Conduits and Cable Trays Dismantling - JSEA FormJayson Escamillan100% (2)

- Job Hazard AnalysisDocument10 pagesJob Hazard AnalysisDave ImpresoNo ratings yet

- Housekeeping Checklist For Contractors: Walking-Working Surfaces General Work EnvironmentDocument4 pagesHousekeeping Checklist For Contractors: Walking-Working Surfaces General Work Environmentcynthia100% (1)

- Angle Grinder Check ListDocument2 pagesAngle Grinder Check ListEdhz Bilog100% (11)

- Personal Protective Equipment (Ppe) Inspection Checklist: Safety HelmetDocument1 pagePersonal Protective Equipment (Ppe) Inspection Checklist: Safety Helmetvini100% (1)

- Safety Check List For Night WorksDocument2 pagesSafety Check List For Night Worksvarunstuff100% (1)

- 1.7b Stacking - Storage Inspection ChecklistDocument2 pages1.7b Stacking - Storage Inspection ChecklistShafie Zubier75% (8)

- Checklist For Equipment Inspection TRANSIT MIXERDocument1 pageChecklist For Equipment Inspection TRANSIT MIXERstansilous100% (1)

- Construction Site Housekeeping ChecklistDocument3 pagesConstruction Site Housekeeping ChecklistMuhammad Zarul Aziri Bin MaamurNo ratings yet

- Electrical Hazards Inspection ChecklistDocument1 pageElectrical Hazards Inspection ChecklistMuhammad Ali Raza100% (1)

- Electrical safety checklistDocument2 pagesElectrical safety checklistnarayana_1430% (1)

- 03 Safety Harness Inspection SheetDocument4 pages03 Safety Harness Inspection Sheetxiangjintao100% (1)

- # 11 WORKING AT HEIGHT ChecklistDocument2 pages# 11 WORKING AT HEIGHT ChecklistDinesh KanukolluNo ratings yet

- HS014 - Portable Electrical Equipment InspectorDocument1 pageHS014 - Portable Electrical Equipment InspectorRetselisitsoe100% (3)

- CHECKLIST - Fire Equipment Inspection - Hose ReelsDocument1 pageCHECKLIST - Fire Equipment Inspection - Hose Reelsle papi100% (1)

- Asphalt Cutter ChecklistDocument1 pageAsphalt Cutter ChecklistDhanu Nikku100% (5)

- Workplace Inspection Checklist For Construction Works - KenyaDocument20 pagesWorkplace Inspection Checklist For Construction Works - KenyaWinstone Audi100% (1)

- Construction Safety ChecklistDocument2 pagesConstruction Safety Checklistwirnos100% (1)

- Daily Safety Inspection ChecklistDocument1 pageDaily Safety Inspection ChecklistNizam lotfi100% (1)

- 13 Checklist For Hammering Drill MachineDocument1 page13 Checklist For Hammering Drill Machinexiangjintao88% (8)

- Equipment Inspection ChecklistDocument2 pagesEquipment Inspection ChecklistHung Hoang100% (1)

- HSE Violation & PenaltiesDocument5 pagesHSE Violation & PenaltiesVladimir Radovanovic100% (1)

- Grinder Checklist2Document3 pagesGrinder Checklist2jovyNo ratings yet

- Portable Power Tool Safety ChecklistDocument3 pagesPortable Power Tool Safety ChecklistBishop Ojonuguwa AmehNo ratings yet

- Machine Guarding Checklist: Questions Requirements For All SafeguardsDocument2 pagesMachine Guarding Checklist: Questions Requirements For All SafeguardsAVENON MardocheeNo ratings yet

- Water Conservation Tips for Construction SitesDocument1 pageWater Conservation Tips for Construction SiteseastNo ratings yet

- Fresh Graduate ResumeDocument2 pagesFresh Graduate ResumeKapil Rathi60% (5)

- Global Harmonization System - The Pictogram: What Are Pictograms?Document2 pagesGlobal Harmonization System - The Pictogram: What Are Pictograms?eastNo ratings yet

- What Are The Labeling Requirements?: Global Harmonization System - LabelingDocument2 pagesWhat Are The Labeling Requirements?: Global Harmonization System - LabelingeastNo ratings yet

- PPE Hazard Assessment FormDocument3 pagesPPE Hazard Assessment FormeastNo ratings yet

- Team Building PDFDocument91 pagesTeam Building PDFeastNo ratings yet

- 1 CSBDocument51 pages1 CSBeastNo ratings yet

- April: Why Safety Belts?Document1 pageApril: Why Safety Belts?eastNo ratings yet

- 01backing CircleofSafetyDocument2 pages01backing CircleofSafetyeastNo ratings yet

- SB 1317 Strenghtening OSHS ComplianceDocument14 pagesSB 1317 Strenghtening OSHS ComplianceAllen de Guzman100% (1)

- INTRERVIEW QUESInstrumentationDocument14 pagesINTRERVIEW QUESInstrumentationNogeshwar Kumar DewanganNo ratings yet

- Crowcon Detective Transportable Gas MonitorDocument5 pagesCrowcon Detective Transportable Gas MonitoreastNo ratings yet

- Health and Safety Improvement PlanDocument3 pagesHealth and Safety Improvement Planeast100% (2)

- HSW Book Sample3032011513232132012581114 PDFDocument6 pagesHSW Book Sample3032011513232132012581114 PDFeast100% (1)

- JSA For Demobilization WorksDocument2 pagesJSA For Demobilization WorksIanne Dee85% (13)

- BASF - Job Vacancy Ad - EHS OfficerDocument1 pageBASF - Job Vacancy Ad - EHS OfficereastNo ratings yet

- JHA PaintingDocument12 pagesJHA Paintingeast100% (1)

- Personal Fall Protection SystemsDocument44 pagesPersonal Fall Protection SystemseastNo ratings yet

- 06 Hot Work PermitDocument1 page06 Hot Work PermiteastNo ratings yet

- Air Heater Performance: May 24, 2012 PMI Revision 00 1Document20 pagesAir Heater Performance: May 24, 2012 PMI Revision 00 1junfaNo ratings yet

- Fall Protection Hierarchy and Restraint vs ArrestDocument1 pageFall Protection Hierarchy and Restraint vs ArresteastNo ratings yet

- Work at Height Rescue-Plan - AbbDocument29 pagesWork at Height Rescue-Plan - AbbeastNo ratings yet

- Ultra-High Pressure Water Jet Safety ReportDocument38 pagesUltra-High Pressure Water Jet Safety ReporteastNo ratings yet

- ElectricDocument42 pagesElectricAbd ZouhierNo ratings yet

- State Hazcom TestDocument2 pagesState Hazcom TesteastNo ratings yet

- Iso9001 2015webinar FinalDocument71 pagesIso9001 2015webinar FinalTakis RappasNo ratings yet

- A5 HBDocument32 pagesA5 HBKaliyamoorthy Samiayya100% (16)

- Tower Crane Test ReportDocument10 pagesTower Crane Test Reportguthale100% (2)

- Personal Fall Protection SystemsDocument44 pagesPersonal Fall Protection SystemseastNo ratings yet

- Safe Management of Health Care WasteDocument20 pagesSafe Management of Health Care WasteeastNo ratings yet

- Advantages of Using A Core Type Design Rather A Shell TypeDocument3 pagesAdvantages of Using A Core Type Design Rather A Shell TypeaocalayNo ratings yet

- Mixed Signal Electronics IntroductionDocument32 pagesMixed Signal Electronics IntroductionMuhammad Waqas AliNo ratings yet

- SPPC OperatorManual V100 EN 03 PDFDocument26 pagesSPPC OperatorManual V100 EN 03 PDFhaitan981No ratings yet

- Ns-Jsra: Risk Type: Risk TypeDocument6 pagesNs-Jsra: Risk Type: Risk TypeMarco MotaNo ratings yet

- Manual CX600 X8Document261 pagesManual CX600 X8volicon voliconNo ratings yet

- Denver Ac-5000w Mk2 - EnglishDocument2 pagesDenver Ac-5000w Mk2 - EnglishPrva CetaNo ratings yet

- Fire Protection System Mechanical ChecklistDocument3 pagesFire Protection System Mechanical ChecklistJon TyackeNo ratings yet

- Spartan - 6 Project Card: User ManualDocument81 pagesSpartan - 6 Project Card: User ManualunchalliNo ratings yet

- Sy365h 173644Document10 pagesSy365h 173644Riko ManurungNo ratings yet

- SD Exit Exm Tuto SoLDocument55 pagesSD Exit Exm Tuto SoLTadesse MegersaNo ratings yet

- Netpro Operation Manual 2k0 4k0 VaDocument20 pagesNetpro Operation Manual 2k0 4k0 VaDanny Dan100% (2)

- HD 110 / HD 110K: - Articulated Tandem Roller With Two Vibratory Drums - Articulated Combi Roller With Vibratory DrumDocument2 pagesHD 110 / HD 110K: - Articulated Tandem Roller With Two Vibratory Drums - Articulated Combi Roller With Vibratory DrumSanNo ratings yet

- Elec Grs Pumps 203seriesDocument5 pagesElec Grs Pumps 203serieschand_yelNo ratings yet

- John Deere 7720 Parts CatalogDocument20 pagesJohn Deere 7720 Parts Catalogalejandro100% (38)

- Saudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechDocument1 pageSaudi Aramco Inspection Checklist: Visual Inspection of Pneumatic Test SAIC-A-2021 25-May-05 MechphilipyapNo ratings yet

- PWC Data Security Report - HealthcareDocument12 pagesPWC Data Security Report - HealthcareWilliamBuckRogersNo ratings yet

- Kirloskar Technologies P. LTD.: Appraisal FormDocument4 pagesKirloskar Technologies P. LTD.: Appraisal Formdihudi.prasantaNo ratings yet

- CFD Bim PDFDocument8 pagesCFD Bim PDFCristina PaduanoNo ratings yet

- Looking at The Future of Manufacturing Metrology R PDFDocument7 pagesLooking at The Future of Manufacturing Metrology R PDFAdven BrilianNo ratings yet

- Apollo Saturn V Facility Description Vol. 3Document124 pagesApollo Saturn V Facility Description Vol. 3Bob Andrepont86% (7)

- 08 - Installation and Maintenance of Health IT Systems - Unit 9 - Creating Fault-Tolerant Systems, Backups, and Decommissioning - Lecture CDocument15 pages08 - Installation and Maintenance of Health IT Systems - Unit 9 - Creating Fault-Tolerant Systems, Backups, and Decommissioning - Lecture CHealth IT Workforce Curriculum - 2012No ratings yet

- A Power Line Communication Tutorial Challenges andDocument17 pagesA Power Line Communication Tutorial Challenges andzeeshanmianNo ratings yet

- G6 Final Transpo-ReportDocument9 pagesG6 Final Transpo-ReportCamille Andrea SequitinNo ratings yet

- Ooad4 5Document91 pagesOoad4 5B happyNo ratings yet

- Design of Engine Cylinder Block : M NareshDocument4 pagesDesign of Engine Cylinder Block : M NareshMudavath NareshNo ratings yet

- 【b】30240301001620 使用说明书 储能三相 sun (5 25) k sg01hp3 eu am2 德业英文Document54 pages【b】30240301001620 使用说明书 储能三相 sun (5 25) k sg01hp3 eu am2 德业英文nguyenvancuong12051999No ratings yet

- Lahan GATIBIDI 80 Asar Text Press FinalDocument89 pagesLahan GATIBIDI 80 Asar Text Press FinalRajan Kumar DahalNo ratings yet

- PT320AT02-2 Product Spec - Ver 1 0 - 20191128 - HKCDocument23 pagesPT320AT02-2 Product Spec - Ver 1 0 - 20191128 - HKCAbir Ahmed100% (7)

- BWT61 ManualDocument38 pagesBWT61 ManualDMaccNo ratings yet

- RX RVRDocument7 pagesRX RVRpcatruongNo ratings yet