Professional Documents

Culture Documents

ASME B31.3 Process Piping

Uploaded by

alvinchuan0 ratings0% found this document useful (0 votes)

406 views1 pagesample of ASME B31.3 process piping calculation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsample of ASME B31.3 process piping calculation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

406 views1 pageASME B31.3 Process Piping

Uploaded by

alvinchuansample of ASME B31.3 process piping calculation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

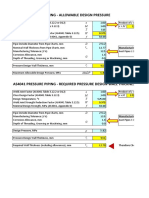

ASME B31.

3 PROCESS PIPING - ALLOWABLE DESIGN PRESSURE

Weld Joint Quality Factor (ASME B31.3 Table 302.3.4) Ej 1.00 Seamless ASTM A312 TP304

Coefficient Y (ASME B31.3 Table 304.1.1) Y 0.40

Design Temperature, C T 525 975F

Weld Joint Strength Reduction Factor (ASME B31.3 Cl. 302.3.5(e)) W 0.975

Material Allowable Stress, MPa (ASME B31.3 Table A-1M) S 82.68 12 ksi

Pipe Outside Diameter from Pipe Charts, mm D 273.2 10.75"

Nominal Wall Thickness from Pipe Charts, mm tm 12.77 Manufacturing Tolerances

Manufacturing Tolerance ( %) 12.5 Aust Pipes 10%; American Pipes 12.5%

Corrosion Allowance, mm 1.6

c

Depth of Threading, Grooving or Machining, mm 0.0

Pressure Design Thickness, mm t 9.59

Maximum Allowable Internal Design Gauge Pressure, MPa MADP 5.82

ASME B31.3 PROCESS PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESS

Weld Joint Quality Factor (ASME B31.3 Table 302.3.4) Ej 1.00 Seamless ASTM A312 TP304

Coefficient Y (ASME B31.3 Table 304.1.1) Y 0.40

Design Temperature, C T 525 975F

Weld Joint Strength Reduction Factor (ASME B31.3 Cl. 302.3.5(e)) W 0.975

Material Allowable Stress, MPa (ASME B31.3 Table A-1M) S 82.68 12 ksi

Pipe Outside Diameter from Pipe Charts, mm D 273.2 10.75"

Manufacturing Tolerance ( %) 12.5 Manufacturing Tolerances

Corrosion Allowance, mm 1.6 Aust Pipes 10%; American Pipes 12.5%

G

Depth of Threading, Grooving or Machining, mm 0.0

Design Pressure, MPa P 5.82 845 psi

Pressure Design Thickness, mm t 9.58 0.377 inches

Minimum Required Thickness (including allowances), mm tm 12.77 0.502 inches

Therefore Choose DN250 S/S pipe will a nominal thickness > 12.77 mm

You might also like

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- B31.3 - Reinf Pad CalculationDocument2 pagesB31.3 - Reinf Pad CalculationasafhoxlNo ratings yet

- Design Calculation of Recycle Oil Injection Insert (Sheet-37)Document30 pagesDesign Calculation of Recycle Oil Injection Insert (Sheet-37)hgagselim2012No ratings yet

- Weight CalculatorDocument2 pagesWeight CalculatorenjoygurujiNo ratings yet

- Sight Glass Selection Guide PDFDocument7 pagesSight Glass Selection Guide PDFani_datNo ratings yet

- Calculation BS 31.3Document1 pageCalculation BS 31.3prabhjot123No ratings yet

- Calc Hoop StressDocument11 pagesCalc Hoop StressApril Trevino100% (1)

- Values of and For Same Comon Materials Have Been Given in Table 13.1Document1 pageValues of and For Same Comon Materials Have Been Given in Table 13.1Trishul Nath PallayNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Calculation of PipeReinforcement ASMEB31 1Document4 pagesCalculation of PipeReinforcement ASMEB31 1threedlabsNo ratings yet

- ASTM A53 Vs A500 EquivalenceDocument6 pagesASTM A53 Vs A500 Equivalenceemmanuilmoulos6339No ratings yet

- Area Reinforcement CalculatorDocument5 pagesArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Vacuum Catch PotDocument1 pageVacuum Catch Potsushant_jhawerNo ratings yet

- Applicability of Caesar II For Stress Analysis of Lines Having DT Ratio More Than 100 PDFDocument2 pagesApplicability of Caesar II For Stress Analysis of Lines Having DT Ratio More Than 100 PDFBogdan ChivulescuNo ratings yet

- ASME VIII Calc - Shell - HeadsDocument4 pagesASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- Max Allowable Pressure of Pipes and Pipellines CER 04022013Document89 pagesMax Allowable Pressure of Pipes and Pipellines CER 04022013Castro Quinteros WinstonNo ratings yet

- Wall Thickness Calculations As Per ASME B31 3 PDFDocument2 pagesWall Thickness Calculations As Per ASME B31 3 PDFAnonymous cyKuQKNo ratings yet

- Kuan 2009 AppendixDocument14 pagesKuan 2009 AppendixMohammed EljammalNo ratings yet

- Shree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetDocument1 pageShree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetSalman KhanNo ratings yet

- Pressure Drop Calculation - 6 Inch Permeate and Reject PumpDocument2 pagesPressure Drop Calculation - 6 Inch Permeate and Reject Pumpalmandhari33No ratings yet

- 4DMechanical VesselDocument26 pages4DMechanical VesselBowo Edhi WibowoNo ratings yet

- Pipe Wall Thickness Calculation @MechEngineersDocument77 pagesPipe Wall Thickness Calculation @MechEngineersHeri KurniawanNo ratings yet

- SR Piping Designer/checkerDocument4 pagesSR Piping Designer/checkerapi-78715367No ratings yet

- Reference:: Anchor ChairDocument4 pagesReference:: Anchor ChairShaheed HossainNo ratings yet

- Asme b31 3 03 PDFDocument3 pagesAsme b31 3 03 PDFAtallah BoufatahNo ratings yet

- Sif B31 3Document10 pagesSif B31 3Sergio SmithNo ratings yet

- BOQ-ValvesDocument4 pagesBOQ-ValvesGourav SharmaNo ratings yet

- Xtra Strong (XS) Size Steel Pipe Weights TAble CalculatorDocument1 pageXtra Strong (XS) Size Steel Pipe Weights TAble CalculatorshownpuNo ratings yet

- Seismic Calculation IS 1893 - RSMDocument3 pagesSeismic Calculation IS 1893 - RSMshazanNo ratings yet

- Cone Calculation PDFDocument4 pagesCone Calculation PDFanil4u29100% (1)

- Lecture 01 Introduction To ProgrammingDocument41 pagesLecture 01 Introduction To ProgrammingRehan Nazam MinhasNo ratings yet

- Top Pipe MomentDocument2 pagesTop Pipe MomentrsubramaniNo ratings yet

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- New Storage Tanks Design GuidelinesDocument6 pagesNew Storage Tanks Design GuidelinespaaryNo ratings yet

- Data Sheet For Silencer PDFDocument3 pagesData Sheet For Silencer PDFAlvin Smith0% (1)

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocument3 pagesDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document4 pagesCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraNo ratings yet

- Bends (Elbows) (ASME B31.3-2012 Para. 304.2.1) : Design ConditionsDocument1 pageBends (Elbows) (ASME B31.3-2012 Para. 304.2.1) : Design ConditionsabhisheknharanghatNo ratings yet

- Pipe Thickness Calculation Data SheetDocument1 pagePipe Thickness Calculation Data SheetAnonymous 6ZWS6IG2J9No ratings yet

- WEP Standard For Reference OnlyDocument37 pagesWEP Standard For Reference OnlyKiran NikateNo ratings yet

- Nozzle Evaluation Sheet: Xxofxx C17058 XXXXXXXX FPSO Carioca MV30Document1 pageNozzle Evaluation Sheet: Xxofxx C17058 XXXXXXXX FPSO Carioca MV30J A S JASNo ratings yet

- Pressure Vessel Calculations ASME SectioDocument11 pagesPressure Vessel Calculations ASME Sectioivan chirinosNo ratings yet

- Pipeline Size CalculationDocument6 pagesPipeline Size CalculationharyjbiNo ratings yet

- 42in Branch Reinforment CalDocument10 pages42in Branch Reinforment CalDhakshina KNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument8 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNo ratings yet

- Asme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureDocument1 pageAsme B31.3 Process Piping - Asme B31.3 Process Piping - Allowable Design Pressureallowable Design PressureRicardo LanderNo ratings yet

- As4041 Pressure Piping - Allowable Design Pressure: E M T W F D ExmDocument8 pagesAs4041 Pressure Piping - Allowable Design Pressure: E M T W F D ExmAkhil CNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument12 pages8 AS4041 ASME B31 3 Pipe Wall ThicknessAnggaNo ratings yet

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument12 pages8 AS4041 ASME B31 3 Pipe Wall Thicknesswhah11No ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- As4041 Pressure Piping - Allowable Design PressureDocument1 pageAs4041 Pressure Piping - Allowable Design Pressurealvinchuan100% (1)

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123100% (1)

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument11 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknessamini_mohiNo ratings yet

- Pipe Wall Thickness (ASME B31.3)Document12 pagesPipe Wall Thickness (ASME B31.3)Rachmad HidayatNo ratings yet

- Pressure Piping Allowable Wall Thickness For Bends (ASME B31.3)Document2 pagesPressure Piping Allowable Wall Thickness For Bends (ASME B31.3)alvinchuanNo ratings yet

- As4041 Pressure Piping Allowable Wall Thickness For BendsDocument1 pageAs4041 Pressure Piping Allowable Wall Thickness For BendsalvinchuanNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument1 pageAS4041 ASME B31 - 3 Pipe Wall ThicknesselleNo ratings yet

- ASME B31.3 Pipe Wall ThicknessDocument33 pagesASME B31.3 Pipe Wall Thicknessaike_5No ratings yet

- Relative Discharging Power of Pipe LineDocument1 pageRelative Discharging Power of Pipe LinealvinchuanNo ratings yet

- Solve Differential EquationDocument4 pagesSolve Differential EquationalvinchuanNo ratings yet

- Pipe Insulation CalculationDocument2 pagesPipe Insulation CalculationalvinchuanNo ratings yet

- DG Flowrate Comparison PDFDocument1 pageDG Flowrate Comparison PDFalvinchuanNo ratings yet

- Diversity FactorDocument3 pagesDiversity FactorgafscottNo ratings yet

- Mass BalanceDocument4 pagesMass BalancealvinchuanNo ratings yet

- DD - 22 Floatation of Circular PipeDocument6 pagesDD - 22 Floatation of Circular PipealvinchuanNo ratings yet

- PUB Simplified Submission ProcessDocument1 pagePUB Simplified Submission ProcessalvinchuanNo ratings yet

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanNo ratings yet

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanNo ratings yet

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanNo ratings yet

- Extracts PG - 12 &13 of SS636Document2 pagesExtracts PG - 12 &13 of SS636alvinchuanNo ratings yet

- Extracts of SS636Document2 pagesExtracts of SS636alvinchuanNo ratings yet

- Auto ClaveDocument1 pageAuto ClavealvinchuanNo ratings yet

- Restrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazineDocument1 pageRestrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazinealvinchuanNo ratings yet

- PUB Simplified Submission ProcessDocument1 pagePUB Simplified Submission ProcessalvinchuanNo ratings yet

- Pipe ThicknessDocument1 pagePipe ThicknessalvinchuanNo ratings yet

- Bio Detention BasinDocument45 pagesBio Detention BasinalvinchuanNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- SS 532-2016+corr 1 - PreviewDocument11 pagesSS 532-2016+corr 1 - PreviewalvinchuanNo ratings yet

- ABCWatersDesignGuidelines 2011Document104 pagesABCWatersDesignGuidelines 2011Jackson TanNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- Singapore Rainfall Equations PDFDocument2 pagesSingapore Rainfall Equations PDFalvinchuanNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- Pipeline Analysis & Calculation Environment: Pipe SelectionDocument6 pagesPipeline Analysis & Calculation Environment: Pipe SelectionalvinchuanNo ratings yet

- Slno Description Symbol Unit Value: Calculation of Shell ThicknessDocument2 pagesSlno Description Symbol Unit Value: Calculation of Shell ThicknessalvinchuanNo ratings yet

- PE Pipeline Analysis & CalculationDocument2 pagesPE Pipeline Analysis & CalculationalvinchuanNo ratings yet

- API Sizing KIM - XLSMDocument1 pageAPI Sizing KIM - XLSMalvinchuanNo ratings yet

- ConsumptionDocument2 pagesConsumptionalvinchuanNo ratings yet

- Expansion Tank SizingDocument2 pagesExpansion Tank SizingSK NGNo ratings yet

- Module2 Riveted Bolted Connections PDFDocument43 pagesModule2 Riveted Bolted Connections PDFRobinson MaturanNo ratings yet

- Thermo QualsDocument26 pagesThermo QualsLuc LeNo ratings yet

- Glossary of Paper TerminologyDocument5 pagesGlossary of Paper Terminologykarzol73No ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityApurv GuptaNo ratings yet

- TES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)Document19 pagesTES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)BetoCostaNo ratings yet

- Specification For Hot Water Boilers-9-10Document2 pagesSpecification For Hot Water Boilers-9-10Karthik AnandanNo ratings yet

- Grupa Mica Iepurasii 2021-2022Document1 pageGrupa Mica Iepurasii 2021-2022Bogdan RăzvanNo ratings yet

- Analysis and Design of Reinforced Concrete Solid Slab BridgeDocument4 pagesAnalysis and Design of Reinforced Concrete Solid Slab BridgeEditor IJTSRDNo ratings yet

- A Comparison of BS en 287 Part 1 and ISO 9606Document3 pagesA Comparison of BS en 287 Part 1 and ISO 9606Joe ClarkeNo ratings yet

- Documents - Pub - Advanced Welding TechnologyDocument60 pagesDocuments - Pub - Advanced Welding TechnologybalamuruganNo ratings yet

- Product Chemical Substances (Name 2) Use Safety MeasuresDocument1 pageProduct Chemical Substances (Name 2) Use Safety MeasuresVin CherNo ratings yet

- En LNG Air Products MCR Coil Wound Heat Exchangers PDFDocument10 pagesEn LNG Air Products MCR Coil Wound Heat Exchangers PDFJoan Andrey Bolaños CruzNo ratings yet

- Penguard Express PDFDocument5 pagesPenguard Express PDFImam SitumeangNo ratings yet

- SAQ Ans 7Document2 pagesSAQ Ans 7harshanauocNo ratings yet

- Laporan Praktikum Elektronika 1 (Els2203) Percobaan 1 Dioda: Karakteristik Dan AplikasiDocument7 pagesLaporan Praktikum Elektronika 1 (Els2203) Percobaan 1 Dioda: Karakteristik Dan AplikasismahsgxNo ratings yet

- Experimental Analysis of Laser Drilling Impacts On Rock PropertiesDocument10 pagesExperimental Analysis of Laser Drilling Impacts On Rock PropertiesAngélica Acosta PérezNo ratings yet

- PQRDocument2 pagesPQRnaseema1100% (1)

- Upcast Brochure ENG 2010Document7 pagesUpcast Brochure ENG 2010Mauricio AlbiniNo ratings yet

- Two Marks AT6601Document13 pagesTwo Marks AT6601Naveen Ashrae0% (2)

- Stabil Road TechnologyDocument72 pagesStabil Road TechnologysatyaNo ratings yet

- Rebar 101Document27 pagesRebar 101Alaym AguilarNo ratings yet

- IES Civil Engineering 2019 PDFDocument24 pagesIES Civil Engineering 2019 PDFAbhinavNo ratings yet

- Strength of Three New Types of Composite Beams: Althoughcompositeconstructionisnotnew, HavingDocument10 pagesStrength of Three New Types of Composite Beams: Althoughcompositeconstructionisnotnew, HavingcmkohNo ratings yet

- 5.1 - Rates, Equilibrium and PH: 5.1.1 - How Fast?Document26 pages5.1 - Rates, Equilibrium and PH: 5.1.1 - How Fast?Arshad KhanNo ratings yet

- AGRI Establishments in MPDocument16 pagesAGRI Establishments in MPG P MishraNo ratings yet

- Stabilization ShellacDocument9 pagesStabilization ShellacbaoNo ratings yet

- Ipc2018-78293-Assessment of Pipeline Spiral Weld Cracks Subjected To Internal Pressure#Neuert2018Document10 pagesIpc2018-78293-Assessment of Pipeline Spiral Weld Cracks Subjected To Internal Pressure#Neuert2018bomikaNo ratings yet

- Advantages and Disadvantages of Warp Knitting Tricot and Raschel MachinesDocument2 pagesAdvantages and Disadvantages of Warp Knitting Tricot and Raschel Machinesntd1011No ratings yet

- CHM256 - Tutorial 6Document2 pagesCHM256 - Tutorial 6Fatimah Azzahrah0% (1)

- Cbse Test Paper-05: Science & Technology (Class-10) Chapter 4. Carbon and Its CompoundsDocument1 pageCbse Test Paper-05: Science & Technology (Class-10) Chapter 4. Carbon and Its CompoundsbannaduraiNo ratings yet