Professional Documents

Culture Documents

Power Plant Design Example

Uploaded by

anoopkntpcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Plant Design Example

Uploaded by

anoopkntpcCopyright:

Available Formats

Power Plant Design Example

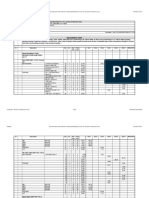

0 1 2 3 5 8 7 6 # # # # # # # # # # # # # # # # # 9 # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # #

Contract - specification 0 0 0

Contract - standards 1 1 Contract 1

Contract - schedule 2 2 2

Contract - erection resp. list 3 3 3

Project plan - schedule 5 l l l l 5 Project plan 5

Project plan - quality plan 8 l l m l 8 8

Project plan - budget 7 l l m l m l 7 7

Project plan - purchasing plan 6 l l m l m m 6 6

Process eng. - mater. & heat bal. # l # #

Process eng.

Process eng. - heat surfaces # l l l # #

Proces eng. - air system # l l m # s #

Process eng. - circulation calc. # l l # m s s #

Strength calculations # l l l l m # #

Process eng. - aux. dimens. # l l l l # #

Process eng. - piping dimens. # l l l m # #

Process eng. - PID prel. # l l s l m # #

Process eng. - PI lists prel. # l l s l m # #

Purchasing - steam drum # l l s l l l m m # m

Purchasing #

Purchasing - pressure part mat. # l l s l m m # m #

Purchasing - steel construction # l l s s l # m m s s s s #

Purchasing - EP, fans # l l s s l l l # #

Purchasing - pressure part manuf. # l l s l m # l m #

Purchasing - heat exchangers # l l s l l l # #

Purchasing - code piping # l l s l m m # m #

Purchasing - feedwater pumps # l l s l l m l # #

Layout

Project plan - erection plan 9 l l l l l 9 m m m m m m m 9

Layout - pressure part # l l s l m l m # s #

Layout - steel construction # l l s m m m # m m m m m s #

Layout - code piping # l l s m m m l s # s s #

Layout - main auxiliaries # l l s l m m m l s s # s s s s #

Layout - ducting # l l s m m m l s s s # s s s #

Layout - process piping # l l s l l m l s l l s # s s #

Layout - cable trays # l l s m l s s s s s # s m #

Layout - interference checking # s m m m m m m m # #

Process eng. - PID final # l l s l l m m m m m # Final PIDs #

Process eng. - PI lists final # l l s l l l # #

Instrumentation - basic eng. # l l s m m l l l l m m m m s # Inst. & elect. #

Instrumentation - detail eng. # l l s m m m m m l l l # m #

Electrification - basic eng. # l l s l l l m m m m # #

Electrification - detail eng. # l l s l l l l m l l l # m #

Detail eng. - pressure part # l l s m l m l m l l m s # m Detail eng. #

Detail eng. - steel construction # l l s m l # #

Project plan - material u.p. # l l s m m l # #

Detail eng. - non pressure part # l l s m m s # #

Detail eng. - code piping # l l s m l l m # #

Detail eng. - ducting # l l s m m l m s # #

Detail eng. - process piping # l l s m m l l # #

Detail eng. - insulation # l l s m l l l l l m # #

Detail eng. - training material # l l l l l l # l l Purchasing #

Purchasing - instrumentation # l l s l l l l l # #

Purchasing - electrification # l l s l l l l l # #

Purchasing - erection # l l l s l l l # #

Purchasing - insulation # l l s l # #

Purchasing - non pressure parts # l l s l # #

Purchasing - process piping # l l s l # #

Purchasing - acid handling # l l s l # #

Project plan - training plan # l l m s # #

Project plan - start up plan # l l m s # #

Erection - steel construction # s s l l l # Erection #

Erection - pressure part # s s l l l m # #

Erection - aux # s s l l l l l l # #

Erection - code piping # s s l l l l l # #

Erection - process piping # s s l l l l l l # #

Erection - instrumentation # l l s l l l # m #

Erection - electification # l l s l l l # m #

Erection - pressure test # s s s l l l l # Start up #

Erection - insulation # s s l l l l l m l m l # #

Start up - training # l l # #

Start up - cold testing # s s l l l l m m m l # #

Start up - acid handling # l l l l l l # #

Start up - puhallukset # l l # #

Start up - liquor running # l # #

Hand over # l s s l l # #

0 1 2 3 5 8 7 6 # # # # # # # # # # # # # # # # # 9 # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # # #

l Information Needed to Start Parallel Concurrent

m Information Needed to Finish (Uncoupled) (Coupled)

s Information Needed to Check Activities Activities

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Question Answers On Steam TurbinesDocument4 pagesQuestion Answers On Steam TurbinesanoopkntpcNo ratings yet

- Defects Liability PeriodDocument5 pagesDefects Liability PeriodChemical.AliNo ratings yet

- 1997feb w08 FeedForwardDocument2 pages1997feb w08 FeedForwardanoopkntpcNo ratings yet

- Electrical Closure Protection RatingDocument3 pagesElectrical Closure Protection RatingSpoonful BurnsideNo ratings yet

- SI (International System of Units) : (Technical Data)Document1 pageSI (International System of Units) : (Technical Data)anoopkntpcNo ratings yet

- nema-IP Rating Chart PDFDocument3 pagesnema-IP Rating Chart PDFAlexander OngNo ratings yet

- LyricsDocument1 pageLyricsanoopkntpcNo ratings yet

- ASME - Performance Test CodesDocument1 pageASME - Performance Test CodesanoopkntpcNo ratings yet

- Boiler Drum Level Transmitter CalibrationDocument4 pagesBoiler Drum Level Transmitter CalibrationPrem Cesc NathNo ratings yet

- Quotes On Sachin Tendulkar by LegendsDocument16 pagesQuotes On Sachin Tendulkar by LegendsanoopkntpcNo ratings yet

- Chess Openings PDFDocument110 pagesChess Openings PDFJohn SteveNo ratings yet

- Miss MoppetDocument8 pagesMiss MoppetanoopkntpcNo ratings yet

- Rubiks Cube 3x3 Solution-EnDocument12 pagesRubiks Cube 3x3 Solution-EnSuchan Khankluay100% (1)

- Sachin Ton of TonsDocument1 pageSachin Ton of TonsanoopkntpcNo ratings yet

- Calories in FoodDocument2 pagesCalories in FoodanoopkntpcNo ratings yet

- PID BasicsDocument8 pagesPID BasicsanoopkntpcNo ratings yet

- Calories in FoodDocument2 pagesCalories in FoodanoopkntpcNo ratings yet

- PID Windup PDFDocument4 pagesPID Windup PDFOualid LamraouiNo ratings yet

- Pid Loop ShapingDocument7 pagesPid Loop ShapingCAFECHINONo ratings yet

- Calin PopescuDocument2 pagesCalin Popescucpcabutin7499No ratings yet

- Chap-5 Framed StructuresDocument12 pagesChap-5 Framed StructurestekalignNo ratings yet

- Reinforcement Steel FormatDocument18 pagesReinforcement Steel FormatRASCON BUILDNo ratings yet

- ULTEGRA Front Chainwheel FC-6600Document1 pageULTEGRA Front Chainwheel FC-6600jack87hornistNo ratings yet

- Chapter 9 EnglishDocument53 pagesChapter 9 Englishhoda melhemNo ratings yet

- Plan Poblacion SibongaDocument13 pagesPlan Poblacion SibongaRiowin GamboaNo ratings yet

- ACI Concrete International Journal Vol 45 No 2 2023 PDFDocument60 pagesACI Concrete International Journal Vol 45 No 2 2023 PDFJardeyFrancisVallejoNo ratings yet

- Railway Section Detail 1Document1 pageRailway Section Detail 1Shreenidhi JoshiNo ratings yet

- Danosa - POLYDAN 50 - GP ELAST. VERT JARDINDocument5 pagesDanosa - POLYDAN 50 - GP ELAST. VERT JARDINAudrey SeninNo ratings yet

- Purlin and Roof Design PDFDocument4 pagesPurlin and Roof Design PDFHassan AlaskaNo ratings yet

- 35 X 60 Modern HouseDocument5 pages35 X 60 Modern HouseChris BiayaNo ratings yet

- Proposed Gulu Logistics Hub Facilities Unpriced Tender B.O.QDocument300 pagesProposed Gulu Logistics Hub Facilities Unpriced Tender B.O.QZu ZhuNo ratings yet

- TNB 2024 - Substation - Design - Booklet - Edition2.0-162Document1 pageTNB 2024 - Substation - Design - Booklet - Edition2.0-162syakirahNo ratings yet

- Quite Pavement System in EuropeDocument50 pagesQuite Pavement System in Europesenoln5No ratings yet

- Construction Specifications - Civil: Expand Dhahran Residential Community Residential Area - Package - 6Document261 pagesConstruction Specifications - Civil: Expand Dhahran Residential Community Residential Area - Package - 6mdabdulhadi88No ratings yet

- 45D-MQ PartsDocument102 pages45D-MQ PartsErnesto GonzalezNo ratings yet

- Hea 4003 24 9DDocument3 pagesHea 4003 24 9Dhugo renzo chavez bernuyNo ratings yet

- Probation Period: Six MonthsDocument2 pagesProbation Period: Six MonthsManilaNo ratings yet

- Daily Construction ReportDocument3 pagesDaily Construction ReportZaxx SlurppNo ratings yet

- JSE Building GuidelinesDocument13 pagesJSE Building GuidelinesArtemisNo ratings yet

- The Effect of Price Changes of Some Major Construction Materials On The Economic Input of Sri Lankan Construction IndustryDocument30 pagesThe Effect of Price Changes of Some Major Construction Materials On The Economic Input of Sri Lankan Construction IndustryRohitha PethiyagodaNo ratings yet

- Lighting - Pendants - LumenWerx - Hex Pendant 1 Cell Direct 1 Cell IndirectDocument4 pagesLighting - Pendants - LumenWerx - Hex Pendant 1 Cell Direct 1 Cell Indirectannada ParabNo ratings yet

- Calcium Bare - CPDocument3 pagesCalcium Bare - CPa73806780No ratings yet

- Joel Pretz Resume 2020NYDocument3 pagesJoel Pretz Resume 2020NYDoris De Guia ScanellaNo ratings yet

- SS 595-1-2014 - PreviewDocument11 pagesSS 595-1-2014 - PreviewpierreguessNo ratings yet

- Adobe Scan 21 Dec 2021Document2 pagesAdobe Scan 21 Dec 2021Dhrisha GadaNo ratings yet

- Ubgmsw 20 M - 2Document3 pagesUbgmsw 20 M - 2abdullah_23320666No ratings yet

- Project Facilities NH26Document7 pagesProject Facilities NH26Saudagar BiswalNo ratings yet

- (Presentation) Contemporary ArchitectsDocument12 pages(Presentation) Contemporary Architectsalexu artNo ratings yet