Professional Documents

Culture Documents

Check List For Chilled Water Secondary Pump: Sl. No Description Remarks

Uploaded by

siruslara6491Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List For Chilled Water Secondary Pump: Sl. No Description Remarks

Uploaded by

siruslara6491Copyright:

Available Formats

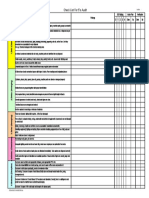

Check List for Chilled Water Secondary Pump

Secondary Pump No.

Sl. No Description YES NO REMARKS

1 Isolate the incoming source and apply LOTO.

2 Make sure that supply is not available at the i/p terminal of the equipment

3 Check for leakage in pipelines

4 Check for abnormal noise or heating of pump and motors

5 Check foundation bolts tightness

6 Check shaft guards are secure

7 Observe pressure gauges are functioning

8 Clean the exterior of the pump and motor

9 Check for leakage in Seal

Remove coupling guard and inspect motor and pump coupling it should be free from

10

damange and with proper alignment

11 Check the tightness of Earthing wire, and ensure the double earthing connected properly.

12 Check the proper working of Remote off push Button.

13 Ensure easy operation of suction valve opening and closing,if so apply lubriction.

Check for any cable colour change in motor cable terminations and Tightness of the

14

termination and if so rectify.

Check for any cable colour change in VFD starter panel and ensure the tightness of all

15

the electrical connection.

16 Check the isolator connection in the Chiller Auxillary panel.

17 Remove the Motor fan guard and clean the fan with a clean brush.

18 Clean the pump and insulated pipe lines externally with cotton cloth.

Switch OFF the power supply and ensure pump shaft rotates freely by hand and Switch

19

ON the Power Supply

20 Clean pump suction strainer.

Check the Over load relay setting.(It should be setted as ).Test and Ensure the O/L

21

operation by pressing the "Test" Button in O/L Relay.

22 Check and Record the Motor load current and Winding resistance Value

23 Apply grease to the drive motor

24 Check and Record the suction and discharge pressure

Run Hours :

25 Log the Total Run Hours and KWH Reading KWH :

PM Done by : Spares Used

Signature :

PM done On :

Start Time :

End time :

Next PM due on :

You might also like

- Monthly PPM Check List For Fire Pump House: Sl. No Description RemarksDocument1 pageMonthly PPM Check List For Fire Pump House: Sl. No Description Remarkssiruslara6491No ratings yet

- Check List For Chilled Water Primary Pump No.: Sl. No Description RemarksDocument1 pageCheck List For Chilled Water Primary Pump No.: Sl. No Description Remarkssiruslara6491No ratings yet

- Check List For Ul Pumps Standard Set D+e+jn PDFDocument6 pagesCheck List For Ul Pumps Standard Set D+e+jn PDFdesign sseNo ratings yet

- AhuDocument1 pageAhusiruslara6491No ratings yet

- Location: Split A/C No.: Monthly PM Check List For SPLIT A/C'sDocument1 pageLocation: Split A/C No.: Monthly PM Check List For SPLIT A/C'ssiruslara6491No ratings yet

- Fire PUMPS T&C ChecklistDocument6 pagesFire PUMPS T&C ChecklistUmair BaBerNo ratings yet

- Power Transformer Pre Commisioning ChecklistDocument26 pagesPower Transformer Pre Commisioning ChecklistRajesh TK100% (2)

- PPM Check List For PAHU: Sl. No Description Remarks/ObservationDocument1 pagePPM Check List For PAHU: Sl. No Description Remarks/Observationsiruslara6491No ratings yet

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityDocument10 pagesTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliNo ratings yet

- AT Half Yearly Maintenance ContractorDocument3 pagesAT Half Yearly Maintenance ContractorKrishna Mohan KolliparaNo ratings yet

- Fire PUMPS T&C ChecklistDocument6 pagesFire PUMPS T&C ChecklistUmair BaBerNo ratings yet

- Standard Operating Procedure: Operation and Preventive Maintenance of TransformersDocument5 pagesStandard Operating Procedure: Operation and Preventive Maintenance of TransformersMaryanthony NamyaloNo ratings yet

- Checklist Boiler and TurbineDocument17 pagesChecklist Boiler and Turbinekeerthi dayarathna50% (2)

- Generator PM ChecklistDocument2 pagesGenerator PM ChecklistYan's Senora Bescoro100% (3)

- Передача вахтиDocument3 pagesПередача вахтиВалерий РыбалкаNo ratings yet

- Daily PC1250 FormDocument1 pageDaily PC1250 FormlilikNo ratings yet

- Unit1C 2019Document38 pagesUnit1C 2019Bavan KanesanNo ratings yet

- ChillerDocument2 pagesChillersiruslara6491100% (1)

- Pre Commissioning Oil Type TransformerDocument4 pagesPre Commissioning Oil Type TransformerKanagaraj Ravi0% (1)

- M04B Pump Positive DisplacementDocument1 pageM04B Pump Positive DisplacementzackteeNo ratings yet

- Cooling Towers: Hvac Plant Do'S and Don'TsDocument11 pagesCooling Towers: Hvac Plant Do'S and Don'TsSYED SHAHBAZNo ratings yet

- Precommissioning Test FormatDocument72 pagesPrecommissioning Test Formatashutosh2009100% (3)

- Tunnel Loading Machine ITC 120N #0516 Check MinutesDocument24 pagesTunnel Loading Machine ITC 120N #0516 Check MinutesARMANDO ROJO100% (1)

- PM Schedule Plan For All MachinesDocument32 pagesPM Schedule Plan For All MachineskumaresanNo ratings yet

- CVHE-F CHILLER COMMISSIONING & STARTUP Checklist - 07102015Document5 pagesCVHE-F CHILLER COMMISSIONING & STARTUP Checklist - 07102015Bernard Bonnin CervantesNo ratings yet

- Land Rover Fault CodesDocument4 pagesLand Rover Fault Codesajac29630100% (2)

- TFR MtnceDocument18 pagesTFR MtnceRajesh TKNo ratings yet

- Void SubstationDocument46 pagesVoid SubstationPrabhat HambireNo ratings yet

- 3.1 Oil Filled Power TransformersDocument32 pages3.1 Oil Filled Power TransformersThameemul BuhariNo ratings yet

- 18002-Int-Fqe-Cl-Pw-001-0 - Checklist-Commissioning of Power Transformer PDFDocument1 page18002-Int-Fqe-Cl-Pw-001-0 - Checklist-Commissioning of Power Transformer PDFVenkataramanan S67% (3)

- Prestartup ChecksDocument3 pagesPrestartup ChecksPrudhvi RajNo ratings yet

- Check List For Diesel Generator: Spares UsedDocument2 pagesCheck List For Diesel Generator: Spares Usedsiruslara6491No ratings yet

- Reactor - For SwitchayrdDocument10 pagesReactor - For SwitchayrdSindhuKumarNo ratings yet

- PM of Oil Type TransformerDocument3 pagesPM of Oil Type Transformerdevraj.singh133No ratings yet

- 08.precommissioning Checklist GeneralDocument19 pages08.precommissioning Checklist GeneralAnujGarg100% (1)

- Power Transformer - For SwitchayrdDocument20 pagesPower Transformer - For SwitchayrdSindhuKumarNo ratings yet

- Несення Вахти в МКОDocument1 pageНесення Вахти в МКОВалерий РыбалкаNo ratings yet

- PT Plant & Make Up WaterDocument5 pagesPT Plant & Make Up WaterPrudhvi RajNo ratings yet

- Updated ChklistDocument29 pagesUpdated ChklistKushal MankaniNo ratings yet

- Cold Start Up ChecklistDocument13 pagesCold Start Up ChecklistEr Karthikeyan V100% (1)

- Sop For Package A.c'sDocument2 pagesSop For Package A.c'sSimhapuri EnergyNo ratings yet

- SpringchecklistDocument1 pageSpringchecklistmcjuddyNo ratings yet

- CL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00Document9 pagesCL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00MohamedElmahdyNo ratings yet

- A/b/c/d/e/f - PassDocument6 pagesA/b/c/d/e/f - PassVikrant DeshmukhNo ratings yet

- HWDocument20 pagesHWAnonymous zpitrB80oNo ratings yet

- Checklist - Pumps ReciprocatingDocument14 pagesChecklist - Pumps Reciprocatingh_patnaikNo ratings yet

- Servis WT 103 Hino PM 1000 Hour 15 Maret 2023Document4 pagesServis WT 103 Hino PM 1000 Hour 15 Maret 2023Damsixboy 999No ratings yet

- Coastal Cold Start Up ChecklistDocument13 pagesCoastal Cold Start Up ChecklistwonderstrikeNo ratings yet

- Cee Dee Transformer Oil Filtration Plant ManualDocument146 pagesCee Dee Transformer Oil Filtration Plant ManualApurba RoyNo ratings yet

- Power Transformer (110kV/66kV/33kV/22kV) General:: The Tata Power Company LTDDocument3 pagesPower Transformer (110kV/66kV/33kV/22kV) General:: The Tata Power Company LTDSaiyan PrideNo ratings yet

- CL GL Hal Ni 205Document4 pagesCL GL Hal Ni 205LismiantoNo ratings yet

- Transformer Check ListDocument2 pagesTransformer Check ListKanhiya Prasad100% (2)

- Preventive Maintenance of 6.6/11KV Circuit Breaker: ProtocolDocument3 pagesPreventive Maintenance of 6.6/11KV Circuit Breaker: ProtocolVikrant DeshmukhNo ratings yet

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- NIBprime Failed Due To Deactivation Bottle Buffer 25 Aug 21Document4 pagesNIBprime Failed Due To Deactivation Bottle Buffer 25 Aug 21Shweta YadavNo ratings yet

- FCU PPM ChecklistDocument1 pageFCU PPM Checklistshabiq93No ratings yet

- Siemens: GP TP NSW LPT Sti CS/ 02/ B/ Dated 01.08.2019Document12 pagesSiemens: GP TP NSW LPT Sti CS/ 02/ B/ Dated 01.08.2019SARAVANAN ANo ratings yet

- Linde ChecklistDocument47 pagesLinde ChecklistVicente TanNo ratings yet

- Nor30p Serv ManDocument187 pagesNor30p Serv Manjason_meyer_14100% (2)

- Pending Jobs UpdatedDocument4 pagesPending Jobs Updatedsiruslara6491No ratings yet

- Part List & SPECDocument19 pagesPart List & SPECsiruslara6491No ratings yet

- Annexure - 3 - Scheme 3Document2 pagesAnnexure - 3 - Scheme 3siruslara6491No ratings yet

- Pump Spares 20.03.2010Document4 pagesPump Spares 20.03.2010siruslara6491No ratings yet

- Critical Spare List For Thermax Oil Fired BoilerDocument1 pageCritical Spare List For Thermax Oil Fired Boilersiruslara6491100% (2)

- Critical Spare ListDocument38 pagesCritical Spare Listsiruslara6491No ratings yet

- IGBC Green Guidelines For Fast Track & Emergency COVID FacilitiesDocument69 pagesIGBC Green Guidelines For Fast Track & Emergency COVID Facilitiessiruslara6491No ratings yet

- Utility Report 07032009Document1 pageUtility Report 07032009siruslara6491No ratings yet

- Steam PurityDocument5 pagesSteam Puritysiruslara6491No ratings yet

- Pump Power Calculation NoteDocument2 pagesPump Power Calculation NoteAsad KhanNo ratings yet

- Utility Online Log For Apr-09Document29 pagesUtility Online Log For Apr-09siruslara6491No ratings yet

- Mrplist01062008 DistributorDocument13 pagesMrplist01062008 Distributorsiruslara6491No ratings yet

- Asme Standards For BoilersDocument4 pagesAsme Standards For Boilerssiruslara6491No ratings yet

- ScrubberDocument1 pageScrubbersiruslara6491No ratings yet

- Atmospheric PressureDocument1 pageAtmospheric Pressurerampw14581No ratings yet

- Emergency LightsDocument3 pagesEmergency Lightssiruslara6491No ratings yet

- ChillerDocument2 pagesChillersiruslara6491No ratings yet

- Motors PDFDocument79 pagesMotors PDFsiruslara6491No ratings yet

- FFT Check ListDocument1 pageFFT Check Listsiruslara6491No ratings yet

- Check List For 5s Audit For UtyDocument1 pageCheck List For 5s Audit For Utysiruslara6491No ratings yet

- Storage Battery M&PDocument84 pagesStorage Battery M&Psiruslara6491No ratings yet

- Check List For Battery Charger: Sl. No Description Remarks/ObservationDocument1 pageCheck List For Battery Charger: Sl. No Description Remarks/Observationsiruslara6491No ratings yet

- Motors PDFDocument79 pagesMotors PDFsiruslara6491No ratings yet

- Good Documentation Practices (GDP)Document34 pagesGood Documentation Practices (GDP)siruslara6491100% (6)

- 50 Activities For Developing Management Skills PDFDocument332 pages50 Activities For Developing Management Skills PDFDanish ButtNo ratings yet

- Muy Importante Clean Room Criterio de AceptacionDocument7 pagesMuy Importante Clean Room Criterio de AceptacionJovanny MarquezNo ratings yet

- Motors PDFDocument79 pagesMotors PDFsiruslara6491No ratings yet

- Good Documentation Practices (GDP)Document34 pagesGood Documentation Practices (GDP)siruslara6491100% (6)

- Good PracticesDocument32 pagesGood Practicessiruslara6491No ratings yet

- ACDC Dyn Solar CalculatorDocument5 pagesACDC Dyn Solar CalculatorArul SankaranNo ratings yet

- 2 SC 2078Document3 pages2 SC 2078gerler jhony hernandez rodriguezNo ratings yet

- Ventiladores Del Sistema AdiabaticoDocument13 pagesVentiladores Del Sistema AdiabaticoVicente SantillanNo ratings yet

- KB Electronics KBPC 240d Manual de UsuarioDocument21 pagesKB Electronics KBPC 240d Manual de UsuarioAndrés Gregorio de las Heras YanzonNo ratings yet

- GIS High-Voltage Test Check List: No Description Contractor Check Result Hyosung VerificationDocument1 pageGIS High-Voltage Test Check List: No Description Contractor Check Result Hyosung Verificationessam khalilNo ratings yet

- KP102 Datasheet Ver2 Rev1Document2 pagesKP102 Datasheet Ver2 Rev1Ciro QuintannaNo ratings yet

- Draka - UC500 23 Cat6a - UFTP LSZH - Sales - 240301 - 143717Document5 pagesDraka - UC500 23 Cat6a - UFTP LSZH - Sales - 240301 - 143717badrquestNo ratings yet

- 405 ZXM7-SHLD108 182 - 1728×1134 (30×28) - 395-415W - 350mm - 20210714 - EDocument2 pages405 ZXM7-SHLD108 182 - 1728×1134 (30×28) - 395-415W - 350mm - 20210714 - Esteven6diaz-2No ratings yet

- Diagramas Electricos e Hidraulicos J2.00-3.00XM E1.50-2.20XMSDocument33 pagesDiagramas Electricos e Hidraulicos J2.00-3.00XM E1.50-2.20XMSArmando OrtaNo ratings yet

- Irfs7530 7ppbfDocument11 pagesIrfs7530 7ppbfAnidiobi OkwudiliNo ratings yet

- A ZVS-PWM Single-Phase Inverter Using A ZVS Transformer-Isolated Step-Up Down DC LinkDocument5 pagesA ZVS-PWM Single-Phase Inverter Using A ZVS Transformer-Isolated Step-Up Down DC Linkjuan8aNo ratings yet

- Topic M6 Electroplating: Learning OutcomesDocument8 pagesTopic M6 Electroplating: Learning OutcomesMurali TharanNo ratings yet

- Laboratory Exercises For Optical Communications - Hardware and SimDocument11 pagesLaboratory Exercises For Optical Communications - Hardware and SimAdam ElsheikhNo ratings yet

- Medium Frequency Coreless Induction Furnaces MFTDocument16 pagesMedium Frequency Coreless Induction Furnaces MFTCem AlpaslanNo ratings yet

- Specification Q5B Asic For RfidDocument21 pagesSpecification Q5B Asic For Rfid4hgtrb0xNo ratings yet

- MBR (F) 20150CTDocument4 pagesMBR (F) 20150CTCassio SousaNo ratings yet

- Coblation Technology White Paper BDocument12 pagesCoblation Technology White Paper BAngelSanchezNo ratings yet

- 3.1 BSMarE 1st Yr Level - REVALIDA SET BDocument11 pages3.1 BSMarE 1st Yr Level - REVALIDA SET BsanidenNo ratings yet

- EC24S7Document46 pagesEC24S7kumaravnish9084No ratings yet

- Q.3 A) Write Short Notes On 1) IMPATT Diode 2) TRAPATT Diode Ans: 1. IMPATT DiodeDocument3 pagesQ.3 A) Write Short Notes On 1) IMPATT Diode 2) TRAPATT Diode Ans: 1. IMPATT DiodeSourav NagNo ratings yet

- Cable Systems - ETAPDocument10 pagesCable Systems - ETAPJoeDabidNo ratings yet

- Chap 1 AssignmentDocument7 pagesChap 1 AssignmentBenjhon S. ElarcosaNo ratings yet

- Automated Solar Powered Pumping Systems For IrrigationDocument10 pagesAutomated Solar Powered Pumping Systems For IrrigationfarizalNo ratings yet

- Certificados InversoresDocument18 pagesCertificados InversoresPiloto PelotaNo ratings yet

- Exam... Electrical Machnes-IDocument31 pagesExam... Electrical Machnes-Icharlesc5746No ratings yet

- Gage and Absolute Pressure Transducers: Special FeaturesDocument4 pagesGage and Absolute Pressure Transducers: Special Featuresaemis2010No ratings yet

- CASE 14 Wind Technology CaseDocument7 pagesCASE 14 Wind Technology CaseOrchester TanNo ratings yet

- Mircom MA-485A User ManualDocument24 pagesMircom MA-485A User ManualJMAC SupplyNo ratings yet

- Ee8703 Renewable Energy Systems L T P CDocument3 pagesEe8703 Renewable Energy Systems L T P CPadukolai KarupaiahNo ratings yet

- RS 002 July 2014 (Welder Test Run Sheet Asep W)Document1 pageRS 002 July 2014 (Welder Test Run Sheet Asep W)Muhammad Fitransyah Syamsuar PutraNo ratings yet