Professional Documents

Culture Documents

Drilling Operations Console PDF

Uploaded by

go25101992Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drilling Operations Console PDF

Uploaded by

go25101992Copyright:

Available Formats

SiteCom Well Advisor

Well Construction Efficiency

In todays environment it is even more important for drilling and completions teams to focus on reducing non-

productive time (NPT) during well construction by enhancing operational integrity and efficiency. Kongsberg Oil &

Gas, in conjunction with BP, developed the SiteCom Well Advisor real-time advisory solution for well operations in

response to this growing focus. By leveraging the existing industry leading SiteCom solution, SiteCom Well

Advisor takes real-time data management to the next level as a decision support system integrating data with

predictive tools and processes. This supports the delivery of the right information to the right place at the right

time allowing for more informed decisions during critical operations.

Drilling Operations Console (DO)

During drilling there are major factors that affect cost, drilling time and safety including the quality of hole cleaning.

The result of ineffective hole cleaning can cause high torque and drag, premature bit wear, differential sticking and

formation fracturing. The Drilling Operations console provides three essential agents to assist in improving drilling

performance.

Features:

Analyzes the quality of the hole

cleaning

Provides an analytical model that

predicts minimum required annular

flow velocity (Critical Annular

Velocity) to clean the well for a

given ROP

Drag chart featuring automatic

calculation of pick-up weights,

slack off weights and free rotating

weights, and comparing them

SiteCom Well Advisor Drilling Operations Console displayed in widgets.

against theoretical numbers

Determines the breakover torque

when starting the rotation of a

Benefits: drill string

Generated in real time Calculates whether the hole

Visualizes the effectiveness of hole cleaning cleaning is sufficient in the

Utilizes sophisticated algorithms to determine the hole cleaning wellbore

status for each section of the wellbore Displays measured and predicted

Locates free rotating weight, slack off weight, pick up weight, and weights vs. depth

breakover weight

Tracks maximum torque used when drilling resumes after a

connection

Monitors average friction factors for hookload and torque

Successes:

Successfully completed field trials

Handed over to Deployment At Scale

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Completion Challenges For Ultra HPHT CompletionsDocument11 pagesCompletion Challenges For Ultra HPHT Completionsgo25101992No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Screen Less Method To Controle Sand ProductionDocument11 pagesScreen Less Method To Controle Sand Productiongo25101992100% (1)

- Flow Control AccessoriesDocument9 pagesFlow Control Accessoriesgo25101992No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Flow Control AccessoriesDocument9 pagesFlow Control Accessoriesgo25101992No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Well Completion EquipmentDocument30 pagesWell Completion Equipmentgo25101992No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Corrosion ControlDocument8 pagesCorrosion Controlgo25101992No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Micro Emulsions in Enhanced Oil Recovery A ReviewDocument15 pagesMicro Emulsions in Enhanced Oil Recovery A Reviewgo25101992No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Surface BOP Stack Operations API - Deviated Well Kill SheetDocument0 pagesSurface BOP Stack Operations API - Deviated Well Kill Sheetjosesito_amoroso2005No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- HPHT & CBM CompletionDocument8 pagesHPHT & CBM Completiongo25101992No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Current Project PDFDocument108 pagesCurrent Project PDFgo25101992No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Gas HydrateDocument91 pagesGas Hydratego25101992No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Energies 10 00152Document18 pagesEnergies 10 00152go25101992No ratings yet

- Underbalanced Well CompletionDocument3 pagesUnderbalanced Well Completiongo25101992No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Properties Selected High ExplosivesDocument37 pagesProperties Selected High Explosivesmahsa100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Ashwagandha PDFDocument22 pagesAshwagandha PDFgo25101992No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Cut FlowersDocument17 pagesCut Flowersgo25101992No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Rotary SystemDocument17 pagesRotary Systemgo25101992No ratings yet

- Drilling Operations ConsoleDocument1 pageDrilling Operations Consolego25101992100% (1)

- Redren FPC BrochureDocument2 pagesRedren FPC Brochurego25101992No ratings yet

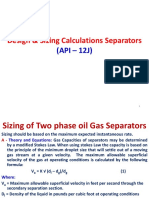

- API-12J SpecificationDocument20 pagesAPI-12J Specificationgo251019920% (2)

- Solar Based Cold StorageDocument5 pagesSolar Based Cold StorageSudhendra Soni100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 002-Apicasingdrift Tabla de ProducionDocument0 pages002-Apicasingdrift Tabla de Producionpelon_90No ratings yet

- Gujarat SubsidyDocument2 pagesGujarat Subsidygo25101992No ratings yet

- Rig Control Drilling Well ControlDocument2 pagesRig Control Drilling Well Controlgo25101992No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- SH-CBM-Vehicle Inspection (LMV & HMV) ChecklistDocument1 pageSH-CBM-Vehicle Inspection (LMV & HMV) Checklistgo25101992No ratings yet

- QA-RD7AE-V8 English API Formula SheetDocument4 pagesQA-RD7AE-V8 English API Formula SheetYogesh GavaliNo ratings yet

- Well Control Equations DrillingformulasDocument13 pagesWell Control Equations DrillingformulastoshoyNo ratings yet

- SeismicDocument8 pagesSeismicgo25101992No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- S. No. Job For Which The Permit Issued Date Opening TimeDocument4 pagesS. No. Job For Which The Permit Issued Date Opening Timego25101992No ratings yet

- Liebherr Drilling Rigs Spec E62005Document20 pagesLiebherr Drilling Rigs Spec E62005MarcoNo ratings yet

- Technical Feasibility Analysis of Utilizing Special Purpose Machine ToolsDocument13 pagesTechnical Feasibility Analysis of Utilizing Special Purpose Machine ToolsCA-VIJAY MORE3344No ratings yet

- NX9 CAM Whats New V1Document49 pagesNX9 CAM Whats New V1lakshmichandranath889100% (1)

- Method of Statement - Earthing With Inwell MachineDocument3 pagesMethod of Statement - Earthing With Inwell Machinehari ramNo ratings yet

- Fabrication Shop Example (Report)Document13 pagesFabrication Shop Example (Report)Mahmoud KassabNo ratings yet

- Gundrilling HandbookDocument49 pagesGundrilling HandbookBooks for the lot100% (1)

- Productivity Improvement of Conventional Drilling MachineDocument38 pagesProductivity Improvement of Conventional Drilling MachineHarshad_S50% (2)

- Back Off String ShotDocument16 pagesBack Off String ShotChoayb Seller100% (1)

- Hydraulic Rock Drill HL 710S: Application DescriptionDocument2 pagesHydraulic Rock Drill HL 710S: Application DescriptionHerd Iman100% (2)

- Me6402 mt2 Notes Rejinpaul PDFDocument227 pagesMe6402 mt2 Notes Rejinpaul PDFRajeshNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 84 2010 Irwin Metal DrillingDocument20 pages84 2010 Irwin Metal DrillingDonizetti ManutençãoNo ratings yet

- Section 25 - Post-Course Exam PDFDocument6 pagesSection 25 - Post-Course Exam PDFayhamNo ratings yet

- Bit SelectionDocument19 pagesBit SelectionFernando AybarNo ratings yet

- Application of Minimum Curvature Method To Wellpath CalculationsDocument8 pagesApplication of Minimum Curvature Method To Wellpath CalculationsVandear GoalcantaraNo ratings yet

- DIY Wood Acrylic Color Changing LED LampDocument13 pagesDIY Wood Acrylic Color Changing LED Lampsachin0307No ratings yet

- Item 4.8 MC-300-ADocument2 pagesItem 4.8 MC-300-Alusoegyi 1919No ratings yet

- Blaugelb FRS Bodentiefer Anschluss EN PDFDocument104 pagesBlaugelb FRS Bodentiefer Anschluss EN PDFTsveta DonevaNo ratings yet

- Machine Tools For MachiningDocument56 pagesMachine Tools For MachiningUmberto PriscoNo ratings yet

- 1 Input Data: Hilti PROFIS Engineering 3.0.81Document8 pages1 Input Data: Hilti PROFIS Engineering 3.0.81Zaido Al HalabiNo ratings yet

- 01/10 - Rock Excavation HandbookDocument6 pages01/10 - Rock Excavation HandbookHakan_KURU100% (1)

- Mastercam C-Axis Tutorial6Document55 pagesMastercam C-Axis Tutorial6xuanphuong27100% (1)

- Drilling Machine Operations & ClassificationsDocument23 pagesDrilling Machine Operations & Classificationsmuneiah100% (1)

- MV Series (MV66A-MV106A) - E-Catalogue - ENG - 2Document12 pagesMV Series (MV66A-MV106A) - E-Catalogue - ENG - 2Dhika PurnomoNo ratings yet

- Catalogo GVN 2016 PDFDocument96 pagesCatalogo GVN 2016 PDFPier De La Cruz BorjaNo ratings yet

- Workshop Practice Series 26 - Home Workshop Hints and TipsDocument63 pagesWorkshop Practice Series 26 - Home Workshop Hints and TipsGOUTHAM RATHINAM100% (3)

- Atlas Copco ROC L8 Specifications PDFDocument4 pagesAtlas Copco ROC L8 Specifications PDFlesantiago29% (7)

- Deep Hole Machining ENGDocument150 pagesDeep Hole Machining ENGCristian Fuentes100% (1)

- Project Report 360 Degree Drilling MachineDocument11 pagesProject Report 360 Degree Drilling MachineSumit Bijwe80% (5)

- Rotary Drilling Products Raise Bore PDFDocument3 pagesRotary Drilling Products Raise Bore PDFIng del PeleNo ratings yet

- Morich Dual Angle LayoutDocument12 pagesMorich Dual Angle Layoutft1ft1No ratings yet