Professional Documents

Culture Documents

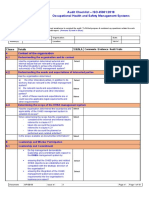

ISO 45001 Gap Analysis Checklist

Uploaded by

Khuda BukshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ISO 45001 Gap Analysis Checklist

Uploaded by

Khuda BukshCopyright:

Available Formats

Gap analysis for transition from OHSAS 18001 to ISO 45001

Clauses of ISO 45001 Clauses of OHSAS 18001 Evidence required Action

needed

4 Context of the organisation

4.1 Understanding your organization New requirement! Have the OH&S-related internal and external

and its context factors and conditions been identified that

could affect, or be affected by, your

organisation?

Have the significant risks and opportunities

been identified?

What drives the OH&S culture of your

organisation?

4.2 Understanding the needs and New requirement! Who might affect or be affected by your

expectations of interested parties activities and what their relevant and significant

interests might be?

Have you taken their needs into account within

the OH&SMS?

4.3 Determining the scope of the 1 Scope & 4.1 Does the written statement of scope allow for:

OH&S management system a) The external and internal issues referred to in

4.1;

b) Requirements referred to in 4.2;

c) The work related activities performed.

4.4 OH & S management system and 4.1 General No significant change.

your processes Requirements

The HSQE Department Ltd

Registered Office: 2, Stafford Place, Weston-super-Mare, BS23 2QZ

T: 01934 316224 E: info@thehsqedepartment.com

Gap analysis for transition from OHSAS 18001 to ISO 45001

Clauses of ISO 45001 Clauses of OHSAS 18001 Evidence required Action

needed

5 Leadership and worker participation

5.1 Leadership and commitment 4.4.1, 4.4.3, 4.4.6 Is top management engaged & leading OH&S,

rather than delegating to someone further

down your organisation.

Are workers being involved directly to protect,

improve performance, and support the OH&S

system.

5.2 OH&S policy 4.2 OH&S policy Does the written policy statement emphasise

communication and participation of workers,

across the organization; commit to satisfy

legal and other requirements; commit to the

hierarchy of controls to OH&S risks?

5.3 Organizational roles, 4.4.1 Resources, roles, responsibility, No significant change

responsibilities, accountabilities and accountability & authority

authorities

5.4 Participation and consultation 4.4.2, 4.4.3, 4.5.1, 4.5.2, 4.5.3 This clause has been substantially strengthened

to capture and promote worker participation,

engagement and communications.

Demonstrate the participation of non-

managerial employees in OH&S management,

including incident investigations, risk

assessments, control and monitoring activities

and internal auditing

The HSQE Department Ltd

Registered Office: 2, Stafford Place, Weston-super-Mare, BS23 2QZ

T: 01934 316224 E: info@thehsqedepartment.com

Gap analysis for transition from OHSAS 18001 to ISO 45001

Clauses of ISO 45001 Clauses of OHSAS 18001 Evidence required Action

needed

6 Planning for the OH&S system

6.1 Actions to address risks and 4.3.1, 4.3.2 & 4.3.3 Have the risks and opportunities from 4.1 been

opportunities documented and have actions been defined to

take advantage of the opportunities and

mitigate the risks?

Demonstrate that these actions have been

effective. This should include compliance to

legal and other requirements.

6.2 OH&S objectives and planning to 4.3.3 Are objectives compatible with the policy

achieve them statement, OH&S risks and opportunities,

business context and adequately resourced?

Objectives and plans to achieve them must be

documented. There should be a record of who

is responsible, agreed timings, measures in

place to establish progress and whether they

have been achieved.

The HSQE Department Ltd

Registered Office: 2, Stafford Place, Weston-super-Mare, BS23 2QZ

T: 01934 316224 E: info@thehsqedepartment.com

Gap analysis for transition from OHSAS 18001 to ISO 45001

Clauses of ISO 45001 Clauses of OHSAS 18001 Evidence required Action

needed

7. Support

7.1 Resources 4.4 No significant change

7.2 Competence 4.4.2 Documented evidence of competence.

Documented evidence that the effectiveness of

training has been checked.

7.3 Awareness 4.4.2 Are workers aware of policy requirements,

hazards & risks relevant to them and their part

in the OH&S performance, including results of

relevant incident investigations?

7.4 Information and communication 4.4.3 Participation and consultation are diffused

through 45001, but this clause adds a

requirement to consider what and why needs to

be communicated and whether the

communication was successful.

7.5 Documented Information 4.4.4 & 4.4.5, 4.5.4 Documented information replaces the idea of

documents and records, but no significant

change is needed.

The HSQE Department Ltd

Registered Office: 2, Stafford Place, Weston-super-Mare, BS23 2QZ

T: 01934 316224 E: info@thehsqedepartment.com

Gap analysis for transition from OHSAS 18001 to ISO 45001

Clauses of ISO 45001 Clauses of OHSAS 18001 Evidence required Action

needed

8. Operation

8.1.1 Operational planning and 4.4.6 Have controls for hazards and risk controls been

control planned and included in operational controls

and do these allow for capabilities of the

workforce?

Are these documented where necessary?

8.1.2 Hierarchy of controls New requirement! Is the hierarchy of OH&S controls correctly

applied?

8.2 Management of change New requirement! When changes to the operation are planned, is

the effect on the O&HMS considered?

8.3 Outsourcing New requirement! The OH&S implications must be controlled as

part of the purchasing process.

8.4 Procurement New requirement! OH&S controls relevant to the purchase of

goods and materials.

8.5 Contractors New requirement! Controls and communication requirements with

regard to contractors worker activities, the

host companys worker activities, and anyone

who may be affected by the activity in the

workplace.

8.6 Emergency preparedness and 4.4.7 Emergency plans take the needs of relevant

response third parties into account and are tested

periodically.

Emergency drills are evaluated and learned

from.

The HSQE Department Ltd

Registered Office: 2, Stafford Place, Weston-super-Mare, BS23 2QZ

T: 01934 316224 E: info@thehsqedepartment.com

Gap analysis for transition from OHSAS 18001 to ISO 45001

Clauses of ISO 45001 Clauses of OHSAS 18001 Evidence required Action

needed

9. Performance evaluation

9.1 Monitoring, measurement, analysis 4.5, 4.5.1 Demonstrate that there is a process in place.

and evaluation Monitoring, measurement, analysis and

evaluation of OH&S metrics must take into

account business context, relevant third parties,

policy risks, opportunities and objectives.

9.1.2 Evaluation of compliance with 4.5.2 Similar to existing arrangements, but the

legal requirements and other frequency and method of compliance checking

need to be considered.

requirements

9.2.1 Internal audit objectives 4.5.5 No significant change

9.2.2 Internal audit process 4.5.5 Workers must be included in the audit process.

9.3 Management review 4.6 Added emphasis on improvement and

communications based on risks, opportunities

and system effectiveness

The HSQE Department Ltd

Registered Office: 2, Stafford Place, Weston-super-Mare, BS23 2QZ

T: 01934 316224 E: info@thehsqedepartment.com

Gap analysis for transition from OHSAS 18001 to ISO 45001

Clauses of ISO 45001 Clauses of OHSAS 18001 Evidence required Action

needed

10 Improvement

10.1 Incident, nonconformity and 4.5.3, 4.5.3.1, 4.5.3.2 Note: Preventive Action has been dropped

corrective action because this is addressed through management

of risks and opportunities.

Corrective action is taken in a timely manner to

control an incident or nonconformity and deal

with the consequences.

Root cause analysis used to understand why an

incident happened.

When corrective action has been completed,

your organisation considers whether further

action is required to prevent a similar incident

or nonconformity occurring in future.

Your organisation considers whether the

potential for a similar problem remains

possibly in another area of the operation and

acts to implement changes if needed.

10.2.1 Continual improvement Employees are involved in continual

objectives improvement

10.2.2 Continual improvement A process that demonstrates continual

process improvement is planned, implemented &

maintained.

The required and actual outcomes of continual

improvement are communicated to employees.

The HSQE Department Ltd

Registered Office: 2, Stafford Place, Weston-super-Mare, BS23 2QZ

T: 01934 316224 E: info@thehsqedepartment.com

You might also like

- ISO 45001 ChecklistDocument16 pagesISO 45001 ChecklistBalaji Rajaraman94% (17)

- ISO 45001.docx Check ListDocument17 pagesISO 45001.docx Check Listmabppu100% (4)

- ISO 45001 Checklist ReviewDocument27 pagesISO 45001 Checklist ReviewRubiyati Inayah100% (6)

- Veera Iso 45001-2018nutshellDocument11 pagesVeera Iso 45001-2018nutshellVeerabahu Nallasivam0% (1)

- ISO 45001 2018 Gap Analysis Checklist Sample PDFDocument5 pagesISO 45001 2018 Gap Analysis Checklist Sample PDFMuhammad Iqbal NiyaziNo ratings yet

- Audit Checklist for ISO 45001Document10 pagesAudit Checklist for ISO 45001Ashraf Serag100% (4)

- ISO 45001 Audit ChecklistDocument17 pagesISO 45001 Audit ChecklistVignesh Nayamozhi100% (3)

- ISO 45001.docx Check ListDocument18 pagesISO 45001.docx Check ListKrishna Vacha100% (1)

- Gap analysis for transition from OHSAS 18001 to ISO 45001Document7 pagesGap analysis for transition from OHSAS 18001 to ISO 45001wf4sr4rNo ratings yet

- ISO 14001:2015 Audit Guide and ChecklistFrom EverandISO 14001:2015 Audit Guide and ChecklistRating: 3.5 out of 5 stars3.5/5 (8)

- Iso 45001:2018Document3 pagesIso 45001:2018fansamaster50% (6)

- 45001:2018 Audit Checklist (Preview)Document7 pages45001:2018 Audit Checklist (Preview)Centauri Business Group Inc.94% (17)

- ISO 45001 ChecklistDocument10 pagesISO 45001 Checklistsaravanakumarpalani100% (3)

- ISO 45001 - Gap Assessment - ChecklistDocument6 pagesISO 45001 - Gap Assessment - Checklistshakti123456789No ratings yet

- ISO 45001-2018 Assessment ChecklistDocument26 pagesISO 45001-2018 Assessment Checklistmuhammad_hatta_adam86% (7)

- ISO 45001 2018 OHSMS - Audit ChecklistDocument7 pagesISO 45001 2018 OHSMS - Audit ChecklistdamonbNo ratings yet

- Clause by Clause Explanation of ISO 45001 2018 enDocument15 pagesClause by Clause Explanation of ISO 45001 2018 enGonzalvus Ahumada100% (11)

- Iso 45001 2018 Manual Documents PDFDocument10 pagesIso 45001 2018 Manual Documents PDFabdelnasser hasan60% (5)

- ISO 45001 Manual-Rev-00-06-07-2018-1 PDFDocument18 pagesISO 45001 Manual-Rev-00-06-07-2018-1 PDFAnonymous vmw7z1WHm83% (6)

- Draft ISO 45001 GuideDocument15 pagesDraft ISO 45001 GuideCristian Camilo Rodriguez93% (15)

- ISO 45001:2018 Awareness OverviewDocument73 pagesISO 45001:2018 Awareness Overviewsanjeev kumar100% (15)

- Iso 45001-2018 Course PDFDocument43 pagesIso 45001-2018 Course PDFAbbi Lone100% (8)

- NQA ISO 45001 Implementation GuideDocument36 pagesNQA ISO 45001 Implementation GuideAnonymous 3eHGEDbx100% (11)

- Checklist of Mandatory Documentation Required by ISO 45001 enDocument12 pagesChecklist of Mandatory Documentation Required by ISO 45001 enashraf90% (10)

- ISO 45001 2018 Versus OHSAS 18001 ClausewiseDocument6 pagesISO 45001 2018 Versus OHSAS 18001 ClausewiseEngilsh Iso80% (10)

- ISO 45001:2018 Gap AnalysisDocument1 pageISO 45001:2018 Gap AnalysisCentauri Business Group Inc.100% (1)

- ISO 45001 Matrix Final VersionDocument4 pagesISO 45001 Matrix Final VersionAlumni99 ST Thomas100% (2)

- Manual PreviewDocument16 pagesManual PreviewMuhammad Yasin67% (6)

- Iso 45001Document56 pagesIso 45001Fhandy Bz100% (5)

- ISO 45001 Guide for Occupational Health and Safety ImplementationDocument54 pagesISO 45001 Guide for Occupational Health and Safety ImplementationALOKE GANGULY100% (4)

- ISO 45001-2018-Basic-Gap-Checklist MasterDocument40 pagesISO 45001-2018-Basic-Gap-Checklist Mastervisutsi50% (2)

- Example of ISO 45001 - 2018 OHSMS Manual - ISO Consultant in KuwaitDocument22 pagesExample of ISO 45001 - 2018 OHSMS Manual - ISO Consultant in KuwaitShengrong Yee100% (1)

- OH&S Requirements in ISO 45001 Clauses - Presentation (Preview)Document9 pagesOH&S Requirements in ISO 45001 Clauses - Presentation (Preview)Centauri Business Group Inc.100% (8)

- ISO 14001 ChecklistDocument7 pagesISO 14001 Checklistsyed zafar ullah shahNo ratings yet

- 2015 Iso 14001Document58 pages2015 Iso 14001Anonymous ZZa7eu100% (4)

- ISO 45001 Documentation Toolkit OverviewDocument2 pagesISO 45001 Documentation Toolkit Overviewvictor100% (1)

- ISO 45001 2018 - Easy VersionDocument13 pagesISO 45001 2018 - Easy VersionKannan JaganNo ratings yet

- ISO 45001 Self AssessmentDocument12 pagesISO 45001 Self Assessmentahmed Mohammed100% (9)

- ISO 450001.2018 ChecklistDocument4 pagesISO 450001.2018 ChecklistNeeru Řathee100% (6)

- ISO 45001-2018 Briefing Presentation-NSAIDocument70 pagesISO 45001-2018 Briefing Presentation-NSAIOssamaIsmail100% (8)

- ISO 45001 Implementation Guide: Everything You Need to KnowDocument30 pagesISO 45001 Implementation Guide: Everything You Need to KnowMuhammad fahmy100% (3)

- Internal Audit Checklist ISO 14001Document9 pagesInternal Audit Checklist ISO 14001Yasir Zoha100% (3)

- ISO 45001 Auditor's Checklist TemplateDocument8 pagesISO 45001 Auditor's Checklist TemplateDemmy Rose Nugas100% (1)

- ISO 45001 ChecklistDocument5 pagesISO 45001 Checklistrajivfr144100% (1)

- ISO 14001 2015 Audit Checklist. DQSDocument19 pagesISO 14001 2015 Audit Checklist. DQSananthu.u100% (3)

- Iso 45001 RevealedDocument34 pagesIso 45001 Revealedarki100% (9)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- ISO 45001 A Complete Guide - 2021 EditionFrom EverandISO 45001 A Complete Guide - 2021 EditionRating: 5 out of 5 stars5/5 (1)

- Clauses of ISO 45001 Clauses of OHSAS 18001 Evidence Required Action NeededDocument7 pagesClauses of ISO 45001 Clauses of OHSAS 18001 Evidence Required Action NeededdanielhvillaNo ratings yet

- MANAGE YOUR MIGRATION TO ISO 45001Document6 pagesMANAGE YOUR MIGRATION TO ISO 45001Shirel RefaeliNo ratings yet

- ISO 45001:2018 Checklist: 4. Context of The Organisation 4.1 Understanding The Organisation and Its ContextDocument50 pagesISO 45001:2018 Checklist: 4. Context of The Organisation 4.1 Understanding The Organisation and Its ContextWilly NaufalindoNo ratings yet

- ISO 45001 2018 Audit ChecklistDocument16 pagesISO 45001 2018 Audit ChecklistSiv KumarNo ratings yet

- ISO 45001 - 2018 Checklist - Part IDocument9 pagesISO 45001 - 2018 Checklist - Part IgwarianilNo ratings yet

- Ohsms ChecklistDocument19 pagesOhsms ChecklistALOKE GANGULYNo ratings yet

- Toxic Gas Fact SheetDocument15 pagesToxic Gas Fact SheetKhuda BukshNo ratings yet

- Work at Heigh at Night SafetyDocument49 pagesWork at Heigh at Night SafetyKhuda BukshNo ratings yet

- Work at Height Safety Question & AnswersDocument34 pagesWork at Height Safety Question & AnswersKhuda BukshNo ratings yet

- HSE Docs 186 HSE Checklists Hseprof ComDocument57 pagesHSE Docs 186 HSE Checklists Hseprof ComMansoor BabbarNo ratings yet

- HSE PLAN by HTTPSDocument52 pagesHSE PLAN by HTTPSKhuda BukshNo ratings yet

- Short Note For Safety OfficerDocument24 pagesShort Note For Safety OfficerKhuda BukshNo ratings yet

- Stamp: Copy No. HolderDocument266 pagesStamp: Copy No. HolderMd EnaamAzharNo ratings yet

- Monthly HSE Performance ReportDocument17 pagesMonthly HSE Performance ReportKhuda BukshNo ratings yet

- Safety GuideDocument53 pagesSafety GuideKhuda BukshNo ratings yet

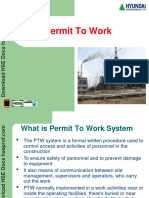

- Permit To Work ProcedureDocument42 pagesPermit To Work ProcedureKhuda Buksh100% (1)

- HSE-BMS-010 Permit To WorkDocument24 pagesHSE-BMS-010 Permit To WorkKhuda BukshNo ratings yet

- HSE Procedure For Planning & AuditingDocument4 pagesHSE Procedure For Planning & AuditingKhuda Buksh100% (1)

- 1691582034614Document16 pages1691582034614Joseph NNo ratings yet

- 500 Technical Questions Safety&Fire-1Document26 pages500 Technical Questions Safety&Fire-1Saad GhouriNo ratings yet

- Checklist For Heavy Equipment - 1Document15 pagesChecklist For Heavy Equipment - 1Katita ChascaNo ratings yet

- HSE Drilling and Well Control ProcedureDocument5 pagesHSE Drilling and Well Control ProcedureKhuda Buksh100% (1)

- HSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXDocument106 pagesHSE (Trainor Et Al) - 2006 - HSE Report No 426 ACUTEXKhuda Buksh100% (1)

- HSE Procedure For Garbage DisposalDocument4 pagesHSE Procedure For Garbage DisposalKhuda BukshNo ratings yet

- NFPAP Member Registration Form - WordDocument1 pageNFPAP Member Registration Form - WordKhuda BukshNo ratings yet

- Weekly Safety InspDocument4 pagesWeekly Safety InspKhuda BukshNo ratings yet

- 02 Abrasive WheelsDocument2 pages02 Abrasive WheelsKhuda BukshNo ratings yet

- 3S Technical Proposal OHSAS ISO Implementation PDFDocument38 pages3S Technical Proposal OHSAS ISO Implementation PDFKhuda BukshNo ratings yet

- Emergency ProceduresDocument23 pagesEmergency ProceduresKhuda BukshNo ratings yet

- 06 Power Tools OperationDocument2 pages06 Power Tools OperationKhuda BukshNo ratings yet

- CV Zafar Ul Haq KhokharDocument1 pageCV Zafar Ul Haq KhokharKhuda BukshNo ratings yet

- Quality PlanDocument21 pagesQuality PlanTAHER AMMAR86% (7)

- 03 Wood CuttingDocument1 page03 Wood CuttingKhuda BukshNo ratings yet

- PPE PROTECTIONDocument3 pagesPPE PROTECTIONKhuda BukshNo ratings yet

- Carbon MonoxideDocument17 pagesCarbon MonoxideKhuda BukshNo ratings yet

- Symmetrical Triangles - Chart Formations That Consolidate Before BreakoutsDocument13 pagesSymmetrical Triangles - Chart Formations That Consolidate Before BreakoutsYin Shen Goh100% (4)

- Rathore - Political SociologyDocument23 pagesRathore - Political SociologyCybs BiasbasNo ratings yet

- Questions About ShoppingDocument4 pagesQuestions About ShoppingPutri Nur AzizahNo ratings yet

- FUJITSU 1.2GHz PLL Frequency Synthesizer Data SheetDocument26 pagesFUJITSU 1.2GHz PLL Frequency Synthesizer Data SheetherzvaiNo ratings yet

- How to Write the Perfect Personal StatementDocument36 pagesHow to Write the Perfect Personal StatementКсенияNo ratings yet

- Evaluate Narrativs Based On How The Author Developed The Element THEMEDocument30 pagesEvaluate Narrativs Based On How The Author Developed The Element THEMEDianArtemiz Mata Valcoba80% (25)

- COVID-19 Pandemic: Clinical Presentation, DiagnosticsDocument40 pagesCOVID-19 Pandemic: Clinical Presentation, DiagnosticsOlin AditamaNo ratings yet

- Fairytale PretestDocument3 pagesFairytale Pretestapi-339190123No ratings yet

- Maloto v. CADocument2 pagesMaloto v. CAMariella Grace AllanicNo ratings yet

- The New Barbarians at The Gate - Debt-Based TakeoversDocument61 pagesThe New Barbarians at The Gate - Debt-Based TakeoversWho's in my Fund100% (1)

- English10 q4 w7 Mod7Document16 pagesEnglish10 q4 w7 Mod7Richander M. MocallayNo ratings yet

- pmwj97 Sep2020 Fashina Ahmed Salah Fakunle Major Barriers To PM in Small Medium Construction CompaniesDocument21 pagespmwj97 Sep2020 Fashina Ahmed Salah Fakunle Major Barriers To PM in Small Medium Construction CompaniesMahamud AliNo ratings yet

- Ode Massacre Gujarat Riots Case JudgementDocument474 pagesOde Massacre Gujarat Riots Case JudgementSampath BulusuNo ratings yet

- Second Group Project - Risk and ReturnDocument3 pagesSecond Group Project - Risk and ReturnJeff RuncornNo ratings yet

- Larvicidal Activity of Some Saponin Containing Plants Against The Dengue Vector Aedes Aegypti.Document11 pagesLarvicidal Activity of Some Saponin Containing Plants Against The Dengue Vector Aedes Aegypti.Dr. Jawale Chetan S.100% (1)

- Understanding Pharmaceutical Quality by DesignDocument13 pagesUnderstanding Pharmaceutical Quality by Designcabeto124211No ratings yet

- The Georgia GuidestonesDocument50 pagesThe Georgia Guidestonesantivenin9No ratings yet

- ITC Strategic Implementation GuideDocument13 pagesITC Strategic Implementation GuidePranav Goyal100% (1)

- Muslim Women in The Tenement Gardens of Colombo: A Story of Marginalization, Legitimized by A Culture of OppressionDocument36 pagesMuslim Women in The Tenement Gardens of Colombo: A Story of Marginalization, Legitimized by A Culture of OppressionSocial Scientists' AssociationNo ratings yet

- Leveraging Consumer Behavior: How Coca-Cola Targets the Indian MarketDocument12 pagesLeveraging Consumer Behavior: How Coca-Cola Targets the Indian MarketKarthikeyan ThiagarajanNo ratings yet

- Complete Travel Sentences Word Box Choices Flights Delays Cabin Service Meals Behavior DivertDocument4 pagesComplete Travel Sentences Word Box Choices Flights Delays Cabin Service Meals Behavior DivertIonela BesleagaNo ratings yet

- Flow Control Using A PID-Controlled ValveDocument5 pagesFlow Control Using A PID-Controlled ValvejaspeiNo ratings yet

- Introduction To National 5 English RuaeDocument20 pagesIntroduction To National 5 English RuaezaminNo ratings yet

- Learning Styles ExplainedDocument4 pagesLearning Styles ExplainedAisyah Nauli SihotangNo ratings yet

- Evaluation of PISONETDocument2 pagesEvaluation of PISONETDave Gulimlim78% (9)

- Tchaikovsky Piano Concerto No 1 in BB Major Op 23 Mov 1Document95 pagesTchaikovsky Piano Concerto No 1 in BB Major Op 23 Mov 1Marta FloresNo ratings yet

- Ombudsman vs. SamaniegoDocument15 pagesOmbudsman vs. Samaniegoheymissruby100% (1)

- EdTPA SES Planning Commentary Danielle WilsonDocument4 pagesEdTPA SES Planning Commentary Danielle WilsonDanielle Wilson70% (10)

- PGDPM S1 Module 2 TestDocument5 pagesPGDPM S1 Module 2 TestLevi MuromboNo ratings yet

- Why is sample size importantDocument98 pagesWhy is sample size importantLaura RossiNo ratings yet