Professional Documents

Culture Documents

HiQSolar 20 Common Mistakes Installing PV Systems

Uploaded by

anand.iitd4358Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HiQSolar 20 Common Mistakes Installing PV Systems

Uploaded by

anand.iitd4358Copyright:

Available Formats

20

Common Mistakes

Installing PV Systems

5 October 2016, v1.2

Introduction

Even the most experienced professionals make mistakes,

and PV systems present many opportunities for errors. In

this paper we list some of the more common issues weve

seen or heard about often enough to be worth mentioning.

Our intention is to be brand agnostic but where we couldnt

resist the urge to put in our own propaganda its in italics.

Enjoy!

Contents

Inverter Physical Mounting ............................................................................................................. 2

1. Not Leaving Enough Room Around Inverters ...................................................................... 2

2. Mounting in Direct Sunlight ................................................................................................ 2

DC-Side Electrical ............................................................................................................................ 2

3. Strings Arent Connected .................................................................................................... 2

4. String Wires Reversed ......................................................................................................... 3

5. Swapped Strings .................................................................................................................. 3

6. Poor Quality Crimping ......................................................................................................... 4

7. Connectors Not Latched ...................................................................................................... 4

8. Connectors Exposed to Moisture While Open .................................................................... 4

9. Excessively High Resistance on DC Side ............................................................................... 4

10. Not Accounting for Differential Thermal Expansion .......................................................... 4

11. Wires Not Long Enough ..................................................................................................... 5

12. Insulation Cold Flow .......................................................................................................... 5

AC-Side Electrical ............................................................................................................................ 5

13. Problems with Grounding ................................................................................................. 5

14. Phase Wiring Issues ........................................................................................................... 5

15. Phase Power Imbalance .................................................................................................... 6

16. Issues with External Voltage Translation Transformers .................................................... 6

17. High Resistance ................................................................................................................. 6

18. Breaker Issues ................................................................................................................... 6

19. Problems with Terminations ............................................................................................. 7

Communications ............................................................................................................................. 7

20. Customer Internet Connections ........................................................................................ 7

Acknowledgements ........................................................................................................................ 7

HiQ Solar, Inc. www.hiqsolar.com Page 1 of 7

20 Common Mistakes Installing PV Systems 5 October 2016

Inverter Physical Mounting

1. Not Leaving Enough Room Around Inverters

The enemy here can be the desire to have everything looking neat in such a way that there is

not enough room around the inverter to allow it to be accessed or removed by a service tech.

Alternatively it can be not being aware of minimum spacing of inverters that need air circulation

or access to change air filters. If there are minimum spacings for a particular inverter they will be

specified in the installation manual.

2. Mounting in Direct Sunlight

Most inverters are rated for outdoor use. However, mounting string inverters on a south-facing

or west facing wall is a common practice with possible negative consequences. Most inverters

have a wide operating temperature range, but will de-rate as they exceed a particular

temperature so the impact is likely to be on energy harvest. In addition, many have fans,

displays, electrolytic capacitors etc. that will degrade over time with temperature and/or UV

exposure, requiring visits for repair or replacement. Overall its recommended to mount

inverters in a shaded location if possible. TrueString inverters are sealed, have no displays, no

electrolytic capacitors, no fans or air filters and can be mounted under the array. Other than the

normal power de-rating at high temperature our inverters can be mounted anywhere.

DC-Side Electrical

3. Strings Arent Connected

This can be very difficult to detect and diagnose with large string and central inverters, but this

error is very common. Easy to see with the TrueString inverters. For example, Figure 1 shows a

graph comparing inverter outputs for an array (a); the lowest performer (#2766) is easy to

identify (b). Looking at the performance summary for that specific inverter it is obvious that one

string (String 1) is the culprit (c).

(b)

(a)

(c)

Figure 1: Identifying the lowest performing inverter in an array

HiQ Solar, Inc. www.hiqsolar.com Page 2 of 7

20 Common Mistakes Installing PV Systems 5 October 2016

4. String Wires Reversed

Very common where custom jumpers are used, can even have same gender connectors on each

end. In addition to the string not producing power, it is possible that this can damage the

inverter. Errors like this are less likely if wiring is clearly identified, such as in the installation of

Figure 2 below.

Figure 2: Clearly identified string polarities make mis-wiring harder

5. Swapped Strings

This is less common, but we have seen it plus and minus wires of unrelated strings connected

to each input. For large string inverters with many strings bundled together it can even be each

side of a string connected to different inverters. As with the previous point, clear labeling at

each end of wiring runs is usually worth the time.

With individual string monitoring and two separate inputs only, it is easier to see on the

TrueString inverter than with large string inverters with many strings wired in parallel.

+" +"

1" 1"

#" #"

+" +"

2" 2"

#" #"

"

Figure 3: Connecting wires from unrelated strings

"

HiQ Solar, Inc. www.hiqsolar.com Page 3 of 7

20 Common Mistakes Installing PV Systems 5 October 2016

For inverters that use two or more strings in parallel per DC input, it is also possible to

accidentally connect the strings in series instead of parallel. This often damages the inverter.

6. Poor Quality Crimping

Use of the wrong tool to crimp connectors can cause overheating of

terminals, open circuits and burning of connectors. Use of the wrong

tool is very common, but use of a crimper other than that specified by

the connector manufacturer will violate code.

7. Connectors Not Latched

An obvious one, but difficult to see visually. If the connection is not

made it can be easy to see with good monitoring; the more dangerous

situation is where the center conductors are not fully mated and over

time start to arc.

8. Connectors Exposed to Moisture While Open

This applies to modules, home runs and inverters. The project is

partially finished then delayed, then a rainstorm comes through, it

snows or whatever. Homeruns have the connectors crimped but not

mated together, and moisture wicks into the wire jacket and this

causes corrosion and performance and reliability issues long after the

install is over. The picture shows a HiQ TrueString inverter in the

process of being installed. The inverter ships with caps on all

connectors to protect them from moisture ingress during installation.

9. Excessively High Resistance on DC Side

Damage or manufacturing defects in modules such as bubbling in a thin-film module can cause

high resistance to occur; the voltage seems ok until the inverter the tries to draw power from

the module, then the voltage collapses and the inverter shuts off. The inverter tries to restart

and the cycle repeats.

10. Not Accounting for Differential Thermal Expansion

In the pursuit of a professional and neat looking install, string wiring is pulled tight and zip-tied

to the racking, but without any thermal expansion margin. Hotter days and colder nights

combined with the fact that the thermal expansion of copper is 2x that of aluminum racking can

lead to:

i) Connector pins being pulled out of sockets leading to disconnection and/or

arcing

ii) Wire crimps being pulled apart

iii) Strain reliefs being broken

iv) Abrasion of insulation repeatedly over time leading to shorting and possible fire

(Bakersfield fire, for example)

HiQ Solar, Inc. www.hiqsolar.com Page 4 of 7

20 Common Mistakes Installing PV Systems 5 October 2016

The longer the wiring run, the bigger the effect.

11. Wires Not Long Enough

Similarly, cutting wires to the exact length to reach the inverter can be a problem. Firstly, it costs

flexibility for later in the install when it is discovered that any string mis-wiring issues have

occurred, and there isnt enough spare length to swap the wires to the correct terminals. It can

also be a problem later when the service tech has to swap an inverter out to a different design.

Good workmanship suggests a Service Loop of between half and one turn of wire inside a

junction box precisely for serviceability later.

12. Insulation Cold Flow

Where wires are tightly and neatly secured to a module frame Wire%

or racking member pass over a sharp corner, over a period of Insula0on%

months or years the pressure of the corner against the cold%ow%

insulation can cause the insulation to flow away from the

pressure until the conductor shorts against the metal frame. Rack%

corner%

AC-Side Electrical

13. Problems with Grounding

Many issues are possible here, ranging from code violations to significant safety issues. Most

installations require the DC side to be ungrounded now that non-isolated (TL) inverters are

common, which simplifies things. A few less obvious ones:

Grounding using dissimilar metals can be metals with very different galvanic values1

such as bare copper wires touching aluminum frames; can be metals with similar (but

not identical) galvanic values such as copper and tin plus the addition of coastal

moisture with salt over a longer period. The result is obviously corrosion. In the case of

coastal conditions, coating with dielectric grease is messy but effective

Painted enclosures can either be grounded to racking etc. with fasteners listed as paint

cutting, or the paint must be cleared off the grounding point during installation

14. Phase Wiring Issues

A Phase Not Connected

Usually relatively easy to detect.

Neutral Connected to Hot Phase

Again, usually relatively easy to detect.

U"lity' A' A' Inverter'

Two Hot Phases Connected to One Side' B' B' Side'

See picture, two phases of the inverter output might

C' C'

accidentally connect to the same grid phase. Commonly

leads to an inverter fault.

1

http://inspectapedia.com/BestPractices/Galvanic_Scale_Corrosion.php

HiQ Solar, Inc. www.hiqsolar.com Page 5 of 7

20 Common Mistakes Installing PV Systems 5 October 2016

15. Phase Power Imbalance

Can be a design issue, or an electrician issue. With a maximum imbalance allowed of 6 kW, this

can be an issue in commercial installs particularly with single-phase inverters. Obviously an

inherently 3-phase inverter such as our TrueString does not have this issue.

16. Issues with External Voltage Translation Transformers

The lack of cost-effective 208V inverters until recently has meant the use of transformers. Some

possible issues:

Neutral not carried through the transformer. If communications between inverter and

gateway is over powerline, this can inhibit them talking if the gateway is on the other

side of the transformer

Transformers have parasitic losses 24 hours a day, so it is common to disconnect them

overnight, controlled by a timer. If power to the timer is interrupted the array can have

productive hours wasted for months or years if nobody notices that the time is offset.

17. High Resistance

Grid voltage measures ok until power is exported from the inverter because of the high

resistance the voltage then rises, and can cause overvoltage tripping of the inverter.

The picture shows one phase of a 3-phase breaker not torqued down properly, which resulted in

a high resistance and overvoltage tripping of the inverter.

Shutdown)

(a)) (b))

18. Breaker Issues

In addition to the example above, breakers can fail in a lot of ways on their own, although this is

more common in older systems they can fail open or closed, or just one phase can fail open or

closed when the handle indicates all three phases are closed or vice versa. Very dangerous,

always de-energize and test, test again before touching dont trust the label on the handle.

Of course there is also selecting the right breaker in the first place sizing it, physical form

factor for the panel board, having the right interruption rating which is something that doesnt

HiQ Solar, Inc. www.hiqsolar.com Page 6 of 7

20 Common Mistakes Installing PV Systems 5 October 2016

come up until its called upon to stop the building catching on fire. The OCPD Interrupt Rating

must be sized to be the same or greater than the short circuit current capability of the utility

connection. Then coordinating with the other overcurrent protection devices.

19. Problems with Terminations

When you have a lot of them or theyre big, theres a lot to get right. These can be terminals,

inverters, splice boxes, other conductors. Are the connections tight, let alone torqued properly,

at least tight? For stranded conductors, are there any wayward strands that could occasionally

arc over to the next conductor? For breakers are the wires terminating properly, and then is the

breaker terminating properly on the bus bars? And there can be an issue with cold flow. After a

connection is torqued, and over time, the soft copper or aluminum conductor gives way and

causes the connection to loosen. It is always advisable to do a follow-up re-torqueing of major

connections some months after installation.

Communications

20. Customer Internet Connections

Using the customers internet connection to keep track of the system performance is a low cost

approach, but can be fraught with issues later. These can include delays getting the system

connected at the beginning while the local IT department drags its feet opening the right ports

on the router. It can catch you later when they take on a new IT guy, or change security policy

and close all the ports that dont directly affect them. From this point of view cellular modems

that are entirely independent of the customer seem expensive but are probably worth the cost.

For cellular modems in faraway areas it can be a good idea to have them on an AC timer to

automatically and regularly power cycle them in case of lock-up.

Acknowledgements

Thanks to Blake Gleason of Sun Light and Power (http://sunlightandpower.com) for help with

this article.

Copyright HiQ Solar, Inc., 2016

www.hiqsolar.com

HiQ Solar, Inc. www.hiqsolar.com Page 7 of 7

You might also like

- Small Winemaker Production and Sales Survey 2017 AustraliaDocument31 pagesSmall Winemaker Production and Sales Survey 2017 Australiaanand.iitd4358No ratings yet

- Terra Form GolobalDocument529 pagesTerra Form Golobalanand.iitd4358No ratings yet

- Rotman MBA Resume Contact Education ExperienceDocument1 pageRotman MBA Resume Contact Education Experienceanand.iitd4358No ratings yet

- International Transcript RequestDocument2 pagesInternational Transcript RequeststoppopNo ratings yet

- International Transcript RequestDocument2 pagesInternational Transcript RequeststoppopNo ratings yet

- Receipt IIT Delhi Transcript Request PDFDocument1 pageReceipt IIT Delhi Transcript Request PDFanand.iitd4358No ratings yet

- Solar Savings CalculatorDocument1 pageSolar Savings Calculatoranand.iitd4358No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Iva 55Document9 pagesIva 55Nasir KarwanNo ratings yet

- 'CMOS Digital Integrated Circuits' Sung Mo Kang, LeblebiciDocument339 pages'CMOS Digital Integrated Circuits' Sung Mo Kang, Leblebicinnn86% (21)

- 193 Um015 - en P PDFDocument736 pages193 Um015 - en P PDFAdelson PimentelNo ratings yet

- ABB FactSheet SYMS - 112018Document2 pagesABB FactSheet SYMS - 112018Muhammad Hassan BalochNo ratings yet

- Syllabus Au SplittedDocument3 pagesSyllabus Au SplittedVeerapathran MNo ratings yet

- Wseries PDFDocument4 pagesWseries PDFsongreNo ratings yet

- AVCCDocument3 pagesAVCCTanya WilkersonNo ratings yet

- Best Digital Marketing Course in Udaipur.Document33 pagesBest Digital Marketing Course in Udaipur.Eduwigs IndiaNo ratings yet

- SN5408, SN54LS08, SN54S08 SN7408, SN74LS08, SN74S08 Quadruple 2-Input Positive-And GatesDocument16 pagesSN5408, SN54LS08, SN54S08 SN7408, SN74LS08, SN74S08 Quadruple 2-Input Positive-And Gatesnadeem hameedNo ratings yet

- Power System StudiesDocument46 pagesPower System Studiesadau100% (1)

- 74LS164Document5 pages74LS164Byron MendozaNo ratings yet

- Cebora S.P.A.: Service ManualDocument27 pagesCebora S.P.A.: Service ManualJefferson ChangoluisaNo ratings yet

- Biometrically Secured ATM Vigilance SystemDocument4 pagesBiometrically Secured ATM Vigilance SystemSoundaryaNo ratings yet

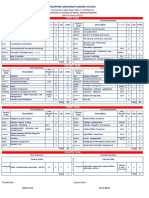

- Philippine Merchant Marine School: First YearDocument5 pagesPhilippine Merchant Marine School: First YearCris Mhar Alejandro100% (1)

- E CommerceDocument16 pagesE CommercesyazwaniNo ratings yet

- Basic Analysis of Counter Rotating TurbineDocument8 pagesBasic Analysis of Counter Rotating Turbinegiuffrericcardo42No ratings yet

- Action Plans and EU Acquis Progress Report 2023 WEBDocument212 pagesAction Plans and EU Acquis Progress Report 2023 WEBRaza KandicNo ratings yet

- Ventilation Calculation 1591013185963Document8 pagesVentilation Calculation 1591013185963mak ksaNo ratings yet

- Electrical Sys - FGPSDocument52 pagesElectrical Sys - FGPSsatender_kumar86100% (1)

- Bizgram Export FileDocument58 pagesBizgram Export FileBizgram Asia0% (1)

- SB 6 VATECHDocument15 pagesSB 6 VATECHMilton SepúlvedaNo ratings yet

- Chapter 3-Part 2 - Angle ModulationDocument34 pagesChapter 3-Part 2 - Angle Modulationyohans shegawNo ratings yet

- Synthesia ManualDocument16 pagesSynthesia ManualSati LallNo ratings yet

- MP 4000 RMM+ Remote MonitoringDocument2 pagesMP 4000 RMM+ Remote Monitoringammonwar1stNo ratings yet

- CEC3010 - DATA-PRIVACY-AND-SECURITY-IN-BUSINESS - LT - 1.0 - 41 - Data Privacy and Security in BusinessDocument3 pagesCEC3010 - DATA-PRIVACY-AND-SECURITY-IN-BUSINESS - LT - 1.0 - 41 - Data Privacy and Security in BusinessRevanta ChoudharyNo ratings yet

- Impact of Partial Shading On The Output Power of PV Systems Under Partial Shading ConditionsDocument10 pagesImpact of Partial Shading On The Output Power of PV Systems Under Partial Shading Conditionsshihab4806No ratings yet

- Maipu MannualDocument12 pagesMaipu MannualKazi BarakatNo ratings yet

- Better Ansible Network Automation With Roles and Custom ModulesDocument22 pagesBetter Ansible Network Automation With Roles and Custom Modulesstanislaw.jachuraNo ratings yet

- Tracer AN Series Solar Charge Controller User ManualDocument44 pagesTracer AN Series Solar Charge Controller User ManualtalibanindonesiaNo ratings yet

- Scientific Recruitment With ResearchGateDocument16 pagesScientific Recruitment With ResearchGateMuhammad OktaviansyahNo ratings yet