Professional Documents

Culture Documents

Selecting Non-Metallic Com-Ponents For API Separators: Water Solutions

Uploaded by

Gladys Gabriela Quispe Ramos0 ratings0% found this document useful (0 votes)

46 views1 pageTratamiento primario aguas oleosas

Original Title

API Separators

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTratamiento primario aguas oleosas

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views1 pageSelecting Non-Metallic Com-Ponents For API Separators: Water Solutions

Uploaded by

Gladys Gabriela Quispe RamosTratamiento primario aguas oleosas

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Water Solutions

Selecting Non-metallic Com-

ponents for API Separators

API separator sludge is heavy and viscous, therefore chain In the past, collector flights had been made of

and flight collector components must be equally heavy redwood. Today, most facilities use non-metallic, fiber

duty. A number of collector chains and flights are avail- glass flights. When selecting a fiberglass flight, note

able. Use the following to help determine your chain and that many resins do not hold up well to the organic

flight selection: compounds found in refinery and petrochemical plant

wastewater, and the flights can quickly delaminate.

Metallic chain has been used with varying degrees of

Also, the moment of inertia of the design and the

success. Types available include cast iron, cast steel and

modulus of elasticity of the material both affect the

stainless steel. Metallic chain is much heavier than non-

strength and stiffness of the flight. The proper combi-

metallic chain, sometimes hindering installation, and

nation is needed to ensure proper movement of sludge.

cast iron and steel components can deteriorate over

time and require replacement. Stainless steel compo- Chain and flight collector components normally have

nents, while less prone to corrosion, are significantly wear shoes attached to them. The wear shoes ride on

more expensive than cast iron or steel. wear strips attached to the tank floor on the bottom

collecting run, and to carrying tracks on the top skim-

The success of non-metallic chain is directly related to

ming run. The wear shoes are normally made of steel

the material composition of the chain. Some non-me-

when using metallic collector components and poly-

tallic chains are prone to chemical attack from organic

ethylene when using non-metallic collectors. Since

compounds in the wastewater, while other types of

non-metallic wear strips can expand under heated con

non-metallic chain can stretch due to high wastewater

ditions and carbon steel wear strips can corrode, stain

temperature. This stretching, or elongation of the

less steel wear strips should be used in most cases.

chain, can result in premature failure of the collector

system as the chain disengages from the sprockets.

Grit in the wastewater can also cause excessive wear

and premature failure on chain connector pins if the

Siemens AG

chain pins are not properly designed. The biggest ad

Freyeslebenstrasse 1

vantage to non-metallic chain is its light weight and 91058 Erlangen, Germany

ease of installation and maintenance. With proper ma-

terial selection and design, non-metallic chain can pro- Siemens AG

vide the same strength and durability as metallic chain, Energy Sector

for less cost, both in materials and labor. Oil & Gas Division

Wolfgang-Reuter-Platz

Like chain, both metallic and non-metallic style collec- 47053 Duisburg, Germany

tor sprockets are available, having the same advantages

and disadvantages, with one exception. Motor drive Siemens Energy Inc.

301 West Military Road

sprockets and collector head shaft sprockets have a sig-

Rothschild, WI 54474, USA

nificant amount of torque and load on them. Some

Phone: +1.715.359.7211

non-metallic sprockets suitable for use on idle shafts email: water.energy@siemens.com

may not be suitable for drive, or high torque, applica-

tions because of material strength. Order No. E50001-D450-A111-X-4A00 | 09.2012 Siemens AG

www.siemens.com/oilgas

You might also like

- Service Manual Pu100Document146 pagesService Manual Pu100Dito Aprian100% (3)

- Denon Dp-300f Service en JPDocument20 pagesDenon Dp-300f Service en JPjoshuaajohnNo ratings yet

- Evh5150 III HeadDocument13 pagesEvh5150 III HeaddavhalenNo ratings yet

- Rush SheetsDocument1 pageRush SheetszandashNo ratings yet

- SAE Recording GuideDocument225 pagesSAE Recording GuidesalvaesNo ratings yet

- Crossover CookbookDocument31 pagesCrossover CookbookManish KubawatNo ratings yet

- Encyclopedia of Electrochemistry, Volume 7b: Inorganic Electrochemistry (Encyclopedia of Electrochemistry) (PDFDrive)Document523 pagesEncyclopedia of Electrochemistry, Volume 7b: Inorganic Electrochemistry (Encyclopedia of Electrochemistry) (PDFDrive)abdulqudus abdulakeemNo ratings yet

- 1 4920401554629984258 PDFDocument278 pages1 4920401554629984258 PDFDaniel Janthinus Kristianto100% (1)

- Identifying Hazardous and Deleterious MaterialsDocument41 pagesIdentifying Hazardous and Deleterious MaterialsJoe GaffneyNo ratings yet

- Frank C. Porter Corrosion Resistance of Zinc and Zinc Alloys 1994Document532 pagesFrank C. Porter Corrosion Resistance of Zinc and Zinc Alloys 1994Carlos Bermejo Alvarez100% (1)

- Bar ScreenDocument16 pagesBar ScreenRizqi Ahsan NashrullahNo ratings yet

- 28-11-11 BA Schalengreiferrechen en FinalDocument59 pages28-11-11 BA Schalengreiferrechen en FinalRadulescu EugenNo ratings yet

- 05.regondi Etude No5Document9 pages05.regondi Etude No5lang chenNo ratings yet

- API Sizing Calculations WebSiteDocument2 pagesAPI Sizing Calculations WebSitejohney20% (1)

- Coarse Bar Screen (Influent PS - RR WWTP)Document12 pagesCoarse Bar Screen (Influent PS - RR WWTP)sauroNo ratings yet

- Figured Bass and Tonality RecognitionDocument8 pagesFigured Bass and Tonality RecognitionOmar ValenzuelaNo ratings yet

- Mechanically Cleaned Bar Screens PDFDocument4 pagesMechanically Cleaned Bar Screens PDFMarioNo ratings yet

- Diminished Chord ChartDocument2 pagesDiminished Chord Chartfilip100No ratings yet

- Topam PDFDocument132 pagesTopam PDFtopanNo ratings yet

- Giulio Regondi's Ten Etudes For Guitar: A Harmonic Analysis: by Jeffrey C. Lambert, D.MDocument23 pagesGiulio Regondi's Ten Etudes For Guitar: A Harmonic Analysis: by Jeffrey C. Lambert, D.MMaribelCastilloFernándezNo ratings yet

- 05 SedimentationDocument70 pages05 SedimentationAnonymous Cpe6vcNo ratings yet

- Paul-Desmond Take FiveDocument2 pagesPaul-Desmond Take FiveWilmer PelayoNo ratings yet

- Secondary Treatment: The Activated Sludge ProcessDocument129 pagesSecondary Treatment: The Activated Sludge ProcessRicardo Vargas LaverdeNo ratings yet

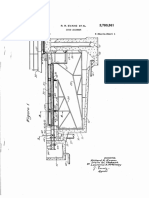

- R. R. Evans Etal 2,780,361: Scum SkimmerDocument10 pagesR. R. Evans Etal 2,780,361: Scum SkimmerrondonjjNo ratings yet

- Keyboard Lab 8/2: Chord ProgressionsDocument3 pagesKeyboard Lab 8/2: Chord ProgressionssuriyaprakashNo ratings yet

- Rexnord ManualDocument170 pagesRexnord ManualFernando AlvaradoNo ratings yet

- PUJOL Etude 21Document4 pagesPUJOL Etude 21hadarNo ratings yet

- Scales and Passages From A.NosovDocument20 pagesScales and Passages From A.Nosovhuong trinhNo ratings yet

- Giovanni Furno (1748-1837) Metodo Facile Breve e Chiara Ed Essensiali Regole Per Accompagnare Partimenti Senza NumeriDocument33 pagesGiovanni Furno (1748-1837) Metodo Facile Breve e Chiara Ed Essensiali Regole Per Accompagnare Partimenti Senza NumeriHeyBoBHeHeNo ratings yet

- FAS - Amps Models Axe III Ares 05.07Document42 pagesFAS - Amps Models Axe III Ares 05.07MarcoNo ratings yet

- Pujol Étude 4Document2 pagesPujol Étude 4gaudronNo ratings yet

- How To Write A Fugue in 20 StepsDocument12 pagesHow To Write A Fugue in 20 StepsOcet RahmanNo ratings yet

- A Tout Le MondDocument4 pagesA Tout Le Mondluca bonsanto0% (1)

- EZdrummer Operation Manual PDFDocument21 pagesEZdrummer Operation Manual PDFberangleblanc100% (1)

- Finntroll Sound & Backline Rider Clubs & Festivals 2015 v3.2 PDFDocument4 pagesFinntroll Sound & Backline Rider Clubs & Festivals 2015 v3.2 PDFProducciones BlackcodeNo ratings yet

- Partimento - Learners GuideDocument3 pagesPartimento - Learners GuidePedro d’AvilaNo ratings yet

- Gusanos Link Belt PDFDocument70 pagesGusanos Link Belt PDFemostajo1351100% (1)

- Biological Method Synthesis of NanoparticlesDocument10 pagesBiological Method Synthesis of Nanoparticlesrohit deshmukhNo ratings yet

- Design and Operations of The Kaldnes Moving Bed Biofilm ReactorsDocument10 pagesDesign and Operations of The Kaldnes Moving Bed Biofilm Reactorsvinhphat90No ratings yet

- Pujol Étude 7Document2 pagesPujol Étude 7gaudronNo ratings yet

- Andrey Nosov: Arpeggiato and Other Guitar Playing TechniquesDocument7 pagesAndrey Nosov: Arpeggiato and Other Guitar Playing Techniqueshuong trinhNo ratings yet

- SISTER MORPHINE CHORDS by The Rolling StonesDocument4 pagesSISTER MORPHINE CHORDS by The Rolling StonesYorch NeilNo ratings yet

- Manual de Servicio Aficio 1515 (Ingles) 1Document705 pagesManual de Servicio Aficio 1515 (Ingles) 1koneru24No ratings yet

- Insanguine RulesDocument13 pagesInsanguine Rulesiacopo grecoNo ratings yet

- TRN Technical Manual-2eDocument21 pagesTRN Technical Manual-2eGregorio Molina Sosa0% (1)

- Sala Elementi SmallDocument49 pagesSala Elementi SmallPedro d’AvilaNo ratings yet

- Service Manual: DSC-F828Document1 pageService Manual: DSC-F828Anonymous Lfgk6vygNo ratings yet

- Pujol Étude 4Document2 pagesPujol Étude 4gaudronNo ratings yet

- Ricoh 1515 Manual PDFDocument68 pagesRicoh 1515 Manual PDFRudy ZydelNo ratings yet

- 05 Scott Joplin On GuitarDocument4 pages05 Scott Joplin On GuitarGDENATANo ratings yet

- Fractal AmpDocument41 pagesFractal AmpAbdielSerrano100% (1)

- Harpsichord 368X: RMI Electro Piano andDocument24 pagesHarpsichord 368X: RMI Electro Piano andAlex TirrellNo ratings yet

- Naugatuck CT Odor Control EvaluationDocument133 pagesNaugatuck CT Odor Control EvaluationRepublican-American100% (2)

- Steel String Strummer: Produced by Troels FolmannDocument11 pagesSteel String Strummer: Produced by Troels FolmannJon SchoenherzNo ratings yet

- Modern Musical Symbols2Document12 pagesModern Musical Symbols2argus-eyedNo ratings yet

- Palmer Cab 112 B ManualDocument116 pagesPalmer Cab 112 B ManualRick BlokzijlNo ratings yet

- Chord Progression - WikipediaDocument10 pagesChord Progression - WikipediaDiana GhiusNo ratings yet

- Ultimate Illustrated Guide To Pedal Boards Illustrated BoardsDocument16 pagesUltimate Illustrated Guide To Pedal Boards Illustrated BoardsJoséG.ViñaG.No ratings yet

- Musical Instrument Amplifier Servicing (Short Article) - R. Johnson (1993) WWDocument3 pagesMusical Instrument Amplifier Servicing (Short Article) - R. Johnson (1993) WWDiego AntonioNo ratings yet

- PX 2200 SeriesDocument90 pagesPX 2200 SeriesRobert Buzz TrombleyNo ratings yet

- IStroboSoft Inapp ContentDocument11 pagesIStroboSoft Inapp Content15101980No ratings yet

- Advantages of Copper Alloy Castings: 1.1. Good CastabilityDocument1 pageAdvantages of Copper Alloy Castings: 1.1. Good CastabilityakmlogaNo ratings yet

- Corrosion Protection BoltingDocument4 pagesCorrosion Protection BoltingachmaddachNo ratings yet

- Crane Rail Welding 978Document3 pagesCrane Rail Welding 978Jurie_sk3608No ratings yet

- Marine Structures: Concrete Waterproofing by CrystallizationDocument6 pagesMarine Structures: Concrete Waterproofing by CrystallizationSiti Rohani IsdrisNo ratings yet

- Assessment of Corrosion in PipelinesDocument31 pagesAssessment of Corrosion in PipelinesRicardo Andres Santamaria Torres100% (2)

- Additives For Lubricating OilDocument18 pagesAdditives For Lubricating OilUjalaNo ratings yet

- eMV Series Brochure 2022Document32 pageseMV Series Brochure 2022Carlos Arturo AcevedoNo ratings yet

- Bell 412-MM-CH53Document24 pagesBell 412-MM-CH53Guadalupe ReyesNo ratings yet

- SEE4121 (2023) - Basic Gas Engineering & Energy Market - Lecture 2 - 16 Jan 2023Document85 pagesSEE4121 (2023) - Basic Gas Engineering & Energy Market - Lecture 2 - 16 Jan 2023MelodyNo ratings yet

- CRA Weld Overlay - Influence of Welding Process and Parameters On Dilution and Corrosion ResistanceDocument6 pagesCRA Weld Overlay - Influence of Welding Process and Parameters On Dilution and Corrosion ResistanceMichael TayactacNo ratings yet

- Flocon 260 Fs PDFDocument2 pagesFlocon 260 Fs PDFdalton2004No ratings yet

- Material Comparison F316L Vs F321 PDFDocument1 pageMaterial Comparison F316L Vs F321 PDFkhaireddinNo ratings yet

- Methods of Concrete Column Repair For Cracks and DamagesDocument3 pagesMethods of Concrete Column Repair For Cracks and DamagesOladunni AfolabiNo ratings yet

- Elster EnCal 3000 H2S Rev 05Document2 pagesElster EnCal 3000 H2S Rev 05Tania NoorNo ratings yet

- Dynalene HC Technical Data SheetDocument4 pagesDynalene HC Technical Data SheetP.B VeeraraghavuluNo ratings yet

- Eddycurrent TestingDocument4 pagesEddycurrent TestingnvemanNo ratings yet

- Astm A 967 2005Document7 pagesAstm A 967 2005Marco VeraNo ratings yet

- Failure of A Black Liquor Tank in A Paper Mill PDFDocument3 pagesFailure of A Black Liquor Tank in A Paper Mill PDFHeru MaulanaNo ratings yet

- 79766012839fe394361ee665771dddab (1)Document37 pages79766012839fe394361ee665771dddab (1)Eduardo García OrtegaNo ratings yet

- Ammonia Plant Maint.Document11 pagesAmmonia Plant Maint.mahmadwasiNo ratings yet

- Msds HCLDocument7 pagesMsds HCLbagus kustantoNo ratings yet

- Redman Fisher GuideDocument16 pagesRedman Fisher Guideikirby77No ratings yet

- Zinc Electrowinning & Zinc CathodesDocument19 pagesZinc Electrowinning & Zinc CathodesfarhadNo ratings yet

- Report Stainless SteelDocument6 pagesReport Stainless SteelAhmed ShokryNo ratings yet

- จำหน่าย Hydac AccumulatorDocument104 pagesจำหน่าย Hydac AccumulatorParinpa KetarNo ratings yet

- Section 3: Conveyor Chain Installation & MaintenanceDocument17 pagesSection 3: Conveyor Chain Installation & MaintenanceEduardo ParedesNo ratings yet

- Designation and Classification of SteelsDocument4 pagesDesignation and Classification of SteelsSam MagomnangNo ratings yet

- Laser Technik Journal - 2011 - Herrmann - The Role of Process Gases in Laser WeldingDocument4 pagesLaser Technik Journal - 2011 - Herrmann - The Role of Process Gases in Laser WeldingWaqas MuneerNo ratings yet