Professional Documents

Culture Documents

DD20 CircularPrecastConcreteManholes PDF

Uploaded by

lian9358Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DD20 CircularPrecastConcreteManholes PDF

Uploaded by

lian9358Copyright:

Available Formats

Design Data 20

Circular Precast Concrete Manholes

Circular precast concrete manhole sections are manholes are covered with structural flat slab covers

versatile in the construction of buried structures; they designed to resist the applied dead and live loads.

may be used as catch basins for stormwater drainage, The riser of a manhole is similar to a straight section

manholes providing access to buried pipelines, junction of concrete pipe with pipe joints at either end. A riser pipe

chambers at the intersection of sewers lines, and used

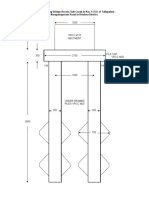

to construct reservoirs or wetwells for pump stations. The Figure 1 Typical Precast Manhole

use of precast concrete manhole structures will reduce

construction time and labor costs, when compared to

cast-in-place or masonry structures.

American Society for Testing Materials (ASTM) Grade Ring

C 478, Standard Specification for Precast Manhole

Sections, covers the manufacturing of the components

used in construction of manhole structures, as well as

the purchasing requirements of products used for the

assembly of manholes. ASTM C 478 does not include

design tables or a method for analysis and design for

manhole components, but does permit acceptance of

a component by proof-of-design testing. Test methods

are found in ASTM C 497, Standard Test Methods for Eccentric Cone Section

Concrete Pipe, Manhole Sections, or Tile.

The typical precast concrete manhole structure

consists of; grade or adjusting rings, a cone or flat slab

cover, riser sections, a base section, and frequently a

base foundation slab. In other variations of manholes,

riser sections are stacked on top of precast tee sections

in the pipeline, or on a cover slab of a buried vault or

junction chamber. The riser sections are usually 48

inches in diameter, but have been manufactured in nearly

every larger pipe size found in ASTM C76 Standard

Specifications for Culvert, Storm Drain, and Sewer

Pipe.

Precast grade rings, or adjusting rings, are stacked Riser Section

on top of the manhole cone or cover slab to provide the

correct finished grade for the manhole casting and cover.

When manholes are installed in roadways, designers

frequently specify a stack of rings at least 6 to 8 inches

high so the grade may be easily lowered, if required

during future construction.

In most precast manhole structures, the riser sections

are topped with either an eccentric or concentric cone.

Within the length of a cone section, the diameter of

the manhole is reduced from the size of the manhole

riser to the diameter of a cast-iron manhole cover and

frame. Special shallow cone sections, or flat cover slabs,

are used for very shallow manholes. Large diameter

Precast Base Section

American Concrete Pipe Association www.concrete-pipe.org info@concrete-pipe.org 1

2012 American Concrete Pipe Association, all rights reserved. DD 20 (11/12)

Figure 2 Forces Acting on Manhole Department of Labors Occupational Safety and Health

(OSHA) Standards, and are published in ASTM C 478

and ASTM C 497.

FORCES ON CIRCULAR MANHOLE RISER

SECTIONS

A circular precast concrete riser is the ideal material

for constructing a vertical buried structure. Manhole

riser sections have a thick high-strength concrete wall

that easily resists the compressive forces caused by

lateral earth and hydrostatic pressure. The mass of

the concrete gives the structure stability in buoyant

installation conditions. See Design Data 22 Flotation of

Circular Concrete Pipe, for additional information on the

effect of buoyancy on buried structures.

Lateral earth pressure. Because manhole risers are

manufactured in standard diameters with the minimum

i i wall thickness directly proportional to the riser diameter, a

general vertical depth limit for all sizes may be calculated.

The most severe loading condition on a riser section

occurs when the ground water elevation is the same

as the surface of the ground. The forces acting on the

riser section are illustrated in Figure 2. The total active

force consists of two components; active lateral earth

H pressure and hydrostatic pressure. Both components

of the load act in a radial direction and are distributed

uniformly around the periphery of the manhole. Radial

forces acting on a circular cross-section result in only

compressive forces on the section. There are no bending

forces in a riser section unless there is a discontinuity

such as a hole for a sewer pipe connection.

Based on the radial load distribution, the lateral earth

pressure and hydrostatic pressure at any depth within

the soil mass is given by the following equation:

wsHKscos i p = wsHKs cos i + wwHKw (1)

wwHKw where: p = total earth and hydrostatic pressure,

pounds per square foot

or a stack of riser pipes is assembled to obtain the proper ws = effective unit weight of backfill material,

height of the structure. Manhole risers are fabricated in pounds per cubic feet

standard lengths that are usually increments of the step H = depth of manhole, feet

spacing. Ks = conjugate ratio for soil

The base section generally has openings through i = angle between backfill surface and the

which water or sewer pipes are installed. Base sections horizontal, degrees

may be manufactured with an integral floor, which ww = unit weight of water, pounds per cubic

functions as a foundation, or be placed on a precast feet

or cast-in-place foundation slab. Precast concrete tee Kw = conjugate ratio for water

pipeline sections serve the same function as a base

section. In most cases, the ground surface is level and i =

The manhole structure may be furnished with zero degrees. Therefore cos i = 1.0 and equation (1)

attached steps or ladders. The dimensions, spacing becomes:

and test strength of steps are specified by United States

American Concrete Pipe Association www.concrete-pipe.org info@concrete-pipe.org 2

2012 American Concrete Pipe Association, all rights reserved. DD 20 (11/12)

p = wsHKs + 62.4H (2) t = thickness of manhole wall, feet

Ks is further defined as: The minimum wall thickness equals one-twelfth the

inside diameter of the manhole, when the thinnest wall

(1 sin ) thickness specified in ASTM C76 is used. Substituting

K= (3)

(1 + sin ) the wall thickness into terms of manhole diameter and,

p, into terms of manhole height, and converting the units

Where = tan = coefficient of friction for the soil to pounds per square inch:

= angle of internal friction of the soil, degrees s = 81.6H x D/ (144 x 2 x D/12)

s = 3.4H (6)

Table 1 lists the normal range of the angle of internal

friction for various types of soil. where: s = compressive stress in the concrete cross-

section, pounds per square inch

Table 1 Normal Range of the Angle of H = depth of manhole, feet

Internal Friction for Various Soil Types

Table 1

The allowable bearing stress of concrete, s, equals

Backfill Material Angle of Internal Friction 45 percent of the minimum required compressive strength

Plastic Clay 0 - 10 of 4000psi for precast manholes or 1800psi. Substituting

Wet, Fine Sand 15 - 30 1800psi into equation (6) and solving for H, finds that the

Dry Sand 25 - 40 maximum depth for a precast manhole riser is in excess

Gravel 30 - 40 of 500 feet.

Compact Clay 25 - 45

1800 = 3.4H

H = 540 feet

For design purposes, the average value of is

assumed to be 30 degrees. Since the tangent of 30 Vertical dead load. Two other factors control

degrees is equal to 1 3 , substation of this value

the maximum depth of a stack of manhole risers; end

3 1 bearing at the joints and the foundation capacity that will

into equation (3) results in Ks = 3 . depend on the site conditions. Again, using the allowable

If the saturated unit weight of soil is 120 pounds bearing stress for concrete of 1800psi, a 48-inch diameter

per cubic foot, effective or unit weight, because of the manhole riser, with minimum wall thickness, could

buoyant effect of the water, is 120 62.4 = 57.6 pounds theoretically support over 1700 feet of riser sections.

per cubic foot. Substituting the effective unit weight for The effects of settlement in the adjacent backfilled soils

saturated soil of 57.6 pcf and Ks = 1 into equation are not easily analyzed and are not included in this

3

(2): analysis. At the joint, only a small portion of the pipe

cross-section remains in contact with the adjacent riser

p = 57.6 x H x 1/3 + 62.4H section. Assuming that the end bearing area in a joint is

p = 81.6H (4) only 25 percent of the full cross-section, a stack of risers

450 feet deep could be constructed.

The radial pressure, p, is equally applied around The maximum allowable depth for a buried precast

the periphery of the manhole section, placing the cross- manhole riser is, for all practical purposes, unlimited.

section in pure compression unless there is an opening

in the section. The compressive stress in any portion OTHER PRECAST MANHOLE DESIGN AND

of the manhole section is found by using the following ANALYSIS CONSIDERATIONS

equation. Flat slab covers. Flat slab covers are frequently used

in roadways and are designed to support traffic loads.

s = pD/2t (5) The method for the analysis and design of manhole cover

slabs is not included in ASTM C 478, but the American

where: s = compressive stress in the concrete cross- Association for Highway and Transportation Officials

section, pounds per square foot (AASHTO) Standard Specifications for Highway Bridges

p = total lateral earth and hydrostatic pressure, provides guidance for designing reinforced concrete

pounds per square foot slabs buried in shallow fills that are capable of supporting

D = inside diameter of manhole, feet highway loads.

American Concrete Pipe Association www.concrete-pipe.org info@concrete-pipe.org 3

2012 American Concrete Pipe Association, all rights reserved. DD 20 (11/12)

AASHTOs Standard H and HS vehicles with specific Figure 3 Typical Assembly Combinations

wheel loads and spacing are commonly accepted as

the basis for live load design of highway structures.

For buried structures, AASHTO Bridge Specifications standard

standard man hole

distribute the live load as a concentrated force distributed man hole frame and

frame and cover

either over a load strip width crossing the span for burial cover

depths less than two feet, or a square or rectangular grade rings

grade rings or brick

shaped area on the top of a concrete slab for fills two feet or brick

and greater. The dead load due to earth backfilled on top flat slab top eccentric

of slabs may be found by multiplying the weight of the cone

soil prism over the slab times a soil structure interaction base base

factor. A factor of 1.15 is adequate for most cases.

The Specifications provide several simplified standard

formulas that make reasonable approximations of live man hole

load bending moments in concrete slabs. Tabulated frame and

cover

formulas that recommend minimum slab thickness based

on span are found in the Concrete Design section of the standard grade rings

man hole or brick

Specifications. Impact must be added to the live load for frame and

fills less than three feet, and live load may be excluded cover eccentric

cone

in the design of slabs that are buried depths greater grade rings

than eight feet. When slabs have full bearing around the or brick transition

section

perimeter of a circular manhole riser, such as bedding in concentric

fresh Portland cement mortar, they may be designed as cone

a two-way slab with a significant reduction in the flexural

requirements. Slabs with less than two feet of cover must base base

have distribution reinforcing placed transverse to the

bottom flexural reinforcing.

standard

Openings. In conventional installations, only a small man hole standard

fraction of the strength of a manhole section is required frame and man hole

cover frame and

to resist lateral and vertical forces. Openings in manhole

grade rings cover

sections do reduce the strength of that section, and may

or brick grade rings

alter the load paths that carry the vertical loads to the

or brick

foundation of the structure. When openings are properly concentric

positioned, or supplemental reinforcing is provided, there cone eccentric

riser cone

will be no adverse affect on the structural performance

of the section. Three common methods of creating an riser

opening in a manhole section are; molded with a circular

riser

form attached to the casting equipment, hand-cut or dug-

out of freshly placed concrete, and cored with a large riser

riser

diameter circular cutter.

If the openings are large, supplemental reinforcement

should be added to the primary reinforcing cage to

redistribute the load from the unsupported portion of the transition

section wall to the intact portion. The location of the holes section

is known during the production process for the first and

second methods, so additional reinforcing can be added

to the primary reinforcing cage to enclose the opening

before the concrete is placed. Cored openings are usually base base

cut into a plain riser section, so the openings occur at

random in the primary reinforcing. The diameter of cored

openings is usually limited in size, so supplemental

reinforcing is not required. Specific information concerning precast concrete manhole assemblies to meet individual project

When an opening is made in a slab cover, reinforcing requirements is available from any member company of theAmerican Concrete Pipe Association.

American Concrete Pipe Association www.concrete-pipe.org info@concrete-pipe.org 4

2012 American Concrete Pipe Association, all rights reserved. DD 20 (11/12)

steel with an area equivalent to one-half the reinforcing

interrupted by the opening shall be added to each side

of the opening. Many designers enclose the opening

with an equal area of reinforcing placed diagonally to

the principle reinforcing.

Diameter of junction manholes. A junction manhole

is installed at the intersection of several sewer lines to

form a chamber in which the inflow may be combined and

directed to the outlet line. The diameter of the junction

manhole must be large enough so that the distances

between adjacent openings have enough strength to

resist lateral and vertical loads, as well as stresses caused

by handling. For non-cored openings, the diameter of the

opening should be four inches greater than the outside

diameter of the connecting pipe. To insure structural

stability of the manhole section, the minimum distance

between adjacent openings should be twelve inches. The

diameter of a cored opening is generally selected for a

proprietary pipe-to-manhole connector, and the minimum

distance between openings should be eight inches. The

diameter of a junction manhole will greatly depend on

the included angle between adjacent pipelines.

Manhole joints and pipe-to-manhole seals.

Manhole joints usually have a tongue and groove

configuration and may be made with or without gasket

seals. The single offset and recessed o-ring gasket are

the most common type of joint seals. Gasketed joints

are popular because most of the labor required to join

sections can be done outside the excavation. Gasket

joints can greatly reduce the infiltration into the manhole

structure. Non-gasketed tongue and groove joints may

be sealed with pre-formed mastic cords, external wraps

or Portland cement mortar. When low infiltration rates

are specified for a pipeline system, pipe-to-manhole

connectors may be effective. Connectors may be cast

into the manhole wall or attached by an expansion ring

in a circular opening formed or cored in the manhole

wall.

American Concrete Pipe Association www.concrete-pipe.org info@concrete-pipe.org 5

2012 American Concrete Pipe Association, all rights reserved. DD 20 (11/12)

Technical data herein is considered reliable, but no guarantee is made or liability assumed.

You might also like

- Given Data: Given Data:: Design of Raft Foundation Design of Raft FoundationDocument8 pagesGiven Data: Given Data:: Design of Raft Foundation Design of Raft FoundationBikram BhusalNo ratings yet

- Design of S R Flanged Beam: Bending Only. (Limit State Method)Document3 pagesDesign of S R Flanged Beam: Bending Only. (Limit State Method)sayali surveNo ratings yet

- Upper Mai Hydroelectric Project: SUPPORT PIERS Dimension DGN Chainage: 0+668.40Document49 pagesUpper Mai Hydroelectric Project: SUPPORT PIERS Dimension DGN Chainage: 0+668.40MohanSharmaNo ratings yet

- Manhole Design - AMRUT - Water Pressure & DryDocument13 pagesManhole Design - AMRUT - Water Pressure & Drynavneet3bawaNo ratings yet

- Single Legged Staircase DesignDocument12 pagesSingle Legged Staircase DesignrahulNo ratings yet

- Analysis On The Causes of Cracks in BridgesDocument14 pagesAnalysis On The Causes of Cracks in BridgesNguyễn Văn MinhNo ratings yet

- Duct Drain Section RCC DesignDocument1 pageDuct Drain Section RCC Designhammad jagirdarNo ratings yet

- RCC - Civil Engineering Objective QuestionsDocument9 pagesRCC - Civil Engineering Objective Questionsutsav_koshtiNo ratings yet

- What Is A Culvert - Types of Culverts, Its Materials and LocationDocument4 pagesWhat Is A Culvert - Types of Culverts, Its Materials and LocationJustin MusopoleNo ratings yet

- IRC Guidelines For Culvert DesignDocument90 pagesIRC Guidelines For Culvert DesignsrijanNo ratings yet

- Nandyal SSE Office: Load Calculations Details of Loads 1 Floor LoadDocument1 pageNandyal SSE Office: Load Calculations Details of Loads 1 Floor Loadravi4paperNo ratings yet

- Retaining Wall With Relief Shelves 6 PDFDocument10 pagesRetaining Wall With Relief Shelves 6 PDFrajivkannanNo ratings yet

- Is 6006 1983Document22 pagesIs 6006 1983kannankrivNo ratings yet

- Alternative Forms of Two Lane T-Beam Bridge Superstructure - Study by Grillage AnalogyDocument9 pagesAlternative Forms of Two Lane T-Beam Bridge Superstructure - Study by Grillage AnalogyAnkur SrivastavaNo ratings yet

- Road Estimate FormatDocument7 pagesRoad Estimate Formatalok jhaNo ratings yet

- Effective WidhDocument17 pagesEffective WidhHimal KafleNo ratings yet

- RCC NP3 Pipe Bedding DesignDocument1 pageRCC NP3 Pipe Bedding DesignSuseendar Ramadoss100% (2)

- Cell K11 1 Cell K11 0.5 For F 0, For F 0Document9 pagesCell K11 1 Cell K11 0.5 For F 0, For F 0HaymanAHMEDNo ratings yet

- High Level Bridge: DPR of Construction of Across Malkua Deverbeli Road at RD - 1900 MDocument23 pagesHigh Level Bridge: DPR of Construction of Across Malkua Deverbeli Road at RD - 1900 Mparas rahangdaleNo ratings yet

- Corbel DesignDocument2 pagesCorbel DesignHanamantrao KhasnisNo ratings yet

- Slab Culvert Irc 21 Irc 112Document5 pagesSlab Culvert Irc 21 Irc 112imamtaNo ratings yet

- Retaining Wall With Relief SlabDocument7 pagesRetaining Wall With Relief Slabrajivkannan100% (2)

- RCC Crash BarrierDocument7 pagesRCC Crash BarrierramanNo ratings yet

- Retaining Walls With Relief ShelvesDocument13 pagesRetaining Walls With Relief ShelvesMike VictorNo ratings yet

- Seismic Design of Bridges Example 8Document36 pagesSeismic Design of Bridges Example 8Mike2322No ratings yet

- RCC Retaining WallSDocument23 pagesRCC Retaining WallSTarunNo ratings yet

- Slab Culvert Irc 21 Irc 112Document5 pagesSlab Culvert Irc 21 Irc 112Rupendra palNo ratings yet

- Design Calculation of AbutmentDocument53 pagesDesign Calculation of AbutmentSreeraja SreevilasanNo ratings yet

- Comparative Study of RCC T-Beam Bridge byDocument32 pagesComparative Study of RCC T-Beam Bridge byPranay Reddy100% (2)

- Design of SPDocument105 pagesDesign of SPashokNo ratings yet

- Cross GirderDocument1 pageCross Girderkarthikmr85No ratings yet

- Pile Capacity NewDocument1 pagePile Capacity NewChowdhury PriodeepNo ratings yet

- Parapet CapacityDocument4 pagesParapet CapacityJemicah YumenaNo ratings yet

- Water Tank Analysis Using STAAD PRO: Mainak GhosalDocument9 pagesWater Tank Analysis Using STAAD PRO: Mainak GhosalEr Bhavesh IngaleNo ratings yet

- Design of Retaining WallDocument6 pagesDesign of Retaining WallSasidhar KatariNo ratings yet

- Bridges-IRC LoadsDocument52 pagesBridges-IRC LoadsNandpal PrashantNo ratings yet

- Retaining WallDocument13 pagesRetaining Wallrasikamal100% (1)

- 08-2011 Friction Slab Crash Barrier PDFDocument9 pages08-2011 Friction Slab Crash Barrier PDFraviNo ratings yet

- AQUEDUCT@KM 31.925 Final - 1 PDFDocument1 pageAQUEDUCT@KM 31.925 Final - 1 PDFvaranasirk1100% (1)

- Chapter 1-3 PDFDocument27 pagesChapter 1-3 PDFRyle AquinoNo ratings yet

- Cross Section Properties (All Dimensions Are in CMS)Document2 pagesCross Section Properties (All Dimensions Are in CMS)Hanamantrao KhasnisNo ratings yet

- Bridge Rating Flowchart SDDocument5 pagesBridge Rating Flowchart SDSuvash DhakalNo ratings yet

- Analysis of Steel ShutterDocument30 pagesAnalysis of Steel Shuttersalahuddin sakuNo ratings yet

- Short Span Bridge.1Document9 pagesShort Span Bridge.1Vinayagamoorthy ChithambaramNo ratings yet

- Isolated Trapezoidal Footing DesignDocument6 pagesIsolated Trapezoidal Footing Designhemantkle2uNo ratings yet

- Lintel DesignDocument5 pagesLintel DesignZayyan Romjon100% (1)

- Study On Seismic Analysis of High-Rise Building by Using SoftwareDocument9 pagesStudy On Seismic Analysis of High-Rise Building by Using SoftwaremonaliNo ratings yet

- Inclined Retaining Wall RCC Design 4mDocument10 pagesInclined Retaining Wall RCC Design 4mRahul GargNo ratings yet

- Irc Crash Barrier LimitationsDocument2 pagesIrc Crash Barrier LimitationsSandipan DharNo ratings yet

- RCC Developers LTD.: Design of Retaining Walls @bridge Approach KM 368+385Document13 pagesRCC Developers LTD.: Design of Retaining Walls @bridge Approach KM 368+385Shivendra KumarNo ratings yet

- BIS Hume PipeDocument7 pagesBIS Hume PipeShiv Pratap SinghNo ratings yet

- Design of Centering For BridgesDocument18 pagesDesign of Centering For BridgesAshish Kurve100% (1)

- Under Reamed Piles DesignDocument9 pagesUnder Reamed Piles DesignKiran AEE BvrmNo ratings yet

- Design of ColumnDocument8 pagesDesign of ColumnAfsar MansuriNo ratings yet

- Irc 006-1966Document40 pagesIrc 006-1966Arun Ks100% (2)

- RCP 24 Inch Class 2Document5 pagesRCP 24 Inch Class 2noto.sugiartoNo ratings yet

- DD 20MDocument5 pagesDD 20Mlian9358No ratings yet

- ACPPA TechSeries 12 JackingCPP FinalDocument6 pagesACPPA TechSeries 12 JackingCPP FinalWilliamray PabloNo ratings yet

- Concrete DamsDocument144 pagesConcrete DamsspattiwarNo ratings yet

- Dash Diet PamphletDocument64 pagesDash Diet PamphletbohnjucurNo ratings yet

- Am J Clin Nutr 1982 Wolgemuth 68 78Document11 pagesAm J Clin Nutr 1982 Wolgemuth 68 78lian9358No ratings yet

- Productivity in ConstructionDocument54 pagesProductivity in ConstructionGwapito TresNo ratings yet

- Volvo - Product 20range 20guide 20 - 204 PDFDocument40 pagesVolvo - Product 20range 20guide 20 - 204 PDFlian9358No ratings yet

- Pricing Sitework PDFDocument21 pagesPricing Sitework PDFlian9358No ratings yet

- 25r 03 PDFDocument35 pages25r 03 PDFlian9358No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Plaster Assemblies Chapter 05 TexturesDocument24 pagesPlaster Assemblies Chapter 05 Textureslian9358No ratings yet

- Tender DocumentDocument16 pagesTender DocumentstrahhhNo ratings yet

- Kerb British Standard Charcon TdsDocument6 pagesKerb British Standard Charcon Tdslian9358No ratings yet

- HTN PamphletDocument20 pagesHTN PamphletMaria Ivy MendozaNo ratings yet

- Project Development Cost EstimatesDocument22 pagesProject Development Cost EstimatesPavideeNo ratings yet

- Road DesignDocument39 pagesRoad DesignshingkeongNo ratings yet

- Diesel Generator Fuel Consumption Chart in Litres PDFDocument1 pageDiesel Generator Fuel Consumption Chart in Litres PDFHla Soe90% (10)

- DD 20MDocument5 pagesDD 20Mlian9358No ratings yet

- Precast Concrete Manhole Bouyancy CalculatorDocument4 pagesPrecast Concrete Manhole Bouyancy Calculatorlian9358No ratings yet

- Irrigation Design ManualDocument140 pagesIrrigation Design Manualabinet100% (8)

- DD 41 Manhole Flotation AnalysisDocument4 pagesDD 41 Manhole Flotation Analysislian9358No ratings yet

- M Design PDFDocument7 pagesM Design PDFlian9358No ratings yet

- Manholes PresentationDocument143 pagesManholes PresentationMar MaslanNo ratings yet

- Burid Pipe Struct DesignDocument7 pagesBurid Pipe Struct DesignsandbadbahriNo ratings yet

- Burid Pipe Struct DesignDocument7 pagesBurid Pipe Struct DesignsandbadbahriNo ratings yet

- DD 22M PDFDocument6 pagesDD 22M PDFlian9358No ratings yet

- Ocpa C P D M: Oncrete IPE Esign AnualDocument145 pagesOcpa C P D M: Oncrete IPE Esign Anuallian9358No ratings yet

- Dash Diet PamphletDocument64 pagesDash Diet PamphletbohnjucurNo ratings yet

- Tender DocumentDocument16 pagesTender DocumentstrahhhNo ratings yet

- HTN PamphletDocument20 pagesHTN PamphletMaria Ivy MendozaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Irrigation Design ManualDocument140 pagesIrrigation Design Manualabinet100% (8)

- Fan Adta-En-50hz-March-2018 - 20180315Document52 pagesFan Adta-En-50hz-March-2018 - 20180315Andi JatmikoNo ratings yet

- Magnesium L Threonate For Depression and Anxiety PDFDocument6 pagesMagnesium L Threonate For Depression and Anxiety PDFRocco LamponeNo ratings yet

- WaterproofingDocument38 pagesWaterproofingPranay GandhiNo ratings yet

- B 700 FDocument25 pagesB 700 FMohammed HdyliNo ratings yet

- Manual GISDocument36 pagesManual GISDanil Pangestu ChandraNo ratings yet

- Asking and Showing Rooms in Hospital2Document17 pagesAsking and Showing Rooms in Hospital2Roland DelNo ratings yet

- Technical Reference For Water Conservation in Cooling TowersDocument41 pagesTechnical Reference For Water Conservation in Cooling TowersDorn GalamarNo ratings yet

- Affidavit: IN WITNESS WHEREOF, I Have Hereunto Affixed MyDocument2 pagesAffidavit: IN WITNESS WHEREOF, I Have Hereunto Affixed Myceleste LorenzanaNo ratings yet

- (VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006Document4 pages(VOLKSWAGEN) Manual de Taller Volkswagen Jetta 1999 2006Carlos AntonioNo ratings yet

- Musculoskeletal 20,000 Series CPT Questions With Answers-CpcDocument16 pagesMusculoskeletal 20,000 Series CPT Questions With Answers-Cpcanchalnigam25100% (7)

- Types of Business OwnershipDocument2 pagesTypes of Business Ownershipprelovedseller bnNo ratings yet

- (Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFDocument441 pages(Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFMuhammad AliNo ratings yet

- UAW-FCA Hourly Contract SummaryDocument20 pagesUAW-FCA Hourly Contract SummaryClickon DetroitNo ratings yet

- Efficiency Improvement Oppertunities With BLDC Fan PDFDocument14 pagesEfficiency Improvement Oppertunities With BLDC Fan PDFjust_4_u_dear_in9549No ratings yet

- Remote Control RC902V1 ManualDocument3 pagesRemote Control RC902V1 ManualdezdoNo ratings yet

- Comprehensive Soup ProjectDocument98 pagesComprehensive Soup ProjectSachin Soni63% (8)

- AAA V Edgardo SalazarDocument2 pagesAAA V Edgardo SalazarNiajhan PalattaoNo ratings yet

- Facebow Tech Spec Gen LRDocument1 pageFacebow Tech Spec Gen LRrojNo ratings yet

- Exercise 3 ASC0304 - 2019-1Document2 pagesExercise 3 ASC0304 - 2019-1Nuraina NabihahNo ratings yet

- 2457-Article Text-14907-2-10-20120724Document6 pages2457-Article Text-14907-2-10-20120724desi meleniaNo ratings yet

- PFA Vs PTFE in InstrumentationDocument5 pagesPFA Vs PTFE in InstrumentationArif HakimNo ratings yet

- Knopp2017 Article OnceACheaterAlwaysACheaterSeriDocument11 pagesKnopp2017 Article OnceACheaterAlwaysACheaterSeriAnda F. CotoarăNo ratings yet

- Shloka Seminar: - DR Vikas SarochDocument15 pagesShloka Seminar: - DR Vikas SarochDrVikas100% (3)

- APPLE FRITTER CAKE Cook Heavenly RecipesDocument4 pagesAPPLE FRITTER CAKE Cook Heavenly Recipes1940LaSalleNo ratings yet

- Reclaimer Inspection ReportDocument51 pagesReclaimer Inspection ReportThiru Malpathi100% (1)

- HMPE1 (Catering MGT.)Document17 pagesHMPE1 (Catering MGT.)Rysyl Mae MoquerioNo ratings yet

- Moody's Financial Metrics 2007Document35 pagesMoody's Financial Metrics 2007Adrian IlieNo ratings yet

- Compositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanDocument13 pagesCompositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanNatalia KovalovaNo ratings yet

- Government of Canada Gouvernement Du CanadaDocument17 pagesGovernment of Canada Gouvernement Du CanadaSaman BetkariNo ratings yet