Professional Documents

Culture Documents

NEXISA

Uploaded by

Stanley PeterCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NEXISA

Uploaded by

Stanley PeterCopyright:

Available Formats

Data Sheet 1668-9C

Nexis A Series

Filter Cartridges

Description

Rated at >99.9% efficiency1 with retention ratings from

0.5 to 120 m

Proprietary CoLD Melt fiber technology

Resists contaminant unloading even at high differential

pressures

Micro-denier melt blown filtration fibers

Media manufactured with a continuous gradient pore

structure

All-polypropylene construction

Free of adhesives, binders, resins, and silicone

Proprietary center core for added strength

(0.5 - 20 m)

Fast rinse-up to 18 Megohm-cm

Certification of conformance including lot identification

Performance Specifications

Filter grades

0.5, 1, 3, 5, 10, 20, 30, 40, 50, 70, 90, 120 m

Maximum differential pressure

0.5-20 m: 1.03 bard @ 82C (15 psid @ 180F)

1.72 bard @ 66C (25 psid @ 150F)

4.14 bard @ 30C (60 psid @ 86F)

30-120 m: 1.72 bard @ 60C (25 psid @ 140F)

3.45 bard @ ambient (50 psid @ ambient)

Rinse-up

Recommended change-out differential pressure2 Rinse-up to 18 Megohm-cm with a minimum of

2.4 bard (35 psid) throughput.

Food and water contact use Autoclaving

Please contact Pall Corporation to verify that the product Single-open-end Nexis A series filter cartridges can be

conforms to your national legislation and/or regional autoclaved for 30 minutes at 121C (250F) under no

regulatory requirements for water and food contact use. end load conditions. However, filter cartridges should be

allowed to cool to normal system operating

Purity

temperatures prior to use.

Nexis A series filter cartridges are free of adhesives,

binders, resins, and silicone. Steam sterilization

1 >99.9% retention rating by ASTM F-795 test. Not recommended.

2 Provided that the maximum differential pressure is not exceeded based

on temperature limits defined above.

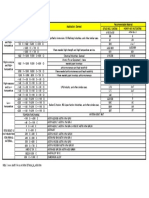

Product Specifications Particle Removal Ratings4 (m)

Materials of construction Cartridge 99.9% 90%

Designation Efficiency Efficiency

Filter media: Polypropylene

Hardware: Polypropylene NXA 0.5 0.5 <0.5

Gaskets/O-rings: Silicone elastomer, EPDM, nitrile, NXA 1 0.95 0.65

fluorocarbon elastomer, NXA 3 2.8 1.5

Santoprene3 (DOE only), FEP, NXA 5 4.1 3.4

FEP encapsulated silicone, NXA 10 9.5 4.7

FEP encapsulated fluorocarbon NXA 20 18.5 13

elastomer NXA 30 27 18

NXA 40 36 20

Dimensions (nominal)

NXA 50 46 27

Outside diameter: 6.4 cm (2.5 in)

NXA 70 65 42

Lengths: 10.2 cm (4 in), 12.7 cm (5 in),

NXA 90 85 55

24.8 cm (9.75 in), 25.1 cm (9.875 in),

NXA 120 105 65

25.4 cm (10 in), 49.5 cm (19.5 in),

50.8 cm (20 in), 74.3 cm (29.25 in),

76.2 cm (30 in), 99.1 cm (39 in),

100.3 cm (39.5 in), 102 cm (40 in)

Typical Flow vs. Differential Pressure for Application Sizing5

Flow rate (lpm) , water at 20C Flow rate (lpm) , water at 20C

0 4 8 12 16 20 24 28 32 36 0 4 8 12 16 20 24 28 32 36

7 0.7 30 m

0.5 m 1 m 3 m 40 m

6 .4 0.6 50 m .04

5 m

5 70 m

Differential pressure (bard)

Differential pressure (bard)

0.5

Differential pressure (psid)

Differential pressure (psid)

90 m

.3 120 m .03

4 0.4

3 10 m .2 0.3 .02

2 0.2

.1 .01

20 m

1 0.1

0 0 0 0

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

Flow rate (gpm), water at 68F Flow rate (gpm), water at 68F

Unit conversion: 1 bar = 100 kPa

3 Registered trademark of Advanced Elastomer Systems.

4 >90% and 99.9% retention ratings by ASTM F-795 test.

5 Flow rate is for a 25.4 cm (10 in) cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

Ordering Information

Pall Part Number = NXA 1 2 U 3 4

Table 1 Table 2 Table 3

Filter grades Cartridge Code End configurations

Code

(m) Code lengths (cm/in)

nominal Blank DOE industrial (no end caps)

0.5 0.5

1X DOE, 2.54 cm (1 in) extended core

1 1 4 10.2 / 4

SOE flat closed end, external 222 O-rings

3 3 5 12.7 / 5 M3

(retrofits other manufacturers Code 0)6

5 5 9.75 24.8 / 9.75 SOE large diameter closed end, external

M3H

9.875 25.1 / 9.875 222 O-rings

10 10

10 25.4 / 10 SOE fin end, external 222 O-rings with locking

20 20 M4

tabs (silicone and EPDM O-rings only)

30 30 19.5 49.5 / 19.5

DOE, internal 120 O-rings (retrofits 213 O-ring

20 50.8 / 20 M5

40 40 style)6

50 50 29.25 74.3 / 29.25 SOE flat closed end, external 226 O-rings

M6

(retrofits other manufacturers Code 6)6

70 70 30 76.2 / 30

SOE fin end, external 226 O-rings (retrofits other

39 99.1 / 39 M7

90 90 manufacturers Code 7)6

120 120 39.5 100.3 / 39.5 SOE fin end, external 222 O-rings (retrofits other

M8

40 102 / 40 manufacturers Code 5)6

DOE, internal O-rings (fits other manufacturers

M10

housings)6

Table 4 SOE flat closed end, internal 120 O-ring (retrofits

M11

other manufacturers X style)6

Code Gasket/O-ring materials M18 SOE flat closed end, external 222 O-ring

S Silicone SOE with internal O-rings (same as M10), closed

M20

N Nitrile end with deep recess

E EPDM DOE DOE with elastomer gasket seals and end caps

V Fluorocarbon elastomer H21 DOE, Santoprene gasket seal

Expanded PTFE (gaskets) XK SOE plastic spring assembly, saw cut end

T

FEP encapsulated silicone (O-rings) SI SOE metal spring/polypropylene cap, saw cut end

FEP encapsulated fluorocarbon elastomer

F

(O-rings) 6 For details, contact Pall Corporation.

Y Santoprene

25 Harbor Park Drive Visit us on the Web at www.pall.com

Port Washington, NY 11050

Pall Corporation has offices and plants throughout the world. For Pall representatives

+1 516 484 3600 telephone in your area, please go to www.pall.com/contact.

+1 800 289 7255 toll free US

Please contact Pall Corporation to verify that the product conforms to your national

Portsmouth - UK legislation and/or regional regulatory requirements for water and food contact use.

+44 (0)23 9230 3303 telephone Because of technological developments related to the products, systems, and/or

+44 (0)23 9230 2507 fax services described herein, the data and procedures are subject to change without

processuk@pall.com notice. Please consult your Pall representative or visit www.pall.com to verify that

this information remains valid. Products in this document may be covered by one

or more of the following patent numbers: EP 0 830 191; US 5,591,335;

US 5,653,833; US 5,681,469; US 5,690,782; US 5,730,820; US 5,733,581;

US 5,741,395; US 5,783,011.

Copyright 2005, 2010, Pall Corporation. Pall, , CoLD Melt, and Nexis are trademarks of Pall

Corporation. indicates a trademark registered in the USA. Filtration. Separation. Solution.SM is

a service mark of Pall Corporation.

1668-9C Produced in the USA June 2010

You might also like

- Lift CalculationDocument3 pagesLift CalculationHussain JiffryNo ratings yet

- Conder Separator Brochure NewDocument8 pagesConder Separator Brochure Newednavilod100% (1)

- Mss sp-60Document5 pagesMss sp-60Mhand AmsNo ratings yet

- NEMA TS2-2003 - Traffic Controller AssembDocument246 pagesNEMA TS2-2003 - Traffic Controller AssembRahul SinganiaNo ratings yet

- BS en 12334-2001Document14 pagesBS en 12334-2001Udit Kumar SarkarNo ratings yet

- 3LPE 1d44a0 PDFDocument33 pages3LPE 1d44a0 PDFHotnCrispy CrispyNo ratings yet

- Nfpa 1986-2023Document70 pagesNfpa 1986-2023José PérezNo ratings yet

- Mil S 901DDocument83 pagesMil S 901DParamaet TamNo ratings yet

- Crash Analysis and SimulationDocument26 pagesCrash Analysis and SimulationNyakakussagaNo ratings yet

- Rack Type Gear Cutters, Metric Module: Specification ForDocument16 pagesRack Type Gear Cutters, Metric Module: Specification ForMariorosales MendezNo ratings yet

- Eurocode 3 - Design of Steel Structures - Part 1-5: Plated Structural ElementsDocument19 pagesEurocode 3 - Design of Steel Structures - Part 1-5: Plated Structural ElementsMangesh BanaleNo ratings yet

- FABCO Pipe Catalog PDFDocument24 pagesFABCO Pipe Catalog PDFMohamed AklNo ratings yet

- NF 16101 Explained PDFDocument8 pagesNF 16101 Explained PDFhammouche_soufianeNo ratings yet

- Mainhole and EtcDocument44 pagesMainhole and Etcameera nabihaNo ratings yet

- Storm Water Standards Manual 2016 2Document172 pagesStorm Water Standards Manual 2016 2Sharif100% (1)

- Accepted Safety Barriers V2 PDFDocument20 pagesAccepted Safety Barriers V2 PDFRichu PaliNo ratings yet

- BS en 558-2-1996, Industrial ValvesDocument29 pagesBS en 558-2-1996, Industrial ValvesDennis Lai Zhan WenNo ratings yet

- Jetfoil - Tunnel FansDocument16 pagesJetfoil - Tunnel FansCallGRNo ratings yet

- Weholite: The Basics ofDocument24 pagesWeholite: The Basics ofbetopagoadaNo ratings yet

- Light Rail Technical Manual for ADA ComplianceDocument47 pagesLight Rail Technical Manual for ADA ComplianceGhazala FarooqNo ratings yet

- 11.5. Road Lighting Performance Requirements 13201 1 2014Document30 pages11.5. Road Lighting Performance Requirements 13201 1 2014Mohamed AliNo ratings yet

- MiniProf BT Brochure 2015 PDFDocument24 pagesMiniProf BT Brochure 2015 PDFVenkatesh SreegirisettyNo ratings yet

- Vertically Installed Axial and Mixed Flow PumpsDocument24 pagesVertically Installed Axial and Mixed Flow Pumpsvinay1999No ratings yet

- p-16-68 - Copper Wire For Earthing - PDFDocument6 pagesp-16-68 - Copper Wire For Earthing - PDFsohaibNo ratings yet

- What Is HDPE PIPEDocument7 pagesWhat Is HDPE PIPEKarthikeyan MoorthyNo ratings yet

- FUNCTIONAL GROUP INTERCONVERSIONS GUIDEDocument6 pagesFUNCTIONAL GROUP INTERCONVERSIONS GUIDEJulia MaramatNo ratings yet

- COP 101 Version 9.1 Document (Text) Jan 2006Document41 pagesCOP 101 Version 9.1 Document (Text) Jan 2006MarcusNo ratings yet

- Free Documents As of Oct 5 - 2011Document488 pagesFree Documents As of Oct 5 - 2011Shirish0% (1)

- 10742Document10 pages10742satish3393No ratings yet

- JSS 52300-1992 PDFDocument68 pagesJSS 52300-1992 PDFNaga Prasad100% (2)

- Iscor RailsDocument3 pagesIscor Railsmgeorgiadis7No ratings yet

- Avk Saudi National Price ListDocument46 pagesAvk Saudi National Price Listjanpaul2481No ratings yet

- Chloride Ion in Water: Standard Test Methods ForDocument9 pagesChloride Ion in Water: Standard Test Methods ForSaravanan Natesan100% (1)

- MSI Pipe and Valve InternationalDocument27 pagesMSI Pipe and Valve InternationalbawwsswwabNo ratings yet

- BS 6447.1984Document17 pagesBS 6447.1984Yaser Al ShabasyNo ratings yet

- Iso 4866 2010 PDFDocument11 pagesIso 4866 2010 PDFSj OnNo ratings yet

- 03 Dual HANDWave Technical DetailsDocument27 pages03 Dual HANDWave Technical DetailsJunior Oña OrdoñezNo ratings yet

- MX Preaction Sprinkler Eng PDFDocument2 pagesMX Preaction Sprinkler Eng PDFNarendra Reddy Bhuma100% (1)

- 1612Document24 pages1612Udomsin WutigulpakdeeNo ratings yet

- FM 1612 PVC Pipe & Fittings For UG FP Service 2016Document27 pagesFM 1612 PVC Pipe & Fittings For UG FP Service 2016andy100% (1)

- Iso Update November2011Document33 pagesIso Update November2011Amira KhattabNo ratings yet

- Apc Irma IV Ibis Protocol Version 100 20060314Document31 pagesApc Irma IV Ibis Protocol Version 100 20060314kohan_xlNo ratings yet

- As ISO 6993.2-2007 Buried High-Impact Poly (Vinyl Chloride) (PVC-HI) Piping Systems For The Supply of GaseousDocument8 pagesAs ISO 6993.2-2007 Buried High-Impact Poly (Vinyl Chloride) (PVC-HI) Piping Systems For The Supply of GaseousSAI Global - APACNo ratings yet

- Development of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PDocument20 pagesDevelopment of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PSen HuNo ratings yet

- Water Quality Regulations 2021 Edition 5Document67 pagesWater Quality Regulations 2021 Edition 5Samer KhaledNo ratings yet

- FTA Noise and Vibration ManualDocument261 pagesFTA Noise and Vibration Manualestebangonzalez0No ratings yet

- Venturi TubeDocument2 pagesVenturi TubeQing JyulyanNo ratings yet

- WW 11 Corrosion Prevention of Steel Pipe 2012Document100 pagesWW 11 Corrosion Prevention of Steel Pipe 2012daskirNo ratings yet

- Astm F 856 - Standard Hvac SymbolsDocument6 pagesAstm F 856 - Standard Hvac SymbolsleandroschroederNo ratings yet

- Saso Gso 1438 2003 e PDFDocument12 pagesSaso Gso 1438 2003 e PDFshafeeqm3086No ratings yet

- As 3778.4.1-1991 Measurement of Water Flow in Open Channels Measurement Using Flow Gauging Structures - ThinDocument7 pagesAs 3778.4.1-1991 Measurement of Water Flow in Open Channels Measurement Using Flow Gauging Structures - ThinSAI Global - APACNo ratings yet

- BS 5480-2 (1982) Design and Performance RequirementsDocument24 pagesBS 5480-2 (1982) Design and Performance RequirementsGregory Simmon100% (1)

- Alstom 12" LED Flashing Light AssemblyDocument24 pagesAlstom 12" LED Flashing Light AssemblyDJNo ratings yet

- Retention Time For N2 System - Room Integrity-2Document2 pagesRetention Time For N2 System - Room Integrity-2anwerquadriNo ratings yet

- Qdoc - Tips Ul 508aDocument56 pagesQdoc - Tips Ul 508aAlexNo ratings yet

- Disco de RoturaDocument2 pagesDisco de RoturauuemnrnfNo ratings yet

- AHS 187 - Air Handling Systems Product Selector GuideDocument8 pagesAHS 187 - Air Handling Systems Product Selector GuideKhang NguyenNo ratings yet

- SCF Series (Ms-02-156) r0Document4 pagesSCF Series (Ms-02-156) r0Heryanto SyamNo ratings yet

- NEXISTDocument3 pagesNEXISTMustafa DaoudNo ratings yet

- SPC Series: Polyester Pleated CartridgesDocument2 pagesSPC Series: Polyester Pleated CartridgesElizabethNo ratings yet

- STRCT Ss A479-304Document1 pageSTRCT Ss A479-304Stanley PeterNo ratings yet

- Bolt SelectionDocument1 pageBolt SelectionStanley PeterNo ratings yet

- Particle Size Conversion Chart from SwecoDocument1 pageParticle Size Conversion Chart from SwecoStanley PeterNo ratings yet

- Particle Size Conversion Chart from SwecoDocument1 pageParticle Size Conversion Chart from SwecoStanley PeterNo ratings yet

- Growse Lining PDFDocument11 pagesGrowse Lining PDFStanley PeterNo ratings yet

- Pescante DiseñoDocument13 pagesPescante DiseñoFernando Reyes GomezNo ratings yet

- Growse LiningDocument11 pagesGrowse LiningStanley PeterNo ratings yet

- Duraflow Catridge ElementDocument2 pagesDuraflow Catridge ElementStanley PeterNo ratings yet

- Pressure Vessel Design For Engineering Plastics: Hoop Stress May NotDocument3 pagesPressure Vessel Design For Engineering Plastics: Hoop Stress May NotStanley PeterNo ratings yet

- Swing Bolts: Steel / Stainless SteelDocument1 pageSwing Bolts: Steel / Stainless SteelStanley PeterNo ratings yet

- Particle Size Conversion Chart from SwecoDocument1 pageParticle Size Conversion Chart from SwecoStanley PeterNo ratings yet

- Particle Size Conversion Chart from SwecoDocument1 pageParticle Size Conversion Chart from SwecoStanley PeterNo ratings yet

- Chain Block DimensionDocument1 pageChain Block DimensionStanley PeterNo ratings yet

- SUPERTHANE Transparent Polyurethane TubingDocument2 pagesSUPERTHANE Transparent Polyurethane TubingStanley PeterNo ratings yet

- JIS ThreadsDocument7 pagesJIS Threadsthailan0% (1)

- Chain Block DimensionDocument1 pageChain Block DimensionStanley PeterNo ratings yet

- Air Specific Gravity 2Document1 pageAir Specific Gravity 2Stanley PeterNo ratings yet

- Enthalpy PDFDocument3 pagesEnthalpy PDFAnonymous NxpnI6jCNo ratings yet

- Air Specific GravityDocument1 pageAir Specific GravityStanley PeterNo ratings yet

- Psv-Screwed Type PDFDocument3 pagesPsv-Screwed Type PDFStanley PeterNo ratings yet

- Air Specific GravityDocument1 pageAir Specific GravityStanley PeterNo ratings yet

- Pressure Vessel Design For Engineering Plastics: Hoop Stress May NotDocument3 pagesPressure Vessel Design For Engineering Plastics: Hoop Stress May NotStanley PeterNo ratings yet

- Globe Valves: ORION S.p.A. Via Caboto, 8 - 34148 Trieste - Italy - Tel. +39 040813204 - Fax +39 040811203Document12 pagesGlobe Valves: ORION S.p.A. Via Caboto, 8 - 34148 Trieste - Italy - Tel. +39 040813204 - Fax +39 040811203Stanley PeterNo ratings yet

- Air Specific GravityDocument1 pageAir Specific GravityStanley PeterNo ratings yet

- Compact HouseDocument209 pagesCompact HouseSerban AlexandruNo ratings yet

- ChemGuide 8677 PDocument32 pagesChemGuide 8677 PPiok Piere TenengNo ratings yet

- E3115 PDFDocument2 pagesE3115 PDFStanley PeterNo ratings yet

- KSM History and Safety Valve DesignDocument56 pagesKSM History and Safety Valve DesignStanley PeterNo ratings yet

- 04 SF PDFDocument4 pages04 SF PDFStanley PeterNo ratings yet

- Etds 6900 20x - v21Document2 pagesEtds 6900 20x - v21Nirupam KediaNo ratings yet

- Welding SymbolsDocument28 pagesWelding SymbolsPandu Pratama YudhaNo ratings yet

- Butterfly ValveDocument2 pagesButterfly ValveKELVIN TECHNOLOGIESNo ratings yet

- Astm A 249 PDFDocument9 pagesAstm A 249 PDFBez SofNo ratings yet

- 1-Architect Material AnalysisDocument25 pages1-Architect Material Analysisk.o.m channel (kmeng)No ratings yet

- Efficient, economical Hankison HF Series Compressed Air FiltersDocument8 pagesEfficient, economical Hankison HF Series Compressed Air FiltersJuan Carlos Vazquez RosasNo ratings yet

- Spoljne Resetke - TPI 03 PZ - ENDocument6 pagesSpoljne Resetke - TPI 03 PZ - ENKundzoNo ratings yet

- Wet Air OxidationDocument18 pagesWet Air OxidationUtkarsh PatilNo ratings yet

- Geosynthetic Institute: GRI Test Method GM19Document12 pagesGeosynthetic Institute: GRI Test Method GM19HeiderHuertaNo ratings yet

- Material and WeldingDocument226 pagesMaterial and WeldingIvan DulicNo ratings yet

- Surface GrindingDocument18 pagesSurface GrindingSachin MohandasNo ratings yet

- Cyclone Fabrication InstructionsDocument8 pagesCyclone Fabrication InstructionsAbhijit MokashiNo ratings yet

- Brazing BookDocument109 pagesBrazing BooksutrimoNo ratings yet

- Pentens: Water-Base Zinc Rich EpoxyprimerDocument2 pagesPentens: Water-Base Zinc Rich Epoxyprimeramelinda jocelinNo ratings yet

- Loctite 7075 TdsDocument1 pageLoctite 7075 TdsSurajPachhadeNo ratings yet

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Mini DOJO ConceptDocument24 pagesMini DOJO ConceptMukesh Sharma Akshu100% (3)

- Technical Data Sheet and Strainer SpecificationsDocument31 pagesTechnical Data Sheet and Strainer SpecificationsAlexNo ratings yet

- Grapple Releasing SpearDocument7 pagesGrapple Releasing SpearALEX MAKANGANo ratings yet

- Report On Sheet Metal FabricationDocument30 pagesReport On Sheet Metal FabricationM.A.K. S. Pathan97% (34)

- Primary and Secondary Wastewater Treatment: Snehal Menon Sinhgad College of Engineering, PuneDocument37 pagesPrimary and Secondary Wastewater Treatment: Snehal Menon Sinhgad College of Engineering, PuneSeema NihalaniNo ratings yet

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Document24 pagesPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNo ratings yet

- Granshot Iron Granulation Technology: Raw Materials and IronmakingDocument4 pagesGranshot Iron Granulation Technology: Raw Materials and IronmakingROWHEITNo ratings yet

- Sikalastomer 710Document1 pageSikalastomer 710Eliza ManNo ratings yet

- Sop For FGDocument3 pagesSop For FGANILNo ratings yet

- Jotaguard 100: Technical Data SheetDocument6 pagesJotaguard 100: Technical Data SheetHector MacavilcaNo ratings yet

- Slide 13 Bending and FormingDocument68 pagesSlide 13 Bending and Formingjohn doeNo ratings yet

- (PR-999) TDS Thermal Etch ResistDocument2 pages(PR-999) TDS Thermal Etch Resistnithu17_4uNo ratings yet

- Parts of A Centre LatheDocument21 pagesParts of A Centre LatheMuralikrishnan GMNo ratings yet

- Detail of Raw MaterialDocument3 pagesDetail of Raw MaterialjacksonNo ratings yet