Professional Documents

Culture Documents

Underground Tank Inspection Reports

Uploaded by

Ravi Kumar VatturiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Underground Tank Inspection Reports

Uploaded by

Ravi Kumar VatturiCopyright:

Available Formats

1. Tank No- UG-05, Type- Underground, Size- 3.0 mtr dia x 8.

9 mtr , Capacity-

70.0 KL, Product-ETHANOL

Observations and Recommendations:- Reference

from EAST

a. Condition of all weld Joints i.e., circumferential and longitudinal joints checked and found

satisfactory.

b. A round patch plate of size 150 mm dia and 16mm thickness was observed on both Dish-

1&2. (Observation only).

c. A round patch plate of size 50 mm dia and 10mm thickness was observed on Sump

bottom (Observation only).

d. Mild pitting & scaling noticed on the bottom of the vessel, it is advised to blast and paint

the tank internally so as to deter the pitting in long run.

e. Thickness Measurement of Tank Shell, Dish End Plate and Appurtenances were carried

out and found satisfactory as complied with drawings.

f. Cracks observed on dyke wall and site drain is chocked that has to repair by carrying civil

work.

g. In conclusion this tank can be taken into service/recharged.

2. Tank Name-OWN USE TANK, Type- Underground, Size- 2.0 mtrdia x 6.5mtr,

Capacity-20.0 KL, Product-HSD

Observations and Recommendations:- Reference from EAST

a. Condition of all weld Joints i.e., circumferential and longitudinal joints checked and

Crack was found on longitudinal weld joint on shell-3(between plate 1 and 2) at

1 o clock position, same has to be grind and filled with weld deposit.

b. No welding was observed internally between manhole to shell and nozzles to shell, same

shall be rectified by full welding.

c. Torn weld cleats noticed across the vessel, same has to be removed by grinding.

d. End stays found dislocated from both end plates same shall be fixed by welding.

e. Stitch welding observed on angular ring to end plates (observation only).

f. Poor workmanship noticed across vessel on all weld joints.

g. Mild pitting and scaling was observed on the bottom of the vessel, thickness

measurement were carried out and recorded, it is advised to blast and paint the tank

internally so as to avert the severity of pitting in long run.

h. A square patch plate of size 100X100 mm and 6 mm thick was observed on shell-4 at 7 o

clock position (observation only).

i. Dimensions of tank are taken to actual.

j. Thickness Measurement of Tank Shell, End plates and Appurtenances were carried out

and recorded.

k. Welding shall be performed by a qualified welder followed by WPS, WQT & PQR and

certificates should be submitted to the inspector who visited at site for post repair

inspection.

l. After carrying out the hot work in the tank, it is recommended to carry out hydro test by

the HPCL location authorities.

m. In conclusion this tank can be taken into service/recharged only after the fulfilment of

above recommendations.

General:

1. Drawings of 70 kl tanks (UG-7 & 5) are traceable with HPCL location authorities.

Drawing of OWN USE tank is not traceable with location authorities and dimensions of tank

were actual.

You might also like

- New Bottom PlateDocument9 pagesNew Bottom PlateEmmanuel kusimo100% (1)

- 24.tank Oil Chalk TestDocument3 pages24.tank Oil Chalk TestShubham ShuklaNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Procedure For Vacuum Box TestingDocument3 pagesProcedure For Vacuum Box TestingZakirUllahNo ratings yet

- Dolly TestDocument1 pageDolly TestmaheshNo ratings yet

- IOCL Refinery Project Tank Settlement Survey ReportDocument1 pageIOCL Refinery Project Tank Settlement Survey Reportarkaprava ghosh100% (1)

- 2018 Uk Cswip Exam FeeDocument7 pages2018 Uk Cswip Exam FeeMostafaRockNo ratings yet

- API 653 Above Ground Storage Tanks Inspector 08-July-2023Document8 pagesAPI 653 Above Ground Storage Tanks Inspector 08-July-2023RAVI0% (1)

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNo ratings yet

- Vessel Cleaning ProcedureDocument6 pagesVessel Cleaning ProcedureZool HilmiNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- CBT QuestionsDocument17 pagesCBT QuestionsNaseer Ahmed SokhalNo ratings yet

- Radiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0Document13 pagesRadiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0BCE DeNo ratings yet

- Fabrication Quality Dossier IndexDocument22 pagesFabrication Quality Dossier IndexAli KayaNo ratings yet

- GTS-PP-120: 3 LayerDocument2 pagesGTS-PP-120: 3 Layershoaib1985100% (1)

- TWI CL Eye Sight Test Form 2016Document2 pagesTWI CL Eye Sight Test Form 2016Savad Alwye100% (2)

- API 653 - Section 650 Flash Card - 36 QuestionsDocument5 pagesAPI 653 - Section 650 Flash Card - 36 QuestionsdanielbellaNo ratings yet

- Welded Tank Oil Storage Inspection StandardDocument106 pagesWelded Tank Oil Storage Inspection StandardiraprobotNo ratings yet

- Oil Chalk Test/Penetrating Oil TestDocument6 pagesOil Chalk Test/Penetrating Oil TestWeld ManiacNo ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- API 570 Pipeline Inspection PDFDocument1 pageAPI 570 Pipeline Inspection PDFKhalidMoutarajiNo ratings yet

- API 653 Study PlanDocument7 pagesAPI 653 Study PlanJeganeswaranNo ratings yet

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Duties of Tank InspectorDocument1 pageDuties of Tank InspectorJawed AlamNo ratings yet

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- STS Co. storage tank fabrication methodologyDocument15 pagesSTS Co. storage tank fabrication methodologypurshottam GHNo ratings yet

- Thickness Qualification Range For PQR and WPQDocument5 pagesThickness Qualification Range For PQR and WPQOuled BladiNo ratings yet

- Inspection of Tanks-1Document6 pagesInspection of Tanks-1Senthil KumarNo ratings yet

- Tank Inspection NotesDocument5 pagesTank Inspection Notesaneeshjose013No ratings yet

- Industrial Plant Inspection GuideDocument5 pagesIndustrial Plant Inspection GuideMohamedNo ratings yet

- Chapter 9: Tank Settlement: Settlement in New ConstructionDocument10 pagesChapter 9: Tank Settlement: Settlement in New ConstructionppatrickkkNo ratings yet

- CV for Mechanical Inspector and Welding InspectorDocument28 pagesCV for Mechanical Inspector and Welding InspectorAJMAL KAREEMNo ratings yet

- API-510 QuestionsDocument21 pagesAPI-510 Questionssjois_hs100% (1)

- Inspection Report - ValvesDocument2 pagesInspection Report - ValvesJaspal KaurNo ratings yet

- API 653 Recertification Quiz - Questions and Answers (Updated April 2021)Document2 pagesAPI 653 Recertification Quiz - Questions and Answers (Updated April 2021)Amani ReidNo ratings yet

- Peaking BandingDocument2 pagesPeaking Bandingsetak100% (4)

- TankInspectionTechniques3Document136 pagesTankInspectionTechniques3Zenon Kociuba100% (1)

- Consultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsDocument6 pagesConsultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsShahbaz KhanNo ratings yet

- Vaccum Test MethodDocument4 pagesVaccum Test MethodMahmud AlamNo ratings yet

- Reconstruction of Pakistan Refinery Tank T-53Document16 pagesReconstruction of Pakistan Refinery Tank T-53javaidahmedshaikh100% (1)

- Pickling Procedure 20 - 08Document2 pagesPickling Procedure 20 - 08Siriepathi SeetharamanNo ratings yet

- API 570 Piping Inspector Certification PrepDocument4 pagesAPI 570 Piping Inspector Certification Prepahmedm2020No ratings yet

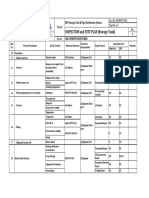

- Inspection & Test Plan TankDocument3 pagesInspection & Test Plan TankJOSHUA SULLEGUE100% (1)

- API 570 Open BookDocument9 pagesAPI 570 Open BookMusa ÇelikNo ratings yet

- API - 510-Open - Book - Mock UpDocument13 pagesAPI - 510-Open - Book - Mock Upprashanth-967782No ratings yet

- API 510 - Book 5Document48 pagesAPI 510 - Book 5Hamza AlamNo ratings yet

- Repairing Corroded Tank Bottoms Safely and Cost EffectivelyDocument5 pagesRepairing Corroded Tank Bottoms Safely and Cost EffectivelylsatchithananthanNo ratings yet

- Sa 263Document8 pagesSa 263Wagner Renato AraújoNo ratings yet

- Shrikant B. Moje CVDocument6 pagesShrikant B. Moje CVPaul PhiliphsNo ratings yet

- 653 Examination Sample QuestionsDocument3 pages653 Examination Sample QuestionsStevenQuekNo ratings yet

- API 653 Questions Monkey PuzzleDocument5 pagesAPI 653 Questions Monkey PuzzleAnuradha SivakumarNo ratings yet

- Construction Methodlogy For Well Foundation: - 1 - VKLR, QmeDocument4 pagesConstruction Methodlogy For Well Foundation: - 1 - VKLR, QmeBalaji ManneNo ratings yet

- Dry-Dock Repair ListDocument6 pagesDry-Dock Repair ListAnwarul Islam100% (3)

- Ce NiriisDocument12 pagesCe NiriiscpîndaruNo ratings yet

- Reply To QueriesDocument4 pagesReply To QueriesMRITYUNJAY PANDEYNo ratings yet

- Hydromechanical - Technical SpecificationsDocument16 pagesHydromechanical - Technical SpecificationsdishkuNo ratings yet

- 01DCivil Jab SafetyDocument6 pages01DCivil Jab Safetymd sarfaraz khanNo ratings yet

- Quality of SurfaceDocument8 pagesQuality of SurfaceNexhat QehajaNo ratings yet

- E690-98 EC Nonmagnetic Exchanger TubesDocument4 pagesE690-98 EC Nonmagnetic Exchanger TubesRavi Kumar VatturiNo ratings yet

- 32 Screw Threads and Gear Manufacturing MethodsDocument21 pages32 Screw Threads and Gear Manufacturing MethodsquockhanhspktNo ratings yet

- RRB Je Previous Year Paper 8thaug Shift2.PDF 51Document11 pagesRRB Je Previous Year Paper 8thaug Shift2.PDF 51sreenu mNo ratings yet

- Twi India Bgas Cswip Fee 2017Document1 pageTwi India Bgas Cswip Fee 2017Ravi Kumar VatturiNo ratings yet

- NDE Personnel Qualification and Certification SystemsDocument18 pagesNDE Personnel Qualification and Certification SystemsSyarif IrwantoNo ratings yet

- Ultrasonic testing requirements for weldsDocument1 pageUltrasonic testing requirements for weldsRavi Kumar VatturiNo ratings yet

- PAUTDocument55 pagesPAUTRavi Kumar VatturiNo ratings yet

- AES and Group Companies - Statement of QualificatiDocument85 pagesAES and Group Companies - Statement of QualificatiRavi Kumar VatturiNo ratings yet

- Comparision of ISO 9712 & ASNTDocument6 pagesComparision of ISO 9712 & ASNTMurali Krishnan Selvaraja100% (1)

- Utawsd1 1Document4 pagesUtawsd1 1Syed AjeezNo ratings yet

- Suvey ApplicationDocument4 pagesSuvey ApplicationDaya KiranNo ratings yet

- Comparision of ISO 9712 & ASNTDocument6 pagesComparision of ISO 9712 & ASNTMurali Krishnan Selvaraja100% (1)

- BS en Iso 16828-2014Document30 pagesBS en Iso 16828-2014Ravi Kumar Vatturi100% (2)

- Online Application For Certification Guide: Do Not Begin Until You Have All Required DocumentationDocument6 pagesOnline Application For Certification Guide: Do Not Begin Until You Have All Required DocumentationizmitlimonNo ratings yet

- Magnetic Partical Test Report2Document2 pagesMagnetic Partical Test Report2Ravi Kumar VatturiNo ratings yet

- E690-98 EC Nonmagnetic Exchanger TubesDocument4 pagesE690-98 EC Nonmagnetic Exchanger TubesRavi Kumar VatturiNo ratings yet

- Stainless SteelDocument89 pagesStainless Steelmarinom1No ratings yet

- GWT Personnel Certification RequirementsDocument17 pagesGWT Personnel Certification Requirementsmjranjbarn0% (1)

- ASME V Art 26 ET PDFDocument32 pagesASME V Art 26 ET PDFRavi Kumar VatturiNo ratings yet

- 8.2 Dgs - Avg - Olympus ImsDocument4 pages8.2 Dgs - Avg - Olympus ImsRavi Kumar VatturiNo ratings yet

- PCN/GEN APPENDIX A Initial Issue 1 Dated 1 October 2011 Certification of Personnel For Guided Wave Testing of PipesDocument7 pagesPCN/GEN APPENDIX A Initial Issue 1 Dated 1 October 2011 Certification of Personnel For Guided Wave Testing of PipesRavi Kumar VatturiNo ratings yet

- Pipe Inspection CameraDocument11 pagesPipe Inspection CameraRavi Kumar VatturiNo ratings yet

- A Baseline and Vision of Ultrasonic Guided Wave Inspection PotentialDocument10 pagesA Baseline and Vision of Ultrasonic Guided Wave Inspection PotentialRavi Kumar VatturiNo ratings yet

- Pipe Inspection CameraDocument11 pagesPipe Inspection CameraRavi Kumar VatturiNo ratings yet

- LPSC Banglore Cost EstimationDocument1 pageLPSC Banglore Cost EstimationRavi Kumar VatturiNo ratings yet

- Balu AbcdefDocument1 pageBalu AbcdefRavi Kumar VatturiNo ratings yet

- Overall Main Broucher - AESDocument6 pagesOverall Main Broucher - AESRavi Kumar VatturiNo ratings yet

- BASIC TIME-4 HOURS NDT CERTIFICATION EXAMDocument20 pagesBASIC TIME-4 HOURS NDT CERTIFICATION EXAMRavi Kumar VatturiNo ratings yet

- 1200 Bunker and Field Rake TM1525Document476 pages1200 Bunker and Field Rake TM1525ZeeNo ratings yet

- Centrifugal ForceDocument11 pagesCentrifugal Forceno oneNo ratings yet

- AAMA Metal Curtain Wall FastenersDocument3 pagesAAMA Metal Curtain Wall FastenersAthumizNo ratings yet

- L P GDocument11 pagesL P GPhi MacNo ratings yet

- Online System, Functions, and PlatformsDocument28 pagesOnline System, Functions, and PlatformsJules Gajes80% (5)

- Procedure: Technical Bid Evaluation For Catodic ProtectionDocument6 pagesProcedure: Technical Bid Evaluation For Catodic ProtectionPer Bagus HandokoNo ratings yet

- DHC Fusion A Fixed Height ENGDocument2 pagesDHC Fusion A Fixed Height ENGSwingster SatNo ratings yet

- 0512 - D - 020 - ANA PeabodyDocument1 page0512 - D - 020 - ANA PeabodyJustin W. ThomasNo ratings yet

- What Is Cross Wall Construction - Features and BenefitsDocument4 pagesWhat Is Cross Wall Construction - Features and BenefitswaynectwNo ratings yet

- Coaltar EpoxyDocument3 pagesCoaltar EpoxyAkhtar aliNo ratings yet

- MTL Product OverviewDocument56 pagesMTL Product OverviewAries dNo ratings yet

- Biochar and Sustainable AgricultureDocument12 pagesBiochar and Sustainable AgricultureSusanThorntonHuNo ratings yet

- YearinInfrastructure2018 DL PDFDocument332 pagesYearinInfrastructure2018 DL PDFLovepreet singhNo ratings yet

- VW - tb.01!07!69 MIL On, DTC P129F and or P310B Stored in ECM Fault MemoryDocument6 pagesVW - tb.01!07!69 MIL On, DTC P129F and or P310B Stored in ECM Fault MemorySlobodanNo ratings yet

- Powerful Solutions for All Your Advertising NeedsDocument5 pagesPowerful Solutions for All Your Advertising NeedsAnonymous kLK2YpITNo ratings yet

- Operating Conditions Liquid: Client: ServiceDocument1 pageOperating Conditions Liquid: Client: ServiceAde IskandarNo ratings yet

- VLSI Physical Design AutomationDocument18 pagesVLSI Physical Design Automationjeevan_raoNo ratings yet

- Quickly Overcome Obstacles: LukasDocument2 pagesQuickly Overcome Obstacles: LukasArrum FirdaNo ratings yet

- Chemrite - NNDocument2 pagesChemrite - NNICPL-RWPNo ratings yet

- Shop Drawing Submittal ReviewDocument2 pagesShop Drawing Submittal Reviewvirat_daveNo ratings yet

- Introduction To Wireless NetworksDocument4 pagesIntroduction To Wireless NetworksDr-Gnaneswar Nadh SatapathiNo ratings yet

- 170904-Nokia 5G Technology Components White PaperDocument13 pages170904-Nokia 5G Technology Components White PaperMuhammad Jamil AwanNo ratings yet

- 2004 Nissan Maxima ESMDocument7 pages2004 Nissan Maxima ESMLeonardo Guajardo0% (1)

- Sheet Pile WallDocument6 pagesSheet Pile Wallully amaliaNo ratings yet

- Surface Preparation: The Essential First Stage Treatment for SteelDocument11 pagesSurface Preparation: The Essential First Stage Treatment for SteelPrabath MadusankaNo ratings yet

- Lecture 08Document3 pagesLecture 08api-3723265No ratings yet

- SSP - 451 - Audi TT-RS - 2.5L - TFSI PDFDocument52 pagesSSP - 451 - Audi TT-RS - 2.5L - TFSI PDFsheba1023No ratings yet

- Concrete Filled Steel TubeDocument12 pagesConcrete Filled Steel TubeYogendra SINGH PATEL100% (1)

- Masonry Wall Footing DesignDocument18 pagesMasonry Wall Footing DesignAnonymous 0JQGC2No ratings yet

- Analysis of The Filament-Wound Glass Reinforced Rectangular Cross Section Composite Pipes in AnsysDocument1 pageAnalysis of The Filament-Wound Glass Reinforced Rectangular Cross Section Composite Pipes in AnsysIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet