Professional Documents

Culture Documents

Modeling AlN Precipitates in Steel Solidification

Uploaded by

Ruy AlvesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modeling AlN Precipitates in Steel Solidification

Uploaded by

Ruy AlvesCopyright:

Available Formats

ARCHIVES

of

FOUNDRY ENGINEERING ISSN (2299-2944)

Volume 13

DOI: 10.2478/afe-2013-0012 Issue 1/2013

Published quarterly as the organ of the Foundry Commission of the Polish Academy of Sciences 63 68

Modeling of the Formation of AlN

Precipitates During Solidification of Steel

D. Kalisz*, S. Rzadkosz

AGH University of Science and Technology,

Reymonta 23, 30-059 Krakw, Poland

* Corresponding author. E-mail address: dorotkapo@yahoo.com

Received 13.07.2012; accepted in revised form 04.09.2012

Abstract

The study was carried out computer simulations of the formation process of AlN precipitates in the solidification of steel. The chemical

composition of steel and non-metallic inclusions formed was determined using the commercial software FactSage. Calculated amount of

precipitates formed during cooling of steel between the liquidus and solidus temperatures under conditions of thermodynamic equilibrium.

In parallel, the computations were performed using your own computer program. It was found that aluminum nitride is formed at the final

stage of solidification, and the condition of its formation is low oxygen content in steel.

Keywords: Computer simulation, Aluminum nitride, Solidification of steel, Continuous casting of steel, Silicon steel

1. Introduction total amount are crucial for optimal steel properties. The present

work deals with the process of AlN precipitates formation during

steel solidification. The AlN play very important role in steel

Formation of non-metallic inclusions in steel ingot obtained in

structure formation, which is particularly important in obtaining

continuous casting machine (CCS) is a complex process. The

high magnetic properties of grain oriented high silicon steel [1].

chemical composition, size and spatial distribution influence the

As aluminum shows high chemical affinity to both oxygen and

structure and properties of cast ingot. The initial non-metallic

nitrogen in steel, the correct determination of the conditions

inclusions resulting from steel de-oxidization are in major part

favourable for AlN formation is rather complicated task [2], [3]

removed in ladle, mainly during argon purging and the remainder

[4], [5]. The aim of the present work was the computer simulation

should be removed in castin tundish. In the ideal case, the steel

of steel components distribution between phases, with special

tapped into the casting mould might be almost inclusions free.

focus on AlN formation. The obtained results are verified with the

However, in casting mold new inclusions are produced in liquid

results of steel sample analysis by means of transmission electron

steel for two reasons: decrease of equilibrium solubility product

microscopy.

with decreasing temperature and segregation of liquid steel

components at the solidification front. These secondary inclusions

may play an important role in structure formation. The

development of technology of steel refining in ladle and casting 2. The object of research

tundish, so called tertiary metallurgy, allows for assure the

relevant conditions for required structure and properties of the The simulation of AlN precipitation in the course of steel

ingot. In high grade steels and specific purpose steels the kind of solidification in continuously cast ingot was carried out for high

emerging inclusions, their chemical composition, dimensions and silicon grain oriented steel (Polish designation ETZ), assigned for

ARCHIVES of FOUNDRY ENGINEERING Volume 13, Issue 1/2013, 63-68 63

Unauthenticated | 89.67.242.59

Download Date | 5/12/13 7:16 PM

electric transformer core. The structure active aluminum nitride - evaluation of minimum value of Gibbs free enthalpy of the

forms in the solid state, what requires sufficient levels of whole system for variable system parameters,

aluminum and nitrogen in steel. AlN precipitated from liquid steel - solution of set of equilibrium constants of possible chemical

is worthless as structure forming agent, as it either floats out from reactions in the system, which describe the exchange of

liquid steel, or, if remains, has too big size to effectively pin the components between phases.

grain boundaries. The steel composition adopted for the In both cases the dependencies of phase composition on the

calculations is given in Table 1. It was obtained from chemical components activities or partial molar Gibbs free enthalpies must

analysis of the sample taken from casting tundish. be known. The first of the above procedures is employed in

commercial programs as FactSage or Thermocalc, the other may

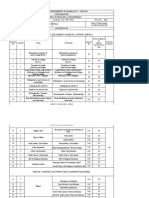

Table 1. be employed in calculations for simpler systems.

Chemical composition of steel adopted in the calculations In the present work the formation of AlN inclusions in the

Chemical composition of steel [mass pct.] system Fe-Al-N-O was first considered. The influence of oxygen

C Mn Si P S Cu Al N O level in steel on AlN formation is strong, as oxygen and nitrogen

1 0,037 0,24 3,01 0,01 0,01 0,45 0,015 0,0125 0,00465 compete in formation the compounds with aluminum: Al2O3 and

2 0,041 0,24 3,0 0,014 0,009 0,42 0,0092 0,0097 0,00181 AlN. This means, that reaching the proper amount of AlN in steel

requires very precise setting of its chemical composition [7], [8].

The computer simulation was performed in two ways: first The calculations of the inter phase equilibrium parameters

using the commercial software FactSage and next using the in the system liquid steel non-metallic inclusions were carried

simple program built for this very purpose. out for steel compositions given in Table 1. The temperatures of

In order to verify the results of simulations the samples taken liquidus and solidus were calculated from relations (3) and (4):

from steel ingot were examined by means of transition electron

microscopy. T = 1809 {100,3[% C] 22,4[% C]2 0,16 + 13,55[% Si] 0,64[% Si]2 + 5,82[% Mn] +

L

+ 0,3[% Mn]2 + 4,2[% Cu]}

3. The simulation of AlN formation in TK = 1809 {415,5[% C] + 12,3[% Si] + 6,8[% Mn] + 124,5[% P] + 183,9[% S] + +4,1[% Al]}

steel with the use of FactSage

The fraction of solid phase fs in each calculation step was

Secondary non-metallic inclusions emerge during the calculated from the relation:

crystallization of steel in continuous casting mould, and to some

extent in the still liquid core of the ingot in the secondary cooling (5)

zone out of the mould. The necessary condition of inclusion where T denotes the temperature of respective calculation step.

formation is to reach the sufficient concentrations of both

inclusion forming components (e.g. aluminum and nitrogen) [6]. The equilibrium crystallization of steel was assumed in the

For given temperature the inclusion forms, if the solubility calculations, what allowed to express the mass of component in

product [Al] [N], which follows from the equilibrium constant of the solid phase as a function of the solid fraction fs:

reaction:

[Al] + [N] = (AlN) (1) (6)

where:

gdzie: mi(s) mass of component i in solid phase

(2) mi(l) mass of component i remained in liquid phase

The composition of metal phase as well as that of inclusions

The aluminum and nitrogen activities in steel depend on its

was calculated by means of FactSage software. From the

composition and temperature. During steel solidification various equations (5) and (6) the fraction of solid phase and the

non-metallic compounds are formed, i.e. oxides, nitrides or concentration of steel components in solid and liquid phase were

sulphides, which may constitute non-metallic phase or exist as

determined. The procedure was repeated for each calculation

separate inclusions. This depends also on physical conditions of

step, until the last fragment of liquid solidified. As a results of

inclusions flotation and bonding in slag phase.

simulations, the solid phase fraction, mass of emerged Al2O3 and

The determination of the amount of emerging AlN requires AlN inclusions as well as micro-segregation of Al, N and O

the consideration of thermodynamic equilibrium in the system:

during of solidification of steel 1 and 2 were determined.

liquid steel non-metallic phase. State of the thermodynamic

equilibrium in the system is described with the set of parameters,

which basically are: temperature, pressure, and mass of each

components in all phases. The masses of components may be

easily converted into mass percent or molar fractions. To

determine this set of system parameters, under assumed total

masses of components in the system, two procedures may be

considered:

64 ARCHIVES of FOUNDRY ENGINEERING Volume 13, Issue 1/2013, 63-68

Unauthenticated | 89.67.242.59

Download Date | 5/12/13 7:16 PM

Fig. 4. The composition of aluminum based non-metallic

inclusions formed in the course of steel nr 2 solidification

4. Simulation of the process of AlN

formation by means of simple program

including micro-segregation

The model of Matsumiya et al [9] was adopted to simulate the

micro-segregation of steel components. Model includes the

process of inclusions formation with simultaneous components

micro-segregation during solidification, what makes the

simulation more realistic. The program used in this study

Fig. 1. The fraction of solid phase fs during solidification of steel determines the concentration of components in liquid phase in

nr. 1 each step of calculations, and controls the resulting current value

of solubility product. If the inclusion have precipitated, the

concentrations of liquid metal components are corrected, i.e.

lowered [3], [6], [10].

The current temperature of solid liquid interface varies

according to the relation:

T0 TK

T = T0 (7)

T TK

1 fS L

T0 TK

where:

T current temperature of solid liquid interface,

T0 melting temperature of pure iron,

Fig. 2. The composition of aluminum based non-metallic TL liquidus temperature of steel,

inclusions formed in the course of steel nr 1 solidification TK temperature of the end of solidification, i.e. the solidus

temperature for the composition of final portion of freezing steel.

The progress of the process of steel solidification may be related

either to fraction of solid phase or to time. The relation between

solid fraction and time is expressed with parabolic law:

df s 1

(8)

dt t

Subsequent portions of solidifying liquid, corresponding to

calculation domains, have higher concentration of dissolved steel

components. For this reason the back diffusion in solid phase may

be observed, directed towards the mould walls. The resulting

concentration gradient in steel may be described with II Ficks

Fig. 3. The fraction of solid phase fs during solidification of steel law:

nr. 2

C 2C

= Di (9)

t x 2

In the liquid phase the homogenization caused by diffusion is

much faster than diffusion in solid, what justifies the assumption

of uniform components concentration in liquid [11], [12], [13].

The calculated progress of crystallization of steel nr 1 was

presented in fig. 5, as a dependence between solid fraction and the

temperature. This plot takes into account the AlN precipitation.

Without precipitation the lower value of final temperature of

solidification TK would be obtained. The activity of AlN in the

solid inclusions was assumed 0.2.

ARCHIVES of FOUNDRY ENGINEERING Volume 13, Issue 1/2013, 63-68 65

Unauthenticated | 89.67.242.59

Download Date | 5/12/13 7:16 PM

The calculations cycle was terminated at the value fs = 0.99. Due

to the minimal amount of liquid further proceeding has no

physical meaning.

The solidification range is 1770 K 1655 K for cooling rate 100

K/min and 1770 K 1645 K for the rate 500 K/min. The lower

temperature value of solidification end at higher cooling rate

results from the reduction of back diffusion in solid. In the

industrial practice the cooling rate of the ingot is within the range

100 500 K/min [14], [15], [16], [17], [18].

Figs 7 and 8 present the change of aluminum concentration in

liquid steel nr 1 (Table 1) in the course of crystallization for two

values of cooling rate. It grows from the initial value 0.015 % up

to 0.05 %. At the cooling rate 500 K/min the distinct bend may be Fig. 6. The temperature variation of calculation domain during

seen at the curve, which corresponds to AlN precipitation. At solidification within its volume for the steel nr 1, at cooling rate

cooling rate 100 K/min such a bend is not observed. Figs 9 and 10 500 K/min. Assumed activity of AlN in inclusion 0.2

demonstrate the variation of nitrogen concentration in the course

of crystallization. During the process the concentration of

nitrogen grows more than two times from the initial value

0.0125 %. At the cooling rate 500 K/min the decrease of nitrogen

concentration close to the end of crystallization may be observed,

due to the AlN formation. This effect corresponds to this

described earlier for Al. Figs. 11 and 12 demonstrate the variation

of solubility product of AlN. At the cooling rate 100 K/min the

real value of solubility product merely approaches the equilibrium

one at the highest values of solid fraction. At cooling rate 500

K/min both curves intersect each other. The crosscut point marks

the beginning of AlN precipitation during crystallization.

The data obtained in the calculations do not directly illustrate

the spatial distribution of inclusions in the structure of the ingot,

as the inclusions are not immediately engulfed through moving

solidification front. They may gather in the interdendritic space or

drift along the solidification front. In the case of silicon steel the

inclusions are considerably weakly engulfed with solidification Fig. 7. Micro-segregation of Al during solidification of steel nr 1

front. at the cooling rate 100 K/min

Fig. 8. Micro-segregation of Al during solidification of steel nr 1

Fig. 5. The temperature variation of calculation domain during at the cooling rate 500 K/min

solidification within its volume for the steel nr 1, at cooling rate

100 K/min. Assumed activity of AlN in inclusion 0.2

66 ARCHIVES of FOUNDRY ENGINEERING Volume 13, Issue 1/2013, 63-68

Unauthenticated | 89.67.242.59

Download Date | 5/12/13 7:16 PM

Fig. 9. Micro-segregation of N during solidification of steel nr 1

at the cooling rate 100 K/min Fig. 12. Comparison of equilibrium value of solubility product of

AlN with the actual value at the cooling rate 500 K/min

5. Non metallic phase in silicon steel

The examination of silicon steel microstructure were carried

out with the aim of determination the chemical composition and

dimension of second phase precipitates, which are formad during

steel solidification. The methods of transmission electron

microscopy and X-ray microanalysis were used. In the

examinations special attention was directed towards identification

of diverse inclusions particles of various chemical composition.

For this reason the samples were examined with optical

microscope prior to TEM studies. Fig 13 presents the

microstructure of silicon steel obtained in transmission electron

microscope. The AlN precipitate of the size approximately 0.5 m

Fig. 10. Micro-segregation of during solidification of steel nr 1 at is visible. The results of point microanalysis from the precipitate

the cooling rate 500 K/min area are given below. Table 2 gives the chemical composition

deduced from X-ray microanalysis. It may be deduced from the

presence of Al, N and Si, that AlN is main component of

precipitate, and oxides of aluminum and silicon are also present.

Table 2.

Chemical composition of AlN precipitate area deduced from X-

ray microanalysis

Pierwiastek [mass pct.] [atom pct.]

2,0 6,4

N 3,5 9,6

O 2,2 5,4

Al 3,2 4,6

Si 17,3 24,0

S 0,3 0,4

Ti 0,0 0,0

Fig. 11. Comparison of equilibrium value of solubility product of Mn 7,2 5,1

AlN with the actual value at the cooling rate 100 K/min Fe 59,1 41,2

Cu 5,3 3,2

Suma 100 100

ARCHIVES of FOUNDRY ENGINEERING Volume 13, Issue 1/2013, 63-68 67

Unauthenticated | 89.67.242.59

Download Date | 5/12/13 7:16 PM

[2] Suzuki, M., Yamaguchi, R., Murakami, K. & Nakada, M

(2001). Inclusion Particle Growth during Solidification of

Stainless Steel. ISIJ Int. 41, 247-256.

[3] Liu, Z., Gu, K. & Cai, K. (2002). Mathematical Model of

Sulfide Precipitation on Oxides during Solidification of Fe-Si

Alloy. ISIJ Int. 42, 950 957.

[4] Kobayashi S. (1999). Thermodynamic Fundamentals for

Alumina Content Control of Oxide Inclusions in Mn-Si

Deoxidation of Molten Steel, ISIJ Intern. 39, 664-670.

[5] Woczyski, W. (2002). Effect of the back-diffusion onto

doublet structure formation and solute redistribution within

alloys solidyfying directionally, with or without convection,

Polish Academy of Sciences, Institute of Metallurgy and

Materials Science, Krakw.

[6] Ma, Z. & Janke, D (1986). Characteristics of Oxide

Precipitation and Growthduring Solidification of Deoxidized

Steel. ISIJ Intern. 38, 46-52.

[7] Paczek, K., Kalisz, D. & Wypartowicz, J. (2004). Problemy

matematycznego modelowania mikrosegregacji skadnikw i

wydzielania wtrce niemetalicznych podczas krzepnicia

stali. II Midzynar. Konf. Cige Odlewanie Stali, 16-18 June

2004, Krynica, Poland, 265-274.

[8] Goto, H., Miyazawa, K., Yamada, W. & Tanaka K. (1995).

Effect of Cooling Rate on Composition of Oxides

Precipitated during Solidification of Steel. ISIJ Int. 35, 708

714.

[9] Matsumiya, T., Kajioka, H., Mizoguchi, S., Ueshima, Y. &

Fig. 13. The microstructure of silicon transformer steel (nr 1) Esalka, H. (1984). Mathematical Analysis of segregation in

obtained in transmission electron microscope with AlN precipitate continuously cast slabs. Trans. ISIJ. 24, 873-882.

visible. The results of point microanalysis from the precipitate [10] Liu, Z., Wei, J. & Cai, K. (2002). A Coupled Mathematical

area are given below Model of Microsegregation and Inclusion Precipitation

during Solidification of Silicon Steel. ISIJ Int. 42, 958 963.

[11] Brody, H.D., Flemings, M.C. (1966). Solute Redistribution in

6. Conclusions Dendritic Solidification. Trans. Met. Soc. AIME. 236, 615-

624.

The AlN precipitates play important role in silicon [12] Clyne, T. W. & Kurz, W. (1981). Solute Redistribution

transformer steel technology. These are formed in the course of During Solidification with Rapid Solid State Diffusion. Met.

steel solidification, and later during steel cooling after hot rolling. Trans. 12A, 965-971.

During the process of steel solidification, in dependence of its [13] Ohnaka, I. (1986). Mathematical Analysis of Solute

composition and cooling rate, the AlN based precipitates of Redistribution During Solidification with Diffusion in Solid

various dimensions and space distribution may be formed. The Phase. Trans. ISIJ. 26, 1045-1051.

chemical composition of the precipitates is also of importance, as [14] Kobayashi, S., Nagamichi, T. & Gunji, K (1988). Numerical

they contain oxides of silicon and aluminum besides dominant Analysis of Solute Redistribution during Solidification

component AlN. The simulation procedure adopted in the present Accompanying / Transformation. Trans. ISIJ. 28, 543-552.

work may be useful in the control of behaviour of AlN based non- [15] Wypartowicz, J. & Kalisz, D. (2004). Kontrola wydziele

metallic precipitates, and, in consequence, in determination the siarczkowych i azotkowych w produkcji blachy

optimum process parameters. transformatorowej o zorientowanym ziarnie. Hutnik. 71(6),

259-264.

[16] Suzuki, M., Yamaguchi, R., Murakami, K. & Nakada, M.

(2001). Inclusion Particle Growth during Solidification of

Acknowledgments Stainless Steel. ISIJ Int. 41, 247-256.

[17] Wypartowicz, J. & Kalisz, D (2005). Oddziaywanie wtrce

This work was done in the contract: 11.11.170.318 niemetalicznych w stali z postpujcym frontem krzepnicia.

Hutnik. 72(1), 2-6.

References [18] Kalisz, D. & Wypartowicz, J. (2004). Behaviour of non-

metallic particles during solidification of silicon steel, Metal

[1] Morita, Z., Tanaka, T. & Yanai, T. (1987). Equilibria of 2004, 13 Midzyn. Konf. Hradec n. Moravici.

Nitride Forming Reactions in Liquid Iron Alloys. Met. Trans.

B, 18B, 195-202.

68 ARCHIVES of FOUNDRY ENGINEERING Volume 13, Issue 1/2013, 63-68

Unauthenticated | 89.67.242.59

Download Date | 5/12/13 7:16 PM

You might also like

- Pre-Fused vs. Blended Fluxes: Their Impact On Cleanliness of Low-Carbon Low-Alloy SteelDocument10 pagesPre-Fused vs. Blended Fluxes: Their Impact On Cleanliness of Low-Carbon Low-Alloy SteelJJNo ratings yet

- Effect of Chemical Composition On Casting PerformanceDocument7 pagesEffect of Chemical Composition On Casting PerformanceSmruti Ranjan PattanayakNo ratings yet

- Galvanizing AHSSDocument3 pagesGalvanizing AHSSTrial_TNo ratings yet

- Analysis On Clogging of Submerged Entry Nozzle in Continuous Casting of High Strength Steel With Rare EarthDocument10 pagesAnalysis On Clogging of Submerged Entry Nozzle in Continuous Casting of High Strength Steel With Rare EarthEvren ÇaprazNo ratings yet

- AL Si CuDocument7 pagesAL Si CuRiedl LaurentiuNo ratings yet

- Question Sheet 2, Solidification: Question Sheet 2 Materials Science Part Ib AQ2 COURSE A: Phase TransformationsDocument3 pagesQuestion Sheet 2, Solidification: Question Sheet 2 Materials Science Part Ib AQ2 COURSE A: Phase Transformationsalisamer60No ratings yet

- Structural and Spectroscopic Characterisations of The Surface Oxide Scales and Inclusions Present On Edge-Burst Hot-Rolled Steel CoilsDocument8 pagesStructural and Spectroscopic Characterisations of The Surface Oxide Scales and Inclusions Present On Edge-Burst Hot-Rolled Steel CoilsmusonlyNo ratings yet

- Study of The Nature of Non-Metallic Inclusions inDocument5 pagesStudy of The Nature of Non-Metallic Inclusions inHasan AlashkrNo ratings yet

- The Effect of Cooling Rate On Micro Structure of AlSi9 Cu AlloyDocument8 pagesThe Effect of Cooling Rate On Micro Structure of AlSi9 Cu AlloysargamsNo ratings yet

- ASTM Paper Material Science and ManagementDocument19 pagesASTM Paper Material Science and ManagementMerviNo ratings yet

- Metals: Modification of Non-Metallic Inclusions in Stainless Steel by Addition of CasiDocument11 pagesMetals: Modification of Non-Metallic Inclusions in Stainless Steel by Addition of CasiShanna LeeNo ratings yet

- j.msea.2012.02.073Document8 pagesj.msea.2012.02.073Ganesh KCNo ratings yet

- Development of Nozzle Clogging IndexDocument13 pagesDevelopment of Nozzle Clogging Indexsdtd.ranchiNo ratings yet

- Thermo-Chemistry of Non-Metallic Inclusions in Ductile Iron: ArticleDocument15 pagesThermo-Chemistry of Non-Metallic Inclusions in Ductile Iron: ArticleMonish KumarNo ratings yet

- Thermodynamics and Agglomeration Behavior On SpineDocument16 pagesThermodynamics and Agglomeration Behavior On SpinePranjal SinghNo ratings yet

- Prediction of Aluminum Nitride Embrittlement in Heavy Section Steel CastingsDocument7 pagesPrediction of Aluminum Nitride Embrittlement in Heavy Section Steel Castingsranesh100% (1)

- The Microstructure and PrecipitationDocument4 pagesThe Microstructure and PrecipitationDACAMOGO DCMGNo ratings yet

- Mechanical properties and microstructure of 316L stainless steel welded to galvanized steelDocument8 pagesMechanical properties and microstructure of 316L stainless steel welded to galvanized steelIlmal YaqinNo ratings yet

- Evaluation of Quality Index of A-356 Aluminum Alloy by Microstructural AnalysisDocument6 pagesEvaluation of Quality Index of A-356 Aluminum Alloy by Microstructural AnalysisRegina Maulydia KarekaNo ratings yet

- Growth Mechanism of Clog Materials in SEN During Continuous Casting of Ti-Added ULC SteelDocument8 pagesGrowth Mechanism of Clog Materials in SEN During Continuous Casting of Ti-Added ULC SteelJJNo ratings yet

- The Effect of Copper Concentration On The Microstructure of Al-Si-Cu AlloysDocument6 pagesThe Effect of Copper Concentration On The Microstructure of Al-Si-Cu AlloysAnand ShivannaNo ratings yet

- Inclusion Characterisation - Tool For Measurement of Steel Cleanliness and Process Control: Part 2Document11 pagesInclusion Characterisation - Tool For Measurement of Steel Cleanliness and Process Control: Part 2Jihane EL HAMZAOUINo ratings yet

- Microstructure of High-Pressure Die-Casting AM50 Magnesium AlloyDocument4 pagesMicrostructure of High-Pressure Die-Casting AM50 Magnesium AlloyrekyNo ratings yet

- Mahfud, MusbahDocument5 pagesMahfud, MusbahFajar FadhilaNo ratings yet

- A Model For The Graphite Formation in Ductile Cast Iron Part I Inoculation MechanismsDocument25 pagesA Model For The Graphite Formation in Ductile Cast Iron Part I Inoculation MechanismsAdams GodoyNo ratings yet

- Optimizing Cr Oxidation in EAF Stainless Steel ProductionDocument8 pagesOptimizing Cr Oxidation in EAF Stainless Steel ProductionJavier Mauricio Neira CastrillonNo ratings yet

- Amezhnov-Rodionova2019 Article EffectOfNon-MetallicInclusionC IntroducaoDocument10 pagesAmezhnov-Rodionova2019 Article EffectOfNon-MetallicInclusionC IntroducaoCaio LacerdaNo ratings yet

- Estudio Termodinamico AceroDocument8 pagesEstudio Termodinamico AceroJuan rodriguezNo ratings yet

- Metals-09-00939 OKDocument14 pagesMetals-09-00939 OKRebeca Francis Moran CamposNo ratings yet

- Microstructure Evolution and Mechanical Behavior of Al-Li Alloy Fabricated by Laser Melting Deposition TechniqueDocument8 pagesMicrostructure Evolution and Mechanical Behavior of Al-Li Alloy Fabricated by Laser Melting Deposition TechniqueRaistlin1No ratings yet

- Barbotare Metan Cercetare 2002Document8 pagesBarbotare Metan Cercetare 2002documfinderNo ratings yet

- Materials 15 00922 PDFDocument14 pagesMaterials 15 00922 PDFahmed titoNo ratings yet

- Metals 08 00268Document10 pagesMetals 08 00268kt rajaNo ratings yet

- ASM Heat Treating Society (Aluminum and Its Alloys)Document6 pagesASM Heat Treating Society (Aluminum and Its Alloys)Finney JacobNo ratings yet

- Kho Swinbourne10 mpm188 EAFDocument9 pagesKho Swinbourne10 mpm188 EAFRICCO LauwisNo ratings yet

- Microstructure and Mechanical Properties of Dissimilar Pure Copper - 1350 Aluminum Alloy Butt Joints by Friction Stir WeldingDocument9 pagesMicrostructure and Mechanical Properties of Dissimilar Pure Copper - 1350 Aluminum Alloy Butt Joints by Friction Stir WeldingSabarina HamidNo ratings yet

- Low-alloy Cast Steel Cracking CausesDocument6 pagesLow-alloy Cast Steel Cracking CausesRajkumar MuthumanickamNo ratings yet

- Influence of Solidification Rate On Material Properties of Cast Aluminium Alloys Based On Al-Si-Cu and Al-Si-MgDocument12 pagesInfluence of Solidification Rate On Material Properties of Cast Aluminium Alloys Based On Al-Si-Cu and Al-Si-Mgkt rajaNo ratings yet

- Al-Zn AlloyDocument7 pagesAl-Zn Alloymohamad60No ratings yet

- A Comparative Study of Corrosion Behavior of An Additively Manufactured Al-6061 RAM2 With Extruded Al-6061 T6Document15 pagesA Comparative Study of Corrosion Behavior of An Additively Manufactured Al-6061 RAM2 With Extruded Al-6061 T6Annamalai NNo ratings yet

- 10208-15101387124325secondary Steel Making OverviewDocument13 pages10208-15101387124325secondary Steel Making OverviewOmar TahaNo ratings yet

- 1-Gustafsson 1986++++++++111++++222+++333Document8 pages1-Gustafsson 1986++++++++111++++222+++333mansourNo ratings yet

- Steel CleanlinessDocument22 pagesSteel Cleanlinessdrbeyer100% (1)

- Microstructural of Second Phases in Ascast and Homogenized Aluminum AlloyDocument7 pagesMicrostructural of Second Phases in Ascast and Homogenized Aluminum AlloyHamed NobariNo ratings yet

- Casting of Aluminum 201 in The Semi Solid State.Document8 pagesCasting of Aluminum 201 in The Semi Solid State.Nahid LatonaNo ratings yet

- Manufacturing Aluminum Composite Using Stir CastingDocument12 pagesManufacturing Aluminum Composite Using Stir CastingSb HaleshNo ratings yet

- Effect_of_steel_composition_and_slag_proDocument5 pagesEffect_of_steel_composition_and_slag_proAbhinandan ChatterjeeNo ratings yet

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocument19 pagesInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNo ratings yet

- Microstructure and Mechanical Properties of Spray Deposited Hypoeutectic Al-Si AlloyDocument4 pagesMicrostructure and Mechanical Properties of Spray Deposited Hypoeutectic Al-Si AlloySantosh GoudarNo ratings yet

- NEW RULE IN DAStDocument12 pagesNEW RULE IN DAStHerdisNo ratings yet

- Structure and properties of recycled AlSi9Cu3 alloyDocument22 pagesStructure and properties of recycled AlSi9Cu3 alloySantosh KumarNo ratings yet

- Effect of ECAP on Microstructure and Properties of 6061 Al Alloy Fabricated by Powder MetallurgyDocument5 pagesEffect of ECAP on Microstructure and Properties of 6061 Al Alloy Fabricated by Powder MetallurgyAkshay DolasNo ratings yet

- Piva 2016Document9 pagesPiva 2016barchid ayyoubeNo ratings yet

- Steel Cleanliness Measurement Techniques for Process ControlDocument11 pagesSteel Cleanliness Measurement Techniques for Process ControlJihane EL HAMZAOUINo ratings yet

- Quality Defects in Alphin Inserts for Combustion Engine PistonsDocument4 pagesQuality Defects in Alphin Inserts for Combustion Engine PistonsrenatoeliegeNo ratings yet

- Analysis of Hydrogen Content in The Main Stages of Low-Alloy Aluminum Alloy Flat Ingot ManufactureDocument5 pagesAnalysis of Hydrogen Content in The Main Stages of Low-Alloy Aluminum Alloy Flat Ingot Manufacturedhinakaranme3056No ratings yet

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- Die Casting Metallurgy: Butterworths Monographs in MaterialsFrom EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsRating: 3.5 out of 5 stars3.5/5 (2)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Coaching MDSP 02Document10 pagesCoaching MDSP 02jay dubouzetNo ratings yet

- Chemical Supplies Company ListingDocument757 pagesChemical Supplies Company ListingAmit Jage50% (4)

- Technical Data Sheet Baltoflake EcolifeDocument5 pagesTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadNo ratings yet

- I-Series GC 600G36 GB WW 1016-3Document40 pagesI-Series GC 600G36 GB WW 1016-3Erick AvNo ratings yet

- MSDS PVCDocument9 pagesMSDS PVCDharu AbdulNo ratings yet

- Venezuela Asfalto Modificado PDFDocument12 pagesVenezuela Asfalto Modificado PDFkarenNo ratings yet

- Rock Proof: Liquid Water Integral WaterproofDocument2 pagesRock Proof: Liquid Water Integral Waterproofimran jamalNo ratings yet

- V Series Catalog Vb015e 05Document64 pagesV Series Catalog Vb015e 05jotalopecincoNo ratings yet

- Siemens Syngas Capable TurbinesDocument8 pagesSiemens Syngas Capable TurbinesAlasdair McLeodNo ratings yet

- Experimental Mechanics Laboratory ManualDocument76 pagesExperimental Mechanics Laboratory Manualprabhaakar100% (1)

- Lubrizol 219Document2 pagesLubrizol 219BobNo ratings yet

- Cepsa Fundicol Hfu: Lubricants For Industrial UseDocument1 pageCepsa Fundicol Hfu: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- Guide To The Layout Requirements For A Commercial Laundry Room PDFDocument11 pagesGuide To The Layout Requirements For A Commercial Laundry Room PDFTueNo ratings yet

- EstimatesDocument5 pagesEstimatesRamil S. ArtatesNo ratings yet

- Naphthaplast F 707 UlDocument2 pagesNaphthaplast F 707 UlÖmer ErcanNo ratings yet

- Summer Training Report at DLWDocument40 pagesSummer Training Report at DLWNilotpal Kumar RaiNo ratings yet

- Thermodynamics control volume analysisDocument6 pagesThermodynamics control volume analysisLUISRONo ratings yet

- 1 PPT - Pavement of Bricks and TilesDocument11 pages1 PPT - Pavement of Bricks and TilesBHANUSAIJAYASRINo ratings yet

- Lincoln Weld Directory C2.10Document32 pagesLincoln Weld Directory C2.10edgarpato100% (1)

- Triplex Stack Mounted Systems 1Document2 pagesTriplex Stack Mounted Systems 1Eng.Gihad EladlNo ratings yet

- Measure and Calculate Fluid Flow Using Orifice, Venturi & Pitot Tube MetersDocument33 pagesMeasure and Calculate Fluid Flow Using Orifice, Venturi & Pitot Tube MetersAeyrul KhairulNo ratings yet

- Sintering PlantDocument24 pagesSintering PlantB R Manikyala Rao100% (1)

- Busines Proposal For Residential ConstructionDocument7 pagesBusines Proposal For Residential ConstructionNatsu Trojanlee QuiritNo ratings yet

- Washing MCDocument8 pagesWashing MCHatsune MikuNo ratings yet

- Trouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic BlisteringDocument10 pagesTrouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic Blisteringandreathome100% (1)

- Mil DTL 46027JDocument23 pagesMil DTL 46027JmurphygtNo ratings yet

- Learning Activity Sheet Science 8, Quarter 3, Week 1: Elements, Compounds, and MixturesDocument14 pagesLearning Activity Sheet Science 8, Quarter 3, Week 1: Elements, Compounds, and MixturesJoan MarieNo ratings yet

- QIS College Engineering & Tech Session Plan Metal CuttingDocument13 pagesQIS College Engineering & Tech Session Plan Metal CuttingKalai ArasanNo ratings yet

- Legacy Product Catalog 2016 PDFDocument40 pagesLegacy Product Catalog 2016 PDFCamilo Andrés Abello RégeasseNo ratings yet

- pd10196 Tetra Alsafe PDFDocument2 pagespd10196 Tetra Alsafe PDFEusebio NavarroNo ratings yet