Professional Documents

Culture Documents

Dywidag Post Tensioning Catalogue 7

Uploaded by

Prateek0 ratings0% found this document useful (0 votes)

113 views1 pageDywidag Post Tensioning Catalogue 7

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDywidag Post Tensioning Catalogue 7

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

113 views1 pageDywidag Post Tensioning Catalogue 7

Uploaded by

PrateekDywidag Post Tensioning Catalogue 7

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Corrugated Duct

Metal ducts represent the most

economical means to create a void for

tensile elements. These thin-walled

(0.25 - 0.60 mm), ribbed sheet metal

ducts provide a fair secondary

corrosion protection with excellent

bond behavior between tendon and

concrete. Primary corrosion protection

is provided by the alkalinity of grout

and concrete.

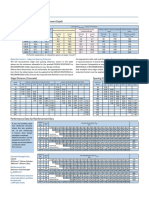

Dimensions of Corrugated Duct (Standard Sizes)

tendon type tendon type sheathing

0.5" 0.6" I.D. O.D.

mm mm

5901 6801 20 25

5902 6802 40 45

5903 6803 50 55

I.D.

5904 6804 55 60

5905 6805 60 65

5907 6806 65 70 O.D.

5909 6807 65 70

5912 6809 75 80

5915 6812 80 85

5920 6815 90 95

5927 6819 95 100

5932 6822 100 105

5937 6827 110 118

6831 120 128

I.D.

6837 130 138

The tendon type number (e.g. 5901, 6801) is composed as follows: the first digit (5 or 6)

identifies the nominal strand diameter in tenth of inches, i.e. 0.5" or 0.6"/ 0.62", the last two

digits (..01) reference the number of used strands (= 1 strand). The second digit O.D.

is an internal code. As regards the 0.6"tendon types, the accessories fit both Grade 250

(GUTS 1770 N/mm2 ) and Grade 270 (GUTS 1860 N/mm2 ) strands.

tendon type tendon type min. support wobble friction

0.5" 0.6" center distances coefficient coefficient

distances1) up to1)

mm m rad/m rad-1

5901 6801 36 1.8 14 x 10-3 0.15

5902 6802 72 1.8 9 x 10-3 0.17

5903 6803 90 1.8 5 x 10-3 0.18

5904 6804 99 1.8 5 x 10-3 0.19

5905 6805 108 1.8 5 x 10-3 0.20

5907 6806 117 1.8 5 x 10-3 0.19

5909 6807 117 1.8 5 x 10-3 0.19

5912 6809 117 1.8 5 x 10-3 0.19

5915 6812 144 1.8 5 x 10-3 0.19

5920 6815 162 1.8 5 x 10-3 0.19

5927 6819 171 1.8 5 x 10-3 0.20

5932 6822 180 1.8 5 x 10-3 0.20

5937 6827 198 1.8 5 x 10-3 0.20

6831 216 1.8 5 x 10-3 0.20

6837 235 1.8 5 x 10-3 0.20

1) according to European Technical Approval

subject to modification, August 2006 7

You might also like

- ALON Data SheetDocument1 pageALON Data SheetTran Manh TungNo ratings yet

- TMMD 100Document3 pagesTMMD 100grupa2904No ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Retaining Rings MetricDocument5 pagesRetaining Rings MetricNur SugiartoNo ratings yet

- Product Sheet ALON PDFDocument3 pagesProduct Sheet ALON PDFMauricio FriedrichNo ratings yet

- 9greens Wire New Rates 8 OctDocument14 pages9greens Wire New Rates 8 OctTejas AgrawalNo ratings yet

- Aluminium ExtruderDocument108 pagesAluminium ExtruderGoutam BiswasNo ratings yet

- NTN Miniature BearingDocument4 pagesNTN Miniature Bearingfc7ojjNo ratings yet

- Bill Item For Roof Shed (Cutting Bending Yard)Document2 pagesBill Item For Roof Shed (Cutting Bending Yard)abhishek pathakNo ratings yet

- Product Zoom 18 - EshopDocument16 pagesProduct Zoom 18 - EshopkenywkNo ratings yet

- Lab 3 - Group 1Document3 pagesLab 3 - Group 1Pilar MNo ratings yet

- Din 04620 1954 (En)Document2 pagesDin 04620 1954 (En)1965karanfil6No ratings yet

- Industrial - Bearings CatalogDocument72 pagesIndustrial - Bearings CatalogShahram NahalgarNo ratings yet

- Metallic Gaskets - Installation & Torque - October 2020Document6 pagesMetallic Gaskets - Installation & Torque - October 2020Alberto CaveroNo ratings yet

- Blending of Aggregate For Bituminous Concrete (As Per Ms-2 Table 2.1)Document18 pagesBlending of Aggregate For Bituminous Concrete (As Per Ms-2 Table 2.1)Krunal Shah100% (1)

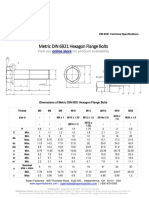

- Metric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityJaganNo ratings yet

- Lightweight High Strength Corrosion Resistant Economical Easy To Install Long Service LifeDocument2 pagesLightweight High Strength Corrosion Resistant Economical Easy To Install Long Service LifeNelson P. ColoNo ratings yet

- Hss Long Series Drills Is: 5102-1969 DIN: 340 & BS 328 Part-1Document3 pagesHss Long Series Drills Is: 5102-1969 DIN: 340 & BS 328 Part-1Peter NomikosNo ratings yet

- Chemical Composition % of Steel S690QL (1.8928) : EN 10025-6-2004Document1 pageChemical Composition % of Steel S690QL (1.8928) : EN 10025-6-2004Miodrag TopalovicNo ratings yet

- Drain Pipe Socket DimensionDocument1 pageDrain Pipe Socket DimensionPrakash KumarNo ratings yet

- MT-A110 Catalog 2023 (En)Document2 pagesMT-A110 Catalog 2023 (En)CnzNo ratings yet

- Daily Report - 31-10-2020Document29 pagesDaily Report - 31-10-2020Sabuj SarkarNo ratings yet

- Rubber Conveyor Belts Steel CordsDocument4 pagesRubber Conveyor Belts Steel CordsnicolasNo ratings yet

- Semiconductor & Special Protection: Protistor® Cylindrical Fuse-LinksDocument6 pagesSemiconductor & Special Protection: Protistor® Cylindrical Fuse-Linkspedro ignacio toledo muñozNo ratings yet

- Lightweight High Strength Corrosion Resistant Economical Easy To Install Long Service LifeDocument2 pagesLightweight High Strength Corrosion Resistant Economical Easy To Install Long Service LifeKY WongNo ratings yet

- Basic Hydrological Experiment Result: TABLE 6.1Document2 pagesBasic Hydrological Experiment Result: TABLE 6.1Ashraf AzhanNo ratings yet

- QAMDocument10 pagesQAMRavi Krishna IIM, CalcuttaNo ratings yet

- Sieve Analysis: Abdullah Gül UniversityDocument6 pagesSieve Analysis: Abdullah Gül UniversityYılmaz UçarNo ratings yet

- Specification Data: Performance Data at Standard Embedment DepthDocument1 pageSpecification Data: Performance Data at Standard Embedment DepthatiattiNo ratings yet

- Practica Calificada Nro. Curso Nombre - Completo SeccionDocument26 pagesPractica Calificada Nro. Curso Nombre - Completo SeccionValeriaNo ratings yet

- Glands For Big Size Cables (M72 Up To M120) : Size Order Symbol Code EANDocument1 pageGlands For Big Size Cables (M72 Up To M120) : Size Order Symbol Code EANsubramanyaNo ratings yet

- 122-354019 GSB-I CoarseDocument32 pages122-354019 GSB-I CoarseARTI PALEKARNo ratings yet

- Civil Engineering Material Q.T.ODocument10 pagesCivil Engineering Material Q.T.ONaison StanleyNo ratings yet

- Price List 2022Document39 pagesPrice List 2022Jan OngNo ratings yet

- Appendix E PARTICLE SIZE-U.S. SIEVE SIZEDocument3 pagesAppendix E PARTICLE SIZE-U.S. SIEVE SIZEVeronica CorreaNo ratings yet

- Mix Design - m40 - Modified 28 Days CcsDocument23 pagesMix Design - m40 - Modified 28 Days CcsKuldeep Chakerwarti100% (2)

- Luminaire PropertyDocument7 pagesLuminaire PropertyLucas NunesNo ratings yet

- Visa Ceiling Measurement Sheet FinalDocument1 pageVisa Ceiling Measurement Sheet FinalpremtheprimeNo ratings yet

- Porosia e Reviduar - 1Document1 pagePorosia e Reviduar - 1Nurie Arifi SermaxhajNo ratings yet

- Kyodo Pipe Producs SpecificationDocument3 pagesKyodo Pipe Producs SpecificationTengku MunzirNo ratings yet

- H05V-K / H07V-K: Low Voltage - Energy and CablingDocument2 pagesH05V-K / H07V-K: Low Voltage - Energy and CablingMuhamad YasrinNo ratings yet

- C-02 Model 7707 Heavy Duty Flexible Coupling - Rev-UDocument3 pagesC-02 Model 7707 Heavy Duty Flexible Coupling - Rev-UDaniel SanNo ratings yet

- Brosur Kaca - AsahimasDocument4 pagesBrosur Kaca - AsahimasMoe HamzanNo ratings yet

- GEO Fabrics HPS Group Data SheetDocument1 pageGEO Fabrics HPS Group Data SheetSergejjjNo ratings yet

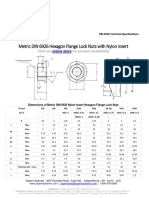

- Metric DIN 6926 SpecDocument4 pagesMetric DIN 6926 Spec叶开No ratings yet

- Gradation of Material: Material 1 Material 2 Material 3 Material 4Document5 pagesGradation of Material: Material 1 Material 2 Material 3 Material 4Deputy DirectorNo ratings yet

- SS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN ASDocument5 pagesSS Bolt Properties STD: Din STD ISO 4017 B.S. DIN933 DIN931 DIN931 GB5783 DIN DIN912 Astm DIN603 Ansi DIN6923 JIS EN ASHithish ReddyNo ratings yet

- UCM - Fabricated Steel MatsDocument1 pageUCM - Fabricated Steel MatsKranthi KumarNo ratings yet

- Viscosity Standard s8000 5171109031Document1 pageViscosity Standard s8000 5171109031Rachel McArdleNo ratings yet

- 7MPa Concrete Blocks TDS - v2Document7 pages7MPa Concrete Blocks TDS - v2Slinky BillNo ratings yet

- Doosan DNM500Document104 pagesDoosan DNM500tmsxptoNo ratings yet

- Abrasion Resistance Test & ASTM D968Document5 pagesAbrasion Resistance Test & ASTM D968ManukantShrotriyaNo ratings yet

- Astm D790-03Document11 pagesAstm D790-03breynnero100% (2)

- DSI-DYWIDAG Bonded PT Using Strands Eu 01 9Document1 pageDSI-DYWIDAG Bonded PT Using Strands Eu 01 9PrateekNo ratings yet

- DSI-DYWIDAG Bonded PT Using Strands Eu 01 9Document1 pageDSI-DYWIDAG Bonded PT Using Strands Eu 01 9PrateekNo ratings yet

- G 14 - 04 (2010) E1Document6 pagesG 14 - 04 (2010) E1jose floresNo ratings yet

- Dywidag Post Tensioning Catalogue 9Document1 pageDywidag Post Tensioning Catalogue 9PrateekNo ratings yet

- DSI-DYWIDAG - Bonded - PT - Using - Strands - Eu - 01 9 PDFDocument1 pageDSI-DYWIDAG - Bonded - PT - Using - Strands - Eu - 01 9 PDFPrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 8Document1 pageDywidag Post Tensioning Catalogue 8PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 4Document1 pageDywidag Post Tensioning Catalogue 4PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 2Document1 pageDywidag Post Tensioning Catalogue 2PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 7Document1 pageDywidag Post Tensioning Catalogue 7PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 3Document1 pageDywidag Post Tensioning Catalogue 3PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 7Document1 pageDywidag Post Tensioning Catalogue 7PrateekNo ratings yet

- DSI-DYWIDAG Bonded PT Using Strands Eu 01 1Document1 pageDSI-DYWIDAG Bonded PT Using Strands Eu 01 1PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 5Document1 pageDywidag Post Tensioning Catalogue 5PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 2Document1 pageDywidag Post Tensioning Catalogue 2PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 8Document1 pageDywidag Post Tensioning Catalogue 8PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 7Document1 pageDywidag Post Tensioning Catalogue 7PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 3Document1 pageDywidag Post Tensioning Catalogue 3PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 9Document1 pageDywidag Post Tensioning Catalogue 9PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 6Document1 pageDywidag Post Tensioning Catalogue 6PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 4Document1 pageDywidag Post Tensioning Catalogue 4PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 5Document1 pageDywidag Post Tensioning Catalogue 5PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 3 PDFDocument1 pageDywidag Post Tensioning Catalogue 3 PDFPrateekNo ratings yet

- Din ISO 1461Document24 pagesDin ISO 1461Prateek100% (3)

- BS en Iso 15630-3-2010 37Document1 pageBS en Iso 15630-3-2010 37PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 1Document1 pageDywidag Post Tensioning Catalogue 1PrateekNo ratings yet

- Dywidag Post Tensioning Catalogue 2Document1 pageDywidag Post Tensioning Catalogue 2PrateekNo ratings yet

- BS en Iso 15630-3-2010Document38 pagesBS en Iso 15630-3-2010Prateek50% (2)

- GSD Puppy Training Essentials PDFDocument2 pagesGSD Puppy Training Essentials PDFseja saulNo ratings yet

- Case 445Document4 pagesCase 445ForomaquinasNo ratings yet

- Patel 2013Document116 pagesPatel 2013hnphuocNo ratings yet

- Water Filling MachineDocument15 pagesWater Filling Machinepallab D RozarioNo ratings yet

- Segmentation of Blood Vessels Using Rule-Based and Machine-Learning-Based Methods: A ReviewDocument10 pagesSegmentation of Blood Vessels Using Rule-Based and Machine-Learning-Based Methods: A ReviewRainata PutraNo ratings yet

- Tips For A Healthy PregnancyDocument2 pagesTips For A Healthy PregnancyLizaNo ratings yet

- A Study On Traditional Medicinal Herbs Used by The Ethnic People of Goalpara District of Assam, North East IndiaDocument6 pagesA Study On Traditional Medicinal Herbs Used by The Ethnic People of Goalpara District of Assam, North East IndiaDr. Krishna N. SharmaNo ratings yet

- Etoricoxib - Martindale 39thDocument2 pagesEtoricoxib - Martindale 39thCachimbo PrintNo ratings yet

- Rectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Document4 pagesRectifier 5G High Density Embedded Power (3U Power Rack, Three Phase Four Wire) E...Lintas LtiNo ratings yet

- Science Magazine February 2020Document133 pagesScience Magazine February 2020Elena González GonzálezNo ratings yet

- Azure Machine Learning StudioDocument17 pagesAzure Machine Learning StudioNurain IsmailNo ratings yet

- Las Tech Drafting 3Q WKDocument13 pagesLas Tech Drafting 3Q WKClemenda TuscanoNo ratings yet

- Solar Charge Controller: Solar Car Solar Home Solar Backpack Solar Boat Solar Street Light Solar Power GeneratorDocument4 pagesSolar Charge Controller: Solar Car Solar Home Solar Backpack Solar Boat Solar Street Light Solar Power Generatorluis fernandoNo ratings yet

- Pusheen With Donut: Light Grey, Dark Grey, Brown, RoséDocument13 pagesPusheen With Donut: Light Grey, Dark Grey, Brown, RosémafaldasNo ratings yet

- Aquaculture Scoop May IssueDocument20 pagesAquaculture Scoop May IssueAquaculture ScoopNo ratings yet

- ARK - Intel® Core™ I3-370m Processor (3M Cache, 2Document3 pagesARK - Intel® Core™ I3-370m Processor (3M Cache, 2Delzi Guindra AdriNo ratings yet

- Kaged Muscle Magazine Issue 1Document41 pagesKaged Muscle Magazine Issue 1hashimhafiz1100% (1)

- Bardonna MenuDocument16 pagesBardonna MenuFarley ElliottNo ratings yet

- RepaHeel Beeswax-Based Gel For Treating Heel Spurs Has Been Produced in EUDocument2 pagesRepaHeel Beeswax-Based Gel For Treating Heel Spurs Has Been Produced in EUPR.comNo ratings yet

- Document List - Eni Progetti - Algeria BRN-MLE - 2019-06-10Document18 pagesDocument List - Eni Progetti - Algeria BRN-MLE - 2019-06-10Naceri Mohamed RedhaNo ratings yet

- Kimi No Na Wa LibropdfDocument150 pagesKimi No Na Wa LibropdfSarangapani BorahNo ratings yet

- Orbitol Motor TMTHWDocument20 pagesOrbitol Motor TMTHWRodolfo ErenoNo ratings yet

- Airport Security Post 9-11Document7 pagesAirport Security Post 9-11lewisNo ratings yet

- Manual GA 55 VSD Atlas CompresorDocument114 pagesManual GA 55 VSD Atlas Compresormondaxa_mme50% (4)

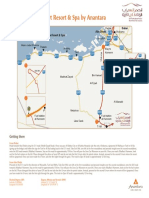

- Qasr Al Sarab Desert Resort Location Map June2012Document1 pageQasr Al Sarab Desert Resort Location Map June2012Anant GârgNo ratings yet

- Practice For Mounting Buses & Joints-374561Document11 pagesPractice For Mounting Buses & Joints-374561a_sengar1No ratings yet

- Precision CatalogDocument256 pagesPrecision CatalogImad AghilaNo ratings yet

- Flusser-The FactoryDocument2 pagesFlusser-The FactoryAlberto SerranoNo ratings yet

- TM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 1Document294 pagesTM 10-3930-669-34 Forklift Truck 6K Drexel MDL R60SL-DC Part 1AdvocateNo ratings yet

- GBJ0232 - en GLX 3101 T2Document43 pagesGBJ0232 - en GLX 3101 T2mnbvqwert100% (2)