Professional Documents

Culture Documents

ESD5500e Series

Uploaded by

Dr.HlaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESD5500e Series

Uploaded by

Dr.HlaCopyright:

Available Formats

G OVERNORS

ESD5500E Series A MERICA

Speed Control Unit C ORP.

Simple Installation and Adjustability Accessory Inputs for Load Sharing

Environmentally Friendly Variable Speed Operation

Adjustable Droop and Idle Circuits Reverse Battery Voltage Pro tected

INTRODUCTION

The ESD5500E Series speed control unit is an all electr onic

device designed to control engine speed with fast and pre-

cise response to transient load changes. This closed l oop

control, when connected to a proportional electric act uator

and supplied with a magnetic speed sensor signal, will on-

c trol a wide variety of engines in an isochronous or roop

d mode. It is designed for high reliability and built ly to

rugged withstand the engine environment.

Simplicity of installation and adjustment was foremost in the

design. Non interacting performance controls allow near op-

timum response to be easily obtained.

The primary features of the ESD5500E Series speed control

unit are the engine STARTING FUEL and SPEED RAMP-

ING adjustments. The use of these features will minimize

engine exhaust smoke experienced prior to attaining engine

operating speed.

Other features include adjustable droop and idle operation, speed signal is applied to Terminals C and D of the speed

inputs for accessories used in multi engine or special appli- control unit. Between these terminals there is an input im-

cations, protection against reverse battery voltage, transient pedance of over 33,000 ohms. Terminal D is internally con-

voltages, accidental short circuit of the actuator and fail safe nected to Terminal E, battery negative. Only one end of the

design in the event of loss of speed sensor signal or battery shielded cable should be connected.

supply.

When a speed sensor signal is received by the controller,

The ESD5500E Series speed control unit is compatible with the signal is amplified and shaped by an internal circuit to

all GAC proportional actuators except the ACB2000 electric provide an analog speed signal. If the speed sensor monitor

actuator. When the ESD5500E Series speed control unit is does not detect a speed sensor signal, the output circuit of

used with a ADC100 Series electric actuator, the DROOP the speed control unit will turn off all current to the actuator.

adjustment range will be less due to this actuators low cur- A summing circuit receives the speed sensor signal along

rent demand. with the speed adjust set point input. The speed range has a

ratio of 8:1 and is adjusted with a 25 turn potentiometer. The

DESCRIPTION output from the summing circuit is the input to the dynamic

control section of the speed control unit. The dynamic con-

Engine speed information for the speed control unit is usu- trol circuit, of which the gain and stability adjustments are

ally received from a magnetic speed sensor. Any other sig- part, has a control function that will provide isochronous and

nal generating device may be used provided the generated stable performance for most engine types and fuel systems.

frequency is proportional to engine speed and meets the

voltage input and frequency range specification. The speed The speed control unit circuit is influenced by the gain and

sensor is typically mounted in close proximity to an engine stability performance adjustments. The governor system

driven ferrous gear, usually the engine ring gear. As the teeth sensitivity is increased with clockwise rotation of the gain

of the gear pass the magnetic sensor, a signal is generated adjustment. The gain adjustment has a range of 33:1. The

which is proportional to engine speed. stability adjustment, when advanced clockwise, increases

the time rate of response of the governor system to match

Signal strength must be within the range of the input ampli- the various time constants of a wide variety of engines. The

fier. An amplitude of 0.5 to 120 volts RMS is required to al- speed control unit is a P I D device, the D, derivative por-

low the unit to function within its design specifications. The tion can be varied when required.

LUCIO VICENCIO Y CIA. LTDA

AVIADOR ZAATU 2025 CONCHALI, SALNTIAGO DE CHILE

luciovicencioltda@gmail.com ISO 9001

www.luciovicencio.cl CERTIFIED

1

During the engine cranking cycle, STARTING FUEL can be The output circuit provides switching current at a frequency

adjusted from an almost closed, to a nearly full fuel posi- of about 500 Hz. to drive the actuator. Since the switching

tion. Once the engine has started, the speed control point frequency is well beyond the natural frequency of the actua-

is determined, first by the IDLE speed set point and the tor, there is no visible motion of the actuator output shaft.

SPEED RAMPING circuit. After engine speed ramping has Switching the output transistors reduces its internal power

been completed, the engine will be at its governed operating dissipation for efficient power control. The output circuit can

speed. At the desired governed engine speed, the actua- provide current of up to 10 amps continuous at 25*C for 12

tor will be energized with sufficient current to maintain the and 24 VDC battery systems. The actuator responds to the

desired engine speed, independent of load (isochronous op- average current to position the engine fuel control lever.

eration). In standard operation, the speed control unit performance is

isochronous. Droop governing can be selected by connect-

ing terminals K and L and the percent of droop governing

can be varied with the droop adjustment control. The droop

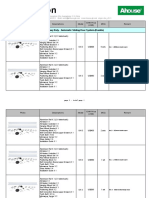

DIAGRAM 1 SYSTEM WIRING DIAGRAM AND OUTLINE range can be decreased by connecting Terminals G and H.

5.750

(146)

5.000 1.031

The speed control unit has several performance and protec-

(127) (26) tion features which enhance the governor system. A speed

anticipation circuit minimizes speed overshoot on engine

startup or when large increments of load are applied to the

GA

OVERNORS C1 OFF ON C2

engine. Engine idle speed can be remotely selected and

MERICA LEAD CIRCUIT SOFT COUPLING

C ON OFF

ORP. STABILITY

DEAD TIME

is adjustable. Accessory inputs to achieve variable speed

operation and multi engine control can be accepted by the

SPEED CONTROL UNIT E3

COMPENSATION

E2 JUMPER

MODEL: ESD5500E

S/N :

GAIN E1

ESD5500E Series speed control unit from GAC load shar-

5.500

(140)

MADE IN AGAWAM, MA U.S.A.

SPEED

IDLE

ing modules, automatic synchronizers, ramp generators and

other accessory engine control modules. Protection against

RAMPING

STARTING

FUEL

5.000

reverse battery voltage and transient voltages is provided.

(127) CAUTION

ENGINE SPEED CONTROL SWITCH

COMPONENT. WHEN INSTALLING SPEED PROFILE

The design is fail safe in the event of loss of speed sensor

OR SERVICING REFER TO

PRODUCT PUBLICATION.

DROOP

- +

signal or battery supply.

PICK-UP DROOP

IDLE

ACTUATOR

BATTERY 10V

AUX OUTPUT

A BC DE F G H J K L MN P

SELECTION CHART

0.266

(6,6)

moDel characteristics

WD554 esD5500e Standard Unit

OPTIONAL ACTUATOR ACCESSORY POWER

esD5520e

CABLE SHIELDING TO

Light Force

SUPPLY

MEET CE DIRECTIVE

ACCESSORY INPUT

*

ACTUATOR

ADD JUMPER FOR 12V

BATTERY OR ACTUATOR esD5522e Enhanced Droop Control

CURRENTS ABOVE 5A

MAGNETIC

CW GROUND REFERENCE

esD5524e Use with SLM100

CLOSE FOR DROOP

PICK-UP

SPEED TRIM esD5526e Use with ATB Application/Anti-Windup Circuit

_ CONTROL - 5K CLOSE FOR IDLE

+ S1

BATTERY

FUSE

15A MAX

esD5528e Anti-Windup Circuit

* SEE SPECIFIC ACTUATOR PUBLICATION FOR PROPER

WIRING OF ACTUATOR BASED ON BATTERY VOLTAGE

SPECIfICATIONS

Performance inPut PoWer

Isochronous Operation................................................ 0.25 % or better DC Supply...........................................12 or 24 20% VDC Battery Systems

Speed Range /Governor...........................................1K - 7.5K Hz Continuous (Transient and Reverse Voltage Protected)

Speed Drift with Temperature............................... 1% Maximum Polarity......................................................Negative Ground (case isolated)

Idle Adjust CW..................................................................60% of Set Speed Power Consumption.....................50 Continuous mA plus actuator current

Idle Adjust CCW..............................................................Less than 1200 Hz Speed Signal Range..................................................................0.5-50 VAC

Droop Range.......................................................................1-5% Regulation Actuator Current Range @ 77F (25C) - (Inductive Load).........Min. 2.5

Droop Adj. Max. (K-L Jumpered)................400 Hz., 75 Hz Per 1.0A change Max 10 Amps Continuous

Droop Adj. Min. (K-L Jumpered)...................15 Hz., 75 Hz Per 1.0A change Speed Sensor Signal......................................................0.5-120 Volts RMS

Speed Trim Range.......................................... 200 Hz

Remote Variable Speed Range......................500-7.5K Hz or any part thereof reliaBilitY

Terminal Sensitivity Vibration.............................................................1G @ 20-100 Hz

J........................................100 Hz., 15 Hz/Volt @ 5.0 K Impedance Testing...................................................................100% Functionally Tested

L.........................................735 Hz., 60 Hz/Volt @ 65 K Impedance

N..........................................148 Hz., 10 Hz/Volt 1 Meg Impedance PhYsical Dimensions.........See DIAGRAM. 1, Wiring Diagram

P.........................................................10 VDC Supply @ 20 mA Max and Outline Weight..............1.2

lb. (0.544 kg) Mounting...........................Any Position,

environmental vertical preferred

Ambient Operating Temperature Range......-40 to +180F (-40 to +85C)

Relative Humidity........up to 95% comPliance / stanDarDs

All Surface Finishes............................Fungus proof and corrosion resistance Agency...........................................................................CE Requirements

RoHS Regulation...........................................................................Compliant

! !" # $ "!%&' ()*+, - . &/' & '

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- GJ-122 Hyuandai MonDocument3 pagesGJ-122 Hyuandai MonDr.HlaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Gac Governör Esd5500e PDFDocument2 pagesGac Governör Esd5500e PDFDr.HlaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- P8039ahl IntelDocument13 pagesP8039ahl IntelDr.HlaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 24C44Document8 pages24C44Dr.HlaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Ahouse Price List For Automatic Sliding Door - OADocument4 pagesAhouse Price List For Automatic Sliding Door - OADr.HlaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ESD5500E Series Speed Control Unit: SpecificationsDocument5 pagesESD5500E Series Speed Control Unit: SpecificationsMurilo FigueiredoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 3.1-Pile Design Calculation For Boundary (p1 To p50)Document24 pages3.1-Pile Design Calculation For Boundary (p1 To p50)layaljamal2No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- IPA Assignment Analyzes New Public AdministrationDocument8 pagesIPA Assignment Analyzes New Public AdministrationKumaran ViswanathanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Face To Face Pre-Intermediate B1Document162 pagesFace To Face Pre-Intermediate B1Andra OlariNo ratings yet

- EtomDocument1 pageEtomarthryxNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Destination Phrasal Verbs @destination - b1 - b2 - c1Document25 pagesDestination Phrasal Verbs @destination - b1 - b2 - c1Samira GulomovaNo ratings yet

- SO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BDocument15 pagesSO CF, Internal Fault Map Class 1A SO CF, Internal Fault Map Class 2A SO CF, External Condition Map Class 1BATMMOBILISNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- RB450G Trouble ShootingDocument9 pagesRB450G Trouble Shootingjocimar1000No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 5 Grade - Lesson 1.3 Dissolving and Back Again: ObjectiveDocument4 pages5 Grade - Lesson 1.3 Dissolving and Back Again: ObjectiveManushka ThomasNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Crafting and Executing StrategyDocument33 pagesCrafting and Executing Strategyamoore2505No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- I2E: Embedding Innovation as Organizational StrategyDocument11 pagesI2E: Embedding Innovation as Organizational StrategyDeepak PanditNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- CHB1 Assignmen5Document2 pagesCHB1 Assignmen5anhspidermenNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- What Is A Lecher AntennaDocument4 pagesWhat Is A Lecher AntennaPt AkaashNo ratings yet

- A Sample of Directory or Instruction:: World Temperatures February 16Document1 pageA Sample of Directory or Instruction:: World Temperatures February 16eksaNo ratings yet

- CA Module Franklin Gari RDocument28 pagesCA Module Franklin Gari RFranklin GariNo ratings yet

- Sinavy Pem Fuel CellDocument12 pagesSinavy Pem Fuel CellArielDanieli100% (1)

- Lower Congo Basin 3D SurveyDocument2 pagesLower Congo Basin 3D SurveyTalis TemNo ratings yet

- ERC12864-12 DemoCode 4wire SPI 2Document18 pagesERC12864-12 DemoCode 4wire SPI 2DVTNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Test Unit 7 m.2Document6 pagesTest Unit 7 m.2Petchara SridakunNo ratings yet

- ASIA INTERNATIONAL FURNITURE MATERIALS CONTRACTDocument2 pagesASIA INTERNATIONAL FURNITURE MATERIALS CONTRACTSALOME URUCHI AGUILARNo ratings yet

- ST326 - Irdap2021Document5 pagesST326 - Irdap2021NgaNovaNo ratings yet

- Mock PPT 2023 TietDocument22 pagesMock PPT 2023 Tiettsai42zigNo ratings yet

- Sewer CadDocument10 pagesSewer CadAlvaro Jesus Añazco YllpaNo ratings yet

- Tutorial Sim MechanicsDocument840 pagesTutorial Sim MechanicsHernan Gonzalez100% (4)

- Smell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaDocument35 pagesSmell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaUniversity of Washington PressNo ratings yet

- Main Sulci & Fissures: Cerebral FissureDocument17 pagesMain Sulci & Fissures: Cerebral FissureNagbhushan BmNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Electromagnetic Braking SystemDocument14 pagesElectromagnetic Braking SystemTanvi50% (2)

- 1136 E01-ML01DP5 Usermanual EN V1.2Document11 pages1136 E01-ML01DP5 Usermanual EN V1.2HectorNo ratings yet

- Lecture 6Document16 pagesLecture 6Dina Saad EskandereNo ratings yet

- Excel Data AnalysisDocument30 pagesExcel Data AnalysisРоман УдовичкоNo ratings yet

- The Importance of WritingDocument4 pagesThe Importance of WritingBogdan VasileNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)