Professional Documents

Culture Documents

Sample Report - API RP 1102 - Highway

Uploaded by

aliyildizx177300 ratings0% found this document useful (0 votes)

320 views5 pagesAPI RP 1102 EXAMPLE STANDARD

Original Title

Sample Report_API RP 1102_Highway

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAPI RP 1102 EXAMPLE STANDARD

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

320 views5 pagesSample Report - API RP 1102 - Highway

Uploaded by

aliyildizx17730API RP 1102 EXAMPLE STANDARD

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

API RP 1102

File no. 1511

Steel Pipelines Crossing

allaboutpipelines Railroads and Highways Page 1 of 5

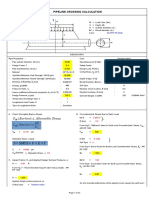

API RP 1102: Highway Crossing

Client : All About Pipelines Date : 28/08/2017

Project : Info Job no. : XXXX

Subject : Sample Report By : Team

Step a Initial Design Information

Pipe and operational characteristics

Outside diameter : D = 12.75 inch

Maximum allowable operating pressure : p = 1000 psi

Steel grade : = Gr X-56

Specified minimum yield strength : SMYS = 56000 psi

Type of pipe : = SMLS

Design factor (barlow stress & fatigue check) : F = 0.72 --

Allowable design factor (equivalent stress check) : Fa = 0.72 --

Longitudinal joint factor : E = 1.00 --

Installation temperature : T1 = Not Applicable

Maximum or minimum operating pressure : T2 = Not Applicable

Temperature derating factor : T = 1 --

Pipe wall thickness : tw = 0.25 inch

Corrosion allowance (pipeline) : CA = 0 inch

Installation and site characteristics:

Cover depth : H = 6 ft

Bored diameter : Bd = 14.8 inch

Soil type : Stiff to very stiff clays and silts

Modulus of soil reaction : E = 1 ksi

Resilient modulus : Er = 10 ksi

Unit Soil Weight : = 120 lb/ft3

Type of longitudinal weld : = 0.72 --

Design wheel load from single axle : Ps = 12 kips

Design wheel load from tandem axles : Pt = 10 kips

Pavement type : = Flexible pavement

Other pipe steel properties:

Youngs modulus : Es = 3.0E+007 psi

Poissons ratio : s = 0.3 --

Coefficient of thermal expansion : T = 6.5E-006 / oF

Copyright NT Technology All rights reserved Generated by: www.allaboutpipelines.com

API RP 1102

File no. 1511

Steel Pipelines Crossing

allaboutpipelines Railroads and Highways Page 2 of 5

Step b Check Allowable Barlow Stress

Equation 8b with: p = 1000 psi SHi (Barlow) = 25500 psi

D = 12.75 inch

tw = 0.25 inch

F = 0.72

E = 1.00 FETSMYS = 40320 psi

T=1

SMYS = 56000 psi

SHi Allowable? YES

Step c Circumferential Stress due to Earth Load

c.1 Figure 3 with: tw / D = 0.020 KHe = 2444

E' = 1 ksi

c.2 Figure 4 with: H/ Bd = 4.9 Be = 0.94

Soil type = B

c.3 Figure 5 with: Bd/ D = 1.16 Ee = 1.12

c.4 Equation 1 with: D = 12.75 inch SHe = 2291 psi

= 120 lb/ft3

Step d - Impact Factor, Fi, and Applied Design Surface Pressure, w

d.1 Figure 7 for highways with: H = 6 ft Fi = 1.47

d.2 Applied design surface pressure, w:

Section 4.7.2.2.1: Flexible pavement Pt = 10 kips

Critical case : tandem axles w = 69.4 psi

Copyright NT Technology All rights reserved Generated by: www.allaboutpipelines.com

API RP 1102

File no. 1511

Steel Pipelines Crossing

allaboutpipelines Railroads and Highways Page 3 of 5

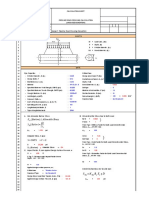

Step e - Cyclic Stresses, SHh and SLh

e.1 Cyclic circumferential Stress, SHh

e.1.1 Figure 14 with: tw / D = 0.020 KHh = 14.2

Er = 10 ksi

e.1.2 Figure 15 with: D = 12.75 inch GHh = 1.00

H = 6 ft (1.8 m)

e.1.3 Table 2 with: R = 1.00

Flexible pavement H = 6 ft (1.8 m) L = 1.00

tandem axles D = 12.75 inch

e.1.4 Equation 5: SHh = 1448 psi

e.2 Cyclic longitudinal Stress, SLh

e.2.1 Figure 16 with: tw / D = 0.020 KLh = 9.8

Er = 10 ksi

e.2.2 Figure 17 with: D = 12.75 inch GLh = 0.99

H = 6 ft (1.8 m)

e.2.3 Table 2 with: R = 1.00

Flexible pavement H = 6 ft (1.8 m) L = 1.00

tandem axles D = 12.75 inch

e.2.4 Equation 6: SLh = 991 psi

Step f - Circumferential Stress dues to Internal Pressurization, SHi

Equation 7 with: p = 1000 psi SHi = 25000 psi

D = 12.75 inch

tw = 0.25 inch

Copyright NT Technology All rights reserved Generated by: www.allaboutpipelines.com

API RP 1102

File no. 1511

Steel Pipelines Crossing

allaboutpipelines Railroads and Highways Page 4 of 5

Step g - Principal Stresses, S1, S2, S3

Es = 3.0E+007 psi

T = 6.5E-006 / oF

T1 = Not Applicable

T2 = Not Applicable

g.1 Equation 9 with: SHe = 2291psi S1 = 28739 psi

SHh = 1448psi

SHi = 25000 psi

g.2 Equation 10 with: SLh = 991psi S2 = 9179 psi

SHe = 2291psi

SHi = 25000 psi

g.3 Equation 11 with: p = 1000 psi S3 = -1000 psi

g.4 Effective stress, Seff :

Equation 12 with: S1 = 28739 psi Seff = 26179 psi

S2 = 9179 psi

S3 = -1000 psi

g.5 Check allowable effective stress Fa = 0.72

SMYS = 56000 psi

Seff = 26179psi

SMYS Fa = 40320 psi

Seff SMYS Fa? YES

Step h Check fatigue

h.1 Girth welds

F = 0.72

Table 3 SFG= 12000 psi

Equation 17 with: SLh = 991psi

SFG F = 8640 psi SLh SFG F ? YES

Copyright NT Technology All rights reserved Generated by: www.allaboutpipelines.com

API RP 1102

File no. 1511

Steel Pipelines Crossing

allaboutpipelines Railroads and Highways Page 5 of 5

h.2 Longitudinal welds

F = 0.72

Table 3 SFL= 23000 psi

Equation 20 with: SHh = 1448 psi

SFL F = 16560 psi SHh SFL F ? YES

Copyright NT Technology All rights reserved Generated by: www.allaboutpipelines.com

You might also like

- Buried Pipe Analysis PDFDocument6 pagesBuried Pipe Analysis PDFPer Bagus Handoko50% (2)

- Cp16 Road Crossing AnalysisDocument3 pagesCp16 Road Crossing Analysisboonico Nicco0% (1)

- Crossing Calculation API Rp1102 TemplateDocument1 pageCrossing Calculation API Rp1102 TemplateBudi SantonyNo ratings yet

- Crossing Calculation API 1102 8inch Sch40 Api5lbrg 1.3depthDocument12 pagesCrossing Calculation API 1102 8inch Sch40 Api5lbrg 1.3depthJoe Kyla83% (6)

- Api RP 1102 - 1993Document11 pagesApi RP 1102 - 1993Nadia Handayani100% (1)

- Buried PipeDocument11 pagesBuried PipeAKKI KUMARNo ratings yet

- Upheavel Buckling CalculationDocument8 pagesUpheavel Buckling Calculationsaravanakkumar boominahtanNo ratings yet

- SP-OS-PL-CAL-0003 Rev. 0 Pipeline Stress AnalysisDocument19 pagesSP-OS-PL-CAL-0003 Rev. 0 Pipeline Stress AnalysisElias EliasNo ratings yet

- API RP 1102 SpreadsheetDocument5 pagesAPI RP 1102 SpreadsheetBehroozNo ratings yet

- Road Crossing Pipeline Load CalculatorDocument7 pagesRoad Crossing Pipeline Load CalculatorZeeshan Ahuja100% (2)

- PTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-PusriDocument16 pagesPTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-Pusrihamid sobirin100% (3)

- Anggita API 1102 01Document22 pagesAnggita API 1102 01Luqmanul HakimNo ratings yet

- Buried Pipe Design: A. P. Moser Steven FolkmanDocument2 pagesBuried Pipe Design: A. P. Moser Steven Folkmannrd97710% (3)

- Buried PipeDocument11 pagesBuried PipePrashant Agrawal100% (4)

- Underground Pipe DesignDocument3 pagesUnderground Pipe Designjobees7850No ratings yet

- Static Calculation of Pipeline Free SpansDocument1 pageStatic Calculation of Pipeline Free SpansMannattil Krishna KumarNo ratings yet

- Buried Pipe Analysis Based On ALADocument6 pagesBuried Pipe Analysis Based On ALADonald.K0% (1)

- Geohazard CalculationDocument13 pagesGeohazard CalculationFemi Richard Fakoya100% (2)

- Pipeline Highway Crossing Design SpreadsheetDocument11 pagesPipeline Highway Crossing Design SpreadsheetBeljun FloresNo ratings yet

- API RP 1102 SpreadsheetDocument6 pagesAPI RP 1102 Spreadsheetm_michael_cNo ratings yet

- GSL TR-02-09 Guideline For Installation of Utilities Beneath Corps of Engineers Levees Using Horizontal Directional DrillingDocument44 pagesGSL TR-02-09 Guideline For Installation of Utilities Beneath Corps of Engineers Levees Using Horizontal Directional DrillingFederico MontesverdesNo ratings yet

- Evaluation of Horizontal Directional Drilling PDFDocument51 pagesEvaluation of Horizontal Directional Drilling PDFCristina PadrónNo ratings yet

- Lateral Buckling of Subsea Pipelines PDFDocument20 pagesLateral Buckling of Subsea Pipelines PDFMukil DevNo ratings yet

- Crossing Calculation API RP1102 (TEMPLATE)Document1 pageCrossing Calculation API RP1102 (TEMPLATE)bebas_amarah100% (5)

- Windows-1256 - Bending Stresses From External Loading On Buried PipeDocument10 pagesWindows-1256 - Bending Stresses From External Loading On Buried PipeAnwar ALkurayshiNo ratings yet

- ASTM F1962 Design Values - PE Pipe Parameters - Soil ParametersDocument2 pagesASTM F1962 Design Values - PE Pipe Parameters - Soil Parametersjua666n100% (1)

- Pipeline Anchor Length Calculation PDFDocument3 pagesPipeline Anchor Length Calculation PDFAlvin SmithNo ratings yet

- Pipeline Buoyancy AnalysisDocument12 pagesPipeline Buoyancy AnalysisbonnicoNo ratings yet

- API RP 1102 SpreadsheetDocument5 pagesAPI RP 1102 SpreadsheetMuhammad Farid TaufikNo ratings yet

- Pipelines Stress Analysis Report MechatronicsDocument10 pagesPipelines Stress Analysis Report MechatronicsJuan Carlos RiveraNo ratings yet

- Stability-Calculation For PipelineDocument2 pagesStability-Calculation For PipelineGeorge100% (1)

- CEPA Surface Loading Stress Excel 2007 2010.Xlsmלחץ על צנרת מתחת לכבישDocument1 pageCEPA Surface Loading Stress Excel 2007 2010.Xlsmלחץ על צנרת מתחת לכבישlameeyNo ratings yet

- API RP 1102 SpreadsheetDocument5 pagesAPI RP 1102 Spreadsheetdrramsay100% (4)

- Zetkin Wall Thickness CalculationsDocument59 pagesZetkin Wall Thickness CalculationsKarthik Channamsetty67% (3)

- River Crossing Pipeline - PaperDocument6 pagesRiver Crossing Pipeline - PaperJoko NugrohoNo ratings yet

- Upheaval Buckling of Gas Injection Pipelines Onshore Abu DhabiDocument12 pagesUpheaval Buckling of Gas Injection Pipelines Onshore Abu DhabiRajneesh KambojNo ratings yet

- Design Burried PipelineDocument44 pagesDesign Burried PipelineSk Abdul RavoofNo ratings yet

- Crossing Calculation API RP1102 (TEMPLATE)Document1 pageCrossing Calculation API RP1102 (TEMPLATE)Hendra Yudistira100% (1)

- AWWA M45 2nd Ed Chapter 5Document32 pagesAWWA M45 2nd Ed Chapter 5miguel medinaNo ratings yet

- Pipelines and Buried PipesDocument22 pagesPipelines and Buried PipesjwochNo ratings yet

- Review of Strain Based Analysis For Pipelines Ref PRCIDocument58 pagesReview of Strain Based Analysis For Pipelines Ref PRCImecemanNo ratings yet

- Stress Analysis of GRPDocument4 pagesStress Analysis of GRPSuthan SelvarajNo ratings yet

- Pipeline Anchor Length CalculationsDocument3 pagesPipeline Anchor Length Calculationslsatchithananthan100% (3)

- Hydraulic Fracturing in Soil During HDDDocument12 pagesHydraulic Fracturing in Soil During HDDamir_hayfaNo ratings yet

- Design Calculation For Crossing by HDD MethodDocument22 pagesDesign Calculation For Crossing by HDD MethodPer Bagus HandokoNo ratings yet

- Finite Element Analysis of A Buried PipelineDocument199 pagesFinite Element Analysis of A Buried Pipelinecoteesh100% (1)

- Anchor FlangeDocument2 pagesAnchor Flangeannu300100% (1)

- Mathcad - 1000 KL Tank1Document23 pagesMathcad - 1000 KL Tank1Zulfikar N JoelNo ratings yet

- C 84524 PS KK1 CAL ST 3K 0020 - R1 Pipeline Buoyancy Control AnalysisDocument7 pagesC 84524 PS KK1 CAL ST 3K 0020 - R1 Pipeline Buoyancy Control AnalysisbonnicoNo ratings yet

- Buried Pipe Design (Flexible) 1Document9 pagesBuried Pipe Design (Flexible) 1Ah Leng Lau100% (2)

- 33 05 23.13 - Horizontal Directional DrillingDocument17 pages33 05 23.13 - Horizontal Directional DrillingThomas Bennett100% (1)

- Buried Pipe Analysis001Document6 pagesBuried Pipe Analysis001Adi Mutawali50% (2)

- Buried Pipe AnalysisDocument6 pagesBuried Pipe AnalysisAnonymous Jq5ttTCNo ratings yet

- Buried Pipe Analysis PDFDocument6 pagesBuried Pipe Analysis PDFDivesh rahul50% (2)

- Sendai: Eversendai Consulting Engineers (P) LTDDocument6 pagesSendai: Eversendai Consulting Engineers (P) LTDFernando Humberto100% (1)

- Duct Bank DesignDocument18 pagesDuct Bank DesignFeroz Khan Patthan100% (1)

- Road Crossing Analysis 20 in Abandoned PipeDocument3 pagesRoad Crossing Analysis 20 in Abandoned Pipedenstar silalahi0% (1)

- Fence CalculatorDocument2 pagesFence CalculatorIjaz MhNo ratings yet

- SP Os PL Cal 0004 Appendix ADocument3 pagesSP Os PL Cal 0004 Appendix ARYZKI EFENDI SIMANULANGNo ratings yet

- Earthmat - Calculations-Noida 10 MeterDocument6 pagesEarthmat - Calculations-Noida 10 MeterAnoop DikshitNo ratings yet

- Dogal Gaz Kuresel Vana 2018Document13 pagesDogal Gaz Kuresel Vana 2018aliyildizx17730No ratings yet

- Deep Anode SystemsDocument26 pagesDeep Anode Systemsaliyildizx17730No ratings yet

- Deep Anode SystemsDocument26 pagesDeep Anode Systemsaliyildizx17730No ratings yet

- BSTVLBLTCHNLGRPRT EngDocument138 pagesBSTVLBLTCHNLGRPRT Engaliyildizx17730No ratings yet

- Formula For Miter Fabrication From Pipe The Piping Engineering WorldDocument9 pagesFormula For Miter Fabrication From Pipe The Piping Engineering Worldaliyildizx17730100% (1)

- Opr 99 - GoogleDocument3 pagesOpr 99 - Googlealiyildizx17730No ratings yet

- Regulations (Standards - 29 CFR) - Occupational Safety and Health AdministrationDocument15 pagesRegulations (Standards - 29 CFR) - Occupational Safety and Health Administrationaliyildizx17730No ratings yet

- Properties of Common LiquidsDocument2 pagesProperties of Common Liquidsaliyildizx17730No ratings yet

- Piping BasicDocument37 pagesPiping Basicaliyildizx17730100% (1)

- Formula For Miter Fabrication From Pipe The Piping Engineering WorldDocument9 pagesFormula For Miter Fabrication From Pipe The Piping Engineering Worldaliyildizx17730100% (1)

- A Practical Guide For Pipeline Construction Inspectors PDFDocument131 pagesA Practical Guide For Pipeline Construction Inspectors PDFaliyildizx17730100% (1)

- Weldolet, Sockolet, Threadolet, Nippolet, Swaged NippleDocument20 pagesWeldolet, Sockolet, Threadolet, Nippolet, Swaged Nipplealiyildizx17730No ratings yet

- DOE - Handbook For Handling, Storing, and Dispensing E85 - Fuel Ethanol - (DEPARTMENT ENERGY, DOE, 2002 34 P)Document34 pagesDOE - Handbook For Handling, Storing, and Dispensing E85 - Fuel Ethanol - (DEPARTMENT ENERGY, DOE, 2002 34 P)aliyildizx17730No ratings yet

- Petroleum GeologyDocument2 pagesPetroleum Geologyaliyildizx17730No ratings yet

- Interpretive Report From TEMEL-BorehollsDocument11 pagesInterpretive Report From TEMEL-Borehollsaliyildizx17730No ratings yet

- 40MF End Suction BrochureDocument4 pages40MF End Suction Brochurerhusseinpos4765No ratings yet

- Ster RadDocument4 pagesSter RadKlos BettoNo ratings yet

- AHMSW 8 Fiche de PhaseDocument12 pagesAHMSW 8 Fiche de PhaseBOUBAKER LOGBINo ratings yet

- 9cbse-ATOMS AND MOLECULES-NOTES-JAN 2023 - UpdatedDocument4 pages9cbse-ATOMS AND MOLECULES-NOTES-JAN 2023 - UpdatedTamers artNo ratings yet

- Catalogo Rieles PDFDocument133 pagesCatalogo Rieles PDFWilliam AguilarNo ratings yet

- Standard Reduction PotentialsDocument1 pageStandard Reduction PotentialsCamiloNo ratings yet

- Ecomax Front Loading DishwashersDocument4 pagesEcomax Front Loading Dishwashersrichard9982No ratings yet

- DSC Products With CodesDocument6 pagesDSC Products With CodesmelvinkuriNo ratings yet

- A2H Actuator CatalogDocument6 pagesA2H Actuator CatalogahnafNo ratings yet

- An Improved Method For Large-Scale Processing of Woad (Isatis Tinctoria) For PossibleDocument6 pagesAn Improved Method For Large-Scale Processing of Woad (Isatis Tinctoria) For PossibleCoimbra Rojas100% (1)

- Tribhuvan University Institute of Science and Technology B.Sc. Entrance Examination 2074Document11 pagesTribhuvan University Institute of Science and Technology B.Sc. Entrance Examination 2074Vijay GalamiNo ratings yet

- Poro Die Casting MethologyDocument3 pagesPoro Die Casting Methologypurushothaman1234566No ratings yet

- SZ-7510-P-DI - Cat (REV 2)Document5 pagesSZ-7510-P-DI - Cat (REV 2)Richard BakerNo ratings yet

- 03 Combustion & Combustion Tuning Part 3Document231 pages03 Combustion & Combustion Tuning Part 3sriramojNo ratings yet

- The Determination of Benzalkonium Chloride in Eye-Drops by Difference SpectrophotometryDocument8 pagesThe Determination of Benzalkonium Chloride in Eye-Drops by Difference SpectrophotometryAngga FgNo ratings yet

- Determination of Copper by AASDocument18 pagesDetermination of Copper by AASWan ShamNo ratings yet

- Philippine National StandardsDocument30 pagesPhilippine National StandardsJonathan Pascua CamachoNo ratings yet

- Topical Finasteride in The Treatment of Androgenic Alopecia. Preliminary Evaluations After A 16-Month Therapy CourseDocument4 pagesTopical Finasteride in The Treatment of Androgenic Alopecia. Preliminary Evaluations After A 16-Month Therapy Coursenobody100% (2)

- Datasheet Altro-AquariusDocument8 pagesDatasheet Altro-AquariusPaola Cares MoralesNo ratings yet

- Overview of The ProcessDocument10 pagesOverview of The ProcessChaitanya PottiNo ratings yet

- Smash 100 ECDocument12 pagesSmash 100 ECAmman BilleNo ratings yet

- Periodic Table 01-InvertDocument17 pagesPeriodic Table 01-InvertSaurabh BhaiNo ratings yet

- Done By: Neha Jain Priya Upadhyay Saanchi AroraDocument13 pagesDone By: Neha Jain Priya Upadhyay Saanchi AroraPriya UpadhyayNo ratings yet

- Catalogo Alu MarketDocument40 pagesCatalogo Alu MarketMiguel Angel Diaz Escobar100% (2)

- 10956Document34 pages10956Neri MtzNo ratings yet

- ANEXO 5 - Catalogo Sumideros JR Smith PDFDocument22 pagesANEXO 5 - Catalogo Sumideros JR Smith PDFCamilo VelásquezNo ratings yet

- Manual RapID NF Plus System5Document25 pagesManual RapID NF Plus System5Eduardo Josue Tuesta MoyohuaraNo ratings yet

- Safety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIDocument10 pagesSafety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIazerNo ratings yet

- Vmts Jee Full Test 5 Question Paper & Answer KeyDocument14 pagesVmts Jee Full Test 5 Question Paper & Answer Keyharshit pandeyNo ratings yet

- Api 510 Q&aDocument13 pagesApi 510 Q&aShaikh Aftab100% (2)