Professional Documents

Culture Documents

Press Release: "Trupunch 5000" Increases Sheet Metal Forming Capacity

Uploaded by

Hafiezul Hassan0 ratings0% found this document useful (0 votes)

99 views2 pagesKathrein-Werke KG invested 500,000 euros to purchase a new punching and nibbling machine called the "TruPunch 5000" from Trumpf to increase their sheet metal forming capacity. The new machine allows for quicker reaction to market demands, faster prototyping with development departments, and increased design freedom for products. The investment was made to secure the economic future of the area and build a solid and flexible sheet metal department.

Original Description:

TruPunch

Original Title

TruPunch 3000

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKathrein-Werke KG invested 500,000 euros to purchase a new punching and nibbling machine called the "TruPunch 5000" from Trumpf to increase their sheet metal forming capacity. The new machine allows for quicker reaction to market demands, faster prototyping with development departments, and increased design freedom for products. The investment was made to secure the economic future of the area and build a solid and flexible sheet metal department.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

99 views2 pagesPress Release: "Trupunch 5000" Increases Sheet Metal Forming Capacity

Uploaded by

Hafiezul HassanKathrein-Werke KG invested 500,000 euros to purchase a new punching and nibbling machine called the "TruPunch 5000" from Trumpf to increase their sheet metal forming capacity. The new machine allows for quicker reaction to market demands, faster prototyping with development departments, and increased design freedom for products. The investment was made to secure the economic future of the area and build a solid and flexible sheet metal department.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Date: 17th November 2010

Reference: ZW/so

Press release No.

Queries:

Contact:

065/2010

Press Office

+49 8031 184-0

Further strengthening of the Rosenheim location with a 500,000 euro investment

TruPunch 5000 increases sheet metal forming capacity

A new punching and nibbling machine at Plant III of KATHREIN-Werke KG in

Rosenheim goes to show that the company even makes investments during

economically turbulent times. The machine, a TruPunch 5000 of the Ditzingen

operation Trumpf, is the new addition to the punching machinery and helps to

substantially boost the capacity during three-shift operation.

Particular characteristics are the extremely dynamic axle drives, the very rapid

exchange of tools and the lowerable active matrices which fulfil the highest demands

on scratch-resistance at a very high level of quality, explained Franz Fenzl, production

supervisor for punching, soldering and plastics technology.

Dipl.-Ing. Johann Ettmller, head of parts production at Kathrein, added: The

implementation of new machining technology in the TruPunch 5000 will widen the

spectrum of processable sheet metal parts considerably. Now, new additional punching

and forming processes are possible, taking the freedom of design into the third

dimension.

The new system makes it possible to react more quickly to the demands of the market.

Another advantage: now prototypes can be quickly assembled in co-operation with the

development departments. At the same time, the freedom of design for products will

increase.

Prof. Dr. Dr. h.c. Anton Kathrein: With this approximately 500,000 euro investment we

have made another indispensable contribution to securing the economic future of our

area. In addition, our sheet metal part department has been built on a very solid and

extremely flexible base. When it came to choosing our supplier, we declined more

economical offers and clearly opted for a German product. Only a few weeks ago,

Visit our website www.kathrein.de

Press release

Kathrein put a new measurement field into service on the Nicklheim Moor.

Caption 1:

A crane had to be used to unload the truck

Caption 2:

Safe on the ground: The TruPunch 5000 in front of the door of the production area at Plant III in

Klepperstrae

Caption 3 and 4:

and in full operation. Control panel operator: Marcel Gerstel.

Visit our website www.kathrein.de

You might also like

- American Machinist 01Document52 pagesAmerican Machinist 01bobammax100% (2)

- BHS DKXS 3,00 Documentation B-08048-100-01Document277 pagesBHS DKXS 3,00 Documentation B-08048-100-01Gem RNo ratings yet

- Small Scale BrickmakingDocument216 pagesSmall Scale BrickmakingSean100% (1)

- Extraction of Metals: - The Chemistry BehindDocument25 pagesExtraction of Metals: - The Chemistry BehindSujit Singh100% (1)

- Chapter 6 FiltrationDocument9 pagesChapter 6 FiltrationAli AimranNo ratings yet

- ACI 304R Guide For Meas., Mix., Transp., & Placing ConcDocument41 pagesACI 304R Guide For Meas., Mix., Transp., & Placing ConcVasanth KumarNo ratings yet

- Risk AssessmentDocument7 pagesRisk AssessmentHafiezul HassanNo ratings yet

- Belt Conveyor Assembly HandbookDocument51 pagesBelt Conveyor Assembly HandbookJong Java100% (1)

- Ethics Practice ProblemsDocument5 pagesEthics Practice ProblemsHafiezul HassanNo ratings yet

- Tape WrappingDocument8 pagesTape WrappingwalitedisonNo ratings yet

- Fabric Inspection Under 4Document5 pagesFabric Inspection Under 4texcons677150% (2)

- Cockpit 3 2010Document60 pagesCockpit 3 2010KNRCSNo ratings yet

- PFISTERER High Voltage Cable FittingsDocument80 pagesPFISTERER High Voltage Cable FittingsKaramat Ali KhanNo ratings yet

- SMS Newsletter 01 2015 enDocument142 pagesSMS Newsletter 01 2015 enomartaha79No ratings yet

- Collapses in Tunnelling PDFDocument194 pagesCollapses in Tunnelling PDFSiahi Shab100% (1)

- Cathelco ICCP Hull Protection SystemsDocument8 pagesCathelco ICCP Hull Protection SystemsdalianbouriNo ratings yet

- Roles and Responsibilities of Plant Commissioning Rev 3Document16 pagesRoles and Responsibilities of Plant Commissioning Rev 3Chijioke ObiNo ratings yet

- 6s1901 Bo (Caja ZF)Document64 pages6s1901 Bo (Caja ZF)Renner Tabraj Espinoza67% (3)

- ISO 8217 2010 Fuel Standard For Marine Distillate FuelsDocument2 pagesISO 8217 2010 Fuel Standard For Marine Distillate FuelsiceburnerNo ratings yet

- Anchor Systems.: Hilti. Outperform. OutlastDocument49 pagesAnchor Systems.: Hilti. Outperform. Outlastthapa786mNo ratings yet

- Static Tests On Complete StructuresDocument40 pagesStatic Tests On Complete StructuresZain AhmedNo ratings yet

- Netzsch Pumpen & Systeme GMBH: OfferDocument6 pagesNetzsch Pumpen & Systeme GMBH: OfferBilel MarkosNo ratings yet

- Glass Production: From Wikipedia, The Free EncyclopediaDocument10 pagesGlass Production: From Wikipedia, The Free EncyclopediaMahfuzur Rahman SiddikyNo ratings yet

- Fuchs 12500 KG Provision Crane - Operating InstructionDocument82 pagesFuchs 12500 KG Provision Crane - Operating Instructionjohn smith100% (1)

- Coatings Formulation: Bodo Müller Ulrich PothDocument4 pagesCoatings Formulation: Bodo Müller Ulrich Pothtrường phạm100% (1)

- Investment Trade: Innovative Cable SolutionsDocument64 pagesInvestment Trade: Innovative Cable SolutionsTradeinvestmentNo ratings yet

- PI RUF Studie-Brikettieren EN V10-FinalDocument8 pagesPI RUF Studie-Brikettieren EN V10-FinalrezaNo ratings yet

- ZAB Seng 25000598 enDocument3 pagesZAB Seng 25000598 enLew Quzmic BaltiyskyNo ratings yet

- WPCDocument8 pagesWPCcipteNo ratings yet

- 2022 in at TL M Ag 000358 01 PDFDocument3 pages2022 in at TL M Ag 000358 01 PDFFco PadillaNo ratings yet

- Sulzer ACHABS-SON1 Offer Rev.1Document21 pagesSulzer ACHABS-SON1 Offer Rev.1Rahul DeyNo ratings yet

- We Care About Feet!: 1st English EditionDocument32 pagesWe Care About Feet!: 1st English EditionpetcudanielNo ratings yet

- FileDesc 1076623Document1 pageFileDesc 1076623Stephen HunterNo ratings yet

- Shreya Injection Molding MachinesDocument40 pagesShreya Injection Molding Machinests.anirudhaNo ratings yet

- Technical Data Sheet: Rothe Erde Large Diameter Slewing BearingDocument19 pagesTechnical Data Sheet: Rothe Erde Large Diameter Slewing BearingAkash RockNo ratings yet

- Container Terminal Focus 2015: Project InformationDocument4 pagesContainer Terminal Focus 2015: Project Informationaccount_meNo ratings yet

- PETROL CatalogueDocument269 pagesPETROL CataloguerashidNo ratings yet

- SUEPO Demo 15-02-25Document2 pagesSUEPO Demo 15-02-25Florian MuellerNo ratings yet

- Letter: Thyssenkrupp FördertechnikDocument15 pagesLetter: Thyssenkrupp FördertechnikchandanjanuaryNo ratings yet

- Schenck - H 40 Bu: Balancing MachineDocument1 pageSchenck - H 40 Bu: Balancing MachineFlavio Ballio100% (1)

- Paper C: European Qualifying Examination 2017Document33 pagesPaper C: European Qualifying Examination 2017hisuinNo ratings yet

- CEN-TC459-SC4 N0453 Agenda For The CENTC 459SC 4-Meeting On 2020-05-05 in DüsseldorfDocument1 pageCEN-TC459-SC4 N0453 Agenda For The CENTC 459SC 4-Meeting On 2020-05-05 in Düsseldorfjackman84No ratings yet

- Numerous at Ferropem !: Foundry VisitsDocument3 pagesNumerous at Ferropem !: Foundry Visitsvasseur_nico1827No ratings yet

- Connection d01 1Document6 pagesConnection d01 1Win ThanNo ratings yet

- Techforum 1 12 enDocument86 pagesTechforum 1 12 enMartin Schweighart MoyaNo ratings yet

- Profis Rebar ReportDocument5 pagesProfis Rebar ReportSowmya MajumderNo ratings yet

- And Guided Marking Machine For Sprayable ThermoplasticsDocument1 pageAnd Guided Marking Machine For Sprayable ThermoplasticsHesham SamirNo ratings yet

- Optional Fuel Pre Filter PARKER 16V4000Document3 pagesOptional Fuel Pre Filter PARKER 16V4000Andres HuertaNo ratings yet

- D Ulrich MoosheimerDocument36 pagesD Ulrich Moosheimer331623468No ratings yet

- Friction, Wear and Wear ProtectionFrom EverandFriction, Wear and Wear ProtectionAlfons FischerNo ratings yet

- SBZ 610 - 13 Profile Machining Centre - ElumatecDocument4 pagesSBZ 610 - 13 Profile Machining Centre - ElumatecDUyNo ratings yet

- Drafts - Masonry - 7 Jul 2023Document7 pagesDrafts - Masonry - 7 Jul 2023anwar alamNo ratings yet

- 2015-11-09 Press Release Lehnhoff - Komatsu EnglDocument2 pages2015-11-09 Press Release Lehnhoff - Komatsu EnglDaniel CringusNo ratings yet

- Bid Book V 3Document74 pagesBid Book V 3ctyvteNo ratings yet

- VoithDocument5 pagesVoithajay4441No ratings yet

- Helmut FischerDocument4 pagesHelmut FischerMatheusFerreiraNo ratings yet

- Info BandasDocument52 pagesInfo BandasfrbadillaNo ratings yet

- TOVP - Rebar - May 12, 2023Document20 pagesTOVP - Rebar - May 12, 2023prabhash kumarNo ratings yet

- Pharmastoppe ProductionDocument30 pagesPharmastoppe ProductionraghaknNo ratings yet

- Pneumatic Impact Treatment: New GenerationDocument31 pagesPneumatic Impact Treatment: New GenerationDavid Budi SaputraNo ratings yet

- Fujitsu Siemens Amilo Xi 1526Document1 pageFujitsu Siemens Amilo Xi 1526sandro2009No ratings yet

- TransSteel Schweissbrenner enDocument26 pagesTransSteel Schweissbrenner enMayank AgarwalNo ratings yet

- PO 525279 98811 Tech DetailsDocument1 pagePO 525279 98811 Tech Detailsentc21sunil.palNo ratings yet

- 45 Manufacturing of High Precision BoresDocument169 pages45 Manufacturing of High Precision BoresTuấnAnhNo ratings yet

- BHTD UreaDocument4 pagesBHTD UrealalitbadheNo ratings yet

- New Sizes: Torqloc Hollow Shaft Mounting SystemDocument3 pagesNew Sizes: Torqloc Hollow Shaft Mounting SystemVilma FloresNo ratings yet

- Nonwovens enDocument36 pagesNonwovens enEn10139No ratings yet

- Drafts - Rebar - Nov 30, 2023Document18 pagesDrafts - Rebar - Nov 30, 2023Narasimha MurthyNo ratings yet

- #1 Tust Publications - Ita-AitesDocument1 page#1 Tust Publications - Ita-Aitesbiles1234No ratings yet

- Tensinews 17Document24 pagesTensinews 17seba villeNo ratings yet

- Sensors, Micro- and Nanosensor Technology: Trends in Sensor MarketsFrom EverandSensors, Micro- and Nanosensor Technology: Trends in Sensor MarketsWolfgang GöpelNo ratings yet

- Short-Range Wireless Communications: Emerging Technologies and ApplicationsFrom EverandShort-Range Wireless Communications: Emerging Technologies and ApplicationsRolf KraemerNo ratings yet

- Fatigue FailureDocument5 pagesFatigue FailureHafiezul HassanNo ratings yet

- Numerical MethodDocument46 pagesNumerical MethodHafiezul HassanNo ratings yet

- Efyp 2 Thesis Comment Page: Area CommentsDocument1 pageEfyp 2 Thesis Comment Page: Area CommentsHafiezul HassanNo ratings yet

- Eçon C ' G:: Ahier D Accompagnement Rammaire Notes ET Exercices SupplémentairesDocument13 pagesEçon C ' G:: Ahier D Accompagnement Rammaire Notes ET Exercices SupplémentairesHafiezul HassanNo ratings yet

- Circuit DesignDocument15 pagesCircuit DesignHafiezul HassanNo ratings yet

- Titanium Green MaterialDocument1 pageTitanium Green MaterialHafiezul HassanNo ratings yet

- Memorial Go-Kart Inc.: 5308 Hwy 175 Hartford, WI 53027 262-644-8375Document5 pagesMemorial Go-Kart Inc.: 5308 Hwy 175 Hartford, WI 53027 262-644-8375Hafiezul HassanNo ratings yet

- Titanium: The Green Metal For The 21st Century: George - Chen@nottingham - Ac.ukDocument1 pageTitanium: The Green Metal For The 21st Century: George - Chen@nottingham - Ac.ukHafiezul HassanNo ratings yet

- Small Business Innovation Research (SBIR)Document132 pagesSmall Business Innovation Research (SBIR)Hafiezul HassanNo ratings yet

- Experiment 5: Impact of Water JetDocument8 pagesExperiment 5: Impact of Water JetHafiezul HassanNo ratings yet

- HijabDocument18 pagesHijabHafiezul HassanNo ratings yet

- Bending Stress Formula Shear Stress FormulaDocument2 pagesBending Stress Formula Shear Stress FormulaHafiezul HassanNo ratings yet

- Power Curve PerformanceDocument7 pagesPower Curve PerformanceHafiezul HassanNo ratings yet

- Small Business Innovation Research (SBIR)Document132 pagesSmall Business Innovation Research (SBIR)Hafiezul HassanNo ratings yet

- Sunmotor Solar Power SystemsDocument10 pagesSunmotor Solar Power SystemsHafiezul HassanNo ratings yet

- Approaching Free Electricity: How The Real-World Differs From Thermodynamic ModelsDocument12 pagesApproaching Free Electricity: How The Real-World Differs From Thermodynamic ModelsHafiezul HassanNo ratings yet

- Research Center For Modeling & Simulation (RCMS) National University of Sciences & TechnologyDocument2 pagesResearch Center For Modeling & Simulation (RCMS) National University of Sciences & TechnologyHafiezul HassanNo ratings yet

- USM AME Advance Manufacturing EngineeringDocument16 pagesUSM AME Advance Manufacturing EngineeringRajesh RajendranNo ratings yet

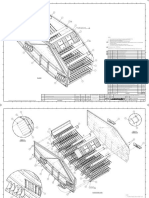

- D A42 1362 0001J 17 Isometric ExtractedDocument3 pagesD A42 1362 0001J 17 Isometric ExtractedAnhNtCaoNo ratings yet

- 24 - 25 PF Furnace'12Document5 pages24 - 25 PF Furnace'12DSGNo ratings yet

- Additive ManufacturingDocument27 pagesAdditive Manufacturinglorraine SandyNo ratings yet

- PROSEDUR REFRIGERANT QUALITY GUIDANCE-Flame TestDocument2 pagesPROSEDUR REFRIGERANT QUALITY GUIDANCE-Flame TestAnonymous DFoXVEHINo ratings yet

- N2XH FE 180/E: Controls, IncDocument2 pagesN2XH FE 180/E: Controls, IncShoaib-Ur -RehmanNo ratings yet

- HR Datasheet RotoscanDocument2 pagesHR Datasheet RotoscanRaúl Jiménez AcevesNo ratings yet

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaNo ratings yet

- 1301A01422 Zaranda 3500Document2 pages1301A01422 Zaranda 3500Edgar FloresNo ratings yet

- Blast Stove ModelDocument2 pagesBlast Stove Modelnag_akNo ratings yet

- MENA Reference MBR Durrat Al BahreinDocument2 pagesMENA Reference MBR Durrat Al BahreinNermeen ElmelegaeNo ratings yet

- Stud Welding Instruction ManualDocument5 pagesStud Welding Instruction Manualedwin jimenezNo ratings yet

- Catalogo Sta Rite BombasDocument160 pagesCatalogo Sta Rite BombasestebanampelosNo ratings yet

- Experiment 1Document4 pagesExperiment 1Kathrine E. BautistaNo ratings yet

- 100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesDocument3 pages100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesPazhamalairajan KaliyaperumalNo ratings yet

- Z&J Technologies GMBH: Conversion Table of EN - Materials vs. US Materials (Assorted by ASTM No.)Document1 pageZ&J Technologies GMBH: Conversion Table of EN - Materials vs. US Materials (Assorted by ASTM No.)Nattapong PongbootNo ratings yet

- Technical Paper SiC Ceramic MembranesDocument5 pagesTechnical Paper SiC Ceramic MembranesEman El DsoukyNo ratings yet

- RoboticsDocument2 pagesRoboticsSathish KumarNo ratings yet

- Suction Cups/grippers: Duraflex® BagDocument2 pagesSuction Cups/grippers: Duraflex® BagBe HappyNo ratings yet