Professional Documents

Culture Documents

TABEL Caracteristici Oteluri Inox

Uploaded by

relu59Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TABEL Caracteristici Oteluri Inox

Uploaded by

relu59Copyright:

Available Formats

Mechanical proprieties Standard dimensions

Mechanical properties

Minimum

Minimum impact Resistance to

proof strength Minimum elogation Hardness

Steel designation 2 energy (ISO-V) KV, (J) intergranular

(N/mm ) Tensile after fracture (%) max.

Heat >10 mm thick corrosion4)

Product (transverse) strength,

1) treatment Rm in

form condition A80<3mm A >=3mm

2 HB as

0,2 % 1 % (N/mm ) thick thick

Name Number HRB or longitudinal transverse delivered sensitized

Rp0,2 Rp1,0 (transverse) (transveres)

2) 3) HV condition condition

X5CrNi18-10 1.4301 210 250 520-720 45 90 60 Y N

X5CrNi18-10 1.4301 230 260 540-750 45 Y N

X2CrNi19-11 1.4306 220 250 520-670 45 Y Y

X2CrNi19-11 1.4306 200 240 500-650 45 90 60 Y Y

X2CrNi18-9 1.4307 220 250 520-670 45 Y Y

X2CrNi18-9 1.4307 200 240 500-650 45 90 60 Y Y

X10CrNi18-8 1.4310 250 280 600-950 40 N N

X2CrNiN18-10 1.4311 290 320 550-750 40 Y Y

X2CrNiN18-10 1.4311 270 310 550-750 40 90 60 Y Y

X5CrNiMo17-

1.4401 240 270 530-680 40 Y N

12-2

X5CrNiMo17-

1.4401 220 260 520-670 45 90 60 Y N

12-2

X5CrNiMo17-

1.4401 220 260 530-680 40 90 60 Y N

12-2

X2CrNiMo17-

1.4404 240 270 530-680 40 Y Y

12-2

X2CrNiMo17-

1.4404 220 260 530-680 40 90 60 Y Y

12-2

X2CrNiMo17-

1.4404 220 260 520-670 45 90 60 Y Y

12-2

X2CrNiMoN17-

1.4406 300 330 580-780 40 Y Y

11-2

X2CrNiMoN17-

1.4406 280 320 580-780 40 90 60 Y Y

11-2

X2CrNiMo17-

1.4432 240 270 550-700 40 Y Y

12-3

X2CrNiMo17-

1.4432 220 260 550-700 40 90 60 Y Y

12-3

X2CrNiMo18-

1.4435 240 270 550-700 40 Y Y

14-3

X2CrNiMo18-

1.4435 220 260 520-670 45 90 60 Y Y

14-3

X2CrNiMo18-

1.4435 220 260 550-700 40 90 60 Y Y

14-3

X3CrNiMo17-

1.4436 240 270 550-700 40 Y N

13-3

X3CrNiMo17-

1.4436 220 260 550-700 40 90 60 Y N

13-3

X3CrNiMo17-

1.4436 220 260 530-730 40 90 60 Y N

13-3

X6CrNiTi18-10 1.4541 220 250 520-720 40 Y Y

X6CrNiTi18-10 1.4541 200 240 520-720 40 90 60 Y Y

X6CrNiTi18-10 1.4541 200 240 500-700 40 90 60 Y Y

X6CrNiNb18-10 1.4550 220 250 520-720 40 Y Y

X6CrNiNb18-10 1.4550 200 240 520-720 40 90 60 Y Y

X6CrNiNb18-10 1.4550 200 240 500-700 40 90 60 Y Y

X6CrNiMoTi17-

1.4571 240 270 540-690 40 Y Y

12-2

X6CrNiMoTi17-

1.4571 220 260 540-690 40 90 60 Y Y

12-2

X6CrNiMoTi17-

1.4571 220 260 520-670 40 90 60 Y Y

12-2

X6CrNiMoNb17-

1.4580 220 260 520-720 40 90 60 Y Y

12-2

X15CrNiSi20-12 1.4828 230 270 550-750 28 223

X15CrNiSi20-12 1.4828 230 270 550 750 30 223

X15CrNiSi25-20 1.4841 230 270 550-750 28 223

X15CrNiSi25-20 1.4841 230 270 550-750 30 223

X12CrNi25-21 1.4845 210 250 500-700 33 192

X12CrNi25-21 1.4845 210 250 500-700 35 192

X8CrNiTi18-10 1.4878 190 230 500-720 40 215

X8CrNiTi18-10 1.4878 190 230 500-720 40 215

X6Cr17 1.4016 260 280 450-600 20 Y N

X6Cr17 1.4016 240 260 450-600 18 Y N

X3CrTi17 1.4510 230 240 420-600 23 23 Y Y

max.

X12Cr13 1.4006 A 20 20 90 200

600

max.

X20Cr13 1.4021 A 15 15 95 225

700

max.

X30Cr13 1.4028 A 15 15 97 235

740

1. CR = cold rolled strip; HR = hot rolled strip ; QP = quarto plate

Standard dimensions

Thickness (mm) 1000x2000mm 1250x2500mm 1500x3000mm 3000x6000mm 3000x6000mm

0.3-0.6 x x

0.6-0.91 x x x

1-12 x x x x x

13-200 x x x x x

You might also like

- 8-Bolted Stiffened End Plate DesignDocument6 pages8-Bolted Stiffened End Plate DesignlucianduNo ratings yet

- Bolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryDocument2 pagesBolts Connection Design Based On AISC Manual 13th Edition: Input Data & Design SummaryRayodcNo ratings yet

- BraceconnectionDocument10 pagesBraceconnectionLeonardo PimentelNo ratings yet

- Beam With TorsionDocument4 pagesBeam With TorsionNikki RobertsNo ratings yet

- Beam - Column Steel SpliceDocument22 pagesBeam - Column Steel Splicerelu59No ratings yet

- Boiler FundamentalsDocument63 pagesBoiler Fundamentalsakrverma2011100% (1)

- NETA Handbook Series I Insulating Oils PDFDocument112 pagesNETA Handbook Series I Insulating Oils PDF1981todurkar50% (2)

- Inverted SiphonDocument39 pagesInverted Siphonalee67% (3)

- Beam GravityDocument11 pagesBeam GravitylucianduNo ratings yet

- Dropped Object AnalysisDocument34 pagesDropped Object AnalysisSivaNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 2018 Physical Metallurgy Principles and Design - Haidemenopoulos, Gregory N PDFDocument490 pages2018 Physical Metallurgy Principles and Design - Haidemenopoulos, Gregory N PDFPhạm Thịnh100% (1)

- SSC Je Disha Publication PDFDocument502 pagesSSC Je Disha Publication PDFPRASHANTNo ratings yet

- Perma PipeDocument83 pagesPerma PipemohamadNo ratings yet

- Cantilever Column & Footing DesignDocument8 pagesCantilever Column & Footing DesignRayodc100% (1)

- Cantilever FrameDocument3 pagesCantilever FrameNikki RobertsNo ratings yet

- Prestressed Concrete Design Lecture NotesDocument52 pagesPrestressed Concrete Design Lecture NotesChristopher John Natividad100% (1)

- Lecture 7 Inclusions and Pinhole Formation in DIDocument33 pagesLecture 7 Inclusions and Pinhole Formation in DILuis Arturo RamirezNo ratings yet

- Climate Change Test ReviewDocument1 pageClimate Change Test ReviewSabrina Lavega67% (3)

- Stainless Steel Billets: Iron and Steel Co. LTDDocument2 pagesStainless Steel Billets: Iron and Steel Co. LTDOrivaldo a. penaNo ratings yet

- Din 17455-85 General Purpose Welded Circular Stainless Steel TubesDocument13 pagesDin 17455-85 General Purpose Welded Circular Stainless Steel TubestanyaNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Ffb Bending ScheduleDocument1 pageFfb Bending ScheduleMarlon KachuwaNo ratings yet

- Dual Phase Steels Voestalpine EN 28092018Document4 pagesDual Phase Steels Voestalpine EN 28092018Silverio AcuñaNo ratings yet

- Peeimoger Compact Ac Gearmotor 001 PDFDocument4 pagesPeeimoger Compact Ac Gearmotor 001 PDFAmpera marzelaNo ratings yet

- DSAH0011986Document12 pagesDSAH0011986Mahdi AlizadehNo ratings yet

- Dual-phase steels data sheet highlights strength propertiesDocument4 pagesDual-phase steels data sheet highlights strength propertiespranayNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- Material Data Sheet for S355J2 and Related Steel GradesDocument3 pagesMaterial Data Sheet for S355J2 and Related Steel GradesRushangNo ratings yet

- Ca Ta Lo GueDocument1 pageCa Ta Lo GueYoci ManaluNo ratings yet

- Yjycoin Yspi0420Document4 pagesYjycoin Yspi0420Mirosław MirekNo ratings yet

- Automotive Product CatalogDocument235 pagesAutomotive Product Catalogn96010028No ratings yet

- Cold Rolled Steel Strip Voestalpine en 111021Document7 pagesCold Rolled Steel Strip Voestalpine en 111021Shailendra SharmaNo ratings yet

- Especificações Gerais - LIQIDocument30 pagesEspecificações Gerais - LIQIJonathan Machado D. SouzaNo ratings yet

- Industrial Batteries - Network Power Sonnenschein Solar Safe Storage Capacity For Renewable Energy. SpecificationsDocument4 pagesIndustrial Batteries - Network Power Sonnenschein Solar Safe Storage Capacity For Renewable Energy. Specificationssebax123No ratings yet

- Xuat Noi LucDocument204 pagesXuat Noi LucToàn Trương Nguyễn MinhNo ratings yet

- Matsika FFB Bending ScheduleDocument1 pageMatsika FFB Bending ScheduleMarlon KachuwaNo ratings yet

- Po Orcelain Housing G Station Type Sur Rge Arres Ster (10k Ka, Clas Ss 3, 7. 8kJ/kV)Document2 pagesPo Orcelain Housing G Station Type Sur Rge Arres Ster (10k Ka, Clas Ss 3, 7. 8kJ/kV)Den WhNo ratings yet

- Dokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfDocument2 pagesDokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfraduonoNo ratings yet

- 5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052Document3 pages5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052MahfudNo ratings yet

- Standard Rectifier, Fast Recovery Diodes - Power DiodesDocument2 pagesStandard Rectifier, Fast Recovery Diodes - Power Diodespetergr8t1No ratings yet

- Sheet1 13636 4004 66) 6000 5) 400 5) 300Document18 pagesSheet1 13636 4004 66) 6000 5) 400 5) 300Alexandru BuguNo ratings yet

- Hot-Dip Galvanized Steel Strip Range of SupplyDocument12 pagesHot-Dip Galvanized Steel Strip Range of SupplyvictorNo ratings yet

- Hot-Dip Galvanized Steel Strip: Range of Supply April 2019Document8 pagesHot-Dip Galvanized Steel Strip: Range of Supply April 2019Meme VillacortaNo ratings yet

- S355JRDocument3 pagesS355JRYasmeen HaiderNo ratings yet

- Dual Phase High Ductility Steels Voestalpine EN 12062019Document2 pagesDual Phase High Ductility Steels Voestalpine EN 12062019RhushikeshNo ratings yet

- Dual Phase High Ductility Steels Voestalpine EN 12062019Document2 pagesDual Phase High Ductility Steels Voestalpine EN 12062019Willian FreireNo ratings yet

- Zetty Catalogue 121Document1 pageZetty Catalogue 121ramukolakiNo ratings yet

- Urdc SicherungenDocument82 pagesUrdc SicherungenTang Soo YeowNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetMahammad ShehattaNo ratings yet

- L1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENDocument1 pageL1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENbrayanNo ratings yet

- Shear Force Diagrem W 110 L 10 P 5 2 X y 0 1100 2 880 4 660 6 440 8 220 10 0 0 0Document3 pagesShear Force Diagrem W 110 L 10 P 5 2 X y 0 1100 2 880 4 660 6 440 8 220 10 0 0 0Dhananjay PatelNo ratings yet

- Oil Tempered Steel WireDocument11 pagesOil Tempered Steel WireHans GoetheNo ratings yet

- Hot Dip Galvanized Steel Strip Voestalpine en 20181002 TwosideDocument5 pagesHot Dip Galvanized Steel Strip Voestalpine en 20181002 TwosideAndy HuffNo ratings yet

- ZWBMD020020Document1 pageZWBMD020020Lucian CostacheNo ratings yet

- pm3600 SeriesDocument3 pagespm3600 SeriesAli AbbasNo ratings yet

- 5050 RGB LED DatasheetDocument13 pages5050 RGB LED DatasheetPeter ade TeacherNo ratings yet

- S355JRDocument3 pagesS355JRaabco.purchaseNo ratings yet

- S355JRDocument2 pagesS355JRThanh NguyenNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetHDNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetZakaria ChaoufiNo ratings yet

- Hot-dip galvanized sheet steel grades mechanical propertiesDocument2 pagesHot-dip galvanized sheet steel grades mechanical propertiesgorakdiasNo ratings yet

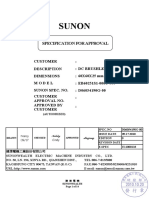

- Sunon Specification Approval for DC Brushless FanDocument14 pagesSunon Specification Approval for DC Brushless FanVictor Mihai Oglinda ElivicNo ratings yet

- Industrial Batteries: System Solutions For RailwaysDocument8 pagesIndustrial Batteries: System Solutions For RailwaysDavid MonederoNo ratings yet

- Structural Steel Tubes GuideDocument56 pagesStructural Steel Tubes GuidevegamasterinNo ratings yet

- Bosch Rexroth Coils RE18325-90Document16 pagesBosch Rexroth Coils RE18325-90Mujahidin AhmadNo ratings yet

- I.T. Park Al-Rusayil: The Public Establishment For Ind. State C1 2Document1 pageI.T. Park Al-Rusayil: The Public Establishment For Ind. State C1 2mukim0201004No ratings yet

- Hybrid Stepper Motors: Technical DataDocument2 pagesHybrid Stepper Motors: Technical DataKomariyahNo ratings yet

- BipolarDocument4 pagesBipolarfranklin ferminNo ratings yet

- Motor & - Controller Products Table 2020Document14 pagesMotor & - Controller Products Table 2020María De Los Ángeles CastilloNo ratings yet

- Sonnenschein A600 en BateriasDocument15 pagesSonnenschein A600 en Bateriasgilberto floresNo ratings yet

- White Paper Guidelines For The Application of Plastic Hinges by Nigel Pritchett, M.D., Elesa UK LTDDocument3 pagesWhite Paper Guidelines For The Application of Plastic Hinges by Nigel Pritchett, M.D., Elesa UK LTDGarry TaylorNo ratings yet

- Applications: Type TestedDocument4 pagesApplications: Type TestedFV AllanNo ratings yet

- EN ACS880-11 HW C A5 With Update Notice PDFDocument236 pagesEN ACS880-11 HW C A5 With Update Notice PDFVitali LursmanashviliNo ratings yet

- 5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeDocument2 pages5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeMemona FayyazNo ratings yet

- Copper Bussman FusesDocument9 pagesCopper Bussman FusesKhaled BellegdyNo ratings yet

- SMRF IbcDocument1 pageSMRF Ibcrelu59No ratings yet

- Welded Connection Design CheckDocument1 pageWelded Connection Design Checkrelu59No ratings yet

- Welding Splice DesignDocument1 pageWelding Splice Designrelu59No ratings yet

- WF OpeningDocument1 pageWF Openingrelu59No ratings yet

- Web Tapered FrameDocument1 pageWeb Tapered Framerelu59No ratings yet

- Steel StairDocument1 pageSteel Stairrelu59No ratings yet

- Web Tapered GirderDocument1 pageWeb Tapered Girderrelu59No ratings yet

- Weld ConnectionDocument1 pageWeld Connectionrelu59No ratings yet

- Water Tank DesignDocument1 pageWater Tank Designrelu59No ratings yet

- CDocument2 pagesCrelu59No ratings yet

- Steel Beam Design With DeckDocument1 pageSteel Beam Design With Deckrelu59No ratings yet

- TripleW ShapesDocument2 pagesTripleW Shapesrelu59No ratings yet

- Steel ColumnDocument2 pagesSteel Columnrelu59No ratings yet

- SMRF CBCDocument1 pageSMRF CBCrelu59No ratings yet

- SCBF IbcDocument2 pagesSCBF Ibcrelu59No ratings yet

- Single Footing Design Telecomm, Transmission & Guyed Tower & PoleDocument1 pageSingle Footing Design Telecomm, Transmission & Guyed Tower & Polerelu59No ratings yet

- Shear Connection Design IPE HEBDocument3 pagesShear Connection Design IPE HEBrelu59No ratings yet

- Roof DeckDocument1 pageRoof Deckrelu59No ratings yet

- Slab DesignDocument1 pageSlab Designrelu59No ratings yet

- U Stair DesignDocument1 pageU Stair Designrelu59No ratings yet

- Rectangular SectionDocument1 pageRectangular Sectionrelu59No ratings yet

- BRBFDocument5 pagesBRBFtonyNo ratings yet

- Turbulent Flow Through Pipes: Friction Factor and Velocity DistributionDocument17 pagesTurbulent Flow Through Pipes: Friction Factor and Velocity Distributiondurga345No ratings yet

- Steel Structure Analysis Seminar ProjectDocument16 pagesSteel Structure Analysis Seminar ProjectDnyaneshwar GawaiNo ratings yet

- 2007 LifengWangDocument211 pages2007 LifengWangYonny Ayala EspinelNo ratings yet

- Eneria Product List: Design Conditions Fuel Gas DataDocument1 pageEneria Product List: Design Conditions Fuel Gas DataPocola AdrianNo ratings yet

- Crust 2017Document41 pagesCrust 2017HELMA B. JABELLONo ratings yet

- CalibrationDocument13 pagesCalibrationAmanjit SinghNo ratings yet

- Module-2 Fundamentals of SurveyingDocument2 pagesModule-2 Fundamentals of Surveyingnonononoway100% (1)

- Distinguishing Between Ionic and Covalent Compounds LabDocument3 pagesDistinguishing Between Ionic and Covalent Compounds LabSamuelNo ratings yet

- RK330-01 Atmospheric Temperature, Humidity & Pressure SensorDocument2 pagesRK330-01 Atmospheric Temperature, Humidity & Pressure SensorRach ToyNo ratings yet

- Rota Meter Flow-MeasurementDocument18 pagesRota Meter Flow-MeasurementMudit BhatiaNo ratings yet

- B-144 - Datasheet - PSVDocument6 pagesB-144 - Datasheet - PSVRameez AhmedNo ratings yet

- Intro CsamtDocument4 pagesIntro CsamtJoshLeighNo ratings yet

- PSA Participant Manual May 2022 ApprovedDocument103 pagesPSA Participant Manual May 2022 Approvedlidyamengistu12No ratings yet

- RAM Frame - Semirigid Diaphragms FAQ - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesDocument8 pagesRAM Frame - Semirigid Diaphragms FAQ - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesPourang EzzatfarNo ratings yet

- Pe312-Natural Gas Engineering S&DDocument33 pagesPe312-Natural Gas Engineering S&DMalugu JohnNo ratings yet

- Temp RTDDocument8 pagesTemp RTDShambhavi VarmaNo ratings yet

- Maintenance Alat Berat Hd785 7pdf PRDocument208 pagesMaintenance Alat Berat Hd785 7pdf PRDeni SubektiNo ratings yet

- Chemical Bonding and Molecular Structure - JEE Main 2021 July Chapter-Wise - MathonGoDocument6 pagesChemical Bonding and Molecular Structure - JEE Main 2021 July Chapter-Wise - MathonGoShantul KhandelwalNo ratings yet

- Studies On Effect of Change in Dynamic Behavior of Crack Using FemDocument7 pagesStudies On Effect of Change in Dynamic Behavior of Crack Using FemMatthew SmithNo ratings yet

- Astm C39Document5 pagesAstm C39Sergio Pascual50% (2)