Professional Documents

Culture Documents

Revenger 5 19 78

Uploaded by

pccdtk0 ratings0% found this document useful (0 votes)

25 views13 pagesRC Plane

Original Title

revenger-5-19-78

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRC Plane

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views13 pagesRevenger 5 19 78

Uploaded by

pccdtkRC Plane

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

fuselage isto build straight and true. It

you have a fuselage jig, the next step wil

ooacy and straightforward, youdon',

‘iigive you a tip on how | assembie the

fuselage without a jig and stil keep it

straight.

‘Draw @ straight line on your buiiging

‘board (a few inches longer than fuse-

lage), Measure width of fuselage and

daw a line parallel to line previously

‘rawn, Draw a centerine between both

Jines (to represent centerline of fuse~

age). Pin fuselage (at mid-section) up

side down, aligning sides wih ines pre-

viously drawn. Join the sides together

(at tail) and! trim lower stringer (1/4” sq)

at an angle unti stringers fit flush to-

gether. Bond together using Hot Stuft

and pin to building board. Using

4/8" x3" balsa sheet, cut bottom sheet-

Ing cross grain and glue to bottom of

fuselage using Wilhold Glue.

(Cut firewall rom 318” {7 ply) areratt

plywood using dimensions shown on

‘drawing. IT 38" ply is not available, cut

‘two pieces, one 1/4” ply andone 1/8" ply

{and glue together using Wilhold Give,

Clamp cecuraly and allow to dry over.

night. I you plan o.use a Foxmount and

‘Southern or Proline gear, youcanayout

the firewall as shown on the plans: if not,

By Dick Russ

Use the same relative location as shown,

‘on plans, but dil holes tosuit mountand

(gearselected, Far nose gear installation

dail four (No. 25 dil) holes for 4-40 blind

juts and four (No, 21 dri) holes for 6-32

blind nuts for engine mount. Note: itis

very important that the firewall be 22

plywood. By using the 3/8” (or larger)

‘you get better vibration andloaddistribu-

tion of tha engine specific fing impulses

throughout the entire fuselage. This not

Only provides for increased power but

tea also reduce the possibly of radio

Taliure due to vibration.

If you use the Fox mount, you will

‘need to make some minor alterations to

‘enhance installation. Using a Dremel

Tool (oF electric dil) equipped with

rotary file, remove enough material on

ack of mount to clear the 4-40 blind

ute, File each beam toa slight angle to

clear engine cowiing

Next chamfer right and left sides of

firewall 3 degrees and epoxy on front of

fuselage. Glamp and allow to dry. Wnen

‘dry, remove fuselage from building

board and install the remaining 1/4” sq.

‘eroas braces across aft fuselage section

Using Wilhold Glue. Stand fuselage tail

fend down and place a small amount of

‘micro-balloons in apex o tal joint. Bond

in place using Hot Stuf.

Temporary install nose gear on fre=

wall Measure fom ton edge of fuselage

down to nose gear and draw a ine on

inside wall) of tank compartment tolo-

cate tank floor. Cut wo 14” (triangle) 6°

tong and Hot Stuffin place or tine drawn.

‘Next cut two 3/4" triangles 3-1/16" ong,

Gut out as required to clear nut plates

and nose gear assombly. Apply a dab of

‘aseline to back of nut plates and epory

‘mangies into comers of fuselage. Cut 3

pieces of 18" x3" x 2-3/4" balsa (cross

Grain) for tank floor Edge give tho

Bieces together (cross grain) using Hot

‘Stuff and cutto shane as shownon raw

ing. Install in tank compariment using

Hot Stutt

if you haven't ile the holes forthe

‘nose steering and thrttle cable, now is

tho timo to-do i. | recommend using

116" music wire for nose steering and

Su-Prine Products Mastered for the

throttle. Dril 1/8" noles in forward bulk-

head. instal guides and secure with a

light fim of minute epoxy

Gut top block (tank cover rom 3/4” x

3.518" x7" balsa, Place on top of tuse-

lage and draw aline on block o shape of

‘nose Section and trim biock to lines.

Draw aline 5/16” inboard of block edge

A NEW AND SLEEK PATTERN AIRCRAFT

FEATURING A LAMINAR AIRFOIL WING

aaa

on ty

aed

eat

Ora

70

Pood

ean)

ey

aT

Pony

ow Wing

ro

ey

Day

beep

DINEDRAL, EAGH TIP

ors

Ea)

Prete

ear Es

Boor

on

Br ea

a

Bry

ean

Bead

Sir

Brute)

irre

Pg

om

Pe cm)

pare

Doe eg

ori

FUEL TANK SIZE

ty

Pa

etry

Coad

ory

Cre

en bran)

oy

omar

arc

ers

Perea)

Gluing top stringer on side. Note outline drawn for

doublers.

(on each side) which represents tank trim length to 33°. Usin

‘ompartment. Remove material within wet the enti sheet on

this area for tank

found the Kavan 14 oz. tank wi

for this installation. Priorto inst

top block, coat the entire tank compart- top sheet into position or

ment with a good sealer, | personally hold in place with maski

preter to use Hobby-Poxy Formula 2 ped around sheet and

glue. This way |can goal the tank com. aide and allow to dry 01

artment and glue the top block on, allin When fuselage top i

tne operation. Hold the top block down masking tape and trim t

(until dry) with rubber bands. with sides

1g warm water,

‘one side only

jearance. (| have Apply a film of Wihold Glue to formers

rks well and along entire lenath of fuselage sides

lingthe (chamfered edge). Carefully place the

n fuselage and

ing tape (wrap-

fuselage). Set

vornight

top sheet flush

Using 1/4" balsa sheet (or scrap), lay Temporarily install nose gear on fire

out the formers 1 through 7 and cut to wall, Cuttwo lower nose blocks from so

shape. Next glue the formers on top of blocks 1-1/8"x x1-1/4" x 6-5/16", Trim

fuselage using Hot Stuff (or Wilhold). each block as required

Fabricate nose cow! by cutting top, {flush with sides) in nose

bottom, and two sides from 3/8 balsa outline of the fuselage si

sheet as shown on drawing. Glue as- block. Remove exct

until locks f

area, Draw an

ides on side of

material from

sembly together using Hot Stuf. Note: blocks. Temporanly reinstall blocks and

The top and bottom pieoes fitinside the trim as required for nose

side pieces. Cut four (4) 1/2" triangle operation. Carve out ©

stock 6" long. Using S-minute epoxy, from blocks to form a con

epoxy triangles inside

ing. Install engine mount

fit cheek cowling. After cowiing fits to mine where and how you!

your satisfaction, epoxy into place using the gear. Personally, |i

5-minute epoxy. Note: Cut or file a half tems” pneumatic actual

ound opening in bottom of cow to drain work exceptionally wel

fuel tion. Cut a small block of

Draw aline (using felttipped pen) 38” and ila 1/16" diameter

(down) paralielto top edge of sides (from hold cylinder attach lug,

top block total). Using

(or plane) remove tho balea (on both — porarily install actuator

mers of cowl face. The blocks are now ready to be

firewall and glued in place but before you do, deter

plano actuate

tors_and they

in this installa

maple 3/8” sq

hole inblock to

Epoxy block to

1d X-Acto knife forward bulkhead and tank floor. Tem:

using a No.

sides) within this area forming a cham- 2 x.3/8” sheet metal screw. Fabricale &

fered edge from top block to tail Select

soft sheet of balsa 1/8" x 5” x 36” an

Cutting fuselage sides.

Wire pushrod using a Goldberg 1/16

text to page S¢

Fuselage sides built up showing vertical stiffeners and

doublers,

Joining sides at forward bulkhead. Note small aluminum

langle brackets in corners for alignment.

Installing upper 1/4"sq. cross braces in aft fuselage.

Installing firewall Installing 1/8 bottom sheeting (eross grain).

View of top formers and top nose block installed. Ventral fin pinned & glued in place

Check tit of nose gear prior to installation. ‘Nose gear installed along with actuator pushrod.

81

‘Build up of tal for fin installation. Fin glued in place.

Fitting ply nose ring to cow! blocks. Installing hardwood wing hold-down blocks.

Lower nose block glued in place with cut-out for retract. Canopy secured in place with cyanoacrylate adhesive

‘and micro-ballons prior to making filet.

Fillet lay-up with Sears filled epoxy coment and Wing fillets made from Sig Epoxolite.

‘miecro-balloons.

Bottom view of stab showing dual elevator pushrod

Ball link used on rudder horn.

‘Servo installation In fuselage. Note Hydralock cylinder

‘and nose steering reduction arm.

>

=

Completed job makes the time and effort worthwhile.

.

Aileron servo and pneumatic gear actuator installation.

‘Note differential allerons and Hydralock installation

\

Rear bracket on tuned pipe using wing hold-cown bolt.

Webra speed .61 using OPS tuned pipe.

Sc

=I

oman —

iameter Kwik-Link wire

lomove actuator and nose gear as-

sembly from fuselage, Mix up abatch of

Hobby-Poxy Formula 2, and paint entire

nose gear compartment. Coat lower

blocks with epoxy and pin into position

and set aside to dry.

Dill (or cut) a large hole in center of

fight cowl and gradually enlarge size of

hole (to enable instalation of engine)

and temporarily install engine on mount

Install spinner and backpiate on engine

fand check alignment of nose cow!

(where nose ring fits) and engine posi-

tion. Sand as required to obtain clear-

‘ance and alignment needed for the

1/16" plywood nose ring. Remove spi=

‘ner and engine and epoxy nose ring to

engine cowi.

Using 80 grit (or 120 grit) sandpaper

and sanding block, shape and contour

fuselage as shown on drawing. After fu-

selage fas been shaped. sand with 320

gritto remove heavy scratches, finishing

Off with 400 grit

Wing Buildup and Assembly:

On both wing cores, glue on the

1/8" x 1/2" balsa leading edge and the

1/4" x3/8" balsa traling edge using

Wilhold Glue. When glue has cried,

B

}

eee

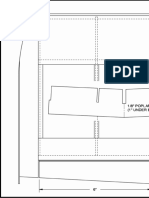

ema ee Sco By THE REVENGER

ence poeeceand so

feaeee a

sand and shape the leading and trailing

fedges as shown on drawing.

Select 14 sheets of medium to soft

x3" x 36" sheets of balsa (to be

sed for wing sheeting). Sheets are to

‘be edge glued to form a large one piece

ppanel, but prior to joining, the sheets

‘mst be straight. Using a straightedge

‘and X-Acto knife (or razor blade) trim

‘both edges of each sheet to be joined.

elect two chests for the loading edge:

(or center sheet) and draw a centerline

{using a fel tipped pin) down center of

‘each sheet. Note: Both center sheets

must be straight grain and soft balsa to

‘enable wrapping around leading edge of

wing panels. Starting with the center

sheet, join the remaining six sheets

(three on each side) by joining with

‘masking tape (one side only). Turn as-

‘sembly over and one at a time bend

‘each sheet back over tape (using tape

as a hinge) and apply a light bead of

Withold Glue along entire joint. Lay

‘down on a flat Surfabe and wipe oft ex:

cess glue and join with masking tape.

Place the wing core (leading edge) on

the centertine ofthe center sheet. Care-

{ully lay the core down (in a roling mo-

tion) as it sheeting wing, Attrailing edge,

draw a line on sheeting approximately

1/4" fom trailing edge. Repeat the pre

ing for the other side of sheeting,

Remove this area trom sheeting and

glue onto opposite end of sheeting form:

ing a wedge shape sheet.

When glue has dried, remove mask-

ing tape. Lay wing sheeting on a smoot

lat eurface and sand both sidee with a

lat sanding block and 320 grt paper.

| won't go into any details on instaling

the landing gear in this wring, The draw

ing should be clear as to how | recom

mend installing Southern FIC retract. I

you plan on using a different gear, |

ould recommend that you follow tno

instructions. For further assistance |

uid like to refer you to an article

wrote in the July 1977 issue of RCM on

Using 320-400 grit sandpaper and flat

sanding block, lightly sand both cores to

remove ridges made by the wire cutter.

Carefully vacuum both cores to remove

he styrofoam dust, and also vacuum

both balsa wing sheets to remove balsa

ust

Using warm water and a sponge, wet

the center sheet of balsa sheeting pane!

wet on side opposite that being glued to

Core). Note: Be sure to test your wing

core to make sure it is compatable

with 3-M-77 before spraying entire

core and sheeting. Turn panoloverand

spray entire panel with 3-M-77 adh

spray (caution -- do not use 3-M

Set sheeting aside while you pr

core. Spray one side of wing core (using

3.M-77) starting at trailing edge and

orking towards leading edge. Be sure

to spray partially around leading edge

(towards other side) to insure @ good

ond. Allow core to dry a few minutes (at

least untithe panels become very tacky)

before continuing, Lay sheeting on 4

smooth flat surface. Take wing core and

place leading edge on centerline of wing

sheeting. Very carefully (with roling ac

ion) pull on sheeting and press core

down on sheeting. Spray opposite side

of core and allow to dry as before. Pick

tre assembly anc carefully press

core down paling on sheeting as cores

ing joined. Place covered core on

craps core was cut from and place on a

iat surface and weight down with books

or similar weights, Let stand for at least

48 hours. Repeat preceeding steps for

When both wings have dried, trim

sheeting flush with tips, wing root and

trailing edge. Sand wing roots to angle

shown on drawing. Coat spar and wing

root(s) with S-minute epoxy and join

wings together. Hold tightly until epoxy

sats up. Tamporanly glue wing tip blocks

fon each wing using a small dab of

S-minule epoxy on each tip. When

epoxy has dried, sand each top to size

and shape shown on drawing, Carefully

break away each tip from wing and ho

low each tip as shown on drawing and

reinstall on wing using Devcon 5-Minute

se

ao

Peery coy

Fuselage sides

Sco

aman

Poa

Frewall

ened

fore

ee

ert

Wing cores

ated

irae

Very

rr

Aierons * ry

f er

read Cr

Cai

ery

osteo

Eopiret aT

eC

Pees

riers

ea

eee

eae)

pores

perry

peor)

mur)

asta

pretend

oerines

errr

eeraies

Pero)

mare

eure

on balsa

ay

eat

ket)

pre)

are

corey

Besta

ry

cy

See ee

‘Cut wing fixed taling edge (houses alleron torque tubes)

arefully locate the wheel well. and

gear Dox and cul out as required Tor

ance. Wheel wellcan be lined using

1/16" balsa or thin cardboard. | woul.

recommend sealing the gear box with

Devcon 5-Minule Epoxy

Aileron Torque Tube:

Cut two pieces of 1/8” ID brass tubing

672" long. Cut two pieces of 1/6" OD

welding rod (or equivalent) approx:

mately 972" long, Bend one end approx

imately 3/4” long. Lubricate rod_with

vaseline and inser into brass tube. Bend

of opposite end of wire 90° to first

bend. Fabricate the other assembly

keeping in mind the bend for the serve

inkage must be opposite of th

completed

Cut a piece from each balsa aileron

stock 7%" long (for aileron linkage!

using an X-Acto gauge (or equivalent)

cut a groove approximately 5132” deep

and §/22" wide down centerline. Place

the right hand and left hand alleron

torque tube in groove and bond wit Hot

Stuf (use caution when applying so as

otto get Hot Stutf on inner fod). Cut a

half round opening on upper surface to

allow movement of torque rod. Fitcheck

‘on wing and cut a corresponding open-

ing in wing. When satisfied with ft, apply

a bead of Devcon &-Minute Epoxy to

edge and bond into place on trailing

edge of wing. Cut two pieces of 1/8" ID

prass tubing 1%4" long, Flatten 3/4” of

feach tube and dil a series of 1/16

diameter holes for linkage. Install tubing

on torque tubes and sweat solder into

place.

Determine location tor alleron servo

‘as shown on drawing and remove this

area from wing. Line with 1/16" balsa

and epony ito lace install hardwood

Astrip of" reinforcing tape should be

installed at the wing center section. |

profer to use. pre-doped pinked edge

grade “A” surface tape that is used on

fabric aircraft (which can be found at

most airports) but fibregalss cloth will

serve the same purpose. If you use the

‘grade "A" tape, bond onto wing with nit

Fate dope. It you use glass tape, bond

conto wing with epoxy.

Horizontal Stabilizer:

‘On both stab cores, glue on the

1/4" x 3/8” trailing edge and 3/8” x 3/8

leading eage using Wiinold Glue, When

glue has dried, carefully (using a sand:

ing block and 320 grt sandpaper) sand

the leading edge to match the airtoil as

‘shown on drawing,

‘Select eight sheets of 1/16" x3"x 12"

soft balsa, Cut four forward shaets the

shape of stab leading edge. Place

pieces on a flat surface and tape the

forward and rear sheets together using

‘masking tape. Turn assembles over (4),

using tape as a hinge and apply a bead

‘of Wilhold Glue to each seam. Wipe off

‘excess glue and join with strips of mask-

ing tape,

‘When assemblies are dry, remove

masking tape. Place on a smooth fat

Surface and lightly sand both ides of

teach sheet. Lightly brush all dust off the

cores and sheeting. Vacuum both the

‘cores and sheets to remove any traces

ff sanding dust. Spray one side of each

‘core and sheeting with 3-M-77 paying

particular attention to the leading edge

fand trailing edge. When adhesive be-

‘comes tacky (approximately 3 to 5 min-

tutes) carefully join both the balsa sheet

ing and the core. Repeat the above for

the other side. Place in core scraps and

press down for 24 to 48 hours. After

Femoving cores, sand the tip ends and

‘epoxy the tips in place. When dry. sand

teach stab half and contour leading edge

and tips as shown on drawing,

‘Sand stab roots to the angle shown on

drawing anc bond together using De-

‘yoon 5Minute Epowy.

Using 2” wide fiberglass tape or pre-

doped arade “A” fabric, apply tape to

‘center section of stab. Ret. Wing section

for specific taping instructions.

Elevators:

Elevators are constructed trom

1/2 x 2" elevator stock that is available

inmost hobby shops. Cut elevator stock

tosize and shape as shown on drawing

Draw a line (using felt tip pen) down

leading edge of both elevators. Using a

plane (or sanding paper) chamfer lead

Ing edge to line previously drawn.

Fin:

Using 9/8” x 3" (medium hard) balsa,

cout three pisces of balsa the size and

shape as Shown on drawing. Assemble

the three pieces on a flat building sur-

face and join one side with strips of

masking tape. Turn assembly over and

bend at seams using tape as a hinge.

‘Apply 2 bead of Wilhold Give to each

Joint. Wipe off excess glue and tape

Joints with slips of masking tape.When

dry, remove tape and sand entire as-

‘sembly to airfoil shape shown on draw-

ing. Note: Do not sand dorsal fin at this,

time, (will be sanded after assembly),

Rudder:

Fabricate rudder rom 1/4” hardbalsa.

Fuudder ie made from two pieces ofbalea

and a sub rudder made from 1/4)

plywood. Cut pieces from balsa and

plywood as shown on drawing. Glue

pieces together using Wilhold Glue.

‘Tape seams and set aside to dry.

Ventral Fin:

Ventral finis a straight cut triangle fab-

rieated from 3/8” sheet, cut to size and

shape as shown on drawing.

‘Assembly:

‘Twill assume that all components of

the Revenger have been shaped and

sanded to where they are ready for

either finishing with a pre-finished cover-

ing (such as Solarfim, MonoKote, etc.)

‘of Coverte (or what have you). Ae with

‘any competition pattern plane, whether

bbeing flown in competition or for just

plain sport flying, weight is a critical fac:

for. With te Revenger, tokeepweightto

a minimum, | would recommend cover-

ing the wing with MonoKote and painting

the fusolage with K & B Super-Poxy, but

again this is up to the builder.

‘Cut two wing hold-down blocks (from

112° hard maple) 3/4” x 1”. Using De-

‘yoon 5-Minute Epoxy, epoxy into posi-

tion in the location shown on drawing,

Note: Apply epoxy on 1” width andinstal

‘lush with wing opening. Position wing

on fuselage and measure distance from

each tip to fuselage. When wing is cen-

tered on fuselage, draw a line on wing

(next to fuselage) using a felt tip pen (to

aid in aligning wing). Cut two 1/4” dow-

‘ls approximately 1/2" long. Grind or

‘sand each dowel to a sharp point. Insert

dowels (point out) into holes in forward

bulkhead, Place wing on fuselage and

align fuselage with lines previously

drawn, Carefully side wing forward until

wing contacts the two dowels (indenting

Jeading edge of wing), then remove

wing. Cut two 1/4” dowels 4” long. Grind

for sang each dowel toa point, and force

into leading edge of wing unt it stops

against front spar. Remove each dowel

land pour a small amount of Devcon

‘5-Minute Epoxy in holes. Coat dowels

‘with epoxy and insert dowels in holes.

Wipe off excess epoxy and set aside to

oy.

Mark location (on side of fuselage) of

wing hold-down blocks. Install wing on

fuselage and mark location (on wing) for

wing hoid-down bolts. Drill a small pilot

hole (for each bolt) through wing into

hhold-down biocks. Remove wing from

fuselage and verily pilot holes are ap:

proximately in center of blocks. Drill and

tap hold-down blocks using a #7 dri

and 1/4" x20 tap. Drill holes in wing

Using @ 3/8" dril. Coat inner surface with

Devcon 5-Minute Epoxy and insert on

Aled Hobbies Wing Bolt bushing (or

fequivalont) Trim bushing flush with sur-

face of wing. Fasten wing to fuselage

using Rocket City oval head wing hold-

down bolts (part #35).

Position norizontal stabilizer on fuse-

lage and align with fuselage, and wing.

riorto installing, permanently check for

decallage angie using a Robart Inci-

dence Meter. Note: If you do not have a

Robart Incidence Meter, | would highly

recommend buying or borrowing one, as

this check s very important. As with any

airplane, the angle of incidence and de-

caallage can mean the difference be-

‘ween 2 good flying plane and one that

just fies!

‘After you are satisfied with the ftofthe

stab, install stab permanently using De-

‘yeon 5-Minute Epoxy. Install the two

Upper pieces (that was previously cut of

during fuselage buildup using S-mnute

epoxy. Fil in voids with scrap balsa

Using epoxy. Install fn. and dorsal fin

Using epoxy. Use caution to make sure

fins straight and vertical Build up re-

maining area using scrap balsa, main-

taining contour of fuselage. ll that re

maine to complete tne emmpenage 1s

the files. You may have your own ideas

on bulding filets, But lke to share

‘mine with you Ihave Wind many differ

ent types of materials but have found

“Sears Filled Epoxy’ cement mixed with

‘micro-balloons to make the smoothest,

Strongest and lightest. Mx up equal

parts ofthe catalyst and resin, and mixin

& large amount of micro-baloons. Blend

toa smooth consistency. Using atonaue

depressor or coffee sire, start bulding

Up the fillet. Fairin filet using your finger

(wet with water). Keep smoothing filet

Until satisiog wth contour. Set aside to

ory

‘On upper surface of wing, cover upper

surface (in fuselage area) with Saran

Wrap (or equivalent) held down with

masking tape. Reinstall wing.on tuse-

{age and tighten bots securely. Mix upa

large amount of Sig Epoxolta and build

Upwing filets. Note:The Sig Epoxoite is.

very strong and durable and builds

Deautiful and large filets. The filets

should be approxmately 3/4” wide at

traling edge and star approximately

43/8” above wing, tapering to asmall filet

at leading ede

Fillets may be contoured using your

finger dipped in water and smoothed out

to where very litle sanding is required

‘Allow io ary overnight prior separating

wing rom fuselage. Use K & B Finishing

Resin, mix with miro-balloons to form

the wing lower filet (use cardboard as @

mold).

The next step brings up a lat of con-

troversy regarding the canopy and what

to do witht | personally ike a dotallod

‘cockpit with pilot and instrument panel

‘The Wing Manufacturing canopy (with

insert lends itself to this typeof insalla-

tion. One of the most atvactve 's one

With the inser (or interior) done in a

irinkio finish. Krinkle finish s available in

an aorosol spray can in many diferent

‘colors. | personaly ike the black Krink

Bond insert on fuselage in position

‘shown on drawing using contact co-

ment. Gut and tim the canopy tot con-

tour of fuselage and install using Hot

Stuf (sparing) around outer edge of

‘canopy. Using 1/4” masking tape, mask

‘off canopy approximately 3/6" above

ledge of canopy. Mix up a batch of Sears

Filled Epoxy Gement and alot of micro-

balloons. Bild filet around canopy from

fuselage to slightly past edge of masking

tape. By Keeping your finger wet (with

water) you can mold the filet to where

very litle sanding is required, When filet

to page 122

a

2 neurle Power At

le Motor Prices

Fox 40 RC Bashing Motor #24000 45.95

Fox 45 RC Bushing Motor #23500 51.95

Comenion! Miter 950203 7.95

ned Mute some 19.95

Shan Etension 0412 (") 2-50

po0m3 (") 2.80

Motor Mount — #50406 ao

Improvements For 1978

+ Resyled Exterior wth ured insand glass Alyinum piston fr Fox 48- Both models

ead casting fish, fun smooter and easier on plugs than

+ Ste! Thrust Washer Standard Equipment older models.

1 Smater Carb Venturi Diameter for im- « Improved head configuration impr

proved carb suction power cutput

«Lighter weight menaitepstonforFox40- New conventional muffr avaliable

Great Motors And Fox Backup Services Too!

+ Tre new Fox Conventional utr bos on «Pra rash nsutance- ay Fox Motor wi

erect ane ts most omer moat wan~ "be compe re uf, no mat Now Sad

out ateation. thecras ata cost not exceeding 6% ofa

a youtly Lanier ype ARE, the Foxs5 wil new motor

handle them easy with he hte enine «Free Adie - All hone cs fr hep are

theatplaneblacssbeterand he smoot —_* ven top prontyn ou shop. Mr Fox es

ew 45s ts easier on he sbuctur than fo take "woube cae” wherever he cn.

any 60s therwse one of our sence spect s

+ Nyou ty te gly stceswost ck but up aimey eae.

Sport type model he new Fox 40 or 45

Bushing motor ofr you a degre of per: i

tomas eiztysngsenonytnten FOX Manufacturing

be a plecant surprise. Try t= yu wil ike Fox Model Airplane Products

i 5405 Towson

+ $350,000 stockot pas to draw rom-99% fort Smith, Aanses 72901

‘tour phone orersare ied re same dy hone 801-046-1856

CUSTOM CRAFT PRODUC TS

If FLORGATE RD, FARMINGDALE, N.Y, 11735

PRU CLs

a eam acl)

SRE E UI ese

Evers a a

DUCTED FAN DESIGN

from page 61/58

162 will also be olferedby Midwest since

the .40 model is such an excellent per

former

Corrections to typoaraphical mistakes

in Parts land lof Ducted Fan Design are

provided below:

Part |; October 1977

P.B2

213

3.30 > (28

Te vanaf BoP Do (22 |

7g = Fan Efficiency

Pas

5 >

ia)

Which hows that, inthe thrust equation,

thrust really depends only on exitdiame-

ter, De. The more complicated expres-

sion is used because the designer is

generally most interested in tan diame.

ter, Do, and the tailpipe contraction ft

lowing the fan (De /Do)

Part Il; November 1977

None

REVENGER

trom page 57

has dried (approximately 8 hours), apply

another strip of 1/4” masking tape on top

(f the previously applied tape. This wil

provide @ guide to cut the upper surface

bfilet. Using caution, cut through epoxy

Using the tape as a guide. Remove bot

strips of tape from canopy. Trim as re-

Quited to provide a emooth edge. Apply

another strip of tape around canopy nex

to the filet edge, then mask off entire

canopy. Fillet can now be sanded to <

feather edge without scratching the

canopy.

to page 12

: Mae aoa O (=)

se ptehagne a Te

G82

Ett ey as

MODEL Se Ee

FUEL s

ett

Corre) Te

orn Pe)

Pere SPR)

Ped $17.00

een) $24.00

aceon)

RANDY

nn Vey po eee ee

AERONAUTICS

Sees

CSRS oe Cee

KRAFT ORANGE COUNTY

DISTRIBUTORS

&

WARRANTY SERVICE

FOR ALL KRAFT R.C. SYSTEMS

Warranty Repalrs On

Expert Repair & Factory Parts

peer ae eee Contact: George Killeen

Repairs On K.S.€., K.G.L. act George Kile

‘And P.C.S. Systems Repair & Distributor Rep,

2817 E. Lincoln Ave. * Anaheim, Ca. 92806» Phone: 630-5061

ery Mite's

SWEET

SIXTEEN

Onder Direct — Kans. add 3%

Totally Complete Kit (except

FLY THE BIGGEST

FOR ONLY

$97.50

res

ak

eric

ALREADY THE PROVEN SUPER TRAINER

124

REVENGER

from page 12248

Rigging:

Rigging is academic forthe seasoned

builder but for those who are relatively

now, Il briefly tell you how I install my

radio gear

First of all, install the servos in the

fuselage as far aft in the fuselage as

Possible. Install the servos or servo tray

on pine rails 38” square. Mount rails

across fuselage and secure in place

lising Deveon 5-Minute Epoxy. Cut four

reinforcement strips from 1/8" balsa in

the shape of a “U" and epoxy on fu

lage sides at end of each rail

‘Assuming you are using pneumatic

actuated landing gear, | ecommend you

install the fil valve and storage tank at

this time, Be sure the ends of the tubing

arenew (cut back ifusing used tubing) 10

prevent line leakage or possibly blowing

off, Experience has proven that one time

moved. I you epoxy the tank to a couple

Of pieces of hard or firm foam, the tank

can be readily removed by breaking

away the foam

Fabricate pushrods trom 5/16” square

spruce. The pushrod for the elevator(s)

should be a dual output to onable eleva:

tors to be adjusted independently

Balancing:

| recommend that the radio be in-

stalled in the relative location shown on

the drawing, The CG should fall within

the forward and aft range as shown on

drawing, if not, use Allied Hobbies

stick-on weights, (or equivalent) to bring

t into the above mentioned range. Do

not fly until the CG is correct.

'Next check the lateral balance of the

wing aircraft. Place the airplane on a flat

table. Using an X-Acto knife, slowly pick

the nose up (using knife edge on end of

spinner) and observe which way (i any)

the wing falls. Install finishing nails

nailed in end of light wing until balance is

Flying

‘Almost every construction article Ive

ever read makes the statement If ths is

your first high performance airplane, got

Someone with experience to help you on

your fist fight.” | must admit this infor

mation ig sound advice,

Prior to the first fight, check controls,

for ease of movement and freedom of

binding. Make sure the ailerons are rig

ged propery, |e. right aileron is up and

left aileron is down when right aileron is

commanded. Check elevator, aileron

land rudder throws to verly they are as

called out on drawing

Triming:

Trimming canbe a very long and tring

process. Ifthe plane has been bul true,

the trimming wil be relatively easy.

to page 128

|

(704) 523-5481

at

2.0. Ror 15028

Pressey Park Chariot, W.C. 28210

‘Mall Orders add $150 fr Handling

In Cont. USA for Cheek or M.

For €.0.0. 946 ational $3.00

(Wot Applicable to Drum Fuel)

1. Shle — has 6% Sle Tar

FUEL - FUEL - FUEL

We Got It!!!

RED-MAX

util) FUEL Clean Bumng

0°!

Proven Reliailty

me GaGa

io $520 $2850 $165.00 F08

woe $770 S180 517500708,

ie $7 S50 Sieoo0Fo8

Be $120 $700 S20 00 FOB

vc, Ud By Rata oompens

WIGR "Cer nate Sane Pree Pane,

Sg Om FOB Cote, NC

OUR MOST POPULAR

FOB

$110.00

10%

RED-MAX

30. GAL.

DRUM

NOW - NEW FORMULA

ive

Ea

ise

4

5208.00 708

We can brew to your

call and let us kno

ectcations — just

ly what you Uke.

“SPRING FUEL SPECIAL”

100 GALLONS in

‘one gallon bottles

‘$450.00 delivered in USA

RED MAX 10%

Kits - Parts - Custom Parts

Plus full line of other RIC Kits.

Accessories and fuels.

All at reasonable mail order prices.

Send For Complete List

4 HELL-BOY *

Now In Stock

GOLDCOAST R/C

Box 328

North Bend, Oregon 97459

128

REVENGER

from page 124148,

Before going into the fine trimming

let's check to seo if the throws are

adequate or too much. After take-o

trim the plane fr straight and level fight

and check your trims on your transmit

ter ifthe tims are approaching fulthrow

to one side oF the other, land the plane

land adjust the throws accordingly

Til assume the plane is now trimmed

for straight and level fight, now let's

check CG location, with airplane fying

straight and level, introduce a rea-

sonably sharp bank to the right or lett

and then neutralize the controls (with

hans of andwatch the pane. sould

continue in the bank for some distance

without gaining or losing alttude. I the

plane climbs. i's tailheavy.andifitdives

roses altude, it's nose heavy

Now lets check for aileron poston:

with plane fying straight and level, pul

Up vertically and neutralize controls

{hands off). ‘Observe ifthe plane con

tinuas straight vertically or pitches for:

ward (asin an outside loop) or back (as

invan inside foop). ithe plane pitches

back, raise both allerons until plane

cimbs staight vera plane pitches

forward, lower both alorone unt plane

climbs vertically up.

‘Now let's check for yaw. Fly the plane

straight at you, pull back on the eleva-

tors, as plane cimbs vertoaly, observe

{plane yaws right or left. Re-rim plane

Untiplane climbs vertically withoutusing

rider

‘Next we'll check for proper thrust

angle. Again with plane fying straight

and level, chop throtle, plane should

continue salght and tevelfor a hunred

feetorsoIiplane climbs, the engine has

too much down thrust. Ifthe nose crops,

the plane doesn’ have enough down

thus.

Now let's take a look atthe loops. Fist

at all, how much elevator do you need?

‘The most important thing is to have

‘enough to make the size of loop you

want without running out at the bottom.

Pill up into a nice big inside loop using

elevator only. Watch the wing tps, does

it track through or does it all out with a

wing tip low? Repeat this several times

land obverve which wing tip is low. Add

weightto the light wing patie atatime

Unt the plane wil track true

‘As with any plane, each has its own

tugnt characterstes, The Hevenger is

no diferent, thas is own. {have found

the preceding to work well for me, but

youmighthave some ideas of your own

Ihave found the Revenger tobe atrue

and honest airplane that not only is en

Joyabe to build and fy, but aso atracts

alot of atterton at contests, especially

with the competion. Good luck with

your new Revenger. a

PRECISION

TOOLS

Touch

Made of finest

SET OF 6—Packed

in see thru bor

ADE SIZES:

7/32. 5/32

Stock No.

32 $4.95

5 DIFFERENT TiPs

INTERCHANGEABLE

Firmly tal by nein

chucking handle

Heat tated Yor ard

3/32 & 1/8. Also Prt

ips type & layout sribe

‘Stock No.425 $3.95

PRO-TOW

Releasable tow hook.

Has snap lock feature for easy

tow line hook up.

Will work on

servo.

Will work on loads to 40 pounds

plus.

Features a locking system thats

‘non critical. Mounting holes will

allow plus or minus 1/2" adjust

ment.

ator oF spoiler

Order Stock No. 72

Price $4.98 ea.

186d.25¢ for post. & handling

ROCKET CITY SPECIALTIES

103 Wholesale Ave., NE

Huntavll, AL 35811

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Joker 25Document1 pageJoker 25pccdtkNo ratings yet

- Akro 804mDocument1 pageAkro 804mpccdtkNo ratings yet

- Little MediatorDocument1 pageLittle MediatorpccdtkNo ratings yet

- F22b Fokker v.23Document15 pagesF22b Fokker v.23pccdtkNo ratings yet

- Magic 20Document1 pageMagic 20pccdtkNo ratings yet

- Super AlulahDocument1 pageSuper AlulahpccdtkNo ratings yet

- Arrow 60 160cm WsDocument1 pageArrow 60 160cm WspccdtkNo ratings yet

- ClergetDocument25 pagesClergetScott CarterNo ratings yet

- Iar-80 Semff Combat Plane FullDocument1 pageIar-80 Semff Combat Plane FullpccdtkNo ratings yet

- Alula 2Document1 pageAlula 2pccdtkNo ratings yet

- Balsa Babyshark Front Mod ManualDocument1 pageBalsa Babyshark Front Mod ManualpccdtkNo ratings yet

- Super Pacer PlansDocument17 pagesSuper Pacer PlanspccdtkNo ratings yet

- 3D Delta: Radius Leading Edge of Wing, Top and BottomDocument1 page3D Delta: Radius Leading Edge of Wing, Top and BottompccdtkNo ratings yet

- AirfoilDocument1 pageAirfoilpccdtkNo ratings yet

- AlulaDocument1 pageAlulapccdtkNo ratings yet

- Aries XJW-120 ArticlesDocument12 pagesAries XJW-120 ArticlespccdtkNo ratings yet

- X-41 Deltastorm FullDocument1 pageX-41 Deltastorm FullpccdtkNo ratings yet

- 10 Super Pacer Plan Material List Traced PartsDocument9 pages10 Super Pacer Plan Material List Traced PartspccdtkNo ratings yet

- 64 OMEGA Plano 1Document1 page64 OMEGA Plano 1pccdtkNo ratings yet

- X-41 Deltastorm Extra WideDocument1 pageX-41 Deltastorm Extra WidepccdtkNo ratings yet

- 3D KamikazeDocument1 page3D KamikazepccdtkNo ratings yet

- 64 OMEGA Plano2Document1 page64 OMEGA Plano2pccdtkNo ratings yet

- Sly Plan With PartsDocument2 pagesSly Plan With PartspccdtkNo ratings yet

- Electro-Glide Plan and ArticleDocument5 pagesElectro-Glide Plan and ArticlepccdtkNo ratings yet

- Electraglide III Plan and ArticleDocument6 pagesElectraglide III Plan and ArticlepccdtkNo ratings yet

- Terej 2 Plan and ArticleDocument3 pagesTerej 2 Plan and ArticlepccdtkNo ratings yet

- Thermal ChargerDocument28 pagesThermal ChargerpccdtkNo ratings yet

- Wasp W-21 Plan and ArticleDocument7 pagesWasp W-21 Plan and ArticlepccdtkNo ratings yet

- Two Much IV Plan and ArticleDocument9 pagesTwo Much IV Plan and ArticlepccdtkNo ratings yet