Professional Documents

Culture Documents

Mantenimiento PDF

Uploaded by

Alexander LuisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mantenimiento PDF

Uploaded by

Alexander LuisCopyright:

Available Formats

S A F E T Y A D V I S O R

Technology No. 4

Engine

Operations

Do you know what to do if the engine burps and

coughs during the runup, or runs rough during cruise?

In-depth systems knowledge can give you the tools

needed to assess the engines actual condition.

Aircraft engines are extremely reliable when properly

cared for, and can deliver years of safe flight. That being

said, not all pilots know as much as they should about

the proper care and maintenance of engines, or that

The engine is

mechanical failure accounts for 15 to 20 percent of all

accidents. Knowing how to manage a powerplant helps

you fly more safely and can minimize the cost of flying.

Whether the aircraft you fly is equipped with a sophisti-

the beating

cated engine monitoring system or not, a basic under-

standing of how engines work is required to correctly

diagnose potential engine problems. For all engines air

is drawn into the engine, mixes with fuel, burns at a

controlled rate and expands, pushing on a piston that

heart of

turns the crankshaft and propeller.

Most piston aircraft engines develop power with four

cycles, or strokes, of each piston inside a cylinder. The

four cycles are intake, compression, power, and exhaust.

the airplane. Cockpit engine controls, usually the throttle, prop con-

trol and mixture, allow a pilot to extract the most effi-

cient performance from the engine and ensure safe and

reliable operation.

FADEC

Full authority digital engine control (FADEC) incorpo-

rates the throttle, mixture, and prop control into one

pilot controlled lever. The FADEC system provides

many benefits, including increased efficiency, lower

fuel burn and troubleshooting tools for diagnosing

engine problems.

Engine Operations Pg. 1

The Basics

Intake Valve: Opens to allow the Exhaust Valve: Opens to allow hot

fuel-air mixture into the cylinder. exhaust gasses to leave the cylinder.

Spark plugs: Provide the electric Cylinders: The controlled burn of the

spark that ignites the fuel-air mixture. fuel-air mixture occurs in the cylinders.

Pistons: The controlled burn forces

Rings: Piston rings encircle the piston

the piston to move within the cylinder.

and seal the combustion chamber.

Crankshaft: Attaches to the connecting

rods and the propeller. The motion of Connecting Rods:

the pistons turns the crankshaft. Attach the pistons to the crankshaft.

Throttle = Air and Fuel source. In your car, if the electrical charging system fails

The throttle is an air valve, opened all the way for full or the ignition is turned off, your engine stops running.

power and closed almost completely at idle. In a carbu- In an airplane, the electrical system can be turned off

reted engine, as the throttle is opened further and further, with the master switch and the magneto-equipped

more and more fuel is automatically drawn through the engine will continue running.

carburetor. The fuel and air combine in the carburetor

throat and are sucked into the cylinder via intake tubes. Each magneto is independent, firing its own set of

spark plugs. If one magneto fails, the aircraft will still fly

In a fuel-injected engine, the pilot still controls the volume safely on the other magneto and its set of spark plugs.

of air entering the engine by moving the throttle, but the

fuel is delivered separately into each cylinder, mixing with

the air inside the cylinders. Fuel-injected engines are more Getting Started

efficient and develop more power than the same-size car- Most piston engines will start with the mixture rich,

bureted engine because of more precise fuel delivery. throttle advanced slightly, and fuel pump On. Still, start-

ing an airplane engine isnt automatic, as it is in a car.

With fuel-injected engines, there is no worry about

carb ice, because there is no carburetor in which the Carbureted Engine

fuel-air mixture can vaporize and cool. The main oper- On carbureted engines, cold starts are arguably the

ational difference with fuel-injected engines is that they most difficult and provide a test of the pilots under-

can be harder to start, especially when hot. standing of aircraft systems.

To start a cold engine, add extra fuel by priming. This

Magnetos = Spark puts fuel directly into one or more cylinders (via the

Aircraft engines have two spark plugs in each cylinder, to intake manifold). Refer to the aircrafts POH (pilots

improve combustion efficiency and to provide a backup operating handbook) for the correct priming technique.

in case one ignition system fails. Feeding the spark plugs Do not pump the throttle, as this will simply force raw

are two magnetos, each of which is self-contained and fuel (which doesnt vaporize as easily in cold weather)

creates the spark, all without an external electrical into the intake system, possibly causing an engine fire.

Engine Operations Pg. 2

1. Intake: As the piston 2. Compression: The

moves down, creating piston moves up, com-

3

more space and lower pressing the fuel-air mix-

pressure inside the cylin- ture into a small space at

4

der, the fuel-air mixture is the top of the cylinder.

sucked into the cylinder.

3. Power: The spark plug 4. Exhaust: After the

fires, igniting the com- rapidly expanding hot

pressed fuel-air mixture. gasses finish moving the

Expanding hot gasses piston, the exhaust valve

force the piston down, opens, allowing the hot

turning the crankshaft gasses to escape. Before

and propeller. the exhaust valve closes,

the intake valve opens

and the piston moves

down, and a fresh fuel-air

charge enters the cylinder.

Part of the fresh charges

job is to help push out

remaining exhaust gas.

The cycle continues.

Signs of Trouble temperature of the mixture to drop below freezing, ice

Engine running a little rough? Notice a slight rpm drop? may form and block the venturi. The blockage can

Whether in flight or on the ground, you may have car- cause a reduction in rpm or even make the engine

buretor ice. stop running.

The symptoms of carb ice are subtle. Pilots who have To prevent or melt the ice, use the carburetor heat.

experienced it say its much easier to recognize the Since warm air is less dense than cold air, effectively

symptoms of carb ice the second time around. enriching the mixture, you will see an rpm drop when

the carburetor heat is turned On. The rpm drop will

Some airplanes are more susceptible to carb ice than continue until the carburetor heat is turned Off.

others; it depends on the design of the engines air-

intake systems. Carb ice is caused by the cooling of the The first time you experience carb ice can be startling,

fuel-air mixture as it passes through the carburetor since application of full carb heat as recommended

throat or venturi. As the fuel-air mixture gains speed in will likely cause brief coughing and choking in the

the venturi, its temperature drops. If there is enough engine as the ice in the carburetor melts and is ingest-

moisture in the air and the acceleration causes the ed by the engine.

Engine Operations Pg. 3

If the outside temperature is below 20 degrees F, the Preheats

engine may need a preheat, both to aid in starting and Different metals in the engine will shrink at varying

prevent engine damage. During a cold start try to avoid rates and parts clearances can become extremely

draining the battery unnecessarily. Leave avionics, elec- small below 20 degrees F. Oil loses some ability to

tric flaps, and aircraft lighting, which all rely on and use lubricate at extremely low temperatures. Starting an

battery power, off until the engine is running. engine in these conditions can cause metal parts to

rub together and cause extreme wear in a very short

Engine Fires time. Preheating helps prevent this wear and also

Excess priming causes large amounts of fuel to pool in helps fuel vaporize easier for quick starting.

the carburetor intake. This fuel can ignite if the There are many types of preheaters available. Hot-air

engine backfires. Most POHs recommend that you preheaters pump hot air into the engine compartment.

keep trying to start the engine after the fire is noticed. Electric preheaters provide electric heat directly to the

This puts the fire out by pulling the flames back into oil pan. New systems that combine cylinder and oil

the engine. If you get the engine started let it run for pan electric preheaters are fast and help prevent dam-

a few minutes before shutting down and examining age by heating the cylinders as well as the oil.

the damage. If the engine does not start turn off the

master and ignition switches as well as the fuel selec-

tor and mixture, abandon the aircraft, and look for a

fire extinguisher or call the fire department.

Fuel-Injected Engine

For some fuel-injected engines that are already hot,

engage the starter and allow the engine to turn while

keeping the mixture at idle cutoff. When the engine Preheater

catches, advance the mixture. If the engine is over-

primed because the mixture was advanced too soon, it When using a hot-air preheater, plug the air intakes on

may be flooded. The starting procedure for a flooded either side of the propeller, and place a blanket over the

engine is similar to the hot-engine start, but the throttle cowling to contain the heated air. Preheat for 15 to 20

may need to be opened (advanced or pushed in) in minutes to ensure even heating for the entire engine.

order to add air that will help purge the excess fuel.

Read the Pilot Operating Handbook (POH) How to Make Your Engine Live Longer

Different engine manufactures have different proce- First and foremost try to fly your engine at least an hour

dures for hot starts. Be sure to reference the POH a week. Far more engines rust out than wear out. They

for the aircraft you fly. rust because the oil drains off the cylinder walls and the

moisture in the air then reacts with the iron in the engine.

Fuel-injected engines use electric primers or the elec- The rust creates roughness, which increases wear.

tric fuel pump to spray fuel into the cylinders for prim- Piston aircraft engines are made mostly of steel and alu-

ing. In some airplanes, the amount of primer fuel is minum, which expand and contract at different rates,

adjusted by advancing the mixture and the throttle. Its depending on temperature. When flying at varying alti-

easy to flood the engine, and then the flooded-start tudes and from one climatic zone to another, temperature

procedure will be needed. changes can be extreme. By keeping large engine temper-

ature changes over a short period of time to a minimum,

A typical flooded (or hot-start procedure) for a fuel-inject- and within prescribed limits, the safety, reliability and

ed engine begins with the mixture at idle cutoff. Next, longevity of the engine are significantly enhanced.

move the throttle to the open position (full power). Check

the POH to see if the fuel pump needs to be On or Off. For example, avoiding rapid descents at idle power near

While cranking the engine, get ready to reverse the throt- your destination airport will help avoid shock cooling,

tle and mixture controls as the engine starts (quickly retard which is the too-rapid cooling of hot engine metals.

the throttle and slowly richen the mixture). It takes some Shock cooling causes stress that can lead to cylinder head

practice to gracefully hot-start a fuel-injected engine. cracks. To avoid this, begin descent planning farther out

Engine Operations Pg. 4

and descend at a slower rate with a low-cruise power set- the amount of air flowing over the engine, leave

ting. Good descent planning takes a little work, but your them open even after leveling off until temperatures

engine and passengers will thank you. This may take stabilize then close them as appropriate. On a hot

some negotiation with ATC, if IFR, or you may have to day, climb at higher airspeeds and lower pitch atti-

increase drag such as lowering the landing gear or flaps to tudes to keep engine temperatures in the green arc.

keep airspeed and resultant engine cooling in check.

Using Gauges for More Precise

Pilots have two ways to control engine temperatures:

fuel flow (throttle and mixture) and airflow (pitch atti-

Temperature Control

tude and cowl flaps, if your airplane is so equipped). All airplanes have an oil temperature gauge, but,

depending on the aircraft, two other sources of engine

Fuel flow is a double-edged sword. As more fuel is pro- temperature information may be available:

vided to the engine (provided the mixture is set cor-

rectly), the more power is developed, which naturally A cylinder head temperature (CHT) gauge measures

means more heat. But extra fuel is also used as a cool- just that, the temperature at the cylinder head. CHT is

ing agent, which is one reason why mixtures are usually a critical indicator of engine health, especially on high-

set full rich for takeoff and initial climb. power turbocharged engines.

CHT can be adjusted with cowl flaps, if equipped, and

by adjusting fuel and airflow. On hot days, you may

need to enrich the mixture, open cowl flaps, lower the

nose, or even reduce power to keep CHTs within lim-

its. Always consult the POH to learn how to manage

high engine temperatures.

Good descent planning helps avoid shock cooling. Pilot control of engine temperatures

To control engine temperature adjust:

Cooling airflow and fuel-air mixture affect engine tem- Cowl flaps (if equipped)

perature, as well. The pilots job is to keep engine tem- Mixture

peratures at settings that maximize engine life. For Attitude

example, an engine with a redline oil temperature of Power setting

250 degrees F will last much longer running at 180

degrees than 240 degrees. Keeping an engine too cool An exhaust gas tempera-

in flight can also be harmful; if oil cannot get hot ture (EGT) gauge measures

enough to burn off water that has condensed in it, inter- the temperature as the

nal engine rust can occur. Engine experts suggest an oil exhaust leaves the cylin-

temperature of around 180 degrees or a little higher as der. If the engine is tur-

a happy medium for typical air-cooled GA engines. bocharged, the gases will

be measured just before

Oils primary function is entering the turbocharger,

to lubricate engine parts, by a turbine inlet tempera-

Single-probe EGT gauge

but with the help of air ture (TIT) gauge.

flowing through the cowl-

ing and the oil cooler it As the mixture is leaned by pulling the mixture control

also transfers heat out of aft, the amount of fuel mixing with the air entering the

the engine. There are two engine is reduced. The fuel-air mixture thus becomes

options for controlling oil leaner because less fuel mixes with the same amount of

cooling: Increase airflow air. When leaning the mixture, the EGT gauge shows the

through the engine and Oil temperature gauge temperature climbing until the cylinder being measured

oil cooler by lowering the reaches its peak temperature (peak EGT), indicating rela-

aircrafts pitch attitude or reducing power, if possi- tively efficient fuel-air combustion. Refer to the POH for

ble. If the airplane has cowl flaps, which increase correct mixture settings at various power settings.

Engine Operations Pg. 5

When the mixture control is moved forward from peak Time between overhaul (TBO) is a recommendation by

EGT, the mixture is said to be rich of peak (ROP) the engine manufacturers to indicate the expected

because more fuel is being added to the fuel-air mix- engine overhaul interval. TBO is given in both hours on

ture. Moving the mixture control aft from the peak EGT the engine and calendar time. Many Lycoming engines,

position removes fuel from the mixture and thus the for example, have an hourly TBO of 2,000 hours and a

mixture is lean of peak (LOP). In both cases, actual EGT calendar TBO of 12 years. If an engine has only 300

is lower than peak EGT. hours but 20 years have passed since its last overhaul, it

is likely in need of an overhaul.

Pilots should lean appropriately anytime they are

below 75% power, regardless of altitude. These intervals are based on extensive engine testing

and years of field experience. Remember that your air-

For most airplanes, correct mixture settings are detailed plane engine operates at much higher power settings for

in the POH. As you gain experience with leaning, youll much longer than a typical car engine. Regular service

find that it saves gallons of fuel and helps the engine run and overhauls are essential to ensure that your engine

better. Follow the POH mixture settings carefully; this is delivers reliable, safe power every time you fly.

not the time to experiment on your expensive engine.

When you and your mechanic decide that its time for

Setting the Mixture major engine service, there are three possibilities:

When you move the mix-

ture control, you are 1. Top Overhaul. Top overhaul refers to repair or

adjusting the ratio of fuel replacement of an engines top end, the cylinders. The

to air delivered to the term top overhaul is not formally defined, however,

engine. Two typical mix- and you may see it used to cover everything from minor

ture settings are best cylinder repairs to complete replacement of all cylinders.

power and best econo-

my. Best power provides Typically a top overhaul includes the removal of one or

the most speed for a specific power setting. At a best more of the engines cylinders, and a rebuild of cylin-

economy mixture setting, you are trading a little ders with existing or replacement parts. It also can

speed for some fuel savings. Best economy results in include the reconditioning of the cylinder walls, inspec-

the most miles per gallon at a specific power setting. tion of the pistons, valve operating mechanism, valve

guides and seats, and replacing piston and piston rings.

Major Surgery (Overhauls) A top overhauled engine carries forward all previous

An annual or 100-hour inspection is done to the entire time in the engine logbook, whereas a factory rebuilt, or

aircraft. The inspection must be signed off in the air- factory remanufactured engine, goes back to zero time.

craft logbook, which means that the inspection applies

to everything on the aircraft. However, it is often helpful Airplanes that seldom fly can develop engine problems

to have the inspection signed off by the mechanic in the due to corrosion, and these are frequently good candi-

engine logbook as well, so that inspection status is dates for some cylinder work between TBO intervals. A

easy to determine. No matter which logbook is used, top overhaul does not extend or reset the TBO interval.

there are specific requirements for the inspection of the

engine. These requirements can be found in the federal 2. Engine Overhaul. An overhaul involves complete dis-

aviation regulations (FARs) and in the manufacturers assembly, cleaning, and renewal or replacement of all

maintenance manuals. engine parts and components. Overhauls reset the TBO

clock back to zero, although the engine continues to

Typical items that a mechanic examines include: engine carry its previous total time.

compression (for leakage inside the cylinders), oil system

(leakage and metal in the oil filter), fuel system (clean fil- Overhaul quality varies, depending on the standards of

ters and leaks, which could cause fires), and exhaust sys- the mechanic or shop performing the overhaul. The min-

tem (leaks could allow carbon monoxide into the cabin imum requirements for an overhaul are to ensure that

or cause fires). parts meet overhaul limits (dimensions), which are not as

Engine Operations Pg. 6

stringent as new part limits. Differences in overhaul pric- Is it possible for the carburetor to ice up during

ing usually reflect the limits used during the overhaul. ground operations?

Yes. Under certain conditions carb icing can occur while

3. Remanufacture. Engine manufacturers are autho- taxiing. If you dont leave the carb heat on for at least 10

rized by the FAA to overhaul an engine to new part lim- seconds during the runup check, the ice might not melt

its using many new parts and to call this engine a factory and could cause lower power output during takeoff and

remanufactured engine. The advantage of this overhaul, possibly engine failure. If the carburetor is iced up during

in addition to all the new parts, is that it comes with a runup, carb heat application will result in an initial small

new, zero-time logbook. The engines previous flight rpm drop, then a rise higher than the runup rpm.

time is no longer relevant.

How do I know if the engine is developing full power

Common Engine Problems (and solutions) during takeoff?

The engine must reach the specified static rpm range

What do I do if the engine runs rough during runup? (before releasing the brakes) at full rpm. Check the POH

Engine roughness while checking the magnetos during for these numbers. If the aircraft cant reach this rpm

runup could indicate a fouled spark plug or other ignition range on the ground there may be a problem with the

system problem. Accelerate the engine to runup rpm and tachometer indication or something wrong with the

lean the mixture until the engine runs rough. Let the engine engine. Possible problems include a worn propeller

run for about 30 seconds. Enrich the mixture then check (fixed-pitch), improperly set propeller governor (con-

the mags again. If this doesnt clear the roughness, have stant-speed), mis-timed magnetos, fouled spark plugs,

the ignition system checked by a mechanic before flying. clogged fuel injector nozzle, or a blocked muffler.

What if the mag drop is more than 200 rpm? What is a hot magneto and how can I troubleshoot this?

A larger than normal mag drop is not as critical as a rough A hot magneto is a magneto that cant be turned off. If

mag. A smooth drop up to 200 rpm is fine. A drop greater someone manually turns the prop with a hot mag, it could

than 200 rpm could indicate a mag-timing problem that begin turning even though the magneto switch is in the

should be checked. A mis-timed magneto can rob some Off position. There are two times you can easily check for

power from the engine and also cause engine damage. a hot mag: during runup and at engine shutdown. If an

rpm drop is not noticed during the mag check on runup,

Can I fly if the carb heat drop is 300 rpm or more you may have a hot mag. During engine shutdown, check

during runup? for a hot mag by running the engine at idle and turning

No. A large carb heat drop during runup, more than the the ignition to Off. If the engine continues running with

typical 50 to 100 rpm, is caused by an exhaust leak inside the ignition in the Off position, the mag is hot.

the shroud where hot air is diverted to the carburetor. All

exhaust leaks are dangerous and must be fixed, because Can I take off if the oil temperature isnt in the green?

firewall air leaks can allow exhaust fumes and possibly Yes, but check to make sure the engine picks up

carbon monoxide from the engine compartment into the smoothly as the throttle is advanced. Throttle advance-

cockpit. A leak can also direct hot exhaust onto vulnera- ment should be smooth and take several seconds from

ble components such as fuel lines and possibly cause a idle to full power. Cold oil doesnt lubricate as well, and

fire in the engine compartment. damage could occur if the oil isnt warm enough. While

engines can be started at very low temperatures, it is

generally safer to preheat below 20 degrees F. Preheat-

ing improves oil lubrication, the fuel vaporizes for easier

starting, and engine parts expand uniformly.

Why is my engine so hard to start, especially when

hot, and what can I do about it?

There are many causes of hard starting, including a

weak battery, fouled spark plugs, worn magnetos, worn

impulse couplings, fuel vapor lock, and improper tech-

nique. Fuel-injected engines can be difficult to start

Engine Operations Pg. 7

when the engine is hot because fuel can turn into vapor on the ground helps prevent spark plug fouling. Just

in fuel lines near the hot engine. With air bubbles/vapor dont forget to enrich the mixture before takeoff.

in the fuel lines the engine will not start or will not run

after starting. One hot-start technique includes a Is it okay to lean below 3,000 feet?

method of purging the fuel lines to eliminate fuel vapor. Yes, you can lean the engine at any altitude. There is no

Follow POH instructions for hot starting, but be sure reason not to lean during cruise; it saves gas and is bet-

that the mechanical items mentioned above arent mak- ter for the engine. While you will still see recommenda-

ing the problem worse. If all else fails, ask your mechan- tions not to lean until reaching 3,000 or 5,000 feet, this

ic for his favorite hot start technique. advice is to keep pilots from forgetting to enrich the

mixture before descending, and it is not related to any

My engine runs very rough while its starting then potential engine problems.

smooths out as it warms up. Is there something wrong?

Yes, there is a strong likelihood that you have a stuck I learned what to do if the engine fails, but what do I

valve. The valve sticks inside the cylinder head when do if there is just a partial power loss?

the engine is cold and the metal parts are contracted. As This is an important question. Instructors rarely teach par-

the engine warms up, the valve eventually loosens and tial power loss, but it is more likely to occur than a com-

the engine runs smoother. A stuck valve is dangerous plete engine failure. Circumstances that can cause a partial

because the sticking can occur during normal operations power loss vary, but the key is to determine if there is

and it can cause catastrophic engine failure. Have this enough power to remain aloft to troubleshoot the problem.

symptom checked thoroughly before flying. If the engine is losing power steadily, youll need to find a

place to land quickly. An example might be a gradual loss

Can I hurt my engine by leaning too much? of oil pressure; the end result is still total engine failure. A

Yes, at higher power settings you can hurt the engine by forced landing is in the very near future. A fuel line or muf-

over leaning. Follow the POH leaning instructions to fler blockage could cause a partial power failure but leave

avoid damage. There is one time that over leaning isnt enough power to stay level. In this case, you may be able

a problem and that is when running at just above idle to nurse the airplane to a nearby airport, but this will

power during ground operations. During a long taxi or a depend on terrain and weather. The bottom line for partial

lengthy wait for takeoff clearance, you can lean the power is to treat it like a full engine failure. Troubleshoot as

engine aggressively without the risk of damage. Leaning needed but plan to land at the nearest suitable airport.

Safe Pilots. Safe Skies.

Copyright 2005, AOPA Air Safety Foundation

421 Aviation Way, Frederick, Maryland 21701 Phone: 800/638-3101

Internet: www.asf.org

Publisher: Bruce Landsberg

Writer: Matt Thurber Editor: Leisha Bell

Special thanks to:

Teledyne Continental Motors Cessna Lycoming SA25-10/05

Engine Operations Pg. 8

You might also like

- Lab ReportDocument9 pagesLab ReportJojenNo ratings yet

- Basic Piston Engine PrinciplesDocument8 pagesBasic Piston Engine PrinciplesAhmad Dayan Ma'shumNo ratings yet

- Private Pilot Ground School: Piston Engine FundamentalsDocument85 pagesPrivate Pilot Ground School: Piston Engine FundamentalsMuhammad Yaumul FajriNo ratings yet

- Powerplant Lab (Reaction Paper)Document3 pagesPowerplant Lab (Reaction Paper)sherina vinoyaNo ratings yet

- Aircraft Systems Chapter Covers Primary ComponentsDocument42 pagesAircraft Systems Chapter Covers Primary ComponentsChasel LinNo ratings yet

- 4 STROKE PETROL ENGINE ArsalDocument5 pages4 STROKE PETROL ENGINE ArsalMuhammad Arslan AfzalNo ratings yet

- IC EnginesDocument52 pagesIC EnginesSethu ramNo ratings yet

- MTC WorkshopDocument19 pagesMTC WorkshopSmart GopiNo ratings yet

- Me 56Document9 pagesMe 56RhizhailNo ratings yet

- Gasoline Engine Performance TestDocument35 pagesGasoline Engine Performance TestaljhonNo ratings yet

- Aircraft Systems: PowerplantDocument4 pagesAircraft Systems: PowerplantHanz EspirituNo ratings yet

- Procedimiento de HOT StartDocument5 pagesProcedimiento de HOT StartmartinNo ratings yet

- Agemp TheoryDocument5 pagesAgemp TheoryAniket DhoneNo ratings yet

- Four Stroke Diesel Engine Lab ReportDocument3 pagesFour Stroke Diesel Engine Lab ReportAsad UllahNo ratings yet

- SAL Institute of Technology and Engineering ResearchDocument19 pagesSAL Institute of Technology and Engineering ResearchDhruvGuptaNo ratings yet

- Automotive Interview and ReviewerDocument20 pagesAutomotive Interview and ReviewerMichael Radan90% (10)

- Assignment 4Document11 pagesAssignment 4levitranNo ratings yet

- Component Parts of Internal Combustion EnginesDocument26 pagesComponent Parts of Internal Combustion EnginesPeter AshrafNo ratings yet

- Spark Plug: Technical Training ManualDocument37 pagesSpark Plug: Technical Training ManualJeremiah UgbokoNo ratings yet

- Fuel PumpDocument9 pagesFuel Pumpstevenotienoodhiambo141100% (1)

- Physical Principles Related To Operation Basic Parts of The Engine Assembly Four Stroke Operating TheoryDocument37 pagesPhysical Principles Related To Operation Basic Parts of The Engine Assembly Four Stroke Operating TheoryVikram PuriNo ratings yet

- Technical Training ManualDocument40 pagesTechnical Training ManualAkashdeep100% (1)

- Engine and Motor (4 Stroke Engine and 2 Stroke Engine)Document27 pagesEngine and Motor (4 Stroke Engine and 2 Stroke Engine)Bias PanduNo ratings yet

- BPS 104 Otto CycleDocument2 pagesBPS 104 Otto CycleHtet Shine LinnNo ratings yet

- Internal Combustion Engine Parts GuideDocument3 pagesInternal Combustion Engine Parts GuideAngelika Pangilinan100% (1)

- AGR 318 Lec 3 - Engine Cons & CompDocument42 pagesAGR 318 Lec 3 - Engine Cons & CompHaikal SapurataNo ratings yet

- CH 06 - Aircraft Systems PDFDocument40 pagesCH 06 - Aircraft Systems PDFFahmi PrayogiNo ratings yet

- CH 06 - Aircraft SystemsDocument40 pagesCH 06 - Aircraft SystemsFahmi Prayogi100% (1)

- Internal Combustion Engine ProcessesDocument80 pagesInternal Combustion Engine Processeschoongwenkang100% (1)

- INTERNAL COMBUSTION ENGINE CLASSIFICATIONSDocument6 pagesINTERNAL COMBUSTION ENGINE CLASSIFICATIONSCamia Empleo100% (1)

- How Small Engines Work: 4-Stroke vs 2-StrokeDocument67 pagesHow Small Engines Work: 4-Stroke vs 2-StrokeRajkumar GuptaNo ratings yet

- Basic Engine Parts ExplainedDocument5 pagesBasic Engine Parts ExplainedhammadNo ratings yet

- lec02Document16 pageslec02cattykaif1No ratings yet

- pp1 Lab 10Document4 pagespp1 Lab 10Mian KaleemNo ratings yet

- Manual of Four Cylinder Four Stroke Petrol Engine Test RigDocument16 pagesManual of Four Cylinder Four Stroke Petrol Engine Test RigDhruv Patel100% (1)

- Engine Basics: Structure and Working PrincipleDocument25 pagesEngine Basics: Structure and Working PrincipleAdi WidiantoNo ratings yet

- Thermodynamics Lab ReportDocument49 pagesThermodynamics Lab Reportjawad60% (5)

- Chapter 1 Introduction: 1.1 Ic EngineDocument54 pagesChapter 1 Introduction: 1.1 Ic Engineavanish SinghNo ratings yet

- Technical Powerplant Questions and AnswersDocument6 pagesTechnical Powerplant Questions and AnswerskomilaNo ratings yet

- Labreport 2Document5 pagesLabreport 2Ezaz ul haqNo ratings yet

- Parts and Working of Four Stroke Petrol EngineDocument6 pagesParts and Working of Four Stroke Petrol EngineHafeez AliNo ratings yet

- Systems and Components of AutomobileDocument34 pagesSystems and Components of AutomobileSuperUserNo ratings yet

- 4-Stroke Petrol Engine ExperimentDocument7 pages4-Stroke Petrol Engine ExperimentMasoud doski100% (1)

- Gasoline Engine Performance TestDocument7 pagesGasoline Engine Performance TestaljhonNo ratings yet

- QB 114462Document15 pagesQB 114462vasanthavananNo ratings yet

- Reciprocating Engines Section BDocument45 pagesReciprocating Engines Section BJuly TadeNo ratings yet

- Asset KowladgeDocument9 pagesAsset KowladgeamrionaNo ratings yet

- Types and components of heat enginesDocument11 pagesTypes and components of heat enginesjoshua jan allawanNo ratings yet

- Fuel SystemDocument16 pagesFuel SystemGovea HeduNo ratings yet

- Types of EngineDocument11 pagesTypes of Enginejoshua jan allawanNo ratings yet

- City and Guilds 9210 Level 6 Module - Unit 128 Applied Thermodynamics OUTCOME 4 - TUTORIAL 3Document13 pagesCity and Guilds 9210 Level 6 Module - Unit 128 Applied Thermodynamics OUTCOME 4 - TUTORIAL 3khumisoNo ratings yet

- Powerplant QuestionsDocument29 pagesPowerplant QuestionsJDany Rincon RojasNo ratings yet

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDocument9 pagesPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalNo ratings yet

- IC TheoryDocument17 pagesIC TheorySam RogersNo ratings yet

- By-Utkarsh Kushwah UpesDocument50 pagesBy-Utkarsh Kushwah UpesJunior michael100% (1)

- Module 1 Engines BasicsDocument50 pagesModule 1 Engines Basicszaidkadiri9No ratings yet

- Power Unit: Personal Water CraftDocument34 pagesPower Unit: Personal Water Craftahmed2014100% (1)

- Unit-II Two Mark QuestionsDocument7 pagesUnit-II Two Mark QuestionshariharanbookNo ratings yet

- Module 5 Fuel and Fuel System 1 MergedDocument101 pagesModule 5 Fuel and Fuel System 1 MergedClarisse AlcaydeNo ratings yet

- Nitric OxideDocument20 pagesNitric OxideGanesh V GaonkarNo ratings yet

- MR23002 D Part Submission Warrant PSWDocument1 pageMR23002 D Part Submission Warrant PSWRafik FafikNo ratings yet

- Junayed - 19 39800 1Document11 pagesJunayed - 19 39800 1gurujeeNo ratings yet

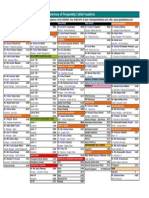

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocument1 pageDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoNo ratings yet

- English Financial Assistance ApplicationDocument4 pagesEnglish Financial Assistance ApplicationAlyssa JenningsNo ratings yet

- TA-Ingles IX - UAPDocument10 pagesTA-Ingles IX - UAPmanuel brennerNo ratings yet

- Fuck Your LawnDocument86 pagesFuck Your Lawnhuneebee100% (1)

- Aphasia PDFDocument4 pagesAphasia PDFRehab Wahsh100% (1)

- Right To HealthDocument9 pagesRight To HealthPriya SharmaNo ratings yet

- Analisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiDocument10 pagesAnalisis Dampak Reklamasi Teluk Banten Terhadap Kondisi Lingkungan Dan Sosial EkonomiSYIFA ABIYU SAGITA 08211840000099No ratings yet

- FB77 Fish HatcheriesDocument6 pagesFB77 Fish HatcheriesFlorida Fish and Wildlife Conservation CommissionNo ratings yet

- Puskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListDocument98 pagesPuskesmas Dua Puluh Tiga Ilir Publishes Vaccination Ticket ListLaboratorium PKM 23 IlirNo ratings yet

- Completed Manuscript 1 5Document52 pagesCompleted Manuscript 1 5SAMANTHA LACABANo ratings yet

- AAR Maintenance 001Document3 pagesAAR Maintenance 001prakash reddyNo ratings yet

- NCMA 217 - Newborn Assessment Ma'am JhalDocument5 pagesNCMA 217 - Newborn Assessment Ma'am JhalMariah Blez BognotNo ratings yet

- SM RSJ 420 800Document77 pagesSM RSJ 420 800elshan_asgarovNo ratings yet

- Mabuhay Wedding Package2006Document3 pagesMabuhay Wedding Package2006Darwin Dionisio ClementeNo ratings yet

- Abstract - Tropen Tag 2011 PDFDocument634 pagesAbstract - Tropen Tag 2011 PDFzmoghesNo ratings yet

- Chapter 3 - CT&VT - Part 1Document63 pagesChapter 3 - CT&VT - Part 1zhafran100% (1)

- Construction and Operation 1. Air Conditioning Control PanelDocument18 pagesConstruction and Operation 1. Air Conditioning Control PanelRoma KuzmychNo ratings yet

- ME JBP 70A Pen Dissolved Oxygen Meter PDFDocument1 pageME JBP 70A Pen Dissolved Oxygen Meter PDFpiknikmonsterNo ratings yet

- Copia de Tissue Response To Dental CariesDocument7 pagesCopia de Tissue Response To Dental Cariesjorefe12No ratings yet

- HR Policy For Hotel IndustriesDocument5 pagesHR Policy For Hotel IndustriesHR Forum India78% (9)

- SVIMS-No Que-2Document1 pageSVIMS-No Que-2LikhithaReddy100% (1)

- Bs8161 - Chemistry Laboratory Syllabus: Course ObjectivesDocument47 pagesBs8161 - Chemistry Laboratory Syllabus: Course ObjectiveslevisNo ratings yet

- FINALS REVIEWER ENVI ENGG Topic 1Document8 pagesFINALS REVIEWER ENVI ENGG Topic 1As ReNo ratings yet

- Ucg200 12Document3 pagesUcg200 12ArielNo ratings yet

- Interface GSKTMTRLBRCHR A4 Int 4webDocument7 pagesInterface GSKTMTRLBRCHR A4 Int 4webROGERIO GUILHERME DE OLIVEIRA MARQUESNo ratings yet

- DR - Hawary Revision TableDocument3 pagesDR - Hawary Revision TableAseel ALshareefNo ratings yet

- Ignition System Spark Test DiagnosisDocument24 pagesIgnition System Spark Test DiagnosisMohamed l'Amine75% (4)