Professional Documents

Culture Documents

TIG and Oxy-Acetylene Welding

Uploaded by

LymePark0 ratings0% found this document useful (0 votes)

16 views1 page04

Original Title

04

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document04

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageTIG and Oxy-Acetylene Welding

Uploaded by

LymePark04

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Hardfacing Alloys

TIG and Oxy-Acetylene Welding

TIG and Oxy-Acetylene Welding

In TIG (Tungsten Inert Gas), also known as Gas Tungsten Welding rods used for TIG welding are also used for

Arc Welding (GTAW), an arc is drawn between a non- hardfacing with the oxy-acetylene welding process.

consumable tungsten electrode and the workpiece. The With the correct operation, a very low level of iron dilution

electrode, the arc, and the weld-pool are protected from can be achieved in the overlay.

the atmosphere with an inert shielding gas. The hardfacing

material is in the form of a rod. Advantages of the TIG Rod is available in these standard diameters:

process include simple manual operation and good control 2,6mm (3/32") (special order)

of the welding arc. The process can also be mechanised, in 3,2mm (1/8")

which case a manipulator is used to move the workpiece in

4,0mm (5/32")

relation to the welding torch and the hardfacing rod or wire.

5,0mm (3/16")

6,4mm (1/4")

8,0mm (5/16")

Rod inventory held in North America is typically in 36"

lengths. In other countries (also available to special order

in the USA and Canada), rod is available in these standard

Shielding Gas Nozzle Tungsten Electrode lengths:

350mm (14")

500mm (20")

9701000mm (38 40" or 3.2 3.3')

Contact Tube 1,2m (approx. 4' or 47")

1,5m (approx. 5' or 60")

2m (approx. 6.5')

Shielding Gas 4m (approx. 13')

Rod inventory held in North America is typically packaged in

Arc 20 lb bundles. Elsewhere, rod is packaged in 10 kg (22 lb)

bundles for the shorter lengths, while longer lengths or larger

Consumable diameters may be bundled in 25 kg (55 lb) bundles. Rod can

also be bundled to customer requirement.

4 kennametal.com/stellite

You might also like

- Catalogue BK FinalDocument16 pagesCatalogue BK Finalole kitiviNo ratings yet

- CATALOGO AnclajesDocument12 pagesCATALOGO AnclajessergioNo ratings yet

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyFrom EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyRating: 5 out of 5 stars5/5 (4)

- LEFIN Scaffolding SystemDocument13 pagesLEFIN Scaffolding SystemLefin SteelNo ratings yet

- EIG Product Catalogue CABLESDocument36 pagesEIG Product Catalogue CABLESjudarangocaNo ratings yet

- Wireprod Chainlink SpecificationsDocument4 pagesWireprod Chainlink Specificationsole kitiviNo ratings yet

- RASCOflex Americas SpecSheetDocument4 pagesRASCOflex Americas SpecSheetJohn loboNo ratings yet

- Slingshot Elastics TestDocument12 pagesSlingshot Elastics TestErnie SheattlerNo ratings yet

- Gripple HVACCatalogDocument12 pagesGripple HVACCatalogPrawin KumarNo ratings yet

- Wire Ropes and DrillingDocument32 pagesWire Ropes and DrillingNed VasicNo ratings yet

- Armature Air Gap Gauge PDFDocument1 pageArmature Air Gap Gauge PDFmansoor hussainNo ratings yet

- Armature Air Gap GaugeDocument1 pageArmature Air Gap GaugeArnold StevenNo ratings yet

- Chatillon GF10 Wire Terminal Test FixtureDocument1 pageChatillon GF10 Wire Terminal Test FixturePASCAL LANDSHEERENo ratings yet

- Rascoflex - Flexible Hose SprinklerDocument4 pagesRascoflex - Flexible Hose SprinklerPaulina CabreraNo ratings yet

- 9 MiningDocument12 pages9 MiningSuelen BarbosaNo ratings yet

- Fiberglass Soil NailsDocument2 pagesFiberglass Soil NailsPrakashNo ratings yet

- F-32A, F-32Ax and F-32R Materials ListDocument6 pagesF-32A, F-32Ax and F-32R Materials ListFilipe RosaNo ratings yet

- Celebrating Over 30 Years of Manufacturing: "The Reamer People", Turbo and FabricationDocument19 pagesCelebrating Over 30 Years of Manufacturing: "The Reamer People", Turbo and Fabricationmk35100% (1)

- SG 318 2 PDFDocument13 pagesSG 318 2 PDFChris GodwinNo ratings yet

- Chainman Catalogue EditDocument57 pagesChainman Catalogue EditRem LaraziNo ratings yet

- Welding Processe1Document3 pagesWelding Processe1Balaji SrinivasanNo ratings yet

- Tubes and ClampsDocument9 pagesTubes and Clampsvsdfsd258No ratings yet

- Cable Glands: Options: OverviewDocument1 pageCable Glands: Options: OverviewAmit Kumar SinghNo ratings yet

- Gagemaker Thread MeasurementDocument22 pagesGagemaker Thread MeasurementAhmed Elsayed100% (1)

- 21-DC - HWDP - NM - FlexDocument33 pages21-DC - HWDP - NM - FlexnjileoNo ratings yet

- 6.8 MM Remington SPC PDFDocument5 pages6.8 MM Remington SPC PDFGerman RodriguezNo ratings yet

- Splice SteelDocument28 pagesSplice SteelNacho Tomé100% (1)

- Wire Rope GuideDocument28 pagesWire Rope Guideajz677100% (1)

- LUMBERLOK Timber Connectors & BOWMAC Structural BracketsDocument30 pagesLUMBERLOK Timber Connectors & BOWMAC Structural BracketsDinh Nam NguyenNo ratings yet

- Drilling Accessories and Use of Double Tube Core Barrels: Drilling Training Centre Gurukul 26/11/2014Document104 pagesDrilling Accessories and Use of Double Tube Core Barrels: Drilling Training Centre Gurukul 26/11/2014mukesh ojha100% (1)

- PELACABLES JONARD - Round Cable Strip & Ring Tools - CST-1900 CST-4000 - 4Document1 pagePELACABLES JONARD - Round Cable Strip & Ring Tools - CST-1900 CST-4000 - 4Euby SanchezNo ratings yet

- Sucker Rods Brochure 851 06Document12 pagesSucker Rods Brochure 851 06Ronald LlerenaNo ratings yet

- MTO Spreader Bar - BP TangguhDocument6 pagesMTO Spreader Bar - BP TangguhokahertaberNo ratings yet

- Flints Wire Rope and TerminationsDocument10 pagesFlints Wire Rope and TerminationsNick FieldNo ratings yet

- Draglineguide9 10Document16 pagesDraglineguide9 10Antonio RibeiroNo ratings yet

- Wind Turbine Foundation SystemsDocument8 pagesWind Turbine Foundation SystemsPrakashNo ratings yet

- ASTM A 499 - 89 Standard Specs For Steel BArs and Shapes, CArbon Rolled From T Rails PDFDocument4 pagesASTM A 499 - 89 Standard Specs For Steel BArs and Shapes, CArbon Rolled From T Rails PDFpolarisNo ratings yet

- Threads and FastenersDocument89 pagesThreads and Fastenerstheleovn50% (2)

- Catalogo TafaDocument8 pagesCatalogo TafaLucy CubillosNo ratings yet

- UDN500 - Chap-5 - Sleeper TypesDocument23 pagesUDN500 - Chap-5 - Sleeper Typesmuhammad aliNo ratings yet

- Product Line - Pulleys and Bushings 1.08Document27 pagesProduct Line - Pulleys and Bushings 1.08Gustavo Mario Torres SantamaríaNo ratings yet

- API 660 Vs TEMADocument5 pagesAPI 660 Vs TEMAALONSO GOMEZNo ratings yet

- 7.62×25mm TokarevDocument5 pages7.62×25mm TokarevJack JackNo ratings yet

- MTO Rigging Equipment (Sling & Shackles) - BP Tangguh ProjectDocument4 pagesMTO Rigging Equipment (Sling & Shackles) - BP Tangguh ProjectokahertaberNo ratings yet

- Anchor Rods: ManufacturingDocument22 pagesAnchor Rods: Manufacturingjacopap100% (1)

- Tap & Ground WireDocument8 pagesTap & Ground WireRangga Pratama PutraNo ratings yet

- Eagle 1640STDocument1 pageEagle 1640STMan NamNo ratings yet

- V3 ECM Tutorial v1.0Document40 pagesV3 ECM Tutorial v1.0lmkkilo3No ratings yet

- Mig WireDocument10 pagesMig WireSathishkumar SrinivasanNo ratings yet

- 65 1104Document6 pages65 1104suresh putNo ratings yet

- Chromium-Iron Sealing Alloys With 18 or 28 Percent Chromium: Standard Specification ForDocument7 pagesChromium-Iron Sealing Alloys With 18 or 28 Percent Chromium: Standard Specification Forruben carcamoNo ratings yet

- Anchor Bolt Specification (Ksi 6.895 Mpa) : Astm F1554Document7 pagesAnchor Bolt Specification (Ksi 6.895 Mpa) : Astm F1554pbp2956No ratings yet

- Standard Wire RopeDocument5 pagesStandard Wire RopeAhmadreza AminianNo ratings yet

- Cabillas Convencionales PDFDocument12 pagesCabillas Convencionales PDFgenesisNo ratings yet

- Shell and Tube Heat Exchangers (API 660 vsTEMA)Document3 pagesShell and Tube Heat Exchangers (API 660 vsTEMA)Aravind MadhuNo ratings yet

- AA Trays and Racks - BakDocument6 pagesAA Trays and Racks - BakBryan BautistaNo ratings yet

- Appleton Cajas GRSSDocument1 pageAppleton Cajas GRSSArq. Giovanni LopezNo ratings yet

- Manual RJ45 AmpDocument20 pagesManual RJ45 AmpMauroNo ratings yet

- Extract Page 22Document1 pageExtract Page 22LymeParkNo ratings yet

- Global Water Market: Current Environment Supports GrowthDocument1 pageGlobal Water Market: Current Environment Supports GrowthLymeParkNo ratings yet

- Extract Page 26Document1 pageExtract Page 26LymeParkNo ratings yet

- Extract Page 23Document1 pageExtract Page 23LymeParkNo ratings yet

- Each Year, An Estimated 5 Million Deaths Worldwide Are Caused by Contaminated WaterDocument1 pageEach Year, An Estimated 5 Million Deaths Worldwide Are Caused by Contaminated WaterLymeParkNo ratings yet

- Extract Page 17Document1 pageExtract Page 17LymeParkNo ratings yet

- Extract Page 25Document1 pageExtract Page 25LymeParkNo ratings yet

- Growing Levels of Contaminants and Micropollutants Have Prompted The Need For More Stringent Monitoring of Surface and GroundwaterDocument1 pageGrowing Levels of Contaminants and Micropollutants Have Prompted The Need For More Stringent Monitoring of Surface and GroundwaterLymeParkNo ratings yet

- Figure 18: Private Sector Participation in WaterDocument1 pageFigure 18: Private Sector Participation in WaterLymeParkNo ratings yet

- Figure 19: 2014 Global Combined Water and Wastewater TariffsDocument1 pageFigure 19: 2014 Global Combined Water and Wastewater TariffsLymeParkNo ratings yet

- Figure 23: Regional Expected Municipal Water and Wastewater Capital SpendingDocument1 pageFigure 23: Regional Expected Municipal Water and Wastewater Capital SpendingLymeParkNo ratings yet

- Investment Opportunities: 1. Utilities 2. Capital Goods & ChemicalsDocument1 pageInvestment Opportunities: 1. Utilities 2. Capital Goods & ChemicalsLymeParkNo ratings yet

- Hardfacing Alloys: Stellite Alloys Deloro AlloysDocument1 pageHardfacing Alloys: Stellite Alloys Deloro AlloysLymeParkNo ratings yet

- Danfoss Cas Temperature SwitchesDocument16 pagesDanfoss Cas Temperature SwitchesLymeParkNo ratings yet

- Robecosam Josefstrasse 218 8005 Zurich SwitzerlandDocument1 pageRobecosam Josefstrasse 218 8005 Zurich SwitzerlandLymeParkNo ratings yet

- Case Study: The Dragon's Thirst For EnergyDocument1 pageCase Study: The Dragon's Thirst For EnergyLymeParkNo ratings yet

- Figure 30: China's Water-Scarce Provinces and Distribution of Water-Intensive Energy ProductionDocument1 pageFigure 30: China's Water-Scarce Provinces and Distribution of Water-Intensive Energy ProductionLymeParkNo ratings yet

- Extract Page 2Document1 pageExtract Page 2LymeParkNo ratings yet

- Extract Page 3Document1 pageExtract Page 3LymeParkNo ratings yet

- Disclaimer: Carbonneutral® PublicationDocument1 pageDisclaimer: Carbonneutral® PublicationLymeParkNo ratings yet

- Manual Metal Arc Weld DepositionDocument1 pageManual Metal Arc Weld DepositionLymeParkNo ratings yet

- Plasma Transferred Arc (PTA) Weld DepositionDocument1 pagePlasma Transferred Arc (PTA) Weld DepositionLymeParkNo ratings yet

- MIG Weld Deposition, Submerged Arc WeldingDocument1 pageMIG Weld Deposition, Submerged Arc WeldingLymeParkNo ratings yet

- 550 Bar Type I Hydrocarbon Vs Type II TestDocument1 page550 Bar Type I Hydrocarbon Vs Type II TestLymeParkNo ratings yet

- MIG Weld Deposition: Alloy Others UNS Asme/ AWS Hardness (HRC) Nominal Analysis of Undiluted Weld MetalDocument1 pageMIG Weld Deposition: Alloy Others UNS Asme/ AWS Hardness (HRC) Nominal Analysis of Undiluted Weld MetalLymeParkNo ratings yet

- Hardfacing AlloysDocument1 pageHardfacing AlloysLymeParkNo ratings yet

- Hardfacing Alloys: Industries ServedDocument1 pageHardfacing Alloys: Industries ServedLymeParkNo ratings yet

- 550 Bar CO Compressor: R Adams and H Miller 74Document1 page550 Bar CO Compressor: R Adams and H Miller 74LymeParkNo ratings yet

- Recent CO2 Pumps - 2010: Photo Courtesy of Sulzer PumpsDocument1 pageRecent CO2 Pumps - 2010: Photo Courtesy of Sulzer PumpsLymeParkNo ratings yet

- CO Miscible Flooding - EOR: R Adams and H Miller 56Document1 pageCO Miscible Flooding - EOR: R Adams and H Miller 56LymeParkNo ratings yet

- Assignment No. 2: Laureles, Lowel M. AENG 414-1Document6 pagesAssignment No. 2: Laureles, Lowel M. AENG 414-1Lowel LaurelesNo ratings yet

- 5-PAW en ToStudentsDocument21 pages5-PAW en ToStudentsDidiTriAmaliaDiNo ratings yet

- Questions CallisterDocument6 pagesQuestions CallisterKanishk ChaudharyNo ratings yet

- KBIIDocument13 pagesKBIInetozx100% (1)

- 3monograph 0-50Document51 pages3monograph 0-50Scorpian HuntNo ratings yet

- E310-10 Standard Reference Radiographs For Tin Bronze CastingsDocument5 pagesE310-10 Standard Reference Radiographs For Tin Bronze Castingsdiego rodriguezNo ratings yet

- Casting Defects & RemediesDocument40 pagesCasting Defects & RemediesMurali80% (5)

- Rothoblaas - Typ S.certificate Eta - enDocument47 pagesRothoblaas - Typ S.certificate Eta - enAndrei GheorghicaNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- SOR 15-16 GujDocument229 pagesSOR 15-16 Gujmtdby29% (7)

- CBA-Series Scotch-Yoke Pneumatic ActuatorsDocument4 pagesCBA-Series Scotch-Yoke Pneumatic Actuatorsprihartono_diasNo ratings yet

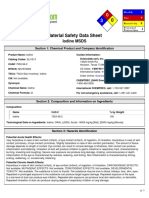

- 5% HCLDocument7 pages5% HCLJoeco Abay-abayNo ratings yet

- Casting DefectsDocument24 pagesCasting DefectsMohamedSabryNo ratings yet

- Field WeldingDocument16 pagesField WeldingIngeniero EstructuralNo ratings yet

- Anodising InformationDocument2 pagesAnodising InformationanbuskpNo ratings yet

- Jindal Steel Power Catálogo PDFDocument17 pagesJindal Steel Power Catálogo PDFikamelyaastutiNo ratings yet

- A591A591MDocument4 pagesA591A591MErnesto SanzNo ratings yet

- Epa 6020aDocument23 pagesEpa 6020acandyNo ratings yet

- Colorimetric Determination of A Copper OreDocument4 pagesColorimetric Determination of A Copper OreOmSilence2651100% (1)

- Manufacturing Process: CastingDocument113 pagesManufacturing Process: CastingOmer AbdullahNo ratings yet

- Chapter 7 SteelDocument44 pagesChapter 7 SteelDdeqz Elina Bueno INo ratings yet

- Design Criteria PDFDocument60 pagesDesign Criteria PDFMohmmad ShaikhNo ratings yet

- Iodine MSDS PDFDocument6 pagesIodine MSDS PDFIsny RamadhanyNo ratings yet

- Cat HY14 3000 Republic, Manatrol - 07 06Document166 pagesCat HY14 3000 Republic, Manatrol - 07 06James PhamNo ratings yet

- Unit 3 BasicsDocument76 pagesUnit 3 BasicsamarparimiNo ratings yet

- A507Document4 pagesA507Shakeel Ahmed100% (1)

- Weldinggradeevent PDFDocument6 pagesWeldinggradeevent PDFnilesh_erusNo ratings yet

- End Mill GrindingDocument4 pagesEnd Mill GrindingtakudomeNo ratings yet

- Steel EquivalentDocument4 pagesSteel EquivalentsudeponnaniNo ratings yet

- 7.8 Cutting Tool Materials CompleteDocument15 pages7.8 Cutting Tool Materials CompleteNikhil Batham67% (6)