Professional Documents

Culture Documents

Engine Limits

Uploaded by

carloselvisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Limits

Uploaded by

carloselvisCopyright:

Available Formats

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

** ON A/C 001-009, 011-050, 101-150, 601-608, 610-710, 712-712, 717-750, 801-850

TASK 71-00-00-860-010-B

Engine Operation Limits, Guidelines and Special Procedures

1. Reason for the Job

This task is for V2500-A5 engines.

2 Job Set-up Information

A. Referenced Information

REFERENCE DESIGNATION

(Ref. 05-51-26-200-001-A). INSPECTION AFTER ENGINE FAILURE

Ref. TSM 77-00-00-810-817 EGT Higher than the Limit on Engine 1 (No Surge or Stall) (Above Idle)

Ref. TSM 77-00-00-810-818 EGT Higher than the Limit on Engine 2 (No Surge or Stall) (Above Idle)

Ref. TSM 77-00-00-810-930 EGT Higher than the Limit on Engine 1 (Idle and below Including Start)

Ref. TSM 77-00-00-810-931 EGT Higher than the Limit on Engine 2 (Idle and below Including Start)

Ref. TSM 77-30-00-810-826 High N1 Vibration Level on Engine 1

Ref. TSM 77-30-00-810-827 High N1 Vibration Level on Engine 2

Ref. TSM 77-30-00-810-828 High N2 Vibration Level on Engine 1

Ref. TSM 77-30-00-810-829 High N2 Vibration Level on Engine 2

Ref. TSM 79-00-00-810-838 Elevated Oil Consumption on Engine 1

Ref. TSM 79-00-00-810-839 Elevated Oil Consumption on Engine 2

Ref. TSM 79-20-00-810-801 No. 4 Bearing-Compartment Scavenge-Valve Stuck Closed or Open

on Engine 1

Ref. TSM 79-20-00-810-802 No. 4 Bearing-Compartment Scavenge-Valve Stuck Closed or Open

on Engine 2

Ref. TSM 79-20-00-810-803 No. 4 Bearing Seal Defective or Scavenge Valve Clogged on Engine 1

Ref. TSM 79-20-00-810-804 No. 4 Bearing Seal Defective or Scavenge Valve Clogged on Engine 2

Ref. TSM 79-20-00-810-809 No. 4 Bearing Scavenge Valve Position Indicator Stuck Closed on En-

gine 1

Ref. TSM 79-20-00-810-810 No. 4 Bearing Scavenge Valve Position Indicator Stuck Closed on En-

gine 2

Ref. TSM 79-20-00-810-811 No. 4 Bearing Scavenge Valve Position Indicator Stuck Open on En-

gine 1

Ref. TSM 79-20-00-810-812 No. 4 Bearing Scavenge Valve Position Indicator Stuck Open on En-

gine 2

Ref. TSM 79-33-00-810-826 Oil Pressure between 60 psi and 80 psi on Engine 1

Ref. TSM 79-33-00-810-827 Oil Pressure between 60 psi and 80 psi on Engine 2

Ref. TSM 79-33-00-810-830 Oil Pressure less than 80 PSI on Engine 1

Ref. TSM 79-33-00-810-831 Oil pressure less than 80 PSI on Engine 2

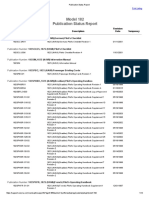

Main Oil Pressure (MOP) Limits during Engine Operation above IDLE SHEET 1

Differential Main Oil Pressure (DMOP) Idle Correction Equation SHEET 1

Rotor Speed Limits SHEET 1

Rotor Speed Limits SHEET 1

Print Date: August 22, 2017 Page 1 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

FOR MINIMUM IDLE OIL PRESSURE CORRECTION

REFER TO THE ENGINE OPERATION LIMITS

ENGINE OIL TEMPERATURE

(MOT) MUST BE 93 C (200 F)

320 OR MORE

300

MAIN OIL PRESSURE (MOP - NO. 4 SCAVENGE PRESSURE ) - PSID

280

260

MAX MOP

240

220

200

180

160

MIN MOP

140

120

100

TOP 9150 to 12800

8000 to 9150 y = 0.04190 12800 to 13600 13600 to 14000 14000 to 16000

80 y = 170 *X -206.02 y = 320 y = -.1125 *X +1850 y = 275

BOTTOM 9200 to 12700 12700 to 13400 13400 to 14250

8000 to 9200 y = 0.021429 y = -0.057143 y = 0.023529 14250 to 16000

y = 115 *X -82.143 *X +915.71 * NH -165.29 y = 170

pwzxxe9471

60

8000 9000 10000 11000 12000 13000 14000 15000 16000 17000

PWV

HIGH ROTOR SPEED (RPM)

N_MM_710000_2_XLN0_01_01

Figure 71(IAE)-00-00-991-15500-13-B / SHEET 1/1 - Main Oil

Pressure (MOP) Limits during Engine Operation above IDLE

** ON A/C 001-009, 011-050, 101-150, 601-608, 610-710, 712-712, 717-750, 801-850

Print Date: August 22, 2017 Page 2 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

Correction Equation:

DMOPm x 105.8108

DMOPc =

0.0367 x NHm - 136 - MOTm x (1.0822E - 4 x NHm - 0.1926)

DMOPc = Delta main oil pressure corrected (psid)

DMOPm = Delta main oil pressure measured (psid)

NH m = High pressure turbine speed measured (rpm)

MOTm = Main oil temperature measured (C)

1. Calculate the DMOP with the correction equation as follows:

A. Use the equation and the measurements from the Pass-off test at Idle conditions

value for NH (rpm). DMOP (psid) and MOT (deg C).

NOTE: The MOT must be higher than 90 deg C.

(3) If the DMOPc is more than or equal to 115 psid, the engine is acceptable.

(4) If the DMOPc is less than 115 psid, refer to Task 79-00-00.

pwzxxe9472

PWV

N_MM_710000_2_ZRN0_01_01

Figure 71(IAE)-00-00-991-23900-13-B / SHEET 1/1 -

Differential Main Oil Pressure (DMOP) Idle Correction Equation

** ON A/C 001-009, 011-050, 101-150, 601-608, 610-710, 712-712, 717-750, 801-850

Print Date: August 22, 2017 Page 3 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

1 BEFORE THE ENGINE IS OPERATED AGAIN:

A. DO A CHECK TO MAKE SURE THE ROTORS ARE FREE.

B. MAKE A VISUAL INSPECTION FOR UNWANTED MATERIAL

IN THE GAS PATH.

C. IF THERE IS NO DAMAGE CONTINUE TO USE THE ENGINE

AFTER YOU CORRECT THE CAUSE OF THE OVERSPEED

AND THE GROUND RUN IS SATISFACTORY.

D. IF THERE IS DAMAGE, DO AN INSPECTION BY THE

INSTRUCTIONS IN THE ENGINE MANUAL.

2 YOU CAN CONTINUE TO USE THE ENGINE FOR 60 HOURS

AFTER YOU DO AN INSPECTION BY THE INSTRUCTIONS

GIVEN IN 1 . YOU CAN CONTINUE TO OPERATE THE ENGINE

FOR MORE THAN 60 HOURS ON THE CONDITION THAT THE

INCIDENT IS EXAMINED BY IAE.

3 YOU MUST REMOVE AND DISASSEMBLE THE ENGINE AND

DO A COMPLETE INSPECTION OF THE RELEVENT

COMPONENTS. REFER TO THE INSTRUCTIONS IN THE

ENGINE MANUAL.

NOTE 1:

NO PROCEDURE IS NECESSARY FOR A TRANSIENT

OVERSPEED IN THIS BAND THAT IS NOT MORE THAN

5 SECONDS.

106

ROTOR SPEED (PERCENT)

104

103% N1 RPM

2

102

101.5% N1 RPM

1

(SEE NOTE 1)

100

REDLINE = 5650 RPM

LOW ROTOR SPEED

N1

ded0006905

N_MM_710000_2_XNN0_01_00

Figure 71(IAE)-00-00-991-15600-13-B / SHEET 1/1 - Rotor Speed Limits

** ON A/C 001-009, 011-050, 101-150, 601-608, 610-710, 712-712, 717-750, 801-850

Print Date: August 22, 2017 Page 4 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

1 BEFORE THE ENGINE IS OPERATED AGAIN:

A. DO A CHECK TO MAKE SURE THE ROTORS ARE FREE.

B. MAKE A VISUAL INSPECTION FOR UNWANTED MATERIAL

IN THE GAS PATH.

C. IF THERE IS NO DAMAGE CONTINUE TO USE THE ENGINE

AFTER YOU CORRECT THE CAUSE OF THE OVERSPEED

AND THE GROUND RUN IS SATISFACTORY.

D. IF THERE IS DAMAGE, DO AN INSPECTION BY THE

INSTRUCTIONS IN THE ENGINE MANUAL.

2 YOU CAN CONTINUE TO USE THE ENGINE FOR 60 HOURS

AFTER YOU DO AN INSPECTION BY THE INSTRUCTIONS

GIVEN IN 1 . YOU CAN CONTINUE TO OPERATE THE ENGINE

FOR MORE THAN 60 HOURS ON THE CONDITION THAT THE

INCIDENT IS EXAMINED BY IAE.

3 YOU MUST REMOVE AND DISASSEMBLE THE ENGINE AND

DO A COMPLETE INSPECTION OF THE RELEVENT

COMPONENTS. REFER TO THE INSTRUCTIONS IN THE

ENGINE MANUAL.

NOTE 1:

NO PROCEDURE IS NECESSARY FOR A TRANSIENT

OVERSPEED IN THIS BAND THAT IS NOT MORE THAN

5 SECONDS.

106

ROTOR SPEED (PERCENT)

104

103% N2 RPM

102 2

101% N2 RPM

1

(SEE NOTE 1)

100

REDLINE = 14950 RPM

HIGH ROTOR SPEED

N2

ded0006906

N_MM_710000_2_XPN0_01_00

Figure 71(IAE)-00-00-991-15700-13-B / SHEET 1/1 - Rotor Speed Limits

** ON A/C 001-009, 011-050, 101-150, 601-608, 610-710, 712-712, 717-750, 801-850

Print Date: August 22, 2017 Page 5 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

3. Job Set-up

Subtask 71-00-00-869-151-A

A. Not Applicable

4. Procedure

Subtask 71-00-00-869-138-A

A. Engine Operation Limits

(1) Exhaust Gas Temperature (EGT) Limits:

(a) Starting, for up to 2 minutes:

635 deg.C (1175.00 deg.F)

NOTE: Refer to engine operation guidelines for more data on starter operation.

(b) Transient:

635 deg.C (1175.00 deg.F)

(c) Take-off, for up to 5 minutes:

635 deg.C (1175.00 deg.F) for V2522, V2524, V2527E and V2527.

650 deg.C (1202.00 deg.F) for V2530 and V2533.

(d) Maximum Continuous:

610 deg.C (1130.00 deg.F)

(e) If the EGT limits are exceeded, refer to the procedures that follow:

1 Do the trouble shooting for EGT higher than limit (above idle) Ref. TSM 77-00-00-810-817

and Ref. TSM 77-00-00-810-818 .

2 Do the trouble shooting for EGT higher than limit (idle or below including start) Ref. TSM 77-

00-00-810-930 and Ref. TSM 77-00-00-810-931 .

(2) Oil Pressure Limits:

(a) Do a check of the oil system if the main oil pressure decrease between 60 psi (4.14 bar) and 80

psi (5.52 bar) for all operating conditions Ref. TSM 79-33-00-810-826 and Ref. TSM 79-33-00-

810-827 .

(b) Do a check of the oil system if the main oil pressure decrease between 320 psi (22.06 bar) and

390 psi (26.89 bar) for all operating conditions Ref. TSM 79-20-00-810-801 , Ref. TSM 79-20-

00-810-802 , Ref. TSM 79-20-00-810-803 , Ref. TSM 79-20-00-810-804 , Ref. TSM 79-20-00-

810-809 , Ref. TSM 79-20-00-810-810 , Ref. TSM 79-20-00-810-811 and Ref. TSM 79-20-00-

810-812 .

(c) The main oil differential pressure must be on or within the limits given during stabilized ground

operation only.

(Ref. Fig. Main Oil Pressure (MOP) Limits during Engine Operation above IDLE SHEET 1)

1 Correction for main oil temperature and HP speed can be applied during stabilized ground

running at idle only using the DMOP Idle Correction Equation.

(Ref. Fig. Differential Main Oil Pressure (DMOP) Idle Correction Equation SHEET 1)

2 If the DMOP is below the lower limit, perform trouble shooting Ref. TSM 79-33-00-810-830

or Ref. TSM 79-33-00-810-831 .

(d) During operation in cold weather, the scavenge oil filter differential pressure switch on the filter

housing, can operate until the main oil temperature gets to approximately 32 deg.C (89.60

deg.F).

Print Date: August 22, 2017 Page 6 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

(e) The No. 4 compartment scavenge oil pressure range is 0 to 205 psig (0 to 1413,4kPa) at the

highest power settings when the No.4 scavenge valve is CLOSED. The normal operating

pressure is 0 to 145 psig (0 to 999.7kPa) after three minutes of stabilization.

(f) The indicated oil pressure can be different between engines by as much as 80 PSIG (551,6kPa)

without this being an indication of an oil system malfunction.

(g) When EIU1(2) is not energized (for instance when channels A and B of FADEC 1 are switched

off, EIU1 is no longer energized; when FADEC 2 channel A is turned off, EIU2 is no longer

energized), the SDAC input (that corresponds to a conversion of a voltage coming from the

pressure sensor) is used to display the ENG1(2) oil pressure on the engine status page.

In some cases, the oil pressure displayed value can be 2 psi (0.14 bar), while the actual oil

pressure is 0, due to the lack of precision of the SDAC acquisition stage near 0 psi (0 bar).

This is a normal phenomenon which no longer exists when the FADEC and EIU are energized

correctly.

(3) Oil Temperature Limits:

(a) The maximum oil temperature is 155 deg.C (311.00 deg.F) (when operation is stabilized for a

minimum of three minutes). If the oil temperature is higher than 155 deg.C (311.00 deg.F), find

the cause of the high temperature, as soon as possible.

(b) The maximum transient temperature is 165 deg.C (329.00 deg.F) for 15 minutes after any high

power operation. If the temperature is higher than 165 deg.C (329.00 deg.F) shut down the

engine and find the cause of the high temperature.

(c) Before operation above idle, the oil temperature must be a minimum of -10 deg.C (14.00 deg.F).

(d) Before operation at high power (Max Continuous(MCT), Climb (CL) or greater, the oil

temperature must be a minimum of 50 deg.C (122.00 deg.F).

(e) At start, the oil temperature must be a minimum of -40 deg.C (-40.00 deg.F).

(4) Rotor Operation Speed limits:

(a) The maximum N1 is 5,650/rpm/100 percent

(b) The maximum N2 is 14,950/rpm/100 percent

NOTE: If the rotor speeds are more than these limits: (Ref. Fig. Rotor Speed

Limits SHEET 1) (Ref. Fig. Rotor Speed Limits SHEET 1)

(5) Nacelle Temperature Limit:

(a) The nacelle temperature advisory comes on at 320 deg.C (608.00 deg.F).

Subtask 71-00-00-869-137-A

B. Engine Operation Guideline

(1) Oil consumption guidelines

(a) Oil consumption is acceptable if the consumption is not more than 0.6 US pints (0.5 Imperial pint)

(approximately 0.3 quart) each hour.

(b) If high oil consumption is experienced greater than 0.3 US Qts/Hr (0.6 pts/hr) Ref. TSM 79-00-

00-810-838 or Ref. TSM 79-00-00-810-839 .

NOTE: If it is found that the oil level has increased by 0.42 US pints (200ccs) or more compared

to before, obtain an oil sample and send it to the laboratory for the fuel contamination

check

(c) The minimum time of operation for a check of oil consumption is 30 minutes. The engine must

have operated at high and low thrust lever positions during these 30 minutes.

Print Date: August 22, 2017 Page 7 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

(2) Starter Operation Guideline

(a) Usual starter operation time must not be more than two minutes.

(b) Do the starter procedure that follows:

1 Do three consecutive cycles (two cycles of two minutes and one cycle of one minute).

2 Stop operation for 15 seconds between cycles to let the starter rotor lubricate again.

3 After three cycles, stop for 30 minutes to let the starter become cool.

4 Do not engage the starter again with the engine motoring above 10 percent N2.

(c) Starter operating pressure is between 30 and 40 psig (206,84 and 275,79 kPa).

(3) Vibration limits and fan trim balance vibration guidelines.

(a) Vibration limits (steady state):

N1 (peak): 5.0 Units

N2 (peak): 5.0 Units

1 Engines that have vibrations within the vibration limits are acceptable.

2 Engines that have N1 peak vibration that exceeds the above limit, trouble shoot per TSM

Ref. TSM 77-30-00-810-826 or Ref. TSM 77-30-00-810-827

3 Engines that have N2 peak vibration that exceeds the above limit, trouble shoot per TSM

Ref. TSM 77-30-00-810-828 or Ref. TSM 77-30-00-810-829 .

4 A non-revenue ferry flight to a maintenance base is permissible with N1 or N2 vibration

above limits, if no fault in the respective trouble shooting procedures in steps 2_ and 3_

above. This condition is permissible for only one engine per aircraft.

(b) Vibration guidelines.

N1 (peak): 2.0 Units

1 Fan trim balance is recommended any time N1 peak vibration exceeds this guideline. N1

vibration levels above this guideline are generally accompanied by perceivable airframe

vibrations. Waiting until N1 peak vibration approaches or exceeds the 5.0 unit limit may

require multiple fan trim balances to bring N1 vibration down to an acceptable limit.

NOTE: 5.0 Units (aircraft display)= 1.5 IPS

2 Aircraft/FCOM correlation.

As stated in the FCOM, if N2 vibration during engine start exceeds limit, start should be

aborted. Subsequent starts may be initiated without maintenance action for up to three

start attempts.

The above limits and guidelines are stable (steady state) levels. Aircraft systems

continually monitor vibration and as such may not be stable, therefore the aircraft level

is advisory and not a limit. Vibration above the advisory level may or may not require

maintenance action, as described in the FCOM; initially depending on icing condition or

other engine parameter shifts and finally whether the advisory level is confirmed at steady

state conditions.

(4) Maintenance action after an unwanted and sudden shutdown of the engine:

(a) If the engine does not have damage after which engine removal is necessary, immediately do

again an engine start.

(b) If there is engine damage such as component seizure or rupture (Ref. AMM TASK 05-51-26-

200-001) . This task includes the engine removal and a detailed inspection of the engine pylon.

Print Date: August 22, 2017 Page 8 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : LTM Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 025-025

Rev. Date : Aug 01, 2017

71-00-00-860-010-B - Engine Operation Limits, Guidelines and Special Procedures

End of document

Print Date: August 22, 2017 Page 9 of 9

AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- Elvis Presley It S Easy To Play ElvisjbbeeDocument3 pagesElvis Presley It S Easy To Play ElvisjbbeecarloselvisNo ratings yet

- Quest For Mysteries (Extracto)Document1 pageQuest For Mysteries (Extracto)carloselvisNo ratings yet

- Apple Models 3000Document16 pagesApple Models 3000carloselvisNo ratings yet

- BOEING 787-8 Balance & Trim Chart: Valid For Seating Versions: A) 30C / 217Y B) 30C / 213YDocument1 pageBOEING 787-8 Balance & Trim Chart: Valid For Seating Versions: A) 30C / 217Y B) 30C / 213YcarloselvisNo ratings yet

- Aerodynamic Flutter BannerDocument11 pagesAerodynamic Flutter BannerRavi TejaNo ratings yet

- Document Evaluation: Airbus 320-200 Boeing 767Document1 pageDocument Evaluation: Airbus 320-200 Boeing 767carloselvisNo ratings yet

- Aerodynamic Flutter BannerDocument11 pagesAerodynamic Flutter BannerRavi TejaNo ratings yet

- Egtm PDFDocument16 pagesEgtm PDFcarloselvisNo ratings yet

- Sil100 11Document18 pagesSil100 11carloselvisNo ratings yet

- UFO Evidence 1964 PDFDocument388 pagesUFO Evidence 1964 PDFcarloselvisNo ratings yet

- Castells F de P - Historical Analysis of HRA RitualDocument95 pagesCastells F de P - Historical Analysis of HRA RitualcarloselvisNo ratings yet

- F. de P. Castells - The Apocalypse of FreemasonryDocument230 pagesF. de P. Castells - The Apocalypse of FreemasonryCosmomindNo ratings yet

- Fighting Fatigue in The Rail IndustryDocument3 pagesFighting Fatigue in The Rail IndustrycarloselvisNo ratings yet

- Vibration Reporting SheetDocument1 pageVibration Reporting SheetcarloselvisNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Flight Stability & Automatic ControlDocument230 pagesFlight Stability & Automatic ControlNimesh W100% (7)

- Easa Fcl-Compliant Pilot Log: The StandardDocument12 pagesEasa Fcl-Compliant Pilot Log: The StandardEm GomezNo ratings yet

- E190 SopsDocument136 pagesE190 SopsLuis PinedaNo ratings yet

- Avionics - Systems and Troubleshooting Cap. 6Document60 pagesAvionics - Systems and Troubleshooting Cap. 6Roberto Figueroa50% (2)

- Martin UAV V-BatDocument2 pagesMartin UAV V-Batc108No ratings yet

- AIP AD 2.1 Jordan 26 APR 2018: Ojaq Ad 2.1 Aerodrome Location Indicator and Name OJAQ - AQABA/King Hussein InternationalDocument11 pagesAIP AD 2.1 Jordan 26 APR 2018: Ojaq Ad 2.1 Aerodrome Location Indicator and Name OJAQ - AQABA/King Hussein InternationalkklrNo ratings yet

- Beech King Air B-100 TPE331-10 ConversionDocument4 pagesBeech King Air B-100 TPE331-10 ConversionPlusaero100% (1)

- Manual Entrenamiento Cessna 208 (001-054)Document54 pagesManual Entrenamiento Cessna 208 (001-054)leonardo100% (1)

- Httpsforums.x Plane - Orgindex.phpfilesfile61751 Airfoillabs King Air 350 Illustrated Checklists V1pdf&do Download&CsrfKe 10Document4 pagesHttpsforums.x Plane - Orgindex.phpfilesfile61751 Airfoillabs King Air 350 Illustrated Checklists V1pdf&do Download&CsrfKe 10Pro-gun/FreedomNo ratings yet

- Patient authorization records reportDocument25 pagesPatient authorization records reportLINA MARCELA VASQUEZ GOMEZNo ratings yet

- Differences 777 Freighter cargo aircraftDocument2 pagesDifferences 777 Freighter cargo aircraftaerologik_347746151100% (1)

- Fiche m53 Ang 2011Document2 pagesFiche m53 Ang 2011Leiser Hartbeck100% (2)

- 407GX Spec SheetDocument10 pages407GX Spec SheetmarjiyonoNo ratings yet

- Ämari Radar Approach ChartDocument1 pageÄmari Radar Approach ChartMIkołaj MorzeNo ratings yet

- MFR Nara - T1a - Ual - Mcaleer Gregory J - 8-12-03 - 00703Document4 pagesMFR Nara - T1a - Ual - Mcaleer Gregory J - 8-12-03 - 007039/11 Document ArchiveNo ratings yet

- MacLean Mobile Aircraft Cockpit Suicide Barrier Cart 2017-10-31Document12 pagesMacLean Mobile Aircraft Cockpit Suicide Barrier Cart 2017-10-31Creighton Kidz100% (1)

- Flight Operations Manual PNLDocument150 pagesFlight Operations Manual PNLannemargrette100% (4)

- Articles Now!Document18 pagesArticles Now!NZHHNo ratings yet

- Piper - PA 28R 180 PDFDocument70 pagesPiper - PA 28R 180 PDFMario GomesNo ratings yet

- Helicopter Flight Theory ExplainedDocument21 pagesHelicopter Flight Theory ExplainedaNo ratings yet

- Combat Aircraft Monthly - September 2015 UK VK Com Stopthepress PDFDocument100 pagesCombat Aircraft Monthly - September 2015 UK VK Com Stopthepress PDFAnonymous N13JdnNo ratings yet

- 52 Doors PDFDocument216 pages52 Doors PDFАртур ПетросянNo ratings yet

- 101101002Document6 pages101101002Ahmed shawkyNo ratings yet

- IFF Family of Products Brochure 09-27-17 WebDocument4 pagesIFF Family of Products Brochure 09-27-17 Web王大明No ratings yet

- Autonomous 3rd and 4th Sem Scheme and Syllabus 2016 17Document597 pagesAutonomous 3rd and 4th Sem Scheme and Syllabus 2016 17Prabhakaran DakshinamurthyNo ratings yet

- Panduan Membuat Pesawat GabusDocument14 pagesPanduan Membuat Pesawat Gabuscu2nkni2nkNo ratings yet

- CE-700 Working Group Initial Cessna 182Document14 pagesCE-700 Working Group Initial Cessna 182Elmer VillegasNo ratings yet

- ICAO Safety RecommendationsDocument7 pagesICAO Safety RecommendationsSigit SasonoNo ratings yet

- Drone Technology SeminarDocument24 pagesDrone Technology SeminarPramit JagateNo ratings yet

- Nigeria Airways Flight 2120: Jump To Navigation Jump To SearchDocument9 pagesNigeria Airways Flight 2120: Jump To Navigation Jump To SearchSatyam SachanNo ratings yet