Professional Documents

Culture Documents

Dextra Prestressing Bar Rev 11 Oct 2016

Uploaded by

Natthawut CheencharoenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dextra Prestressing Bar Rev 11 Oct 2016

Uploaded by

Natthawut CheencharoenCopyright:

Available Formats

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 1 of 14

SYSTEM DESCRIPTION

Pre-stressing bars are applied for permanent works such as

connecting various segments of bridge structures, shear keys

for seismic resistance at the connection of segments or

girders and piers, and reinforcement of piers that are subject

to horizontal pre-stressing forces. They are also applicable for

temporary works such as anchoring of temporary steel frame

supports and lifting bars for segment launching trusses, and

connecting bar segments before pre-stressing. These bars

need to have sufficient strength properties to carry the heavy

loads of structures and pre-loading to balance the external

loads structures are subjected to at a later stage.

P.T. bar for shear key

Dextra offers smooth and fully threaded bars depending on the design requirements.

The bars comply with ASTM A722, and are equivalent to BS4486 and JIS G 3109.

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 2 of 14

Shear Keys Components

PT Bars Components

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 3 of 14

BENEFITS

Homogeneous material, isotropic and with high tensile strength. Good resilience and resistance to

fatigue.

High impact strength at various temperatures.

Large plasticity and very high ductility at low temperature.

Low stress loss on fine thread

The system can be used in both cases of bonded and unbonded pre-stressing internal and external

dismountable.

Higher elongation compared to traditional products.

Wide range of corrosion protection such as cement grout, wax injection or coating with plastic heat

shrinking sleeve.

High strength of bars leads to less congestion and ease of installation.

Ability to detention and re-tension.

DESIGN

Dextras pre-stressing bars are designed in accordance with following standards;

BS-EN 1992-1-1 (Eurocode 2)

BS-EN 1993-1-1 (Eurocode 3)

ACI 318-08

APPLICATIONS

Pre-stressing of concrete structures

Seismic protection

Heavy lifting

PRODUCT RANGE

Smooth bars are available in diameters from 28 to 100 mm.

Fully threaded bars are available in diameters 25, 32, 36, 40, 50

and 63.5 mm

All bars can be supplied in lengths up to 11.8 m.

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 4 of 14

SMOOTH BARS

APPLICATIONS

Shear Keys for Metro above ground structure

Wind Mill for pre-stressing of concrete foundation

Bridge construction for temporary or permanent application

STEEL GRADES

Smooth bars are available in three grades as shown in Table 1

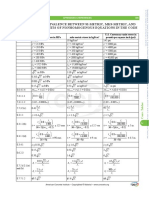

Yield Tensile E- Elongation

Grade Strength strength Modulus at failure

N/mm N/mm N/mm %

835/1030 835 1,030 205,000 12

930/1080 930 1,080 205,000 10

1050/1200 1,050 1,200 205,000 10

Table 1 Mechanical properties of smooth bar

LOAD CAPACITY

Tables 2 show the capacity of bars at 100% of guaranteed strength. The user should

compare required ultimate loads to the provided values and working loads to the result

of the multiplication of the provided value and specified maximum stressing factor in

order to meet these requirements.

Grade 835/1030 Grade 930/1080 Grade 1050/1200

Nominal

Linear Un- Un- Un- Un- Un-

shaft Thread Un-

weight factored factored factored factored factored

dia. size factored

Ultimate Yield Ultimate Yield Ultimate

Yield Load

Load Load Load Load Load

mm kg/m kN kN kN kN kN kN

28.0 M30 4.83 468 577 521 605 589 673

31.0 M33 5.92 579 714 645 749 728 832

34.0 M36 7.13 682 841 760 882 858 980

37.0 M39 8.44 815 1,005 907 1,054 1,025 1,171

40.0 M42 9.86 936 1,155 1,042 1,211 1,177 1,345

43.0 M45 11.40 1,091 1,345 1,215 1,410 1,371 1,567

45.0 M48 12.48 1,230 1,517 1,370 1,591 1,547 1,768

49.0 M52 14.80 1,468 1,811 1,635 1,898 1,846 2,109

53.0 M56 17.32 1,695 2,091 1,888 2,192 2,132 2,436

57.0 M60 20.03 1,972 2,433 2,197 2,551 2,480 2,834

61.0 M64 22.94 2,234 2,756 2,489 2,890 2,810 3,211

65.0 M68 26.04 2,551 3,147 2,841 3,300 3,208 3,666

69.0 M72 29.35 2,889 3,564 3,218 3,737 3,633 4,152

75.0 M78 34.67 3,435 4,237 3,826 4,443 4,319 4,936

80.0 M83 39.45 3,926 4,843 4,373 5,078 4,937 5,642

85.0 M88 44.54 4,450 5,489 4,956 5,755 5,595 6,395

90.0 M93 49.93 5,006 6,175 5,576 6,475 6,295 7,195

95.0 M98 55.63 5,596 6,902 6,232 7,237 7,036 8,042

100.0 M103 61.64 6,218 7,670 6,925 8,042 7,819 8,936

Table 2 Smooth bars load capacity

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 5 of 14

PHYSICAL PROPERTIES

Linear

Nominal dia. Thread

weight

size

mm kg/m

28.0 M30 4.83

31.0 M33 5.92

34.0 M36 7.13

37.0 M39 8.44

40.0 M42 9.86

43.0 M45 11.40

45.0 M48 12.48

49.0 M52 14.80

53.0 M56 17.32

57.0 M60 20.03

61.0 M64 22.94

65.0 M68 26.04

69.0 M72 29.35

75.0 M78 34.67

80.0 M83 39.45

85.0 M88 44.54

90.0 M93 49.93

95.0 M98 55.63

100.0 M103 61.64

Table 3 : Smooth bars physical properties

ACCESSORIES

The main accessories for PT bars are summarized in Table 4

Table 4 Main Accessories

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 6 of 14

Flat Corner

Height, m

width width

Nominal dia. Thread Flat Swivel

size s e

Hex nut Hex nut

mm mm mm mm

28.0 M30 24 30 46 53.1

31.0 M33 26 33 50 57.7

34.0 M36 29 36 55 63.5

37.0 M39 31 39 60 69.3

40.0 M42 34 42 65 75.1

43.0 M45 36 45 70 80.8

45.0 M48 38 48 75 86.6

49.0 M52 42 52 80 92.4

53.0 M56 45 56 85 98.1

57.0 M60 48 60 90 103.9

61.0 M64 51 64 95 109.7

65.0 M68 54 68 100 115.5

69.0 M72 58 72 105 121.2

75.0 M78 62 78 114 131.6

80.0 M83 66 83 117 135.1

85.0 M88 70 88 125 144.3

90.0 M93 74 93 132 152.4

95.0 M98 78 98 140 161.7

100.0 M103 82 103 147 169.7

Table 5 Smooth bar hex nut dimensions

Plates are made of steel grade S355JR as per EN 10025 or equivalent. Nuts are per ISO 898 Part 2.

The use of swivel bearing plates and nuts allow angular deflections of up to 7.

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 7 of 14

Connecting couplers and turnbuckles are also available.

Grade 835/1030 Grade 930/1080 Grade 1050/1200

Nominal

dia. Thread Outside Outside Outside

size Length, A diameter, Length, A diameter, Length, A diameter,

B B B

mm mm mm mm mm mm mm

28.0 M30 74 45 77 45 85 45

31.0 M33 82 50 85 50 94 50

34.0 M36 89 55 93 55 102 55

37.0 M39 96 60 101 60 111 60

40.0 M42 104 65 108 65 119 65

43.0 M45 111 70 116 70 128 70

45.0 M48 118 75 124 75 136 75

49.0 M52 129 80 134 80 148 80

53.0 M56 138 85 145 85 159 85

57.0 M60 149 90 155 90 171 95

61.0 M64 158 95 166 95 183 100

65.0 M68 169 100 176 105 195 105

69.0 M72 179 110 187 110 207 110

75.0 M78 194 115 203 120 225 120

80.0 M83 207 130 217 130 240 130

85.0 M88 220 130 230 140 255 140

90.0 M93 233 140 244 140 270 150

95.0 M98 246 150 257 150 285 160

100.0 M103 259 160 271 160 300 160

Table 6 Smooth bar coupler dimensions

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 8 of 14

FULLY THREADED BARS

APPLICATIONS

Bridge Construction:

Temporary or permanent stressing of segments

Lifting bars

STEEL GRADES

Fully threaded bar are available in three grades as shown in Table 7

Yield Tensile E- Elongation

Grade Strength strength Modulus at failure

N/mm N/mm N/mm %

830/1030 830 1,030 200,000 6

930/1080 930 1,080 200,000 6

1080/1230 1,080 1,230 200,000 6

Table 7 Mechanical properties of fully threaded bar

LOAD CAPACITY

Tables 8 show the capacity of bars at 100% of guaranteed strength. The user should

compare required ultimate loads to the provided values and working loads to the result

of the multiplication of the provided value and specified maximum stressing factor in

order to meet these requirements.

Grade 830/1030 Grade 930/1080 Grade 1080/1230

Cross-

Nominal section Linear Yield Ultimate Yield Ultimate Yield Ultimate

diameter area weight load load load load load load

mm mm kg/m kN kN kN kN kN kN

25 491 4.1 408 506 457 531 531 604

32 804 6.65 668 829 748 869 869 990

36 1,018 8.41 845 1,049 947 1,100 1,100 1,253

40 1,257 10.34 1,043 1,295 1,169 1,358 1,358 1,546

50 1,964 16.28 1,630 2,023 1,827 2,121 2,121 2,416

63.5 3,167 26.20 2,629 3,262 2,945 3,420 3,420 3,895

75 4,417 36.10 3,667 4,550 4,109 4,771 - -

Table 8 Fully threaded bars load capacity

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 9 of 14

PHYSICAL PROPERTIES

Nominal Nominal Linear

Dv Dh h b l

dia. Section Area weight

mm mm mm mm mm mm mm kg/m

25.00 25.00 25.00 1.60 6.00 12.00 490.90 4.10

32.00 32.00 32.00 2.00 7.00 16.00 804.20 6.65

36.00 36.00 36.00 2.20 8.00 18.00 1018.00 8.41

40.00 40.00 40.00 2.50 8.00 20.00 1256.60 10.34

50.00 50.00 50.00 3.00 9.00 24.00 1963.50 16.28

63.50 63.50 63.50 3.00 12.00 22.00 3167.00 26.20

75.00 74.50 75.00 3.00 - 20.00 4417.00 16.28

Table 9 Fully threaded bars physical properties

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 10 of 14

ACCESSORIES

Nominal

L SW D Weight

dia.

mm mm mm mm kg/m

25.00 54.00 50.00 57.00 0.65

32.00 72.00 65.00 75.00 1.45

36.00 80.00 65.00 75.00 1.65

40.00 100.00 70.00 81.00 2.09

50.00 110.00 80.00 92.00 2.71

63.50 115.00 100.00 115.00 4.58

75.00 135.00 120.00 - 7.65

Table 10 Fully threaded bar : Flat hex nut

Norminal

L SW D Weight

dia.

mm mm mm mm kg/m

25.00 54.00 50.00 50.00 0.60

32.00 72.00 65.00 65.00 1.35

36.00 80.00 65.00 65.00 1.50

40.00 100.00 70.00 70.00 2.00

50.00 110.00 80.00 80.00 2.60

63.50 115.00 100.00 100.00 5.00

75.00 135.00 120.00 - 7.65

Table 11 Fully threaded bar : Spherical hex nut

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 11 of 14

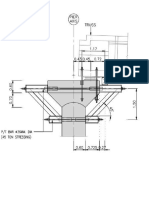

Nominal Hole

L1 L2 R1 R2 Weight

dia. diameter

mm mm mm mm mm mm kg/m

25.00 120.00 120.00 13.50 20.00 35.00 2.10

32.00 140.00 140.00 15.50 24.00 45.00 3.50

36.00 150.00 150.00 15.00 30.00 50.00 5.00

40.00 160.00 160.00 15.00 30.00 55.00 6.00

50.00 200.00 200.00 17.50 50.00 65.00 14.00

63.50 240.00 240.00 20.00 50.00 80.00 21.80

Table 12 Fully threaded bar : Bearing plate dimensions

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 12 of 14

Nominal dia. L1 D1 Weight

mm mm mm kg/m

25.00 126 50 1.30

32.00 168 60 2.25

36.00 180 70 3.60

40.00 220 74 4.63

50.00 270 88 8.05

63.50 260 102 9.05

Table 13 Fully threaded bar : Coupler dimensions

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 13 of 14

QUALITY ASSURANCE

Every component of the Dextra pre-stressing bar is manufactured under consistent quality

assurance as required by ISO 9001 certification. Load-bearing components are all

individually marked with a lot number that enables full traceability. Traceability of bars is

achieved through both the mill certificates and the certificates of compliance provided

together with the delivery notes. The customer is advised to keep a proper record of the

location of each batch. Full project files are provided to the client together with the goods.

A Certificate of Compliance with related quality and test reports are provided with each

delivery.

A final dossier comprised of all drawings, calculation notes, and quality documents can be provided at the

end of the supply period, upon request.

SURFACE FINISH

There is no specific surface finish required for pre-stressing bars; specific coatings are available upon

request.

CORROSION PROTECTION

The smooth bars are normally supplied in a HDPE tube injected with grease. However, they may be

protected from corrosion by various means; to be specified by the client: cement grout, wax, plastic shrink

films, paint, etc. These various types of protection may be applied on site or in a workshop.

INSTALLATION SEQUENCE

Installation sequence of Dextras pre-stressing bars is dependent on application purposes, pre-stressing,

post-tensioning, shear key, heavy lifting etc. The installer should follow the Technical Specification in the

Project Contract Documents. Dextra is committed to providing service during installation.

DISCLAIMER

Galvanization of the smooth bars may be possible, provided that the temperature of the hot dip does not

exceed 450C and the dipping time is less than 15 minutes.

If the bars are going to be tensioned, they should not be epoxy-painted as the epoxy layer may crack

during tensioning.

Fully threaded bar properties should be compared against the design requirements such as stress loss

and fatigue properties prior to application.

No welding/heating should be attempted on Dextras pre-stressing bars without consulting a welding

engineer and without the approval of the Design Engineer. Dextra assumes no liability or guarantees for

any of its products that are welded/heated without prior written authorization.

CUTTING

Pre-stressing bars can be cut with a friction circular blade but gas cutting is strictly prohibited.

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

PRODUCT DATASHEET

DEXTRA PRE-STRESSING BARS SYSTEM Page 14 of 14

HANDLING AND STORAGE

Pre-stressing bars are delivered in bundles. Threads are protected by thick fabric or plastic pipe. The bars

are slightly oil-coated to limit corrosion during shipping and must be cleaned by solvent before use.

According to their superior ductility, bars are less likely to sustain damage due to poor handling. Use of a

spreader bar for lifting is not compulsory but is recommended. Do not store pre-stressing bars directly on

the ground: use wooden sleepers, in a covered area.

INFORMATION FOR INQUIRIES

For each inquiry, customers are requested to provide the following information to Dextra :

1) The required diameter of bar.

2) The required working and ultimate load.

3) The length of the bar from face to face of concrete and the length of the threads.

4) The Bill of Quantity

5) The bar surface finished if any.

6) The type of corrosion protection required.

7) The accessories required.

8) The details of the surface on which the plates will bear.

9) The type of structure where the bars will be used, temporary or permanent.

10) The application (Join a drawing or a sketch of the bars in place and Technical Specification).

11) The tensioning load.

12) The delivery date and location.

PROVISIONS FOR CHANGES

As we strive for continuous improvement of all our products, Dextra reserves the right to modify the

contents of this document at any time without prior notice.

www.dextragroup.com DM PDS 013 Rev 11 PT Bar- Oct 2016

You might also like

- Otis Elevator Emergency Phone ManualDocument28 pagesOtis Elevator Emergency Phone ManualBB Players100% (2)

- ProStar® Chassis Built June 14, 2010 and AfterDocument319 pagesProStar® Chassis Built June 14, 2010 and AfterHilario Gayosso CruzNo ratings yet

- Structural Steel Fabrication SpecificationDocument40 pagesStructural Steel Fabrication SpecificationNatthawut Cheencharoen80% (5)

- CFLHD Production RatesDocument7 pagesCFLHD Production RatesabhiazadNo ratings yet

- ACI 318-19 Equivalencias de EcuacionesDocument9 pagesACI 318-19 Equivalencias de EcuacionesLeonel SanchezNo ratings yet

- Site Criteria and Loads On Structure: ASCE 7-98 / IBC 2000Document13 pagesSite Criteria and Loads On Structure: ASCE 7-98 / IBC 2000Randy Camaclang100% (1)

- IMS DB FundamentalsDocument59 pagesIMS DB FundamentalsJain_Manoj83No ratings yet

- ACI 350 3 06 Appendix B Seismic Loads For Liquid Containing Rectangular RC Tank Rev01 04 Nov 2014 PDFDocument13 pagesACI 350 3 06 Appendix B Seismic Loads For Liquid Containing Rectangular RC Tank Rev01 04 Nov 2014 PDFLuis Gil MorenoNo ratings yet

- Structural AnalysisDocument54 pagesStructural AnalysisNay linNo ratings yet

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014Document19 pagesACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014manoj_mousamNo ratings yet

- Balasto Segun TerzaguiDocument2 pagesBalasto Segun TerzaguiCivilNo ratings yet

- Suspension 1Document10 pagesSuspension 1Ibrahim AbotalebNo ratings yet

- CI3907 GranosikDocument3 pagesCI3907 GranosikdeviationzNo ratings yet

- Bs 3293Document18 pagesBs 3293nguyenmainam0% (1)

- Rules of Thumb For Steel StructuresDocument5 pagesRules of Thumb For Steel StructuresLincs lincoln100% (1)

- Designing Reinforced Concrete WallsDocument8 pagesDesigning Reinforced Concrete WallsAndrea SalcedoNo ratings yet

- Método de Nakamura 1989 Microtremores 1Document10 pagesMétodo de Nakamura 1989 Microtremores 1rlprNo ratings yet

- BIM Management - BIM@SGDocument2 pagesBIM Management - BIM@SGNatthawut CheencharoenNo ratings yet

- Nikon D800 PDFDocument14 pagesNikon D800 PDFmamarraoulNo ratings yet

- Soldadura de Barras de Refuerzo para Estructuras de Concreto Reforzado en Zonas SismicasDocument59 pagesSoldadura de Barras de Refuerzo para Estructuras de Concreto Reforzado en Zonas SismicasSibyl Guardado100% (1)

- VDA Field Failure Analysis - Joint Quality Management in The Supply Chain - Marketing and Service PDFDocument60 pagesVDA Field Failure Analysis - Joint Quality Management in The Supply Chain - Marketing and Service PDFserchecko1No ratings yet

- CTT Elastomeric BearingsDocument20 pagesCTT Elastomeric Bearingsjajaytt100% (1)

- The New ISO 55002:2018 Guidelines For The Application of ISO 55001Document2 pagesThe New ISO 55002:2018 Guidelines For The Application of ISO 55001tiagofernandes000No ratings yet

- Applications of Sustainable Post-Tensioned Concrete SlabsDocument12 pagesApplications of Sustainable Post-Tensioned Concrete Slabsmohamed.s.elsayedNo ratings yet

- Gawac 3.0 - User Guide Manual - R8Document29 pagesGawac 3.0 - User Guide Manual - R8Benjamin BarrientosNo ratings yet

- Civil Engineering - For WebDocument28 pagesCivil Engineering - For WebbathinsreenivasNo ratings yet

- Limits and Fits Pr1171 - 1172Document1 pageLimits and Fits Pr1171 - 1172Teguh Nugraha KusnanNo ratings yet

- Flame Relay A 285 K 2.2: For DIN-rail MountingDocument3 pagesFlame Relay A 285 K 2.2: For DIN-rail MountingMohamed MusaNo ratings yet

- BS en 1264-1-2021Document34 pagesBS en 1264-1-20217620383tlNo ratings yet

- The Ductility of Coupeld Shear WallsDocument414 pagesThe Ductility of Coupeld Shear WallsJorgeLuisSeguraNo ratings yet

- Elementos de Sistemas de Prefabricados de PuentesDocument347 pagesElementos de Sistemas de Prefabricados de PuentesWaldo Enrique Quispe PalominoNo ratings yet

- 7-Lecture-7 One Way Continuous SlabDocument39 pages7-Lecture-7 One Way Continuous SlabRubab ZahraNo ratings yet

- Diseño Muro en GavionesDocument4 pagesDiseño Muro en GavionesErnesto GomezNo ratings yet

- Use of Shear Lugs For Anchorage To Concrete: January 2009Document9 pagesUse of Shear Lugs For Anchorage To Concrete: January 2009Sandeep BhatiaNo ratings yet

- Stability Prediction On Armor Blocks For Submerged Breakwater by Computational Fluid DynamicsDocument14 pagesStability Prediction On Armor Blocks For Submerged Breakwater by Computational Fluid DynamicsHaryo ArmonoNo ratings yet

- RC Box Culvert & U-Ditch: DescriptionDocument1 pageRC Box Culvert & U-Ditch: DescriptionAgung Mahendra STNo ratings yet

- FIU Bridge Collapse Investigative ReportDocument2 pagesFIU Bridge Collapse Investigative ReportGary DetmanNo ratings yet

- AVWin 98Document12 pagesAVWin 98elianNo ratings yet

- Example 24.2-Investigation of Stresses at Prestress Transfer and at Service LoadDocument3 pagesExample 24.2-Investigation of Stresses at Prestress Transfer and at Service LoadMario Antonio Gomez CruzNo ratings yet

- Physical Properties Strand PDFDocument1 pagePhysical Properties Strand PDFlilik riyantiNo ratings yet

- Wafflemat Design WhitepaperDocument13 pagesWafflemat Design WhitepaperantiacidoNo ratings yet

- Losa Colaborante en SAP2000Document5 pagesLosa Colaborante en SAP2000Mauricio_Vera_5259No ratings yet

- Concrete column design per ACI 318-19Document1 pageConcrete column design per ACI 318-19Manuel Mendoza JaraNo ratings yet

- Flat Plate-VoidedDocument12 pagesFlat Plate-VoidedVinitNo ratings yet

- Dereje GudetaDocument174 pagesDereje GudetaBIRUK FEKADUNo ratings yet

- Determine Embedment Depth and Tie Rod Force for Anchored BulkheadDocument7 pagesDetermine Embedment Depth and Tie Rod Force for Anchored BulkheadJulien MhannaNo ratings yet

- Pti Publication Order Form: Unit Price, Dollars ($U.S.) Format, Print/ Digital Total PTI Members NonmembersDocument2 pagesPti Publication Order Form: Unit Price, Dollars ($U.S.) Format, Print/ Digital Total PTI Members NonmembersVipin Kumar ParasharNo ratings yet

- Lpile Group ModuleDocument2 pagesLpile Group ModuleMUHAMMAD ALINo ratings yet

- Shear Key Deck Design GuideDocument52 pagesShear Key Deck Design GuideAnonymous jLLjBdrNo ratings yet

- Calculation Report For Fence Foundation Model HP3000: REV Description Engineering Approval Boss DateDocument9 pagesCalculation Report For Fence Foundation Model HP3000: REV Description Engineering Approval Boss DateGerardo JoseNo ratings yet

- Phan Mem FBDocument919 pagesPhan Mem FBAnonymous DNb6yWERfBNo ratings yet

- What Is WafflematDocument3 pagesWhat Is WafflematAn100% (1)

- 4 - 4 Diseño de Zapatas ClaseDocument5 pages4 - 4 Diseño de Zapatas ClaseNicolas NuñezNo ratings yet

- Material Drucker Prager-Extended&CapDocument4 pagesMaterial Drucker Prager-Extended&CapKamal GmNo ratings yet

- Column Beam Fiber SectionDocument3 pagesColumn Beam Fiber SectionJayanthan MadheswaranNo ratings yet

- Concrete padestal uplift capacityDocument96 pagesConcrete padestal uplift capacityfaizan ashiqueNo ratings yet

- LI - 00.164 - XXX - Hormigon Armado y Pretensado - Bernat PDFDocument382 pagesLI - 00.164 - XXX - Hormigon Armado y Pretensado - Bernat PDFGustavo G. Lima100% (1)

- 07-Strip Footing PDFDocument12 pages07-Strip Footing PDFHusein El MazloumNo ratings yet

- Ajax Bolt Installation GuideDocument5 pagesAjax Bolt Installation GuidePortlander52No ratings yet

- Uang 1991 ESTABLISHING R (OR RW) AND CD FACTORS FOR BUILDING SEISMIC PROVISIONSDocument10 pagesUang 1991 ESTABLISHING R (OR RW) AND CD FACTORS FOR BUILDING SEISMIC PROVISIONSMaria AngelNo ratings yet

- MD5 - With ExampleDocument7 pagesMD5 - With ExampleAhmed Hesham89% (19)

- S03-LRB-en - LIB - Catálogo PDFDocument16 pagesS03-LRB-en - LIB - Catálogo PDFrapaigNo ratings yet

- Norma Astm A1007Document9 pagesNorma Astm A1007Alfredo RangelNo ratings yet

- Finite Element Applications in Geotechnical Engineering: H. Ercan TaşanDocument25 pagesFinite Element Applications in Geotechnical Engineering: H. Ercan TaşanhasanNo ratings yet

- Assignment 9Document2 pagesAssignment 9thulfNo ratings yet

- Moment Redistribution Principles Using ACI 318-02Document19 pagesMoment Redistribution Principles Using ACI 318-02aladinsaneNo ratings yet

- Axial Capacity of Drilled Shafts in Rock PDFDocument9 pagesAxial Capacity of Drilled Shafts in Rock PDFRodrigo Muñoz ValderramaNo ratings yet

- Risafoot Ejemplo I-1Document3 pagesRisafoot Ejemplo I-1Eliud CastilloNo ratings yet

- VSL Colombia Peldar Bridge EnvigadoDocument2 pagesVSL Colombia Peldar Bridge EnvigadoblaqhaqarNo ratings yet

- Engine ClassificationDocument7 pagesEngine ClassificationEslam Abd El HamedNo ratings yet

- Arch Dam Geometry Generator Tool for Finite Element AnalysisDocument2 pagesArch Dam Geometry Generator Tool for Finite Element AnalysisTariq MahmoodNo ratings yet

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFFirdaus AdnanNo ratings yet

- Punching Shear Check in Reinforced Concrete SlabsDocument7 pagesPunching Shear Check in Reinforced Concrete Slabscocococo1100% (1)

- PT Bar Systems Brochure 17.05.29Document8 pagesPT Bar Systems Brochure 17.05.29SACHINNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Spring CalculationsDocument1 pageSpring CalculationswarhamniNo ratings yet

- Production RatesDocument17 pagesProduction Ratesyonatan1351No ratings yet

- LECTURE 3 - Shear StressesDocument13 pagesLECTURE 3 - Shear StressesAbe SaulnierNo ratings yet

- Roughness Conversion TableDocument1 pageRoughness Conversion Tabledreamingscientist3393No ratings yet

- Revised Load and Resistance Factors For The AASHTO LRFD - Andrzej S. Nowak PDFDocument13 pagesRevised Load and Resistance Factors For The AASHTO LRFD - Andrzej S. Nowak PDFNatthawut CheencharoenNo ratings yet

- Hardness conversion and metric screw thread excerptsDocument1 pageHardness conversion and metric screw thread excerptsNatthawut CheencharoenNo ratings yet

- Epoxy JointDocument2 pagesEpoxy JointNatthawut CheencharoenNo ratings yet

- 15.12.16, 11:13 Cubus Front Support Frame: Scale 1:49.3 StructureDocument5 pages15.12.16, 11:13 Cubus Front Support Frame: Scale 1:49.3 StructureNatthawut CheencharoenNo ratings yet

- HZS60 Concrete Mixing StationDocument6 pagesHZS60 Concrete Mixing StationNatthawut CheencharoenNo ratings yet

- Production RatesDocument17 pagesProduction Ratesyonatan1351No ratings yet

- Genset 79-102-125 kVADocument2 pagesGenset 79-102-125 kVANatthawut CheencharoenNo ratings yet

- TG 1200MDocument12 pagesTG 1200MNatthawut CheencharoenNo ratings yet

- Chord OCT16Document5 pagesChord OCT16Natthawut CheencharoenNo ratings yet

- 7718Document1 page7718Natthawut CheencharoenNo ratings yet

- Repair of Unbonded Single Strand Tendons - July 2005Document5 pagesRepair of Unbonded Single Strand Tendons - July 2005Natthawut CheencharoenNo ratings yet

- The Power of Prestressing J. StraskyDocument19 pagesThe Power of Prestressing J. StraskyNatthawut CheencharoenNo ratings yet

- 04 Omniksol 3k 4k 5k TL enDocument2 pages04 Omniksol 3k 4k 5k TL enomnikshanNo ratings yet

- PC Replacement PolicyDocument3 pagesPC Replacement PolicyChristopher GuestNo ratings yet

- 16 Black Box TestingDocument28 pages16 Black Box TestingJuan Manuel RomeroNo ratings yet

- XM 1800 S ManualDocument4 pagesXM 1800 S ManualbernardqwertyNo ratings yet

- TEGAM Model 2340/2350 High Voltage Amplifier ManualDocument19 pagesTEGAM Model 2340/2350 High Voltage Amplifier ManualenticoNo ratings yet

- CPC5620 21Document18 pagesCPC5620 21teguhscribdNo ratings yet

- Material Handling Flow PatternDocument20 pagesMaterial Handling Flow PatternAli WarsiNo ratings yet

- Acrolon 218 HSDocument4 pagesAcrolon 218 HSAndres MoralesNo ratings yet

- Pseudo CodesDocument6 pagesPseudo CodesVinti PandeyNo ratings yet

- WeldFit Energy BrochureDocument8 pagesWeldFit Energy BrochureRaymundo AlarconNo ratings yet

- EOI Notice No 6)Document5 pagesEOI Notice No 6)Chandeshwor ShahNo ratings yet

- Annual NASA Design Competition 2013: A Rchitectural Sensitiz Ation An Observation - . .Document5 pagesAnnual NASA Design Competition 2013: A Rchitectural Sensitiz Ation An Observation - . .radhemadhaviNo ratings yet

- VGA Video Splitters: February 1998 AC056A-R2 AC056AE-R2 AC057A-R2 AC057AE-R2 AC058A-R2 AC159A-R2 AC160A-R2Document18 pagesVGA Video Splitters: February 1998 AC056A-R2 AC056AE-R2 AC057A-R2 AC057AE-R2 AC058A-R2 AC159A-R2 AC160A-R2Your Brand New LookNo ratings yet

- HSN 0101Document130 pagesHSN 0101Jessica PerryNo ratings yet

- Call 800-DIESELS (343-7357) : Natural Gas EngineDocument10 pagesCall 800-DIESELS (343-7357) : Natural Gas EnginereycoeleNo ratings yet

- Goip Sms Interface enDocument10 pagesGoip Sms Interface enNoli Bellen RafalloNo ratings yet

- About KotsonsDocument31 pagesAbout KotsonsVinayak GargNo ratings yet

- Shell Corena Oil AP Advanced Synthetic LubricantDocument2 pagesShell Corena Oil AP Advanced Synthetic LubricantGanesh AnandNo ratings yet

- Document Section: To Group By, Drag Column Caption Here ..Document25 pagesDocument Section: To Group By, Drag Column Caption Here ..fabio_sgNo ratings yet

- D4239-05 Sulfur High Temperature TubeDocument8 pagesD4239-05 Sulfur High Temperature TubeVladimir KrzalicNo ratings yet

- BHL Type: Discrepancy SwitchDocument10 pagesBHL Type: Discrepancy Switchinsan_soft6498No ratings yet

- Types of Coating PansDocument46 pagesTypes of Coating Pansعبدالعزيز بدرNo ratings yet