Professional Documents

Culture Documents

Gear Design For Quiet Reduction Gear

Uploaded by

Travis WoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gear Design For Quiet Reduction Gear

Uploaded by

Travis WoodCopyright:

Available Formats

Acoustic

Properties

OF INDUSTRIAL

MACHINERY

PART II

Understanding noiseits origins and why its occurringcan help avoid

problems and lead to better outcomes in the manufacturing environment.

Provided by Philadelphia Gear

20 GEAR SOLUTIONS FEBRUARY 2007 gearsolutionsonline.com

Introduction:

In the early 1970s the Occupational Safety and Health Act (OSHA) manufacturers, and users in the areas of Fundamentals of Sound as

generated more awareness, concern, and a need to control industrial Related to Gears (Part I), Sources, Specifications and Levels of Gear

noise (sound levels). This in turn created a need to advance technical Sound (Part II), and Gear Noise Control (Part III). The work of two gear

knowledge on industrial product sound generation and to set sound engineersBill Bradley at Philadelphia Gear Corporation and Richard

standards on all types of equipment. However, the complexity of the Schunck at the Falk Corporationformed a majority of the information

subject made most sound standards difficult to apply or interpret that went into this AGMA Gear Sound Manual that was first published

properly. Therefore, some of the major gear manufacturers developed in 1978. The information was originally issued as three separate

literature to disseminate knowledge to their product users on acous- documents. In 1987 the information was combined and published

tical measurements, level control, and sound attenuation for gear as one document. The latest version of this AGMA Information Sheet

driven equipment. was updated between 2002 and 2004 and published as AGMA 914-

Also at this time, the AGMA Acoustical Technology Committee was B04. It contains additional references and information such as typical

formed to standardize methods for sound measurement and geared levels generated and analysis methods for those who wish more on

product acceptance testing. It also developed a Gear Sound Manual the subject.

to provide improved communication between project engineers, gear

This white paperthe second in a two-par t seriesis to inform you generally on the topic of noise as related to Philadelphia Gear

Corporation industrial products. Realizing that you lack the time, background or inclination to read texts on acoustics, this outline will

be kept as brief as possible. The first installment appeared in the Januar y issue of Gear Solutions magazine, and can be found at

[www.gearsolutionsonline.com].

Section II: Designing Noise Out of Gears Type of Gearing

The best time to solve a gear-noise problem is at the design stage. Retro- For quiet operation, parallel-shaft gears such as spur, helical, and double

fixing is usually expensive and unsatisfactory. Many factors play a role helical are preferred to right angle and crossed-axis gearing. The primary

in ensuring a quiet gear mesh. Adjusting one or more of them before the reason is that spur and helical gears make it possible to maintain tight

hardware is manufactured adds little to the cost, but may make a signifi- tolerances and to operate with minimum friction.

cant difference in noise level. However, to complicate matters, there is Helical gear types have the added advantage of maintaining more than

always the need for a balance between low noise and satisfactory perfor- one tooth in contact during operation (helical overlap). Because of this, it

mance. The most important design factors that influence the noise level is possible to get as much as 12 dbA reduction in noise by using them

of a gear set are: instead of spur gears.

With double helical gears, there is the problem of correctly manufactur-

Type of gearing ing the two helices with exactly the same phase and accuracy; in other

Quality level words, without apex runout for weave. Any slight deviations in manufactur-

Tooth profile ing, coupled with the axial mass inertia of the gear, will prevent equal load

Surface finish sharing and smooth operation; this will contribute to vibration and noise.

Pitch Thus, for smooth, noise-free operation, the optimum type of gear

Gear runout and unbalance throughout all speed ranges is the single helical gear. Any thrust or over-

Pressure angle turning loads that single helical gears may induce are easily offset by

Gear ratio modern design techniques.

Recess action

Resonance

Profile modification Tooth Profile

Lubricant viscosity Tooth profiles other than the common involute type have been developed

Overlap ratio over the years. None of them have been widely accepted, mainly because

Type of bearings they lack sufficient advantages and manufacturing history to justify deviat-

Backlash ing from the involute form.

Material Gears with circular-arc tooth profiles, for example, can retain more

Tooth loading lubricant between mating teeth, thus tending to reduce noise and wear.

Housing However, the circular-arc form is still largely experimental, and has not

gearsolutionsonline.com FEBRUARY 2007 GEAR SOLUTIONS 21

proved to be inherently quieter than involute

gears. Additionally, manufacturers are generally

tooled for involute types, which is one of the

main reasons why other tooth forms have not

been adopted.

Other forms have been designed specifi-

cally to carry much higher loads than equivalent

involute types. These may be just as noisy, if

FIGURE 1: A 20-DEGREE PRESSURE ANGLE IS THE BEST COMPROMISE BETWEEN STRENGTH AND not noisier, than conventional involute types.

QUIETNESS. OTHER TOOTH FORMS MAY BE USED WHERE ONE FACTOR OR THE OTHER IS MORE IM-

PORTANT. A 14-1/2 DEGREE TOOTH GIVES LESS NOISE AND 25 DEGREE GREATER STRENGTH. Extensive experience with involute gears has

led to profile modification for quieter operation.

This experience is not available for other tooth

forms.

Pitch

For quiet, smooth operation, the finest pos-

sible pitch should be selected for the given

load conditions. The finer the pitch, the higher

the number of teeth in contact. This increases

the amount of tooth overlap, both transverse

and helical. The higher tooth overlap produces

a smoother transfer of load, reducing dynamic

oscillation of the gear mesh. This will result in a

quieter gear train even tough the finer pitch will

produce a higher mesh frequency.

Of course, the finer the pitch, the smaller the

tooth size and the lower the strength rating of

the gear set. To compensate for this, there are

several choices: enlarge the pitch diameters,

make the gears wider, or use the higher hard-

ness material and precision-grind.

One drawback to the use of finer-pitch ground-

tooth gears is that more time is needed to

manufacture the teeth, which adds to the cost

of the gearing.

Pressure Angle

Where a low noise level is a key requirement,

the lowest possible pressure angle should be

chosen. With the ever-increasing need for higher-

capacity gears, many designers have tended to

the 25 pressure angle in place of the more

common 14 1/4 and 20 pressure angles (Fig.

1). The 25 pressure angle gears do indeed pro-

vide greater load capacity; but such gears tend

to be noisier, because the contact angle and

transverse overlap ratio are lower. In general,

a 20-pressure angle is a good compromise

between quiet operation and high load capacity.

Recess Action

In cases where a gear drive will be transmitting

load in only one direction of rotation, recess-

action gears can provide a further reduction

in noise. In gears of the full-recess type, the

22 GEAR SOLUTIONS FEBRUARY 2007 gearsolutionsonline.com

teeth of one of the gears in mesh have all-addendum profiles, while the

mating gear has all-dedendum teeth (Fig. 2). In these gears, contact

occurs during the recess portion of the tooths engagement and disen-

gagement cycle. Contact during the approach action, and some of the

resulting detrimental scraping effects, are avoided.

The reason for the undesirable effects of approach-action contact can

be understood by looking at a standard involute gear pair, as shown in Fig.

2a. Initial contact occurs at A when the lower gear is rotating counterclock-

wise. The approach action takes place from A to B, and recess action from

B to C, when contact ceases.

During contact, the action is a combination of sliding and rolling.

Approach-action friction tends to increase scuffing, wear, and noise.

There is a change in the direction of sliding at the rolling point of the pitch

line that tends to break down the oil film, causing increased friction. The

recess phase of the meshing, on the other hand, is a sliding-out action.

Friction is lower and in a direction to help rotating (Fig. 2b). Thus, the effect

of recess action on the teeth is less severe than the approach action.

It is possible to design a semi-recess action system that combines the

benefits of full recess action with those of standard action. Such gears are

more common than the full-recess types.

Tooth Modification

Often overlooked, proper tooth modification is very important if the gear FIGURE 2: COMPARISON OF INVOLUTE GEARS (A) AND FULL-RECESS

is to be quiet and long-lived. Dynamic studies have shown that most high- GEARS (B). IN FULL-RECESS GEAR SETS, THE TEETH OF ONE OF THE

GEARS HAVE ALL-ADDENDUM PROFILES, WHILE THOSE OF THE MAT-

powered gears, as well as many lightly loaded ones, require modification ING GEAR ARE ALL DEDENDUM.

of the tooth profile. This ensures smooth sliding of the teeth into and out

of contact without knocking and compensates for misalignment, errors in

gearsolutionsonline.com FEBRUARY 2007 GEAR SOLUTIONS 23

manufacture, and deflections under load. However, a value of 2.0 is generally best for

Tip and root relief are important. The tips reducing noise and dynamic loads. Quality Level

of the pinion teeth are thinned slightly, begin- One of the easiest ways to reduce noise is to

ning at a point halfway up the addendum specify higher AGMA quality levels. As shown

(Fig. 3a). This modification prevents the Backlash in Fig. 6, at higher quality numbers, the total

tooth tip from striking one of the opposite Adequate tooth clearance (backlash) must be dynamic load is reduced. Generally, AGMA

teeth before it begins to pick up the load, provided for thermal and centrifugal expansion. Quality 12 or better is needed for smooth

or striking the trailing flank of the preceding A tight backlash is usually required only with operation.

teeth when rolling out of mesh. The root of reversing drives, where lost motion and impacts Of course, higher quality levels cost more.

the pinion is also thinned to allow for the during reversing may be a problem. For example, going from Quality Number 8

tips of the gear teeth. In some cases, even The operating temperature of a steel gear or to 12 means an increase in cost of 25 to

the hydrodynamic effect of the lubricating oil gear rim might be 100 F or more above ambi- 50 percent, mostly because of the need for

can cause the teeth to emit a rapping sound ent conditions; also, at high speeds, centrifugal special, high-accuracy finishing and grinding

during operation, even though there is no forces can become considerable. Expansion equipment and techniques.

physical contact at or near the tips. results, and the too-tight gear set begins to

Crowning of the tooth flank is another howl. It is relatively simple to calculate fairly

extremely important tooth modification. Load accurately the total anticipated expansion, and Surface Finish

deflections and slight errors in alignment of the resulting amount of backlash needed. Surface finish should be as fine as possible.

the gear housing in the bearing bores can Several methodsshaving, for examplecan

cause hard contact on the flank ends of the be used to obtain a good finish. However, where

tooth. It is therefore desirable to crown the Tooth Loading a superior finish is needed, grinding is usually

gear (form a barrel shape, Fig. 3b) to center As shown in Fig. 5 the higher the tooth loading chosen.

the contact area. As the load increases, a factor, K, the lower the total dynamic load and, Machining can cause periodic undulations

smooth spreading of the contact occurs consequently, the lower the amplitude of vibra- on the gear teeth; these should be kept to less

until the entire flank is loaded. tion and sound. Factor K is proportional to the than 50 to 100 in. Such undulations usually

tangential driving force, W, on the gears:

Overlap Ratio K = (W/F d) [(mG + 1)/mG]

Designing can reduce gear noise at the mesh

so that the total overlap ratio is an integral where F = face width, d = pinion pitch diam-

number of teeth. Tests have shown that if eter, and mG = speed ratio

the ratio is exactly 2.0so that exactly two

teeth are always in contactthe smoothest Quieter operation results from higher load-

transfer of load is obtained. ings because there are always some inaccura-

Overlap ratio expresses the average num- cies in gears, regardless of the quality level to

ber of teeth in contact; in spur gears, it is which they are manufactured. With higher load-

obtained by dividing the length of the line ings, tooth deflections are greater and errors

of action by the normal pitch. With helical have less effect on uniform transmission of FIGURE 3: TOOTH MODIFICATION IS IMPORTANT

IF A MESH IS TO BE QUIET. SHOWN HERE ARE

gears, the total overlap is the combination power through the gear set. TIP AND ROOT RELIEF (A) AND BARRELED

of the transverse overlap and the helical TOOTH FLANK (B). IN EACH CASE, THE SOLID

overlap. LINES REPRESENT THE MODIFIED FORM.

As an example, assume that a gear pair

has an overlap ratio of 1.5. At first, there

will be two pairs of teeth in contact (Fig. 4a)

until a point is reached (Fig. 4b), where the

leading pair disengages at C. After disen-

gagement, the trailing pair will be the only

pair in contact until another pair engages.

Thus, at some point, two teeth are in contact

sharing the load, and at another point one

tooth will assume the entire load. This sets

up an oscillation about the deflection of the

tooth that, although small, adds to sound

generation.

With a higher overlap ratio, more teeth

are in contact to share the load, providing FIGURE 4: ACTION OF TEETH WITH CONTACT RATIO OF 1.5. IN (A), TWO TEETH ARE IN CONTACT, AT

A AND B. HOWEVER, AS THE MESH TURNS (B) THE LEADING PAIR OF TEETH DISENGAGES AT C AND

increased capacity. An overlap ratio of 3.0 ONLY ONE SET IS IN CONTACT UNTIL THE NEXT SET ENGAGES. SUCH ACTION CAN SET UP OSCILLA-

is often best for maximum load capacity. TIONS THAT CAN ADD TO NOISE.

24 GEAR SOLUTIONS FEBRUARY 2007 gearsolutionsonline.com

result from cyclic runouts and inaccuracies in

the master wheel of hobbing machines used to

machine the gears. They can cause such odd

phenomena as, say, a mesh noise frequency

indicating 132 teeth when the bull gear actually

has 215 teeth. Upon investigation, the 132 fre-

quency will turn out to be the number of teeth in

the master wheel on the hobbing machine.

Gear Runout and Imbalance

There is little sense in having Quality Number

14 gears, for example, with tooth tolerances

held to within a few ten-thousandths of an

inch, and then specifying two or three thou-

sandths tolerances on the alignment and

parallelism of the bores. All alignments and

runouts should be in keeping with the quality

level used.

Quality Spiral Bevel Gears

to AGMA 13

FIGURE 5: EFFECT OF TOOTH LOADING FACTOR, Overton Gear now offers Klingelnberg Spiral Bevel Gears

K, ON DYNAMIC LOAD. AS LOAD DECREASES,

SO DOES NOISE. as a hard cutor lapped gear set up to 85 in diameter.

For smooth and quiet operation with 30% increased load carrying

capacity capable of pitch line velocities in excess of 20,000 ft./min.

Ask about our Gleason bevels up to 100.

530 Westgate Dr. Addison, IL 60101

FIGURE 6: EFFECT OF QUALITY LEVEL ON TOTAL

DYNAMIC NOISE. ALTHOUGH, MORE COSTLY, A

Overton Gear (630) 543-9570 Fax: (630) 543-7440

info@overtongear.com

HIGHER QUALITY LEVEL CAN OFFER A SIGNIFI-

& Tool Corporation www.overtongear.com

CANT REDUCTION IN NOISE.

gearsolutionsonline.com FEBRUARY 2007 GEAR SOLUTIONS 25

For optimum quiet operation, the unbalance in the rotors should two types of resonances to be concerned about. One is caused by

be limited to less than U = 3W/N the rotating parts and is associated with critical speeds; the second

involves the support cases, foundation, and structures.

where U = rotor unbalance, oz-in.; W = weight of rotor, lb; N = The critical speeds (resonances) of the rotating parts should be at

speed, rpm least 20 percent from the operating speeds, from their multiples (har-

monics) and from the mesh frequencies of the gear teeth. The farther

the operating speed is from the critical speeds, the less chance there

Gear Ratio will be of detrimental effects.

A non-integral gear ratio should be selected to prevent a tooth on the Resonances of gear cases and other supporting members should

pinion from contacting periodically the same teeth on the mating gear. also be 20 percent from operating speeds, multiples, and tooth-mesh

In most applications, an exact gear ratio is not necessary; by juggling frequencies. This may be difficult to obtain at times, so that a more

the ratios slightly, it is possible to obtain an odd tooth, called the practical minimum may be 10 to 15 percent, depending on how accu-

hunting tooth. rately the resonant frequencies can be calculated.

As an example, a gear pair with 30 teeth on the pinion and 120

teeth on the gear has a speed reduction ratio of 4:1. A particular tooth

on the pinion will contact teeth 1, 31, 61, 91, and continue to repeat Lubricant Viscosity

the cycle, contacting the same four teeth. If a 30/121 pair is used The higher the viscosity of the gear lubricant, the greater the

instead, the reduction ratio becomes 4.03: 1, and the odd tooth on damping action at the mesh, and the quieter the operation.

the 121-tooth gear will not contact the same tooth on the pinion every However, higher viscosities will result in some loss in operating

four cycles. For example, a tooth on the pinion will contact teeth 1, efficiency and power. Most designers of high-speed gears choose

31, 61, 91, 121, 30 60, 90, etc. and will not repeat the cycle until all a light grade of turbine oil (ISO 32 or ISO 46) because it is the

teeth on the gear have been contacted. same oil used in the turbine or compressor. But from the stand-

point of the gear box itself, oils of ISO 68 or ISO 100 are better

suited, provided that the power loss is not a problem. Besides

Resonance quieting the gears, the oils with a higher viscosity will cut down

Any resonating member is a source of vibration and sound. There are gear tooth scoring and wear.

CUSTOM BEVEL GEAR MANUFACTURING

PER YOUR SPECIFICATIONS AND/OR SAMPLE

PROVIDING INVERSE ENGINEERING TO MAKE A CLONE OF YOUR SAMPLE

SPIRAL BEVEL GEARS: 66" PD IN-HOUSE STEEL MATERIAL WAREHOUSE

STRAIGHT BEVEL GEARS: 80" PD FULL HEAT TREATING SERVICES

SPURS-HELICALS-SPLINE SHAFTS EDM WIRE BURNING

GEARBOX REPAIR/REBUILDS

BREAKDOWN

BREAKDOWN SERVICES

SERVICES

4809 U.S. HIGHWAY 45 SHARON, TN 38255

TOLL FREE: (800)-238-0651 PHONE: (731)-456-2636 FAX: (731)-456-3073

EMAIL: inquiry@brgear.com www.brgear.com

Family owned and operated since 1974

26 GEAR SOLUTIONS FEBRUARY 2007 gearsolutionsonline.com

Type of Bearings

Both hydrodynamic (sleeve type) bearings and rolling element

(anti-friction type) bearings can be used to suppor t gear shaft-

ing. Hydrodynamic bearings, which operate on an oil film, pro-

vide for quieter operation. Hydrodynamic bearings typically have

higher friction losses and require more lubrication oil than rolling

element bearings. For standard applications, rolling element

bearings are usually less expensive than hydrodynamic bearings.

The par ticular application often dictates the choices of bearing

types.

Material

The type of material chosen for the gear can have a significant

effect on noise. Cer tain metals, such as the manganese-cop-

per alloys, can dampen vibrations considerably. However, such

alloys lose their damping characteristics at about 150 F.

Unfor tunately; many enclosed gears operate above this tempera-

ture in industrial applications. Non-metallics, which also have

good damping characteristics, have relatively low load carr ying

capabilities, and are more difficult to manufacture accurately.

In general, alloy steels are still the best choice. A sur face

hardened precision tooth ground gear set today is the preferred

tooth treatment method to maximize gear-set ratings. Superior

ground tooth accuracy and fine tooth sur face finishes made pos-

sible by current state of the ar t tooth grinding machiner y also

provide quieter operating characteristics.

Housing

Proper housing design can go a long way toward blocking the

transmission of sound to the environment. Generally, a cast-iron

housing will be deader, or quieter, than a welded steel hous-

ing. However, welded steel has many advantages. It is stronger

and more easily designed to meet custom requirements.

To improve the damping characteristics of welded steel hous-

ings; thin, flat plates should be avoided, because they can be

excited by rotating components and mesh frequencies. Additional

mass can be added, as well as stiffeners, and reinforcing ribs

to break up plate-section resonances. If fur ther noise damping

Gears complete to print up to 16 inches in is required, a layer of synthetic material such as felt, synthetic

diameter offering AGMA class 12 quality rubber, or polymer can be sandwiched between two steel plates

to form a constrained layer of damping material.

Gear grinding services up to 27.8 inches in To cut down the transmission of noise through the floor, the

diameter featuring newer CNC gear grinders housing should be mounted on a vibration-isolating material

placed directly under the gear box. A relatively stiff laminated

Quantities of 1 to 100 pcs. rubber or other type of material should be used to absorb the

higher frequencies.

Analytical Gear Charts to insure quality

ABOUT THE AUTHORS:

Bill Bradley developed this material when he was chief test engi-

neer for the Philadelphia Gear Co. He is currently vice president of

the AGMAs technical division [www.agma.org]. Richard Schunck is

a staff engineer with Rexnord Industries, LLC [www.rexnord.com].

This material was compiled by Jules DeBaecke, vice president of

4884 STENSTROM ROAD ROCKFORD, IL 61109 engineering at Philadelphia Gear, and Sudhakar Rao, gear analyst.

PHONE: 815-874-3948 FAX: 815-874-3817 Go online to [www.philagear.com].

w w w . r a y c a r g e a r . c o m

28 GEAR SOLUTIONS FEBRUARY 2007 gearsolutionsonline.com

You might also like

- Re Voltage StabilityDocument27 pagesRe Voltage StabilityTravis WoodNo ratings yet

- Anandaram BaruaDocument1 pageAnandaram BaruaTravis WoodNo ratings yet

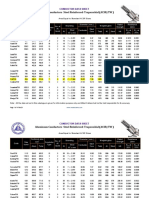

- Aluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Document4 pagesAluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Travis WoodNo ratings yet

- Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Document6 pagesEnhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Travis WoodNo ratings yet

- Unidirectional Corona RingDocument2 pagesUnidirectional Corona RingTravis WoodNo ratings yet

- April Is The Cruellest MonthDocument1 pageApril Is The Cruellest MonthTravis WoodNo ratings yet

- KSEB Technical SPec PDFDocument279 pagesKSEB Technical SPec PDFTravis WoodNo ratings yet

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended Practicesvjs270385No ratings yet

- Analysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceDocument7 pagesAnalysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceTravis WoodNo ratings yet

- 1363 Bolts and Nut Standard PDFDocument7 pages1363 Bolts and Nut Standard PDFTravis WoodNo ratings yet

- Double Sampling-Wha It Means PDFDocument17 pagesDouble Sampling-Wha It Means PDFTravis WoodNo ratings yet

- Ceramic Manufacturing PDFDocument41 pagesCeramic Manufacturing PDFTravis WoodNo ratings yet

- Innovative Adhesive For Sandwich SystemsDocument20 pagesInnovative Adhesive For Sandwich SystemsTravis WoodNo ratings yet

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 pagesEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosNo ratings yet

- Study of Single and Double Sampling PlansDocument14 pagesStudy of Single and Double Sampling PlansTravis WoodNo ratings yet

- Mud Architecture: I J I R S E TDocument6 pagesMud Architecture: I J I R S E TJazzNo ratings yet

- Ehv Disconnectors For Smart GridDocument2 pagesEhv Disconnectors For Smart GridTravis WoodNo ratings yet

- Transformer Factory Assembly Area LayoutDocument55 pagesTransformer Factory Assembly Area LayoutTravis Wood100% (2)

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodNo ratings yet

- 3 Sec-III-Hardware Fittings & AccessoriesDocument49 pages3 Sec-III-Hardware Fittings & AccessoriesTravis WoodNo ratings yet

- Fretting Fatigue in Overhead ConductorsDocument16 pagesFretting Fatigue in Overhead ConductorsTravis WoodNo ratings yet

- CT Grounding To Avoid Nuisance TrippingDocument2 pagesCT Grounding To Avoid Nuisance TrippingTravis WoodNo ratings yet

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodNo ratings yet

- Anil Agarwal: Research: Mud As A Traditional Building MaterialDocument10 pagesAnil Agarwal: Research: Mud As A Traditional Building MaterialTravis WoodNo ratings yet

- ElectricalDocument34 pagesElectricalTravis WoodNo ratings yet

- An Introduction To Conway's Games and NumbersDocument30 pagesAn Introduction To Conway's Games and NumbersSilentSparrow98No ratings yet

- Spacer Damper IssuesDocument5 pagesSpacer Damper IssuesTravis WoodNo ratings yet

- Bolt InterlocksDocument5 pagesBolt InterlocksTravis WoodNo ratings yet

- CB Spec SvenskaDocument44 pagesCB Spec SvenskaTravis WoodNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Maag Gear Box Wpu 182fDocument188 pagesMaag Gear Box Wpu 182fMahmoud Mohammad60% (5)

- Haydon - Kerk - Catalog - 2017 MAR DIG LRDocument265 pagesHaydon - Kerk - Catalog - 2017 MAR DIG LRRuben PauwelsNo ratings yet

- Doosan Machine Tools NC Boring Mill DBC SeriesDocument52 pagesDoosan Machine Tools NC Boring Mill DBC Seriessynmax100% (1)

- Axial Control Valve BrochureDocument9 pagesAxial Control Valve BrochureJeromeNo ratings yet

- Foote-Jones Lubrication ManualDocument40 pagesFoote-Jones Lubrication ManualbwelzNo ratings yet

- Relay With Hysteresis & Dead Zone, Saturations / Coulomb Friction & BackslashDocument12 pagesRelay With Hysteresis & Dead Zone, Saturations / Coulomb Friction & Backslashfarah haniNo ratings yet

- Backlash compensation made easy through dual loop motion controlDocument2 pagesBacklash compensation made easy through dual loop motion controlSam SamovarkovNo ratings yet

- Chapter 9-SPUR GEARS AND GEAR TRAINSDocument64 pagesChapter 9-SPUR GEARS AND GEAR TRAINSMohammed Al-OdatNo ratings yet

- QSK 19 TorqueDocument91 pagesQSK 19 TorqueEmmanuel OgungbemiNo ratings yet

- Automatic clamps simplify die casting mold changesDocument16 pagesAutomatic clamps simplify die casting mold changesKrishna Mohan T.RNo ratings yet

- XYZ Katalog Centra 2010-2012Document20 pagesXYZ Katalog Centra 2010-2012Boutef El HachemiNo ratings yet

- KISSsoft 2019 Tutorial 16-The-Tolerance-For-The-External-Diameter-Of-The-WormDocument17 pagesKISSsoft 2019 Tutorial 16-The-Tolerance-For-The-External-Diameter-Of-The-WormNguyễnVănLăngNo ratings yet

- Gear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemDocument6 pagesGear Group (Front) - Install - Idler Gear Only: Desmontagem e MontagemJose nildo lobato Mendes MendesNo ratings yet

- Zukio Off-Road Differential GuideDocument16 pagesZukio Off-Road Differential Guidepuiu_tNo ratings yet

- Accessory and Load Gearbox ProblemsDocument36 pagesAccessory and Load Gearbox ProblemsJJ100% (1)

- SAE Gear Design Course - C0223 - th003Document194 pagesSAE Gear Design Course - C0223 - th003mirekjanda100% (5)

- Comparison ISO Standards 1328-1:1995 and 1328-1:2013: April 2014Document5 pagesComparison ISO Standards 1328-1:1995 and 1328-1:2013: April 2014Joan Camilo PovedaNo ratings yet

- Axsm 8941Document50 pagesAxsm 8941Known_UserNo ratings yet

- FME Ch14Document43 pagesFME Ch14Jessica Tatiana Muñoz OrtizNo ratings yet

- Instruction Manual: CL-60A Centre Lathe (415V) 460 X 1500mm Turning CapacityDocument89 pagesInstruction Manual: CL-60A Centre Lathe (415V) 460 X 1500mm Turning CapacityantagonicoNo ratings yet

- Lec 4Document16 pagesLec 4Shubham SharmaNo ratings yet

- Kerk Catalog 2008 PDFDocument74 pagesKerk Catalog 2008 PDFhexapodoNo ratings yet

- 2.4 Precaution of Usage For Anti Backlash Spur GearsDocument2 pages2.4 Precaution of Usage For Anti Backlash Spur Gearsnay hlaing SoeNo ratings yet

- Dokumen - Tips - Caterpillar Cat 420d Backhoe Loader Prefix FDP Service Repair Manual fdp07199 18399 1594410712 PDFDocument23 pagesDokumen - Tips - Caterpillar Cat 420d Backhoe Loader Prefix FDP Service Repair Manual fdp07199 18399 1594410712 PDFHugo PinedaNo ratings yet

- Preview ANSI+AGMA+2008-C01Document7 pagesPreview ANSI+AGMA+2008-C01Alaa MaherNo ratings yet

- Gears PDFDocument45 pagesGears PDFSanmukh ShindeNo ratings yet

- NX enDocument44 pagesNX enAri SusantoNo ratings yet

- Automatic Transmission Overhaul GuideDocument62 pagesAutomatic Transmission Overhaul GuideDERLIS RAMIREZ100% (2)

- Unit 2 Screw Thread - Gear Elements - Surface FinishDocument53 pagesUnit 2 Screw Thread - Gear Elements - Surface FinishDeepak MisraNo ratings yet