Professional Documents

Culture Documents

TankBlanketing Basic PDF

Uploaded by

Galuh Ajeng0 ratings0% found this document useful (0 votes)

24 views3 pagesOriginal Title

TankBlanketing Basic.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views3 pagesTankBlanketing Basic PDF

Uploaded by

Galuh AjengCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Tank Blanketing Basics Covered

For More Information on this topic visit the author's website

Tank Blanketing, or padding, refers to applying a cover of gas over the surface of a stores commodity; usually a

liquid. Its purpose is either to protect or contain the stored product or prevent it from harming personnel, equipment,

or the environment. In most cases the blanketing gas is nitrogen, although other gases may be used.

Blanketing may prevent liquid from vaporizing into the atmosphere. It can maintain the atmosphere above a

flammable or combustible liquid to reduce ignition potential. It can make up the volume caused by cooling of the

tank contents, preventing vacuum and the ingress of atmospheric air.

Blanketing can simply prevent oxidation or contamination of the product by reducing its exposure to atmospheric

air. It can also reduce the moisture content. Gas such as nitrogen is supplied in a very pure and dry state.

The list of products blanketed is extensive ---- everything from adhesives, catalyst, chemicals, fats and oils, foods,

fuels, inks, pharmaceuticals, photographic chemicals, soaps, and water.

Pressure Points

In order to effectively perform any of these functions the blanketing system must be capable of pressurizing the

vapor space and accurately maintaining that pressure.

Further, conserving the amount of gas used requires that the blanketing pressure be very low. Additionally, it must

be less than the tank's pressure capability. This pressure also must be below the normal tank venting pressures top

prevent unnecessary actuation of these devices and the subsequent discharge of blanketing gas, as well as product

loss.

These functions have been performed in various ways over the years. One method involves continuous purging,

whereby blanketing gas introduced into the tank as a continuous flow exits through a vent or other opening. This

method is wasteful of the blanketing gas and not always effective in maintaining an inert atmosphere.

Another approach employs a simple, direct-operated pressure-reducing valve (PRV) to blanket the tank. However,

these devices are the best suited to a continuous flow rate. When used to blanket a tank they must throttle over a

wide flow range. Ranging from a shut-off to a full flow condition varies the controlled pressure significantly due to

droop and lockup conditions.

Pressure variations can be as much as 30 percent below or 20 percent above setpoint. The results are the poor

control, wasting of blanketing gas, and possibly not maintaining the necessary atmosphere within the tank.

Another Approach

One of the more effective techniques relies on a blanketing system with the necessary controls and valving to sense

and maintain the set pressure within the tank to as close as 0.25 inch w.c. [water column] ( 0.009 psi). Set

pressures of 0.5 inch w.c. are possible and common.

Such a system will directly sense the tank pressure, control the inlet blanketing gas pressure if required and, through

a main control valve, throttle blanketing gas into the tank.

The system may also provide a purge in the sensing and main supply piping, plus reverse flow protection to keep

product out of the blanketing system. The installation may also require a pressure switch to monitor tank pressure

and perform alarm or control functions in response to over- or under-pressure conditions.

Operation, Activation

When blanketing gas enters the typical system (figure 1), the first-stage regulator (A) reduces inlet pressure from

high to low. (This is not always required.) From here, the gas flows to the main control valve (E), which is closed

when the tank is at or above its setpoint.

Supply is also piped to a filter regulator (B) supplying the pilot loading pressure - typically 10 psi - for actuation of

the main flow control valve. This reduced pressure then floes through an orifice (C) and to the lower case of the

main flow control valve as well as to the inlet of a sensing regulator (D).

The sensing regulator includes a diaphragm, which directly senses tank pressure. Its design, weighted and inverted,

allows sensitivity to as close as 0.1 inch w.c. as well as the ability to sense and control vacuums at any pressure up

to the inlet pressure. The outlet of the sensing regulator connects to the tank vapor space.

In operation, if tank pressure is below setpoint, the spring will move the sensing regulator diaphragm upward,

opening the seat and allowing flow from the filter regulator through the orifice and into the tank. The size of the

orifice limits the volume flowrate of gas to the tank. This minimal flow may be all that's necessary to satisfy a small

demand.

However, as demand increases due to pump-out or thermal cooling, the pressure drops in the pilot loading line that

connects (C) to main valve (E). This then reduces the pressure applied to the underside of the main valve diaphragm,

which allows the spring to move the diaphragm, throttling the main valve open and supplying blanketing gas to the

tank.

Setpoint Response

When the tank reaches setpoint, tank pressure operating against the sensing regulator diaphragm causes the seat to

close. This blocks pilot loading flow and pressure rises to the 10 psi setting. This pressure then operates against the

main valve diaphragm, causing the main flow control valve seat to close. Flow to the tank ceases.

At pressures below the setpoint the sensing regulator will throttle, varying pressure in the sensing system and then

throttling the main valve. The amount of throttling is proportional to the offset from setpoint. Therefore, as tank

pressure rises and approaches the setpoint, the main valve throttles and is closing as the tank reaches setpoint. This

maintains accurate setpoints and reduces overshooting.

In addition to a blanketing system, the tank will contain the emergency vent as well as normal pressure and vacuum

vents --- all of which must be properly sized for outgassing from pump-in, increases in temperature, drop in

barometric pressure, or fire. The vacuum relief provides redundant tank protection for unforeseen conditions, loss of

blanketing gas supply or system failure.

The selection of a blanketing pressure is very important. It

must be less than the tank's pressure capability, and also

should allow some dead-band below the tank vent operating

pressure to avoid interaction.

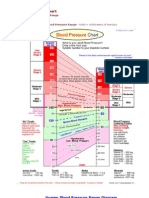

Figure 2 illustrates a tank blanketed to 0.5 inch w.c. having

an allowable working pressure of 6 ounces per square inch. A

pressure of 0.25 inch w.c. added for shut-off results in a

maximum blanketing pressure of 0.75 inch w.c. The tank has

a normal pressure breathing vent that starts to open at 1.5

ounces per square inch (2.6 inches w.c.) and is full open at

1.8 ounces per square inch (3.1 inches w.c.).

Further, an emergency vent opens at 3 ounces per square inch

(5.2 inches w.c.) and is fully open at 3.5 ounces per square

inch (6.1 inches w.c.). There is a dead-band of 2.1 inches

w.c. between the two vents. The dead-band between the

blanketing system and the normal vent is 2.6 -0.75 = 1.85

inches w.c. The presence of an adequate dead-band will

ensure stable operation and avoid unnecessary loss of

blanketing gas or product going out an open tank vent.

Proper sizing is important for stable operation. Under-sizing

can result in tank pressures dropping well below the setpoint

as the main flow control valve struggles to keep up with

demand. Over-sizing is less critical. However, taken to an

extreme, it can result in unstable operation due to exceeding

setpoint.

Blanket Summary

A gas blanketing system will effectively contain gases within

the vapor space of a tank. Such a system can contain the gas,

or protect the tank contents form contact with atmospheric

air. It also can maintain the vapor space contents at an oxygen concentration level low enough to prevent ignition of

flammable vapors.

The system are simple to use and require little, if any, maintenance. They are capable of blanketing at pressures as

low as 0.5 inch w.c., minimizing consumption of blanketing gas.

Nitrogen is the most common blanketing gas, but others are used if compatible with the process. From a virtually

endless list of products that qualify for blanketing, those that are volatile as well as those sensitive to contact with

moisture or air are all candidates.

This article was written by Paul R. Ostand and editied by Joshua Sinsel of McNeil Consumer Healthcare

Author's Comments:

"Since the original publication date there have been advances in the technology used to provide gas blankets. While

this article does not illustrate these, the basics discussed in the article are still valid."

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Blood Pressure ChartDocument5 pagesBlood Pressure Chartmahajan1963100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Process Equipment Cost Estimation ReportDocument80 pagesProcess Equipment Cost Estimation Reportwriteandrewpaul7707100% (1)

- K Value of FittingsDocument4 pagesK Value of FittingsJoydip Misra100% (6)

- Delta P in Diving - Risks and Prevention PDFDocument87 pagesDelta P in Diving - Risks and Prevention PDFfrgonzalezNo ratings yet

- Unit 6Document13 pagesUnit 6VeronicaNo ratings yet

- Step by Step Calculation of NPSHaDocument7 pagesStep by Step Calculation of NPSHaAnonymous serSMsnggNo ratings yet

- 660 MW Sipat BoilerDocument88 pages660 MW Sipat BoilerTochi Krishna Abhishek100% (4)

- Ammonia StandardDocument73 pagesAmmonia StandardPedram100% (1)

- Fire and Gas in The Process Industry Jon Hind PaperDocument40 pagesFire and Gas in The Process Industry Jon Hind PaperLieu Dinh PhungNo ratings yet

- Linda Howard Placere ExclusivapdfDocument72 pagesLinda Howard Placere ExclusivapdfalexeNo ratings yet

- Circulating Fluidised Bed Boiler Technology Coal Oil Power - PDF (Application PDFDocument16 pagesCirculating Fluidised Bed Boiler Technology Coal Oil Power - PDF (Application PDFGaluh AjengNo ratings yet

- Crude Oil Viscosity & API ChartDocument3 pagesCrude Oil Viscosity & API ChartGaluh Ajeng100% (1)

- Gas Safety and Material Compatibility Data Chart: Materials of Construction Hazards For HumansDocument2 pagesGas Safety and Material Compatibility Data Chart: Materials of Construction Hazards For HumansGaluh AjengNo ratings yet

- S130 20Document10 pagesS130 20Galuh AjengNo ratings yet

- Drain Traps: Product OfferingDocument2 pagesDrain Traps: Product OfferingGaluh AjengNo ratings yet

- Liquid Drain TrapsDocument8 pagesLiquid Drain TrapsgracemanotocNo ratings yet

- Design Minerall Processing PlantDocument20 pagesDesign Minerall Processing Plantdarioharloc2272No ratings yet

- Drain Traps: Product OfferingDocument2 pagesDrain Traps: Product OfferingGaluh AjengNo ratings yet

- Biodiesel SpecificationDocument12 pagesBiodiesel Specificationseptian pratamaNo ratings yet

- Organic Rankine CycleDocument175 pagesOrganic Rankine CycleGaluh AjengNo ratings yet

- Five Valve Manifolds - Operation: Hex Model HM53 & 77 Gas Metering Manifold Hex Model HM55 & 56 Blowdown ManifoldDocument1 pageFive Valve Manifolds - Operation: Hex Model HM53 & 77 Gas Metering Manifold Hex Model HM55 & 56 Blowdown ManifoldGaluh AjengNo ratings yet

- Why The Shipping Industry Is Betting Big On Ammonia - IEEE SpectrumDocument8 pagesWhy The Shipping Industry Is Betting Big On Ammonia - IEEE SpectrumGaluh AjengNo ratings yet

- Fixed or Semi Fixed Fire Protection SystemDocument10 pagesFixed or Semi Fixed Fire Protection SystemkhorzooNo ratings yet

- 21.02.2019 IEA Chapter 3 Hydrogen Carriers Delivery PlanDocument19 pages21.02.2019 IEA Chapter 3 Hydrogen Carriers Delivery PlanGaluh AjengNo ratings yet

- LC 26750Document5 pagesLC 26750Alberto AyónNo ratings yet

- 13 Venting Requirements PDFDocument4 pages13 Venting Requirements PDFAngel LugoNo ratings yet

- qt7z69v4wp NosplashDocument34 pagesqt7z69v4wp NosplashGaluh AjengNo ratings yet

- Biodiesel SpecificationDocument12 pagesBiodiesel Specificationseptian pratamaNo ratings yet

- Coal Combustion Products: Fly AshDocument2 pagesCoal Combustion Products: Fly AshGaluh AjengNo ratings yet

- Biodiesel Standards - SpecificationDocument2 pagesBiodiesel Standards - SpecificationGaluh AjengNo ratings yet

- Steam TablesDocument1 pageSteam TablesGaluh AjengNo ratings yet

- Venting Q and A PDFDocument5 pagesVenting Q and A PDFyulianus_srNo ratings yet

- B30 MSDSDocument11 pagesB30 MSDSGaluh AjengNo ratings yet

- Dust ControlDocument2 pagesDust ControlGaluh AjengNo ratings yet

- BETE - Spray CoverageDocument1 pageBETE - Spray CoverageGaluh AjengNo ratings yet

- API RP 2210 - 2000 Flame Arresters For Vents of TanksDocument2 pagesAPI RP 2210 - 2000 Flame Arresters For Vents of TanksGaluh AjengNo ratings yet

- Hazardous InformationDocument23 pagesHazardous InformationGaluh AjengNo ratings yet

- Properties of Gas Condensates - Application of Reservoir Fluid StudiesDocument9 pagesProperties of Gas Condensates - Application of Reservoir Fluid StudiesAlejandro PerezNo ratings yet

- Roleplay Blood PressureDocument3 pagesRoleplay Blood Pressurebella raraNo ratings yet

- Superimposed Dead Loads and Live Loads Load MagnitudeDocument8 pagesSuperimposed Dead Loads and Live Loads Load MagnitudeLouieNo ratings yet

- (57)Document5 pages(57)DewiNo ratings yet

- Install and Maintain a Gas Wok RangeDocument31 pagesInstall and Maintain a Gas Wok RangeNugrohoNo ratings yet

- An Article On Tank Bulging Effect or Bulging Effect of Tank ShellsDocument4 pagesAn Article On Tank Bulging Effect or Bulging Effect of Tank ShellsiaftNo ratings yet

- Fluid Mechanics Course OutlineDocument3 pagesFluid Mechanics Course Outlinemeku44No ratings yet

- DS1081 LPCO2 Refrigerated Storage Units Revision 07-18-18Document8 pagesDS1081 LPCO2 Refrigerated Storage Units Revision 07-18-18kidmuNo ratings yet

- Datasheet Differential Pressure Sensor SDP1108 SDP2108Document7 pagesDatasheet Differential Pressure Sensor SDP1108 SDP2108jaijadduNo ratings yet

- Transmission Pressures - Test and Adjust-1Document5 pagesTransmission Pressures - Test and Adjust-1Nasrul arulNo ratings yet

- The Relationship of Thickening Time, Gel Strength, and Compressive Strength of Oilwell CementsDocument10 pagesThe Relationship of Thickening Time, Gel Strength, and Compressive Strength of Oilwell CementsGreg CerrutiNo ratings yet

- Smoke Control: Section 4/chapter 12Document12 pagesSmoke Control: Section 4/chapter 12Ramyaa LakshmiNo ratings yet

- Topic 1 General Physics PDFDocument17 pagesTopic 1 General Physics PDFChandini JosephNo ratings yet

- Elastic Settlement Shallow Foundations - A Critical Review 2 PDFDocument35 pagesElastic Settlement Shallow Foundations - A Critical Review 2 PDFmohdpat05100% (2)

- On The Theory of Seismic and Seismoelectric Phenomena in A Moist SoilDocument19 pagesOn The Theory of Seismic and Seismoelectric Phenomena in A Moist SoilRobbi HidayatNo ratings yet

- Pressure Drop GraphsDocument201 pagesPressure Drop GraphsMuh AsharNo ratings yet

- 2014 - 0011B PIPE SIZING FOR WATER SUPPLY and DISTRIBUTIONDocument34 pages2014 - 0011B PIPE SIZING FOR WATER SUPPLY and DISTRIBUTIONMedina BNo ratings yet

- BFE-FM200-EPFS-000-02 - System Datasheet (UL)Document52 pagesBFE-FM200-EPFS-000-02 - System Datasheet (UL)SajjadNo ratings yet

- Jessica Agar: Search Subjects LOG INDocument7 pagesJessica Agar: Search Subjects LOG INJamiel CatapangNo ratings yet

- Airox Presentation - 248Document36 pagesAirox Presentation - 248mino pharm0% (1)

- Limitations To The Use of Effective Stresses in Partly Saturated Soils-Jennings & BurlandDocument20 pagesLimitations To The Use of Effective Stresses in Partly Saturated Soils-Jennings & BurlandAnonymous GnfGTwNo ratings yet

- LRFD Aashto 3-27-38Document12 pagesLRFD Aashto 3-27-38HFLORESHERRAIZNo ratings yet

- Process Data Sheet for North Oil Company Choke ValveDocument5 pagesProcess Data Sheet for North Oil Company Choke ValveANIL KUMARNo ratings yet