Professional Documents

Culture Documents

AG - 266level EN B 03 - 2011 PDF

Uploaded by

DHANASEKAR NATARAJANOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AG - 266level EN B 03 - 2011 PDF

Uploaded by

DHANASEKAR NATARAJANCopyright:

Available Formats

Application Description AG/266level-EN Rev.

2600T Series Pressure Transmitters

Cost Effective Flanged Level Measurements

Pressure Measurement

Engineered solutions for all

applications

Premium performance measurements

Get the best performance for your level measurements with

the 266DHH flanged level transmitter.

Reduce instrument costs an average 15%

In many cases level measurements do not need a diaphragm

seal but just a flanged connection.

Flanged mounted level transmitter convenience

266DDH is more performing and less expensive compared to

conventional diaphragm seal equipped devices.

2600T Series Pressure Transmitters

Cost Effective Flanged Level Measurements

General description and introduction

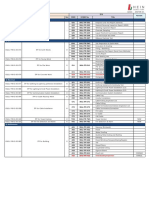

A huge part of the direct mount pressure transmitters are Total probable error comparison

installed on level measurement applications. Very often users or 266DHH Vs 266DDH

0,700%

even engineering companies specify flanged process connection TPE (of cal span)

and as a consequence they ideally link the flanged connection to 0,600%

a diaphragm seal. Thanks to our product portfolio we do have Calibrated span : 600 mbar

the opportunity to be proactive and help our customer in defining 0,500%

Amb. Temp Variation : 28C

Process connection : 2" ANSI 150

a better solution for clean fluid level or pressure measurement.

0,400%

Understanding the difference

To appreciate how to eliminate diaphragm seals in these 0,300%

applications, you must first gain an understanding of how seal

systems function. The diaphragm seal system is an additional 0,200%

hydraulic circuit installed between the sensor diaphragm and the

process. A diaphragm seal system can be used for many 0,100%

different reasons such as:

0,000%

Highly viscous process fluid which may clog a conventional 266DHH 266DDH

transmitter pressure ports.

Extreme process fluid temperatures which are not compatible

with the transmitter and may not be reduced within the 266DDH Perfect application for the critical condition in level

transmitter temperature limits through traditional methods of measurement

using condensation pots or bending sensing lines. 266DDH with S26 series diaphragm seal can be used when

higher process temperature (>120C / 248F) fluids need to be

266DHH Fast and realiabile solution for the common level measured or where Stainless steel is not compatible with the

measurement corrosion resistance requirement of the process fluid.

The 266DHH has been especially designed for the most When the process fluid is or can become very viscous, a

commom level measurement applications. diaphragm flush to the wall of the tank may be needed.

The S26 diaphragm seal with extended diaphragm is the

1. Improve the reliability of the product obvious solution also when exotic wetted materials are needed.

The transducer diaphragm is directly in contact with the process

fluid that enters the cavity. This design does not require any

further separation and thanks to the generous diameter of the

transducer diaphragm (40 mm/1.5 in.) it is not prone to clogging.

2. Improve the accuracy of the measurement

With the shortest and the most simple hydraulic circuit, total

performances are significantly improved.

Just to make an example:

In a level measurement where the calibrated span is 6000

mmH2O (236wc), considering an ambient temperature variation

of 28C (82 F) and a process connection of 2 ANSI 150 the

Total Probable Error of the 266DHH is 0,098% of calibrated

span, while the error of ABBs diaphragm level model 266DDH

with a 2 ANSI 150 S26F high performance diaphragm is 0,648%

of calibrated span.

This tells us that the 266DHH is 6 times more accurate in real

operating conditions compared with diaphragm seal equipped Figure 1: Extended diaphragm seal. The extension allows the diaphragm to

devices. be flush to the internal walls of the tank.

2 AG/266level-EN Rev. B | 2600T Series Pressure transmitters

The difference in application between the flush diaphragm

and the 266DHH:

Compared with traditional flush diaphragm seal systems, the

266DHH features:

Compatibility with process connection

Better performances and response time

The suggestions in application:

266DHH can be used in many level measurememt applications

where the fluid is clean like water, oil and gasoline etc.

High YES 266DDH + S26

Process fluid

viscosity ext. diaphragm

NO

Figure 2: Flush diaphragm seal. The diaphragm is flush to the process

temp. > YES 266DDH + S26

connection and the process fluid enters the cavity.

120C flush diaphragm

NO

Ok with NO

SST 316L?

YES

266DHH

15% list price compared to a 266DDH

Figure 3: 266DHH design. The process fluid acts directly on the internal

transducer diaphragm.

2600T Series Pressure transmitters | AG/266level-EN Rev. B 3

Contact us

To find your local ABB contact visit Note

AG/266level-EN Rev. B 03.2011 | 3KXP0000004R3001

We reserve the right to make technical changes or

www.abb.com/contact

modify the contents of this document without prior

notice. With regard to purchase orders, the agreed

For more product information visit particulars shall prevail. ABB does not accept any

www.abb.com responsibility whatsoever for potential errors or

possible lack of information in this document.

We reserve all rights in this document and in the

subject matter and illustrations contained therein.

Any reproduction, disclosure to third parties or

utilization of its contents - in whole or in parts is

forbidden without prior written consent of ABB.

Copyright 2010 ABB

All rights reserved

You might also like

- Book1-SCR DOC1Document1 pageBook1-SCR DOC1DHANASEKAR NATARAJANNo ratings yet

- Bootless LugsDocument4 pagesBootless LugsDHANASEKAR NATARAJANNo ratings yet

- CTI-36 STD InfoDocument1 pageCTI-36 STD InfoDHANASEKAR NATARAJANNo ratings yet

- Material Reference - Rubber ProductsDocument3 pagesMaterial Reference - Rubber ProductsDHANASEKAR NATARAJANNo ratings yet

- Compare Honda City, Ford Fiesta and Mitsubishi AttrageDocument4 pagesCompare Honda City, Ford Fiesta and Mitsubishi AttrageDHANASEKAR NATARAJANNo ratings yet

- Accident Free, Lady Driven Ford Focus 2008 For Sale.: You Are HereDocument6 pagesAccident Free, Lady Driven Ford Focus 2008 For Sale.: You Are HereDHANASEKAR NATARAJANNo ratings yet

- Apple Iphone 5s Vs Samsung A5Document4 pagesApple Iphone 5s Vs Samsung A5DHANASEKAR NATARAJANNo ratings yet

- Accident Free, Lady Driven Ford Focus 2008 For Sale.: You Are HereDocument6 pagesAccident Free, Lady Driven Ford Focus 2008 For Sale.: You Are HereDHANASEKAR NATARAJANNo ratings yet

- Msds - MegDocument2 pagesMsds - MegDHANASEKAR NATARAJANNo ratings yet

- KAHRAMAA Drinking Water Quality RequirmentDocument59 pagesKAHRAMAA Drinking Water Quality RequirmentWael Abdel-MageedNo ratings yet

- Compare Cars - 2Document4 pagesCompare Cars - 2DHANASEKAR NATARAJANNo ratings yet

- CVT - Continuously Variable TransmissionDocument15 pagesCVT - Continuously Variable TransmissionDHANASEKAR NATARAJANNo ratings yet

- Yuga - Wikipedia, The Free EncyclopediaDocument5 pagesYuga - Wikipedia, The Free EncyclopediaDHANASEKAR NATARAJANNo ratings yet

- How Many States Are There in The United StatesDocument3 pagesHow Many States Are There in The United StatesDHANASEKAR NATARAJANNo ratings yet

- Hyundai Accent 2014 VS Mitsubishi Attrage 2014 VS Honda City 2014Document4 pagesHyundai Accent 2014 VS Mitsubishi Attrage 2014 VS Honda City 2014DHANASEKAR NATARAJANNo ratings yet

- Specific Heat of Food and FoodstuffDocument6 pagesSpecific Heat of Food and FoodstuffDHANASEKAR NATARAJAN100% (1)

- Sea Water Air Conditioning - Makai Ocean EngineeringDocument13 pagesSea Water Air Conditioning - Makai Ocean EngineeringDHANASEKAR NATARAJANNo ratings yet

- Letter To MotherlandDocument3 pagesLetter To MotherlandDHANASEKAR NATARAJANNo ratings yet

- 16-12-2016 Ashrae SeminarDocument23 pages16-12-2016 Ashrae SeminarDHANASEKAR NATARAJANNo ratings yet

- Yuga - Wikipedia, The Free EncyclopediaDocument5 pagesYuga - Wikipedia, The Free EncyclopediaDHANASEKAR NATARAJANNo ratings yet

- HVAC Chilled Water Distribution SchemesDocument56 pagesHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- Apple Iphone 5s Vs Samsung A5Document4 pagesApple Iphone 5s Vs Samsung A5DHANASEKAR NATARAJANNo ratings yet

- Specific Heat of Food and FoodstuffDocument6 pagesSpecific Heat of Food and FoodstuffDHANASEKAR NATARAJAN100% (1)

- Industrial Area Road Map of District Cooling PlantsDocument1 pageIndustrial Area Road Map of District Cooling PlantsDHANASEKAR NATARAJANNo ratings yet

- Specific Heat of Food and FoodstuffDocument9 pagesSpecific Heat of Food and FoodstuffDHANASEKAR NATARAJANNo ratings yet

- Thermal InsulationDocument2 pagesThermal InsulationDHANASEKAR NATARAJANNo ratings yet

- Specific Heat of Food and FoodstuffDocument6 pagesSpecific Heat of Food and FoodstuffDHANASEKAR NATARAJAN100% (1)

- 5 Steps To Chiller EfficiencyDocument10 pages5 Steps To Chiller EfficiencyDHANASEKAR NATARAJANNo ratings yet

- Cooling Tower ArticleDocument7 pagesCooling Tower ArticleAudrey Patrick KallaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lightening The Load - Marco Polo Leads The WayDocument28 pagesLightening The Load - Marco Polo Leads The WaydmaproiectNo ratings yet

- EV Super SessionDocument26 pagesEV Super SessionrajuwithualwaysNo ratings yet

- LS H NPT 3KDocument2 pagesLS H NPT 3KBenjaz AvilaNo ratings yet

- Royal Military College of Science - Cranfield University: ReliabilityDocument4 pagesRoyal Military College of Science - Cranfield University: ReliabilitySanjay MehrishiNo ratings yet

- Hilman Rollers BrochureDocument8 pagesHilman Rollers BrochureSyafiq HalimNo ratings yet

- Article 10 Leak TestingDocument24 pagesArticle 10 Leak TestingAnonymous OsAs5Hg23No ratings yet

- API Standard 660 TI PDFDocument7 pagesAPI Standard 660 TI PDFJoko KumboroNo ratings yet

- Effect of Using Pozzolanic Materials On The Properties of Egyptian Soils PDFDocument7 pagesEffect of Using Pozzolanic Materials On The Properties of Egyptian Soils PDFHery BudiantoNo ratings yet

- Dictionary of Boiler TerminologyDocument27 pagesDictionary of Boiler TerminologyAlka Seltzer100% (34)

- Instruction Manual: A959 1:18 4WD Offf-Road Buggy RC CarDocument6 pagesInstruction Manual: A959 1:18 4WD Offf-Road Buggy RC CarLäůrã MîrëllNo ratings yet

- d4-260 - Inboard DieselDocument2 pagesd4-260 - Inboard DieselxxxxxxxxxxxxNo ratings yet

- DampavaultDocument8 pagesDampavaultchillerz69No ratings yet

- M E LAB 3 Experiment 4 Heat Losses From Pipes 3Document20 pagesM E LAB 3 Experiment 4 Heat Losses From Pipes 3Alister Mae ZafraNo ratings yet

- ME / M.Tech-Mechanical 2017-2018: Sno Projects List Design AnalysisDocument5 pagesME / M.Tech-Mechanical 2017-2018: Sno Projects List Design AnalysisSanjay ShelarNo ratings yet

- 4812159895Document642 pages4812159895El Aleman0% (1)

- IST CVCM Accommodations & Registration for Vibration Analysis Level-II Course April 2015Document2 pagesIST CVCM Accommodations & Registration for Vibration Analysis Level-II Course April 2015HaseebPiracha0% (1)

- Piping Specification ChecklistDocument6 pagesPiping Specification ChecklistBinodh DanielNo ratings yet

- M38A1 MaintenanceDocument391 pagesM38A1 MaintenanceTom E Hixon100% (1)

- Belt Drive: Prof. H. D. Mhatre 1Document22 pagesBelt Drive: Prof. H. D. Mhatre 1PHOOL KUMAR PATELNo ratings yet

- Pickling and Passivation ProcedureDocument5 pagesPickling and Passivation ProcedureBoby Thomas100% (5)

- 000 Itp-Itr List - r11Document3 pages000 Itp-Itr List - r11Qii BagerNo ratings yet

- Accordion Fold Book: by Diane Weintraub and Kathy MillerDocument2 pagesAccordion Fold Book: by Diane Weintraub and Kathy Millerapi-25909634No ratings yet

- Chapter - Introduction To PlcsDocument15 pagesChapter - Introduction To Plcssivabalan100% (2)

- BSRM Makes DifferentDocument13 pagesBSRM Makes Differentahsan_russelNo ratings yet

- Esaote P80i User Manual PDFDocument50 pagesEsaote P80i User Manual PDFJ NarvaezNo ratings yet

- Spark Test of Metals: B B A ADocument4 pagesSpark Test of Metals: B B A ALovely NievesNo ratings yet

- Propane LPGDocument9 pagesPropane LPGYeabsraNo ratings yet

- Turbine ElsterDocument4 pagesTurbine Elsterpalotito_eNo ratings yet

- O&M Manual For 4.12TCA & 6.12TCADocument101 pagesO&M Manual For 4.12TCA & 6.12TCAniceashwin7933% (3)

- Assignment1 AnsDocument8 pagesAssignment1 AnsHadirah DunglahNo ratings yet