Professional Documents

Culture Documents

UT Bearing-Quality Steel Testing

Uploaded by

HaseebPirachaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UT Bearing-Quality Steel Testing

Uploaded by

HaseebPirachaCopyright:

Available Formats

One Source for

Asset Protection

Solutions

Products & Systems Division Application Brief

A completely digital Ultrasonic (UT) data acquisition and analysis program can test bearing-quality steel in minutes and analyze the results in seconds with all relevant data digitally stored and

archived. A process that used to take hours is now completed in a matter of minutes with MISTRAS state-of-the-art digital system configuration.

Ultrasonic Bearing-Quality Steel Testing

Bearing-quality steel testing, a process that would hardware and software. UTwin also displays automatically. It can also verify reference

traditionally take hours, can now be performed any combination of A-, B- and C- scans desired. standards to help ensure proper future test

in minutes and seconds thanks to MISTRAS Complete system PC and Windows 7 procedures as well as current analysis.

Ultrasonic testing expertise and solutions. operating system Fully integrated PC and Cluster Location This allows users to identify

operating system works hand-in-hand with a specific location for inclusion assessment or

MISTRAS Ultrasonic (UT) scanning systems testing, analysis and imaging hardware and simply test the entire C-Scan image.

meet the requirements outlined in the ASTM software Table listing of all inclusions detected with

Standard Practice for Detection of Large 10 MHz, focused immersion transducer data listed below

Inclusions in Bearing-Quality Steel by Ultrasonic MISTRAS offers a variety of transducers used Provides X/Y and depth location of

Method, ASTM E588-03. with all of product and system applications. detected inclusions

This model is specifically matched with the UT Provides minimum/maximum/average

COMPONENTS Bearing-Quality Steel application.

This complete digital data acquisition, imaging, amplitude

Digital storage capabilities for test set-up and Provides square area of indication

and analysis system configuration is a mix of

hardware and software designed to expedite data Stores preferences for future or easily

C-Scan image is marked a number

testing and analysis with unparalleled results. recreate a test scenario days after initial trial.

correlating to table listing

X/Y/Z, UT Immersion scanning tank 3-axis A-, B-, and C-Scan Displays With UTwin,

UT immersion system is rugged and rigid ANALYSIS DISPLAYS

While testing takes just minutes, analysis is you can display any combination of A-, B- and

enough for industrial and laboratory use and C-Scans for easy and productive comparing

is a fast, accurate method to locate, classify done in seconds and can be displayed in ways

depending on your needs. Thanks to our industry- and contrasting. Mix any combination of

and quantify defects. C-Scans, B-Scans, numeric plots, and even 3-D

P/R & A/D Boards MISTRAS designs and

leading software, UTwin, analysis displays can

do everything from establish logical inclusion views. If room is getting tight, UTwin will let

fabricates (in-house) the majority of its you add more pages.

ultrasonic boards employing state-of-the-art levels to mark inclusions detected on C-Scans

with a number that corresponds to a table listing. FFT (fast Fourier transform) Frequency

surface mount and FPGA technologies. Analysis Display Allows users to test, chart,

Flaw Analysis, Counts Inclusions This

UTwin C-scan acquisition, imaging and feature is capable of establishing 1-20 levels, and analyze power levels at different levels to

analysis software system This includes with logic, to qualify an inclusion count identify and quantify any inclusions.

cluster and flaw analysis with motion-control

WORLDWIDE HEADQUARTERS:

195 Clarksville Rd Visit our website for an office near you Local Presence,

Princeton Jct, NJ 08550 USA

T: +1.609.716.4000 F: +1.609.716.0706 www.mistrasgroup.com Global Reach!

E-MAIL: sales@mistrasgroup.com

Specications subject to change without notice. Copyright 2013 MISTRAS Group, Inc. All Rights Reserved. #200A-13103-01 www.mistrasgroup.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

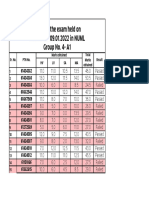

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No. 4-A1Document2 pagesResult of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No. 4-A1HaseebPirachaNo ratings yet

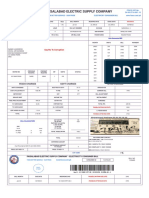

- Fesco Online Bill January 1Document1 pageFesco Online Bill January 1HaseebPirachaNo ratings yet

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML A2Document2 pagesResult of The Exam Held On 08.01.2022-09.01.2022 in NUML A2HaseebPirachaNo ratings yet

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No.5-A1Document1 pageResult of The Exam Held On 08.01.2022-09.01.2022 in NUML Group No.5-A1HaseebPirachaNo ratings yet

- FESCO GST No. Bill DetailsDocument1 pageFESCO GST No. Bill DetailsHaseebPirachaNo ratings yet

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDocument1 pageResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNo ratings yet

- b2 Karachi Result 21.01.2022Document1 pageb2 Karachi Result 21.01.2022HaseebPirachaNo ratings yet

- b2 Karachi Result 21.01.2022Document1 pageb2 Karachi Result 21.01.2022HaseebPirachaNo ratings yet

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDocument1 pageResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNo ratings yet

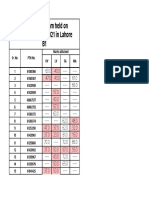

- Result of The Exam Held On 23.10.2021-25.10.2021 in Lahore B1Document2 pagesResult of The Exam Held On 23.10.2021-25.10.2021 in Lahore B1HaseebPirachaNo ratings yet

- Result of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedDocument1 pageResult of The Exam Held On 08.01.2022-09.01.2022 in NUML B2: HV LV SA MA 1 2 3 4 5 Sr. No. PTN No. Marks ObtainedHaseebPirachaNo ratings yet

- Fesco Online Bill January 2Document1 pageFesco Online Bill January 2HaseebPirachaNo ratings yet

- Result of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2Document1 pageResult of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2HaseebPirachaNo ratings yet

- Result of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2Document1 pageResult of The Exam Held On 18.12.2021-19.12.2021 in Lahore B2HaseebPirachaNo ratings yet

- b2 Karachi Result 21.01.2022Document1 pageb2 Karachi Result 21.01.2022HaseebPirachaNo ratings yet

- Result of The Exam Held On 08.01.22-09.01.2022 in NUML B1Document2 pagesResult of The Exam Held On 08.01.22-09.01.2022 in NUML B1HaseebPirachaNo ratings yet

- Fesco Online Bill January 2Document1 pageFesco Online Bill January 2HaseebPirachaNo ratings yet

- Fesco Online Bill January 2Document1 pageFesco Online Bill January 2HaseebPirachaNo ratings yet

- Complete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320Document38 pagesComplete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320allah ditta shafiNo ratings yet

- Fluid Mechanics 101: Calculators & ToolsDocument11 pagesFluid Mechanics 101: Calculators & ToolsHaseebPirachaNo ratings yet

- Fesco Online Bill January 1Document1 pageFesco Online Bill January 1HaseebPirachaNo ratings yet

- Ausschreibung Helmut-Schmidt-Programm enDocument7 pagesAusschreibung Helmut-Schmidt-Programm enGemechuNo ratings yet

- FESCO GST No. Bill DetailsDocument1 pageFESCO GST No. Bill DetailsHaseebPirachaNo ratings yet

- Complete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320Document38 pagesComplete Postcode List For Pakistan: Listed in Postcode Order From 10010 To 97320allah ditta shafiNo ratings yet

- FESCO GST No. Bill DetailsDocument1 pageFESCO GST No. Bill DetailsHaseebPirachaNo ratings yet

- Fesco Online Bill January 1Document1 pageFesco Online Bill January 1HaseebPirachaNo ratings yet

- Fesco Online Bill January 2Document1 pageFesco Online Bill January 2HaseebPirachaNo ratings yet

- Faisalabad Electric Supply Company: Say No To CorruptionDocument2 pagesFaisalabad Electric Supply Company: Say No To CorruptionHaseebPirachaNo ratings yet

- Faisalabad Electric Supply Company: Say No To CorruptionDocument2 pagesFaisalabad Electric Supply Company: Say No To CorruptionHaseebPirachaNo ratings yet

- Fesco Online BillDocument2 pagesFesco Online BillHaseebPirachaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- How To Create A WebsiteDocument72 pagesHow To Create A WebsiteCarlosNo ratings yet

- Visual Basic Fundamentals for Computer ScienceDocument12 pagesVisual Basic Fundamentals for Computer ScienceshubhammukriNo ratings yet

- In This Exercise, You Will Learn How To:: Exercise: RADIOSS Linear Statics Setup For A Shell AssemblyDocument7 pagesIn This Exercise, You Will Learn How To:: Exercise: RADIOSS Linear Statics Setup For A Shell AssemblySaikiran SayabugariNo ratings yet

- Poulami Mukhopadhyay: Professional SummaryDocument4 pagesPoulami Mukhopadhyay: Professional SummarySounak PattadarNo ratings yet

- 6422A-En Implementing Managing Windows Server 08 HyperV-TrainerManualDocument332 pages6422A-En Implementing Managing Windows Server 08 HyperV-TrainerManualDanial TanNo ratings yet

- Dual Boot (Kalyway - Iatkos - Leo4all - Jas - Ideneb) 10.5.2 To 10.5Document9 pagesDual Boot (Kalyway - Iatkos - Leo4all - Jas - Ideneb) 10.5.2 To 10.5Niranjan GanjawalaNo ratings yet

- Koha PresentationDocument36 pagesKoha Presentationbhat LibraryNo ratings yet

- Repo Lokal Ubuntu 12.04Document1 pageRepo Lokal Ubuntu 12.04Muharom Mam'zelleNo ratings yet

- FieldSeeker Core and Windows ULV FAQ 2022Document12 pagesFieldSeeker Core and Windows ULV FAQ 2022nNo ratings yet

- Understanding Operating Systems Through Nachos StudyDocument22 pagesUnderstanding Operating Systems Through Nachos StudyChris LazarNo ratings yet

- Gate Pass Management System Using Android (App) : Prerana Khandekar, Vaishnavi Patil, Vikas SolankeDocument6 pagesGate Pass Management System Using Android (App) : Prerana Khandekar, Vaishnavi Patil, Vikas SolankeWowskinNo ratings yet

- Pragma directive in C - What is #pragma startup and #pragma exitDocument7 pagesPragma directive in C - What is #pragma startup and #pragma exitrajdattaNo ratings yet

- S:No Socail Bookmarking Live LinksDocument6 pagesS:No Socail Bookmarking Live LinksMoeezNo ratings yet

- Anusha Rajan Resume PinkDocument2 pagesAnusha Rajan Resume Pinkapi-406137007No ratings yet

- Com Site Pro Brochure 2010Document4 pagesCom Site Pro Brochure 2010rlopezrlopezNo ratings yet

- Notability MultiPages View Bookmarks and SearchingDocument5 pagesNotability MultiPages View Bookmarks and Searchingtiwari_anunay1689No ratings yet

- Python 101 - Introduction To PythonDocument81 pagesPython 101 - Introduction To Pythonsunny131987No ratings yet

- Sample Questions For C9510-418: Ibm Websphere Application Server V9.0 Network Deployment Core Server AdministrationDocument3 pagesSample Questions For C9510-418: Ibm Websphere Application Server V9.0 Network Deployment Core Server AdministrationJose DominguezNo ratings yet

- Vinoth Kumar: Sharepoint Framework Extensions (SPFX)Document13 pagesVinoth Kumar: Sharepoint Framework Extensions (SPFX)kiran2710No ratings yet

- Windows Administrator L2 Interview Question - System AdministratorDocument7 pagesWindows Administrator L2 Interview Question - System AdministratorAdminnivas100% (1)

- XBMC User GuideDocument17 pagesXBMC User Guideapi-320473608No ratings yet

- Interfaces and Inheritance QuestionsDocument8 pagesInterfaces and Inheritance QuestionspolashNo ratings yet

- Smoke and Sanity Testing. - Software TestingDocument4 pagesSmoke and Sanity Testing. - Software TestingSuresh KumarNo ratings yet

- Business Model Canvas: Key Partners Key Activities Value Propositions Customer Relationships Customer SegmentsDocument2 pagesBusiness Model Canvas: Key Partners Key Activities Value Propositions Customer Relationships Customer SegmentsMarvin TorreNo ratings yet

- Computer Syllabus 2020-21Document1 pageComputer Syllabus 2020-21Jatin PandeyNo ratings yet

- Service Bulletin: Carestream Health, Inc., Rochester, NY 14608Document4 pagesService Bulletin: Carestream Health, Inc., Rochester, NY 14608Art MessickNo ratings yet

- Understanding Nosql Basics Using Mongo DBDocument18 pagesUnderstanding Nosql Basics Using Mongo DBapoorvaNo ratings yet

- Awash Valley CollegeDocument2 pagesAwash Valley CollegeHaccee TubeNo ratings yet

- DummiesGuideDocument51 pagesDummiesGuideMilorad SpasicNo ratings yet

- Event-Driven Microservices: © 2020 Confluent, IncDocument25 pagesEvent-Driven Microservices: © 2020 Confluent, IncStefan MirkovicNo ratings yet