Professional Documents

Culture Documents

Tekla SD 2017 Service Pack 4

Uploaded by

akankwasaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tekla SD 2017 Service Pack 4

Uploaded by

akankwasaCopyright:

Available Formats

Tekla Structural Designer 2017 Service

Pack 4

This release will upgrade your installation to Tekla Structural Designer 2017 Service Pack 4

version number 17.0.4.55 and should be installed to ensure optimum function of the program.

It includes a number of issue resolutions as detailed below.

If you are updating from a version earlier than Tekla Structural Designer 2017 Service Pack 3

(version 17.0.3.50) you can find details of enhancements and fixes included in all previous

releases in Tekla User Assistance (TUA) and Tekla Downloads. You will find all the main

releases listed in the Knowledge base area of TUA under Release notes while those for

Service Packs can be found under Updates. Links to release notes together with the version

number can also be found in Tekla Downloads (login required).

Licensing & Installation

Licensing - no new license is required for this version.

Installation - this service pack requires Tekla Structural Designer 2017 to be installed

and will upgrade this to version 17.0.4.55.

o Previous Versions and file compatibility - Files from all previous versions

can be opened in Tekla Structural Designer 2017 SP4 however note that once

saved they cannot then be opened in an older version. If you wish to retain

this option we therefore recommend using the File > Save As option to save

a new version of the file and retain the original.

Issues with Associated Bulletins

Design (Static) and Analyse All (Static) - this issue relates to the following Head

Codes which feature an Amplified forces analysis method; Eurocode (all countries),

BS (all countries ), Australia. The issue only occurred when this Amplified forces

method was selected for Design. In some circumstances the amplification factor

(termed kamp ) was not applied. It was clear when the issue occurred as it was flagged

by warnings in the Process Window that Total reactions vs Applied loading did not

balance and errors in the Load Summary check. The issue only applied to Tekla

Structural Designer 2017 Service packs 2 and 3 and is fixed in this Service Pack. For

more information please see Product Bulletin PBTSD-1706-2 (14089).

Isolated Foundation Design - Pad Bases - BS (all countries ), India and US (ACI)

Head Codes - for rectangular bases the Passive Resistance used in the Sliding check

was incorrect in that the resistance for the X-direction was transposed with that for the

Y-direction. The issue is fixed in this Service Pack. For more information please see

Product Bulletin PBTSD-1707-1 (53627).

Enhancements & Fixes

General & Modelling

Review View - a dedicated button for the Steel+ function (which allows graphical

review and editing of steel sections and grades) is reinstated on the Ribbon (14029).

Preview - core models (created by the File > Save Model Only command) can now be

previewed using the Windows Preview pane (4229).

File Opening and Saving:

o Rarely models containing incomplete or unexpected data could fail to open

(14135).

o In some circumstances a program error Error while saving file! could occur

when attempting to save a file (53498).

o The save process is enhanced to handle potential issues caused by a slower

network response when saving files to a network location (53594).

BIM Integration - Cellbeam Export - the export now caters for user-defined steel

grades being encountered during export. When this occurs the export attempts to find

and assign a similar Cellbeam steel grade and issues the warning; Unknown steel

grade; using a standard one (13986).

Edit - Copy - Steel Brace Pairs - a program error could occur when creating copies of

existing brace pairs if the copy reference point was inadvertantly clicked more than

once (53481).

Grid and Construction Lines - Parallel (quick) - multiple construction lines could not

be created in one operation by using the method of typing a number of spacings,

separated by commas, in the Specify Distance(s) entry box (14095).

Frames and Slopes - Show References - the Show references command is added

to the context menu displayed when a frame or slope is right-clicked in the Structure

Tree. This list objects referenced by the selected plane. In addition, hidden

frames/slopes (denoted by grey shading of the frame/slope icon) are now also listed in

the Structure Tree. Hidden frames/slopes can only be deleted once all references to

them from objects have been removed (14105).

Analysis & Results

Solver model:

o Rarely generation of the solver model could fail in models containing

incomplete or unexpected data. This would cause program errors or prevent

completion of the analysis or design processes (14136).

o Semi-rigid diaphragms - where a support was applied to a panel with the

diaphragm option set to semi-rigid, the diaphragm 2D element mesh was not

attached directly to the support (53304).

Loading

Seismic ELF and Wind Loading - Building Torsion Loads - a new load application

method is implemented which removes limitations of the previous method (10460,

12081, 12682, and 13724).

o The US ASCE 7 wind loading code and all seismic loading codes require

consideration of an overall building torsion (usually considered to apply at

floors) which accounts for an eccentricity in the application of the lateral

loads. Tekla Structural Designer automatically calculates and applies such

loads in special loadcases automatically created by the Seismic Wizard and

Wind Loadcases dialog. For Seismic Loading, individual Seismic Torsion

loadcases containing only the torsion loads are created for the two orthogonal

building directions. For wind loading, loadcases are created which include

both the torsion and lateral loads for the nominated wind direction or

directions.

o Previously the building torque was applied via individual torsion loads at the

points within the structure which received lateral loads. This method worked

well in models with rigid diaphragms or continuous framing throughout.

However in models with partial, semi-rigid, or no diaphragms and pin end

members (typically steel structures) it could produce unexpected effects such

as; local torsion forces in individual columns; torsion loads at supports; a

reduction in the effective overall building torque. This is illustrated in the

pictures below of a simple example; a one-storey steel structure with pin

ended beams, a lateral system of steel braces and a semi-rigid diaphragm roof.

o In the new method of application a system of lateral, radial push-pull loads

are applied to points in the structure producing the overall torsion.

o For ELF Seismic these loads can be viewed directly in the Results View via

the Seismic button on the Results Ribbon while viewing a Seismic

Torsion loadcase. This is shown in the picture below Left.

o The application method for Wind torsion (in the "+/- MT" cases) is exactly the

same, but these cases also include the lateral wind loads and so the graphical

application is not quite so clear. However the change in the direction and

values of the decomposed wind point loads can be discerned (when compared

to those of a case without torsion) - the loads shown are the combined

resultants of the lateral wind point loads and the radial 'push-pull' torsion

loads. This is shown in the picture above Right.

Wind Loading - Eurocode - in exceptionally large models, the dimensions of wind

wall and/ or roof panels could exceed the bounds of the design code table for the size

factor cs (NA to BS EN 1991-1-4:2005 Table NA.3) causing wind load decomposition

to fail. This would cause program errors or prevent completion of the analysis or

design processes. The issue could be worked around by turning off automatic

calculation of the structural factor (in the Wind Loadcases dialog) and entering a

manual value determined by the engineer for cscd , or by reducing the crosswind

breadth of affected wind panels (via the B Override wind panel property in the

Wind view ) such that the table bounds were not exceeded. A workaround is no

longer required (14080, 14148)

Design

General

Foundations - Pile Caps - triangular shaped three-pile cap:

o The self weight and surcharge loads were those of a rectangular shape with the

same length and width dimensions and were thus larger than the correct values

(14041).

o The "Smallest pile edge distance" calculation could be incorrect when the

User Defined Arrangement option was used in the interactive pile cap editor

to move a pile since the method assumed a rectangular shape. Corrected

validation in the editor now prevents this circumstance (53495).

o The pile cap short horizontal/vertical edge dimension (on plan) is corrected to

"pile dimension + 2 * edge distance" in length where formerly it was "pile

dimension + edge distance" (the edge distance in question has a default of

150mm and is set via Design Options > Concrete > Foundations > Isolated

Foundations > Piles > Minimum pile edge distance) (53495).

Concrete Design - Walls - Interactive Design - in some circumstances an incorrect fail

status was displayed with no clear cause when Use ties/links (on the lateral tab) was

set Off but the (hidden) tie/link spacing of zero was still being checked (53478).

Wind Drift - combinations set to be inactive were still checked. If any failed, a

spurious failure status would be reported in the Status tree when all check results in

Tabular data showed a pass (14137).

Head Code BS

Steel Design - Buckling Combined check - in the design details the interaction

equation for the minor axis check from Cl. 4.8.3.3.3(c) omitted a 0.5 factor. This was

a display issue which did not affect the calculated ratio (14129).

Head Code EC

Steel Design - Westok Cellbeams - Auto-design - efficiency improvements have made

the auto-design process several times faster which can significantly reduced the total

design time (53661).

Head Code US

Composite Beam Design - Auto-design - in some circumstance the stud auto-layout

process could fail causing the design process to be terminated. The issue would occur

only for parallel decking cases, in auto-design and stud layout mode, and where the

Stud Connector Strength setting to allow groups of 4 studs was set to on (the 1, 2 and

3 studs group options were not affected). The workaround was to uncheck the 4 studs

setting in which case auto-design and stud layout would complete and in most cases

an acceptable design solution would result. This workaround is no longer required

(14104).

Reports & Drawings

Model Report - Foundation Reactions - when the setting for Combination Factors was

set to Service the report was not created (13738).

Detail Drawings:

o Concrete Beams:

In some circumstances the reinforcement label text giving the bar size

and number could be drawn in an incorrect location (14089).

For top pattern 1 when the supporting member was an in-plane wall,

the lines showing reinforcement location for bars at the end of supports

could be drawn outside the beam ends (53595)

o Concrete Columns - for columns which contained very short stacks (around

250mm or less), the detail drawing and the column schedule could fail to

generate due to problems with the detailing equations for very short lengths.

Stacks of such a short length are unusual and quite likely to be the result of

modelling errors however the detailing and scheduling processes are enhanced

to cater for this circumstance (14066).

Notes:

The number in brackets after an item denotes an internal reference number. This can be

quoted to your local Support Department should further information on an item be required.

32bit (x86) and 64bit (x64) Versions

Service packs are available for both 32bit (x86) and 64bit (x64) versions of Tekla Structural

Designer. Before downloading, check which version you have currently installed via the

Information button at the top right of the Tekla Structural Designer window, then download

the appropriate service pack

You might also like

- ETABS Version 9.2.0 Release NotesDocument16 pagesETABS Version 9.2.0 Release NotesJose Ramon MarcanoNo ratings yet

- Read MeDocument8 pagesRead MeSaulo LopezNo ratings yet

- ReleaseNotes PDFDocument21 pagesReleaseNotes PDFFrancisco Jose Arista QuinteroNo ratings yet

- Learn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareDocument108 pagesLearn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareRahul Kumar100% (2)

- Release Not Ese Tabs 2015 V 1510Document7 pagesRelease Not Ese Tabs 2015 V 1510jwanroNo ratings yet

- SAP2000V1108ReadMe PDFDocument10 pagesSAP2000V1108ReadMe PDFNicoPerezTerraNo ratings yet

- Structural Analysis and Design: STAAD - Pro Concrete Design (FAQ)Document7 pagesStructural Analysis and Design: STAAD - Pro Concrete Design (FAQ)turbobrikNo ratings yet

- ReleaseNotes PDFDocument6 pagesReleaseNotes PDFla_civilNo ratings yet

- Release Notes Csi Bridge 2016 V 1820Document16 pagesRelease Notes Csi Bridge 2016 V 1820Ihab El AghouryNo ratings yet

- Optimization Using TOSCADocument16 pagesOptimization Using TOSCAJunyan GuoNo ratings yet

- Sinbeam Design Software: General UseDocument5 pagesSinbeam Design Software: General Usexerxes92005No ratings yet

- Advance Design What Is New 2024.1.2 ENDocument6 pagesAdvance Design What Is New 2024.1.2 ENkheang amgNo ratings yet

- ReleasenotesDocument35 pagesReleasenotesdenise_rosales_1No ratings yet

- SCD Aisc 360 10Document25 pagesSCD Aisc 360 10ஆனந்த் கிருஷ்ணன்No ratings yet

- Release Notes Safe V 2000Document10 pagesRelease Notes Safe V 2000BANAT OGLUNo ratings yet

- ArcelorMittal A3CSoftware Manual PDFDocument49 pagesArcelorMittal A3CSoftware Manual PDFAlfonso José García LagunaNo ratings yet

- STAAD+PRO - NRC Verfication Manual 2005Document154 pagesSTAAD+PRO - NRC Verfication Manual 2005Jose Rojas-GuzmanNo ratings yet

- Release Notes Csi Bridge V 2210Document10 pagesRelease Notes Csi Bridge V 2210hichem titouNo ratings yet

- Understanding Wind LoadsDocument10 pagesUnderstanding Wind LoadsmurdicksNo ratings yet

- General: In-Product ViewDocument2 pagesGeneral: In-Product ViewSunday PaulNo ratings yet

- Tekla Structural Designer 2023 Release Notes - 0Document111 pagesTekla Structural Designer 2023 Release Notes - 0TeaMeeNo ratings yet

- Read MeDocument10 pagesRead MeJose Sosa CarmeloNo ratings yet

- Framecad-Bs En1991-13-2006Document11 pagesFramecad-Bs En1991-13-2006Aie BantuganNo ratings yet

- Read MeDocument5 pagesRead MeKairenNo ratings yet

- 2019 ATUG Tower WhatsNewDocument9 pages2019 ATUG Tower WhatsNewMehdi TrabelsiNo ratings yet

- Tekla - Eurocode Portal Frame InformationDocument11 pagesTekla - Eurocode Portal Frame InformationMikeNo ratings yet

- Concrete Frame Design Manual: Hong Kong Code of Practice 2013Document57 pagesConcrete Frame Design Manual: Hong Kong Code of Practice 2013huyxpkissNo ratings yet

- Version Information 27052016Document31 pagesVersion Information 27052016Catalin PopaNo ratings yet

- Release Notes Sap 2000 V 2110Document11 pagesRelease Notes Sap 2000 V 2110thekrauser96No ratings yet

- Structural Design of Hangar For AirportDocument18 pagesStructural Design of Hangar For Airportsanusi69100% (3)

- Release Notes SAP2000 V 2200Document6 pagesRelease Notes SAP2000 V 2200padeepNo ratings yet

- SAP2000 Version 11.0.8 Release NotesDocument24 pagesSAP2000 Version 11.0.8 Release NotesNicoPerezTerraNo ratings yet

- Release Notes Sap 2000 V 2320Document6 pagesRelease Notes Sap 2000 V 2320hichem titouNo ratings yet

- CBDocument99 pagesCBnabnajNo ratings yet

- SFD Aisc 360 10 PDFDocument191 pagesSFD Aisc 360 10 PDFthanzawtun198180% (5)

- RM Bridge CONNECT Edition V11 Update 8 Release Notes (May 2020)Document21 pagesRM Bridge CONNECT Edition V11 Update 8 Release Notes (May 2020)Ave Robin M. RamosNo ratings yet

- Sap2000 GeneralDocument64 pagesSap2000 GeneralAnggit PraNo ratings yet

- Release Not Ese Tabs 2016 V 1600Document21 pagesRelease Not Ese Tabs 2016 V 1600Ahmad FuqahaNo ratings yet

- Design of Turbo-Generator Foundations: C.Ravishankar, C. Channakeshava, B. Sreehari Kumar, G V RaoDocument8 pagesDesign of Turbo-Generator Foundations: C.Ravishankar, C. Channakeshava, B. Sreehari Kumar, G V RaoAlastair KerrNo ratings yet

- Version 5.0c Release NotesDocument4 pagesVersion 5.0c Release Notesthanzawtun1981No ratings yet

- STAAD - Pro and SAP (Comparison of Features)Document11 pagesSTAAD - Pro and SAP (Comparison of Features)kalpanaadhiNo ratings yet

- 2.13 CFD-BS-8110-97 PDFDocument46 pages2.13 CFD-BS-8110-97 PDFDiego Armando Rincon ArizaNo ratings yet

- Csibridge V23.1.0 Release Notes: Notice Date: 13-March-2021Document7 pagesCsibridge V23.1.0 Release Notes: Notice Date: 13-March-2021127blablaprNo ratings yet

- Pipe Stress Analysis by Computer CAESAR II PDFDocument11 pagesPipe Stress Analysis by Computer CAESAR II PDFAbhijeetNo ratings yet

- STRAP - Manual Strap 2017 - MÓDULO PROTENDIDODocument53 pagesSTRAP - Manual Strap 2017 - MÓDULO PROTENDIDOMarcos SouzaNo ratings yet

- Masterseries Updated-Notes 0CTOBER 2008Document60 pagesMasterseries Updated-Notes 0CTOBER 2008Christian Nicolaus Mbise0% (1)

- SpaceBolt ESA EvaluationDocument4 pagesSpaceBolt ESA EvaluationFrancisco PolanoNo ratings yet

- Read MeDocument6 pagesRead MejarisbonNo ratings yet

- Grund ForceDocument150 pagesGrund ForceFabrizio MansuetoNo ratings yet

- INDOT Practice Pointers 1-14-15Document4 pagesINDOT Practice Pointers 1-14-15Mike2322No ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Design and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesFrom EverandDesign and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Design for High Performance, Low Power, and Reliable 3D Integrated CircuitsFrom EverandDesign for High Performance, Low Power, and Reliable 3D Integrated CircuitsNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- Complete PCB Design Using OrCAD Capture and PCB EditorFrom EverandComplete PCB Design Using OrCAD Capture and PCB EditorRating: 5 out of 5 stars5/5 (1)

- Midas Gen - Integrated Analysis and Design System For Building and General StructuresDocument1 pageMidas Gen - Integrated Analysis and Design System For Building and General StructuresakankwasaNo ratings yet

- Brian Scheme Design Model (1) 2Document1 pageBrian Scheme Design Model (1) 2akankwasaNo ratings yet

- 470Document3 pages470akankwasaNo ratings yet

- 160Document6 pages160akankwasaNo ratings yet

- Cannot Open GSDDocument8 pagesCannot Open GSDakankwasaNo ratings yet

- Midas Gen: RC Beam Serviceability Checking ResultDocument2 pagesMidas Gen: RC Beam Serviceability Checking ResultakankwasaNo ratings yet

- 452 1Document6 pages452 1akankwasaNo ratings yet

- Kigumba Workshop WELDINGDocument1 pageKigumba Workshop WELDINGakankwasaNo ratings yet

- Kigumba Workshop InstrumentationDocument1 pageKigumba Workshop InstrumentationakankwasaNo ratings yet

- Footing Design MidasDocument8 pagesFooting Design MidasakankwasaNo ratings yet

- Kigumba Workshop WELDINGDocument1 pageKigumba Workshop WELDINGakankwasaNo ratings yet

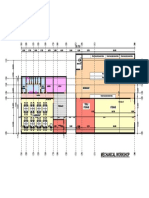

- Elegu Staff Houses. Floor PlansDocument1 pageElegu Staff Houses. Floor PlansakankwasaNo ratings yet

- Kigumba Workshop WELDINGDocument1 pageKigumba Workshop WELDINGakankwasaNo ratings yet

- Footing Design MidasDocument8 pagesFooting Design MidasakankwasaNo ratings yet

- Input Data: Notes: HistoryDocument5 pagesInput Data: Notes: HistoryakankwasaNo ratings yet

- 434Document8 pages434akankwasaNo ratings yet

- 443Document2 pages443akankwasaNo ratings yet

- Plot 39 - Typical Lintol Sections.Document1 pagePlot 39 - Typical Lintol Sections.akankwasaNo ratings yet

- 39Document8 pages39akankwasaNo ratings yet

- 38Document6 pages38akankwasaNo ratings yet

- Plot 2683 and 2684 Mpererwe Apartments 4-BeamdesDocument13 pagesPlot 2683 and 2684 Mpererwe Apartments 4-BeamdesakankwasaNo ratings yet

- Childrens Church 1Document1 pageChildrens Church 1akankwasaNo ratings yet

- Protastructure Analysis ResultsDocument8 pagesProtastructure Analysis ResultsakankwasaNo ratings yet

- 37Document8 pages37akankwasaNo ratings yet

- Etabs Lateral Loads.Document10 pagesEtabs Lateral Loads.akankwasaNo ratings yet

- Etabs 2016 16.2Document7 pagesEtabs 2016 16.2akankwasaNo ratings yet

- Quick Start Guide Concrete Complete-A2Document7 pagesQuick Start Guide Concrete Complete-A2akankwasaNo ratings yet

- Wind Loads - Analysis in Etabs 2016 16.2Document420 pagesWind Loads - Analysis in Etabs 2016 16.2akankwasaNo ratings yet

- Wall Types Library Edit Beam Wall Load Wall Types Library Building SetoutDocument3 pagesWall Types Library Edit Beam Wall Load Wall Types Library Building SetoutakankwasaNo ratings yet

- Prota Structural Analysis DocumentDocument5 pagesProta Structural Analysis DocumentakankwasaNo ratings yet

- SRDF Solutions PDFDocument192 pagesSRDF Solutions PDFJimmy UkoboNo ratings yet

- Alumni Placment 2014 2021Document131 pagesAlumni Placment 2014 2021samyakNo ratings yet

- Eligible Credit Cards Will Be DisplayedDocument14 pagesEligible Credit Cards Will Be DisplayedShradhaNo ratings yet

- Os ShivaniDocument208 pagesOs ShivaniUmashankar MishraNo ratings yet

- Washer Tech Data SheetDocument16 pagesWasher Tech Data SheetDavid LovatoNo ratings yet

- Automatic Packaging MachineDocument64 pagesAutomatic Packaging Machinesajid aliNo ratings yet

- File WSM - 0000793 - 01.pdf From Thread Scania 124L 420HPi - Opticruise - Błąd E090 I E092 PDFDocument145 pagesFile WSM - 0000793 - 01.pdf From Thread Scania 124L 420HPi - Opticruise - Błąd E090 I E092 PDFBota NicusorNo ratings yet

- Nav1 Aplan2Document4 pagesNav1 Aplan2Jemar lucidoNo ratings yet

- 5S Implementation Plan at Work PlaceDocument18 pages5S Implementation Plan at Work Placebrock100% (24)

- Removal of Default Vbe 8 - BBB GraphicsDocument4 pagesRemoval of Default Vbe 8 - BBB Graphicsmario nogueraNo ratings yet

- Acue 3000 V1Document36 pagesAcue 3000 V1MARCO SILVA CABREJONo ratings yet

- New Microsoft Office Word DocumentDocument6 pagesNew Microsoft Office Word DocumentBoyi VenkatramanaNo ratings yet

- PC Industry Analysis - 2009Document22 pagesPC Industry Analysis - 2009nnshah18No ratings yet

- CMN OIL FREE COMPRESSOR - CompressedDocument4 pagesCMN OIL FREE COMPRESSOR - CompressedAriantoNo ratings yet

- Safer Children in A Digital World: The Report of The Byron ReviewDocument226 pagesSafer Children in A Digital World: The Report of The Byron ReviewJeff Pratt100% (2)

- 1st Place & Galloway Street NE - Appendix ADocument111 pages1st Place & Galloway Street NE - Appendix ADistrict Department of TransportationNo ratings yet

- Railways Docks Harbor EngineeringDocument4 pagesRailways Docks Harbor Engineeringsanthoshkumar2012No ratings yet

- Certified Information Systems Auditor (CISA) 2019 Information System Auditing TranscriptDocument15 pagesCertified Information Systems Auditor (CISA) 2019 Information System Auditing TranscriptMahmoudAbdElGhaniNo ratings yet

- PC5108FLR v2.0 Installation Instructions: General EnclosuresDocument2 pagesPC5108FLR v2.0 Installation Instructions: General EnclosuresMario Gabriel MoralliNo ratings yet

- 98-375 01 SlidesDocument31 pages98-375 01 SlidesЙонка МарковаNo ratings yet

- Solutions in Power Conditioning: Vertex - 3 kVA - 150 kVADocument2 pagesSolutions in Power Conditioning: Vertex - 3 kVA - 150 kVAfinhasNo ratings yet

- Abinitio Scenarios QuestionDocument33 pagesAbinitio Scenarios QuestionAashrita VermaNo ratings yet

- DBMS Final Exam (1) 147-166Document20 pagesDBMS Final Exam (1) 147-166Sriharsha BNo ratings yet

- BFD2 ManualDocument180 pagesBFD2 Manuallarrygates100% (6)

- Ceic3006 Lecture 5Document88 pagesCeic3006 Lecture 5sarahNo ratings yet

- BillDocument5 pagesBillnewo arcegaNo ratings yet

- UL Series ManualV2Document12 pagesUL Series ManualV2AndrewJ73No ratings yet

- Lab # 5 Objective:Analyze Queue Variables Queue Variables DescriptionDocument8 pagesLab # 5 Objective:Analyze Queue Variables Queue Variables Descriptionkamran khanNo ratings yet

- Bentonite Grinding MachineDocument2 pagesBentonite Grinding MachineNickRuiNo ratings yet

- The Fire Alarm System Based On Iot: January 2022Document6 pagesThe Fire Alarm System Based On Iot: January 2022ILham FadhillNo ratings yet