Professional Documents

Culture Documents

Modalloy : Product Datasheet Non Ferrous Metal Treatment

Uploaded by

Sumeet RatheeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modalloy : Product Datasheet Non Ferrous Metal Treatment

Uploaded by

Sumeet RatheeCopyright:

Available Formats

Issue number 4 Product Datasheet - Non Ferrous Metal Treatment

Date :11-01-2001

MODALLOY*

MODALLOY 5 (Al - 5% Sr) Sr) and MODALLOY 10 (Al - 10% Sr).Sr).

In easy -to-

to-use cast form for modifying the aluminium die casting and

sand casting alloys of hypo -eutectic and eutectic composition .

General description MODALLOY 5/10 are potent modifier for Al-Si hypo-eutectic and eutectic alloys.

They are available in cast waffle form. They are particularly suitable for all alloy

properzies,gravity die castings such as cylinder heads, manifolds, aluminium alloy

wheels and sand casting alloys.

Purpose The purpose of modifying eutectic and

hypo-eutectic Al-Si alloys is to change

the accicular form of silicon to a

spheroidal or globular form. The

modified structure results in improved

mechanical properties in both the

as-cast and heat treated condition.

Conventionally Al-Si hypo-eutectic and

eutectic alloys are treated with sodium

in the metallic form or with salt based

modifiers to obtain the desired structure.

However, pure sodium is very difficult to

handle and salt based modifier can

cause some amount of moisture and

gas pick up if not formulated, stored or

used properly. The effect of

modification with sodium fades with

holding times and is lost on remelting.

Excessive sodium additions or over

modification reduce tensile values

appreciably. The chemical reaction of

sodium based fluxes reduce crucible life

substantially and pollute the

environment due to fume generation.

Use of MODALLOY 5/10 overcomes

many of the above problems. The

recovery of strontium is both higher and

more reproducible for a given practice

as compared to sodium. It has far

superior fade resistance and hence

retains the modification effect over a

much longer period of time. There is no

evidence of my detrimental

over-modification effects with strontium

as in case of sodium. Use of

MODALLOY 5/10 is far more

environmental friendly than the

conventional salt based modifiers.

Since no chemical reaction is involved,

crucible life can be improved.

Benefits CASTING WITH IMPROVED AND CONSISTENT MECHANICAL AND

METALLURGICAL PROPERTIES :

MODALLOY 5/10 improves as-cast

mechanical properties such as tensile

strength and elongation. The longer

lasting modification effect gives

consistent metallurgical and mechanical

properties of the casting.

BETTER MACHINABILITY :

The refined metallurgical structure and

improved distribution of silicon phase

gives better machinability and improved

surface texture

ENVIRONMENTAL CLEANLINESS :

Use of MODALLOY 5/10 gives cleaner

working environment since no chemical

reaction is involved.

CONVENIENT TO STORE, HANDLE AND USE :

Shapes being available in the cast

waffle form, they are easy to handle and

use. Being metallic in nature, they do

not pick-up any moisture.

Instructions for use 1. Prepare the desired alloy composition.

Follow the normal fluxing and

cleansing procedure recommended for

using suitable flux from COVERAL*

range.

2. Degas the melt by MOBILE

DEGASSING UNIT (MDU) and dross

off using small quantity of a suitable

flux from COVERAL range.

3. After the degassing operation, add

Fosperl BT as per requirement. After

grain refinement, add pre-calculated

quantity of MODALLOY 5/10

depending on the melt size and rabble

it to ensure homogeneity of the

composition.

Addition techniques -

MODALLOY 5

An application rate of 0.5% of

the melt will be adequate for

gravity die castings to give

residual strontium level of 0.02 -

0.025% for satisfactory

modification effect.

MODALLOY 10

An application rate of 0.25% of

the melt will be adequate for

gravity die castings to give

residual strontium level of 0.02 -

0.025% for satisfactory

modification effect.

Note -

Addition level can vary

considerably since it is function

of casting process, alloy

composition and solidification

rate of the casting. In case,

charge contains returns treated

with MODALLOY 5/10, lower

additions may be possible,

however, the practice needs to

be established for subsequent

application rate.The above

mentioned application rate is to

be used as guideline.

4. Wait for minimum 10 minutes for

modification effect to take place.

5. Take a sample for checking the

modification effect, if satisfactory

start the cast.

Standard packing MODALLOY 5/10 are available in 50 kg

HDPE Bgs. Each cast waffle weighs 200

gms + 20 gms.

Precautions Degassing and fluxing using chlorine

based products to be avoided after

modification using MODALLOY 5/10,

otherwise it results in strontium loss.

FOSECO products are manufactured in India by FOSECO INDIA LIMITED. All

information that is provided in this leaflet is to the best of our knowledge true and

accurate. Any claim arising out of defective material will be limited to replacement. The

company accepts no liability for any consequential losses and damages. The word

Foseco is a Registered Trade Name. For further information contact your local Foseco

Representative.

Foseco India Ltd. Sanaswadi, Pune 412 208. Ph:(02137) 568100, Fax: (02137) 568160

Registered Trade Mark * Trade Mark

You might also like

- Training ModuleDocument44 pagesTraining ModulegereNo ratings yet

- Zeolites in Petroleum RefiningDocument6 pagesZeolites in Petroleum RefiningAlina SmochinaNo ratings yet

- Sulphur Concrete: Modern Concrete Materials and Technology (Cv895)Document26 pagesSulphur Concrete: Modern Concrete Materials and Technology (Cv895)Rachana B HNo ratings yet

- Masterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteDocument2 pagesMasterrheobuild: High Range, Water Reducing Superplasticiser For Rheoplastic ConcreteweamNo ratings yet

- Use of Concrete Admixtures in Self-Compacting SystemsDocument45 pagesUse of Concrete Admixtures in Self-Compacting SystemsAmmad AlizaiNo ratings yet

- Frothers For Mineral ProcessingDocument33 pagesFrothers For Mineral ProcessingAnonymous caHv3DvtNo ratings yet

- Masterrheobuild 3250: High Range Water-Reducing Admixture For ConcreteDocument3 pagesMasterrheobuild 3250: High Range Water-Reducing Admixture For Concretemido_20067581No ratings yet

- Basf Masterseal 550 TdsDocument3 pagesBasf Masterseal 550 Tdsraza102No ratings yet

- Alkali-Free Liquid AcceleratorDocument2 pagesAlkali-Free Liquid AcceleratorVietpapayaNo ratings yet

- TDS - MasterRheobuilld 1100Document2 pagesTDS - MasterRheobuilld 1100Taposh PaulNo ratings yet

- Lube Tech 131 Estolides The Innovative Alternative of Ester Base OilsDocument7 pagesLube Tech 131 Estolides The Innovative Alternative of Ester Base OilsMohafizarNo ratings yet

- MasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGDocument3 pagesMasterRheobuild 1100 Formerly Known Rheobuild 1100 - EGvahab_shaikNo ratings yet

- Geniosil Stpe 10Document2 pagesGeniosil Stpe 10GİZEM D.No ratings yet

- Mobilgrease Moly 50Document4 pagesMobilgrease Moly 50Banti SidhiwalaNo ratings yet

- Egyptian Journal of Petroleum Research on Acrylate Salt Copolymers as Lost Circulation MaterialsDocument11 pagesEgyptian Journal of Petroleum Research on Acrylate Salt Copolymers as Lost Circulation MaterialsAmany AymanNo ratings yet

- Masterlife Ci 220 v5Document2 pagesMasterlife Ci 220 v5Tech BoyNo ratings yet

- Brochure Hardeners For WaterglassDocument18 pagesBrochure Hardeners For WaterglassAlejandro LozanoNo ratings yet

- Masterseal 550: Description AdvantagesDocument3 pagesMasterseal 550: Description AdvantagesmariaNo ratings yet

- Additives: Civil Engineering Materials 267Document10 pagesAdditives: Civil Engineering Materials 267CalvinhaoweiNo ratings yet

- Recovering Molybdenite From Ultrafine Waste Tailings by Oil Agglomerate Flotation PDFDocument7 pagesRecovering Molybdenite From Ultrafine Waste Tailings by Oil Agglomerate Flotation PDFMonica Ulloa LamasNo ratings yet

- Fly Ash Geopolymer Concrete PropertiesDocument9 pagesFly Ash Geopolymer Concrete PropertiesHonin AlshaeerNo ratings yet

- Tabla de Resistencia de Acero Vidriado - Worldwide Glasteel 9100Document20 pagesTabla de Resistencia de Acero Vidriado - Worldwide Glasteel 9100m.hernandez.corona92No ratings yet

- Hydraulic 6105Document8 pagesHydraulic 6105Deltalube TangerangNo ratings yet

- Dental Luting Cements Objectives:: Course Date: 10/10 Expiration Date: 10/13Document14 pagesDental Luting Cements Objectives:: Course Date: 10/10 Expiration Date: 10/13Dampee ReturnNo ratings yet

- Can Wetting and Dispersing Additives Improve The Durability of CoatingsDocument10 pagesCan Wetting and Dispersing Additives Improve The Durability of CoatingsManuel ChireNo ratings yet

- CALCIUM FORMATE ACCELERATORDocument2 pagesCALCIUM FORMATE ACCELERATORm_shahbaghiNo ratings yet

- 11 Glass - Ionomer MaterialsDocument36 pages11 Glass - Ionomer MaterialsPepo BelovedNo ratings yet

- New Generation of Catalysts: Tomsk - 2019Document12 pagesNew Generation of Catalysts: Tomsk - 2019Кирил МетанолNo ratings yet

- Improving The Lubrication and Anti-Corrosion Performance of Polyurea Grease Via Ingredient OptimizationDocument21 pagesImproving The Lubrication and Anti-Corrosion Performance of Polyurea Grease Via Ingredient Optimizationrabbitwzq1314No ratings yet

- Corrosion Behaviour of Sol-Gel Treated and Painted AA2024 Aluminium AlloyDocument10 pagesCorrosion Behaviour of Sol-Gel Treated and Painted AA2024 Aluminium AlloyAdrian OrtizNo ratings yet

- Masterglenium Sky 8705Document2 pagesMasterglenium Sky 8705usenuyaNo ratings yet

- Zeolite 2Document8 pagesZeolite 2BijiNo ratings yet

- Basf Masterseal 550 Waterproof Wall CoatingDocument3 pagesBasf Masterseal 550 Waterproof Wall Coatingmeja.gamerNo ratings yet

- AdmixtureDocument42 pagesAdmixtureAryyaka SarkarNo ratings yet

- New Generation of Catalysts: Made by Students of 2D6V Group: Korober Sofya Solovey Ivan Sochenkov Kirill Temirbolat AsetDocument10 pagesNew Generation of Catalysts: Made by Students of 2D6V Group: Korober Sofya Solovey Ivan Sochenkov Kirill Temirbolat AsetКирил МетанолNo ratings yet

- 002.scott LaRueDocument25 pages002.scott LaRuemitch980No ratings yet

- Technical Index: Sodium Molybdate Corrosion Inhibitor Standards & ApplicationsDocument4 pagesTechnical Index: Sodium Molybdate Corrosion Inhibitor Standards & ApplicationsNgân LêNo ratings yet

- Impact properties of geopolymer composites with fly ash and PVA fiberDocument14 pagesImpact properties of geopolymer composites with fly ash and PVA fiberDerLorenaNo ratings yet

- OIL WELL CEMENT ADDITIVES Critical Review of The Common PolymersDocument13 pagesOIL WELL CEMENT ADDITIVES Critical Review of The Common PolymersHala AbdalwahabNo ratings yet

- Combined Desilication and Phosphorus Modification For High-Silica ZSM-5 Zeolite With Related Study of Hydrocarbon Cracking PerformanceDocument9 pagesCombined Desilication and Phosphorus Modification For High-Silica ZSM-5 Zeolite With Related Study of Hydrocarbon Cracking PerformanceCecilia ManriqueNo ratings yet

- Cement & Concrete Composites: Othmane Boukendakdji, El-Hadj Kadri, Said KenaiDocument8 pagesCement & Concrete Composites: Othmane Boukendakdji, El-Hadj Kadri, Said Kenairamakrishna 1729123No ratings yet

- MasterSeal 550Document38 pagesMasterSeal 550Ahmad ElghazolyNo ratings yet

- MasterRheobuild 1100 v1Document2 pagesMasterRheobuild 1100 v1Vivek GaurNo ratings yet

- Organic sand binders reduce emissions and improve core performanceDocument1 pageOrganic sand binders reduce emissions and improve core performanceanudattNo ratings yet

- Glass IonomerDocument21 pagesGlass Ionomertalal_11No ratings yet

- Basf MasterLife 222 TdsDocument2 pagesBasf MasterLife 222 TdsWei ThienNo ratings yet

- 5 Pdfsam Motrol13cDocument6 pages5 Pdfsam Motrol13cWilson WanNo ratings yet

- Mobil-Iocaengrsmomobilith SHC PMDocument3 pagesMobil-Iocaengrsmomobilith SHC PM황철No ratings yet

- Delvo Stabiliser: Cement Hydration Control AdmixtureDocument2 pagesDelvo Stabiliser: Cement Hydration Control AdmixtureDoby YuniardiNo ratings yet

- MasterSeal 550Document3 pagesMasterSeal 550Gavriel NgNo ratings yet

- Reliance Industries Limited Reliance Industries Limited: Chemical EORDocument21 pagesReliance Industries Limited Reliance Industries Limited: Chemical EORmexx4u2nvNo ratings yet

- Masterrheobuild 1126 v2Document2 pagesMasterrheobuild 1126 v2Shub KotiNo ratings yet

- Molybdenum PDFDocument6 pagesMolybdenum PDFJessie PimentelNo ratings yet

- Masterseal 550 TdsDocument3 pagesMasterseal 550 TdsMohammed EssamNo ratings yet

- AADE-19-NTCE-102 - SantosDocument5 pagesAADE-19-NTCE-102 - Santosjahehe2000No ratings yet

- Restorative Materials: GalliumDocument7 pagesRestorative Materials: GalliumRawzh Salih MuhammadNo ratings yet

- Conventional and Contemporary Luting CementDocument10 pagesConventional and Contemporary Luting CementSahar BalafifNo ratings yet

- Calibra Technical ManualDocument34 pagesCalibra Technical ManualDiaa Eldin SaadNo ratings yet

- Low Carbon Stabilization and Solidification of Hazardous WastesFrom EverandLow Carbon Stabilization and Solidification of Hazardous WastesDaniel C.W. TsangNo ratings yet

- Drilling DepthDocument2 pagesDrilling DepthSumeet RatheeNo ratings yet

- Packing StandardDocument1 pagePacking StandardSumeet RatheeNo ratings yet

- New Product Development Plan - Iym 21C: Activities Nov. 17 Dec ' 17Document1 pageNew Product Development Plan - Iym 21C: Activities Nov. 17 Dec ' 17Sumeet RatheeNo ratings yet

- Jane Cartwright: Project EngineerDocument2 pagesJane Cartwright: Project Engineerdoan80No ratings yet

- Nehjfwf Dfjhkfoc - 2hjkfjDocument1 pageNehjfwf Dfjhkfoc - 2hjkfjSumeet RatheeNo ratings yet

- Process Audit Die CastingDocument12 pagesProcess Audit Die CastingSumeet RatheeNo ratings yet

- Mom 22.9.16Document1 pageMom 22.9.16Sumeet RatheeNo ratings yet

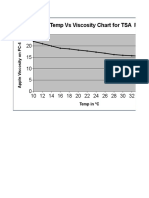

- Temp Vs VisDocument2 pagesTemp Vs VisSumeet RatheeNo ratings yet

- Honda Disc 83521-BDocument7 pagesHonda Disc 83521-BSumeet RatheeNo ratings yet

- CEO Highlights Credit Union's 2004 Successes and 2005 GoalsDocument3 pagesCEO Highlights Credit Union's 2004 Successes and 2005 GoalsShekhar MohadikarNo ratings yet

- Ge1 Audit Plan Aug 2017Document10 pagesGe1 Audit Plan Aug 2017Sumeet RatheeNo ratings yet

- Internal Audit ChecklistDocument37 pagesInternal Audit ChecklistSumeet Rathee100% (5)

- Lec 36Document26 pagesLec 36plachinaNo ratings yet

- Ge1 Audit Plan Aug 2017Document10 pagesGe1 Audit Plan Aug 2017Sumeet RatheeNo ratings yet

- Invoice 2571657515Document1 pageInvoice 2571657515Sumeet RatheeNo ratings yet

- Mom With Wenfeng and Lai: Wenfeng Lohia Auto IndDocument3 pagesMom With Wenfeng and Lai: Wenfeng Lohia Auto IndSumeet RatheeNo ratings yet

- 2017 Years Technology Department Objective: Target JanuaryDocument2 pages2017 Years Technology Department Objective: Target JanuarySumeet RatheeNo ratings yet

- 322348640 (2)Document3 pages322348640 (2)Sumeet RatheeNo ratings yet

- Deepak Antil: Curriculum VitaeDocument2 pagesDeepak Antil: Curriculum VitaeSumeet RatheeNo ratings yet

- lec37DGFGH PDFDocument30 pageslec37DGFGH PDFSumeet RatheeNo ratings yet

- MsaDocument22 pagesMsaSumeet RatheeNo ratings yet

- lec37DGFGH PDFDocument30 pageslec37DGFGH PDFSumeet RatheeNo ratings yet

- Packing Approval SheetDocument2 pagesPacking Approval SheetSumeet RatheeNo ratings yet

- 143 Icon FunDocument1 page143 Icon FunSumeet RatheeNo ratings yet

- 18 Bold ChevronsDocument2 pages18 Bold ChevronsSumeet RatheeNo ratings yet

- HMCL Supplier PPAP ChecklistDocument6 pagesHMCL Supplier PPAP ChecklistSumeet RatheeNo ratings yet

- Temp Vs VisDocument2 pagesTemp Vs VisSumeet RatheeNo ratings yet

- Mom With Wenfeng and Lai: Wenfeng Lohia Auto IndDocument3 pagesMom With Wenfeng and Lai: Wenfeng Lohia Auto IndSumeet RatheeNo ratings yet

- VDA6Document229 pagesVDA6Louie_197973% (11)

- Explore the ATR-42 Turboprop Regional AirlinerDocument3 pagesExplore the ATR-42 Turboprop Regional AirlinerShankar SubramaniamNo ratings yet

- Definition of Important Postal TermsDocument9 pagesDefinition of Important Postal TermsPostamsterNo ratings yet

- Complete Streets Policy Analysis 2011Document66 pagesComplete Streets Policy Analysis 2011shakes21778No ratings yet

- Mcom II MGMT Retail Management Practice QuestionsDocument3 pagesMcom II MGMT Retail Management Practice QuestionsAryan MehtaniNo ratings yet

- Contract & ProcurementDocument18 pagesContract & ProcurementMooni Khan100% (1)

- Flat SlabDocument11 pagesFlat SlabMasroor Ansari100% (2)

- Client List Salary Disbursement IssuesDocument8 pagesClient List Salary Disbursement IssuesG Balaji EinsteinNo ratings yet

- Autocheck 1HD1KBM17DB667931Document6 pagesAutocheck 1HD1KBM17DB667931HarleyNo ratings yet

- Passage Plan - Amsterdam - TuxpanDocument11 pagesPassage Plan - Amsterdam - TuxpanAdrian Cretu100% (1)

- Mold Maintenance StepDocument0 pagesMold Maintenance StepMonica JoynerNo ratings yet

- (1-V) Rules For Materials 2013Document354 pages(1-V) Rules For Materials 2013Anak BaruNo ratings yet

- SCL underground structure clearance standardsDocument12 pagesSCL underground structure clearance standardsjunaid112No ratings yet

- Mini Riset Bahasa InggrisDocument22 pagesMini Riset Bahasa InggrisMadara AfifNo ratings yet

- ReferenceDocument2 pagesReferencenersesboghosNo ratings yet

- DWA Concrete SpecDocument38 pagesDWA Concrete SpecLouisAucampNo ratings yet

- China Global Investment Tracker1Document252 pagesChina Global Investment Tracker1indiabhagat101No ratings yet

- Transpo TSN - First Exam Coverage 2016-2017 (Atty Valencia)Document22 pagesTranspo TSN - First Exam Coverage 2016-2017 (Atty Valencia)Lizette Kaye Estillore100% (1)

- Calculating airline costs and how routes profitability is determinedDocument3 pagesCalculating airline costs and how routes profitability is determinedNeetesh KumarNo ratings yet

- Primary Crusher Wall, Dyer Quarry, Birdsboro, PADocument4 pagesPrimary Crusher Wall, Dyer Quarry, Birdsboro, PAFrans van der MerweNo ratings yet

- LogisticDocument2 pagesLogisticHarry Ortiz0% (3)

- Problems On Operating CostingDocument2 pagesProblems On Operating Costingcoolstuf4uNo ratings yet

- Harbour and Docks LectureDocument46 pagesHarbour and Docks LectureSyed Rizwan100% (1)

- Annexure 1B (18416) PDFDocument275 pagesAnnexure 1B (18416) PDFRahim KhanNo ratings yet

- Indian Standard Is CodeDocument5 pagesIndian Standard Is Codepriyanka236No ratings yet

- Forwarding AgentDocument4 pagesForwarding AgentFakhrul HisyamNo ratings yet

- Faa Ac 150-5230-4aDocument2 pagesFaa Ac 150-5230-4ahseqamanagerNo ratings yet

- Laser Cutting Sheet Metal Fabrication Melior Laser Company Intro 05 2013Document14 pagesLaser Cutting Sheet Metal Fabrication Melior Laser Company Intro 05 2013Kirke71No ratings yet

- TPE Lecture 5Document28 pagesTPE Lecture 5Fortiter FysproNo ratings yet

- 2-GASM 7.01 InglizceDocument30 pages2-GASM 7.01 InglizceÜnal çevikbaş100% (1)

- API 510 Rerating Extract PDFDocument3 pagesAPI 510 Rerating Extract PDFmjmehta81No ratings yet