Professional Documents

Culture Documents

ER316L

Uploaded by

slowmosquito0 ratings0% found this document useful (0 votes)

106 views1 pageThis document provides technical information on stainless steel bare wire alloy ER316L, including its chemical composition, recommended welding parameters for MIG, TIG and submerged arc welding processes, and typical mechanical properties of the deposited weld metal. ER316L is primarily used for welding low carbon molybdenum-bearing austenitic alloys and conforms to AWS A5.9 and ASME SFA A5.9 standards. Parameters like wire diameter, amperage, voltage and shielding gases are listed for each welding process.

Original Description:

Filler Metal Tech

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides technical information on stainless steel bare wire alloy ER316L, including its chemical composition, recommended welding parameters for MIG, TIG and submerged arc welding processes, and typical mechanical properties of the deposited weld metal. ER316L is primarily used for welding low carbon molybdenum-bearing austenitic alloys and conforms to AWS A5.9 and ASME SFA A5.9 standards. Parameters like wire diameter, amperage, voltage and shielding gases are listed for each welding process.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

106 views1 pageER316L

Uploaded by

slowmosquitoThis document provides technical information on stainless steel bare wire alloy ER316L, including its chemical composition, recommended welding parameters for MIG, TIG and submerged arc welding processes, and typical mechanical properties of the deposited weld metal. ER316L is primarily used for welding low carbon molybdenum-bearing austenitic alloys and conforms to AWS A5.9 and ASME SFA A5.9 standards. Parameters like wire diameter, amperage, voltage and shielding gases are listed for each welding process.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

WELDWIRE COMPANY, INC.

Technical Information

Stainless Steel Bare Wire

Alloy: WW316L Conforms to Certification: AWS A5.9

Class: ER316L ASME SFA A5.9

Alloy ER316L Welding Data

Weld Process: Used for Mig, Tig, and Submerged Arc

AWS Chemical Composition Recommended Welding Parameters

C = 0.03 max Si = 0.30 0.65

GMAW Mig Process Reversed Polarity

Cr = 18.0 20.0 P = 0.03 max

Wire Wire Amps Volts Shielding Gas CFH

Ni = 11.0 14.0 S = 0.03 max

Diameter Feed Gas

Mo = 2.0 3.0 Cu = 0.75 max

Short Arc Welding

Mn = 1.0 2.5

.030 13-26 40-120 16-20 Argon+2% O2 25

.035 13-26 60-140 16-22 Argon+2% O2 25

Spray Arc Welding

Deposited Chemical Composition % (Typical)

C = 0.015 Mo = 2.50 P = 0.010 .035 20-39 140-220 24-29 Argon+2% O2 38

.045 16-30 160-260 25-30 Argon+2% O2 38

Cr = 18.75 Mn = 1.80 S = 0.010 1/16 10-16 230-350 27-31 Argon+2% O2 38

Ni = 12.25 Si = 0.34

GTAW Tig Process

Wire Amps Voltage Gases

Diameter DCRP

Deposited All Weld Metal Properties

.035 60-90 12-15 Argon 100%

.045 80-110 13-16 Argon 100%

Data is typical for ER316L weld metal deposited by Mig using 1/16 90-130 14-16 Argon 100%

Argon + 2% oxygen and Tig using 100% Argon as the 3/32 120-175 15-20 Argon 100%

shielding gas. Data on sub-arc is not given as they are

Note: Parameters for tig welding are dependent upon plate thickness and

dependent on the type of flux used. welding position.

Other shielding Gases may be used for Mig and Tig welding.

Shielding gases are chosen taking Quality, Cost, and

Mechanical Properties (R.T.) Operability into consideration

Yield Strength 59,000psi Submerged Arc Welding

Tensile Strength 88,000psi Reverse Polarity is suggested

Elongation 35% Wire Diameter Amps Volts

Reduction of Area 39%

3/32 250-450 28-32

Application 1/8 300-500 29-34

5/32 400-600 30-35

3/16 500-700 30-35

ER316L filler metal is primarily used for welding low carbon

molybdenum-bearing austenitic alloys. This low carbon alloy Both Agglomerated and fused fluxes can be used for submerged arc welding.

is not as strong at elevated temperatures as ER316H. Note: The chemical composition of the flux mainly affects the

chemistry of the weld metal and consequently its corrosion

resistance and Mechanical properties.

If additional information is needed Contact Weldwire Company, Inc. 800-523-1266

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Er308l PDFDocument1 pageEr308l PDFnargissuhailNo ratings yet

- Er308 PDFDocument1 pageEr308 PDFKhedira Al JibrillNo ratings yet

- Physical Electronics: Handbook of Vacuum PhysicsFrom EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDocument2 pagesClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasNo ratings yet

- ERNiCr 3Document1 pageERNiCr 3Cemal NergizNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- ER70S-2 Mild SteelDocument1 pageER70S-2 Mild SteelNadeemNo ratings yet

- Midalloy ER309 PDFDocument1 pageMidalloy ER309 PDFAnonymous hk1fhAkwyNo ratings yet

- E309LMo 16Document1 pageE309LMo 16faiz oeNo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationchepurthiNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationdfmolinaNo ratings yet

- Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)Document1 pageClassifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)felipeNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- L1 12783 en Thermanit 25 09 CuT 1SC6A00G 3394780 ENDocument1 pageL1 12783 en Thermanit 25 09 CuT 1SC6A00G 3394780 ENcycsi02No ratings yet

- 90cual Mig WireDocument1 page90cual Mig WireAris WicaksonoNo ratings yet

- Doclib 4677 Autocraft 316lsi DatasheetDocument1 pageDoclib 4677 Autocraft 316lsi Datasheetamir moniriNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- Ok Tubrod 14.30a PDFDocument1 pageOk Tubrod 14.30a PDFqaNo ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Midalloy ER80S B6 EB6Document1 pageMidalloy ER80S B6 EB6joel cisnerosNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Böhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantDocument1 pageBöhler Ffb-Ig: TIG Rod, High-Alloyed, Heat ResistantSerhii MishchenkoNo ratings yet

- Alloy 309Document3 pagesAlloy 309Branko FerenčakNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Document1 pageClassifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Joni HartonoNo ratings yet

- CF10MC (1.4571)Document3 pagesCF10MC (1.4571)Gilcimar Cavalcante GilcimarNo ratings yet

- GBTDocument1 pageGBTRaviTeja BhamidiNo ratings yet

- Stainarc 309L-17 (Rev 1)Document1 pageStainarc 309L-17 (Rev 1)LIM hoon boonNo ratings yet

- ERCUDocument1 pageERCURogério JuniorNo ratings yet

- Gas Tungsten Arc WeldingDocument2 pagesGas Tungsten Arc WeldingIGNACIO MADRINAN BORRERONo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Product Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'C7 TGNo ratings yet

- Technical Report (CSF-81TM)Document5 pagesTechnical Report (CSF-81TM)matiasg.sanchezv95No ratings yet

- B - Boehler CN 25 9 CuT IG - TRDocument1 pageB - Boehler CN 25 9 CuT IG - TRalbertorebellatoNo ratings yet

- Kiswel K-309LTDocument1 pageKiswel K-309LTOmer IkhlasNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- 25 35 4CNbDocument1 page25 35 4CNbRomy MiftachNo ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- Valve Material SpecificationDocument5 pagesValve Material Specificationapi-9572051No ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Metrode Cryogenic ER316 B-38Document5 pagesMetrode Cryogenic ER316 B-38Claudia MmsNo ratings yet

- Bavaria en BA-TIG 310Document1 pageBavaria en BA-TIG 310cocoNo ratings yet

- Unibraze ER316L PDFDocument1 pageUnibraze ER316L PDFsmpoe017No ratings yet

- Welding of Copper and Its AlloysDocument30 pagesWelding of Copper and Its Alloysaj87_goswami100% (2)

- Welding ConsumableDocument82 pagesWelding ConsumableAzmin BorkhanNo ratings yet

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- Introducing... : ... A New Paradigm in Personal, Real-Time, Biologically Protected AirDocument8 pagesIntroducing... : ... A New Paradigm in Personal, Real-Time, Biologically Protected AirslowmosquitoNo ratings yet

- Directive 2006-42-CE - Machinery PDFDocument63 pagesDirective 2006-42-CE - Machinery PDFeng13No ratings yet

- Vite Esagonale Con Gambo Parzialmente Filettato Filettatura Metrica Iso A Passo Grosso - Cat.ADocument1 pageVite Esagonale Con Gambo Parzialmente Filettato Filettatura Metrica Iso A Passo Grosso - Cat.AslowmosquitoNo ratings yet

- Uvtop260 FW To39 LEDDocument5 pagesUvtop260 FW To39 LEDslowmosquitoNo ratings yet

- Uvtop260 FW To39 LEDDocument5 pagesUvtop260 FW To39 LEDslowmosquitoNo ratings yet

- TPS61165 High-Brightness, White LED Driver in WSON and SOT-23 PackagesDocument38 pagesTPS61165 High-Brightness, White LED Driver in WSON and SOT-23 PackagesslowmosquitoNo ratings yet

- Datasheet - HK - 10103594-0001lf - 1345144 - Connettore USB - J6 PDFDocument1 pageDatasheet - HK - 10103594-0001lf - 1345144 - Connettore USB - J6 PDFslowmosquitoNo ratings yet

- Object: Iso 3834 and Welding CoordinatorDocument1 pageObject: Iso 3834 and Welding CoordinatorslowmosquitoNo ratings yet

- SwingDocument2 pagesSwingslowmosquitoNo ratings yet

- UVC-LED Full PDFDocument11 pagesUVC-LED Full PDFslowmosquitoNo ratings yet

- Who TRS 924 A4Document75 pagesWho TRS 924 A4Andres AbrilNo ratings yet

- Brevetto MAschera-US20100132715A1Document8 pagesBrevetto MAschera-US20100132715A1slowmosquitoNo ratings yet

- Data Sheet: Cl7001C3: Ultraviolet C Light Emitting Diode FeaturesDocument7 pagesData Sheet: Cl7001C3: Ultraviolet C Light Emitting Diode FeaturesslowmosquitoNo ratings yet

- Asme Ix T-Joint Set-OnDocument1 pageAsme Ix T-Joint Set-OnslowmosquitoNo ratings yet

- Defining The Effectiveness of Uv Lamps Installed in Circulating Air For DuctworkDocument49 pagesDefining The Effectiveness of Uv Lamps Installed in Circulating Air For DuctworkPhạm Quang HuyNo ratings yet

- Object: Iso 3834 and Welding CoordinatorDocument1 pageObject: Iso 3834 and Welding CoordinatorslowmosquitoNo ratings yet

- Object: Iso 3834 and Welding CoordinatorDocument1 pageObject: Iso 3834 and Welding CoordinatorslowmosquitoNo ratings yet

- OCEANMAX For Oil Gas Application by Brunton ShawDocument36 pagesOCEANMAX For Oil Gas Application by Brunton ShawslowmosquitoNo ratings yet

- Filler Metal PDFDocument1 pageFiller Metal PDFslowmosquitoNo ratings yet

- Extract From ASTM A240MDocument4 pagesExtract From ASTM A240MslowmosquitoNo ratings yet

- RaccordiasmeDocument30 pagesRaccordiasmeslowmosquitoNo ratings yet

- Object: Iso 3834 and Welding CoordinatorDocument1 pageObject: Iso 3834 and Welding CoordinatorslowmosquitoNo ratings yet

- 31 MM 98 MMDocument4 pages31 MM 98 MMslowmosquitoNo ratings yet

- Annex 2: Filler Metal CertificateDocument1 pageAnnex 2: Filler Metal CertificateslowmosquitoNo ratings yet

- ER316LDocument1 pageER316LslowmosquitoNo ratings yet

- Numeri Di Telaio CUP SDocument3 pagesNumeri Di Telaio CUP SslowmosquitoNo ratings yet

- Michelin Race Tire CatalogDocument12 pagesMichelin Race Tire CatalogShashi MauryaNo ratings yet

- Porsche VIN Decoder - StuttcarsDocument3 pagesPorsche VIN Decoder - StuttcarsslowmosquitoNo ratings yet

- 306 960 1 PBDocument16 pages306 960 1 PBslowmosquitoNo ratings yet

- Osmc710h EngDocument2 pagesOsmc710h EngslowmosquitoNo ratings yet

- Defect EliminationDocument4 pagesDefect EliminationHossein100% (1)

- SNO-I-DS-001 - 0 Instrument Data Sheet For Shutdown and Blowdown Valves (Revise)Document174 pagesSNO-I-DS-001 - 0 Instrument Data Sheet For Shutdown and Blowdown Valves (Revise)ono_czeNo ratings yet

- MR ValvesDocument56 pagesMR ValvesIdris SiddiquiNo ratings yet

- Spirex": Onepiece Spiral Flexible CouplingDocument1 pageSpirex": Onepiece Spiral Flexible CouplingHazim HazimNo ratings yet

- 3 Esrtos IntroDocument8 pages3 Esrtos IntroVijayaraghavan VNo ratings yet

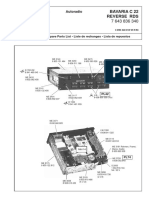

- Bavaria Reverse RdsDocument15 pagesBavaria Reverse RdsDušan JovanovićNo ratings yet

- Tay Township User Fees and Service Charges BylawDocument27 pagesTay Township User Fees and Service Charges BylawMidland_MirrorNo ratings yet

- Patrol Box PlansDocument6 pagesPatrol Box PlansPePe ProjectsNo ratings yet

- Fatwa Darul Uloom Deoband - Vol 1Document276 pagesFatwa Darul Uloom Deoband - Vol 1Ahlehaq100% (3)

- Babies of 2010Document16 pagesBabies of 2010Sierra Nevada Media GroupNo ratings yet

- Stereo Conversion Preamplifier: GeneralDocument2 pagesStereo Conversion Preamplifier: GeneralFRANK NIELE DE OLIVEIRANo ratings yet

- NC100HDocument2 pagesNC100HDouglas GilbNo ratings yet

- ABM Chain HoistDocument14 pagesABM Chain HoistZuwairi NawawiNo ratings yet

- Aip Enr 2.1-1 India 1 Aug 2007Document28 pagesAip Enr 2.1-1 India 1 Aug 2007itsrijoNo ratings yet

- Yousif Alotaibi 01 CVDocument3 pagesYousif Alotaibi 01 CVyousefx20No ratings yet

- Cost BreakdownDocument241 pagesCost Breakdownbilisuma sebokaNo ratings yet

- Group 2 (ME 03) - Hoa Phat GroupDocument42 pagesGroup 2 (ME 03) - Hoa Phat GroupLê Thành DanhNo ratings yet

- Different Type of ChillersDocument7 pagesDifferent Type of ChillersMAGDY KAMEL100% (3)

- Curriculam Vitae: ObjectiveDocument4 pagesCurriculam Vitae: ObjectiveSachin DeoNo ratings yet

- Dynamic Arrays With The Arraylist Class Chapter Xii TopicsDocument38 pagesDynamic Arrays With The Arraylist Class Chapter Xii TopicsRocket FireNo ratings yet

- 33R 15Document10 pages33R 15Ingenieria Ec100% (5)

- ManualDocument90 pagesManualBhárbara Idk100% (1)

- QuestionsDocument7 pagesQuestionsallanrnmanalotoNo ratings yet

- Catálogo EC200DDocument912 pagesCatálogo EC200DCasa da Madeira100% (1)

- LSV-08-2 NCPDocument2 pagesLSV-08-2 NCPishtiaqNo ratings yet

- Job Report 2Document6 pagesJob Report 2Sahr, Cyprian FillieNo ratings yet

- Reviewer in Hairdressing (From Mastery Test)Document7 pagesReviewer in Hairdressing (From Mastery Test)peanut nutterNo ratings yet

- Catalogo EpirocDocument7 pagesCatalogo EpirocAngel García0% (1)

- Asme eDocument41 pagesAsme eAnonymous wWOWz9UnWNo ratings yet

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFbosschellenNo ratings yet