Professional Documents

Culture Documents

QW 482

Uploaded by

Ramu NallathambiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QW 482

Uploaded by

Ramu NallathambiCopyright:

Available Formats

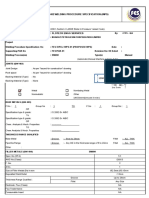

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-201.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name Flowserve India Controls Pvt Ltd By: Ramu Nallathambi

Welding Procedure Specification No. 02 Date 18-Nov-16 Supporting PQR No.(s) 02

:

Revision No. See Cover Date See Cover

Welding Process(es) GTAW Type (s) Automatic

JOINTS (QW-402) Details

Joint Design See permitted figures (right) or per constr. dwg BUTT JOINT

Root Spacing Not Required

Backing (Yes) Yes (No) Yes

Backing Material (Type) Material or Weld Metal

(refer to both backing and retainers)

Metal Nonfusing Metal

FIG A (BUTT JOINT) FIG B (CORNER JOINT) FIG C (EDGE JOINT)

Nonmetalic Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the root spacing and the details of weld groove may be

specified.

FIG D (LAP JOINT) FIG E (TEE JOINT)

(At the option of the Mfgr., sketches may be attached to illustrate joint

design, weld layers and bead sequence, e.g., for notch toughness proc-

dures, for multiple process procedures etc.)

Other (Describe)

Figure A Figure B Figure C Figure D Figure E

*BASE METALS (QW-403)

P-No. 8 Group No. 1 to P-No. Group No.

OR

Specification type and grade

to Specification type and grade

OR

Chem. Analysis and Mech. Prop. None

to Chem. Analysis and Mech. Prop. None

Thickness Range: 25 mm (1") to Unlimited

Base Metal: Groove None Fillet None

Other

Maximum Pass Thickness 1/2 inch (13 mm) (Yes) (No)

*FILLER METALS (QW-404)

Spec. No. (SFA)

5.21

AWS No. (Class) ER CoCr-A

F-No. 72

A-No. None

Size of Filler Metals -45 to +180 Microns

Filler Metal Product Form Powder

Supplemental Filler Metal None

Weld Metal

Thickness Range: Minimum 0.05" (1.27

mm)

Groove None

Fillet None

Electrode-Flux (Class) None

Flux Trade Name None

Consumable Insert No

Other

*Each base metal-filler metal combination should be recorded individually.

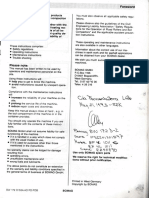

QW-482 (Back)

WPS No. Rev

POSITIONS (QW-405) POST WELD HEAT TREATMENT (QW-407)

Position(s) of Groove Temperature Range

Welding Progression: Up Down Time Range

Position(s) of Fillet

PREHEAT (QW-406) GAS (QW-408) Percent Composition

Preheat Temp. Min. Gas(es) (Mixture) Flow Rate

Interpass Temp. Max. Shielding

Preheat Maintenance Trailing

(Continuous or special heating where applicable should be recorded) Backing

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC Polarity

Amps (Range) Volts (Range)

(Amperage and voltage range should be recorded for each electrode size,

position, and thickness, etc. This information may be listed in a tabular

form similar to that shown to the right or below.)

Tungsten Electrode Size and Type

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW

(Spray arc, short circuiting arc, etc.)

Electrode Wire feed speed range

TECHNIQUE (QW-410)

String or Weave Bead String or Weave

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding, etc.) Brushing, grinding, chipping

Method of Back Gouging Grinding

Oscillation

Contact Tube to Work Distance

Multiple or Single Pass (per side) Multiple

Multiple or Single Electrodes Multiple

Travel Speed (Range)

Peening

Other No Single Pass To Exceed 1/2" In Thickness Pulsed Power Supply not permitted

Flux is not to be added to the face of the joint

Filler Metal Current

Other

(e.g., Remarks, Com-

Weld Travel

Type and Amperage Voltage ments, Hot Wire

Layer(s) or Process Classification Diameter. Speed

Polarity Range Range Addition, Technique,

Pass (es) Range

Torch Angle, Etc.)

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Smaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointDocument3 pagesSmaw Manual See Permitted Figures (Right) or Per Constr. DWG Butt JointNirmala DeshaNo ratings yet

- WPS Format GuideDocument2 pagesWPS Format GuideKhaled bouhlelNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)MALABAR TIMESNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- PWPS Eksperimen Super DuplexDocument33 pagesPWPS Eksperimen Super Duplexryan.sNo ratings yet

- Wps PQR FormDocument8 pagesWps PQR Formmayank0738No ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- QW-482 WELDING PROCEDURE SPECIFICATIONS (WPSDocument1 pageQW-482 WELDING PROCEDURE SPECIFICATIONS (WPSlinaNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Welding Procedure Specification for ASME Section IXDocument4 pagesWelding Procedure Specification for ASME Section IXRahul MoottolikandyNo ratings yet

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- WPS FormatDocument2 pagesWPS FormatmanjuNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Form WPS for MIG Welding ProcedureDocument10 pagesForm WPS for MIG Welding ProcedurePrakash PatelNo ratings yet

- QW 482 Suggested Format For Welding ProcedureDocument1 pageQW 482 Suggested Format For Welding ProcedureNisarg PandyaNo ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- WPS-01_FCAW-3G-(E250BR to E250BR-A36)_CSWIP_03.10.2023 (Group-1)_Groove Joints (002)Document11 pagesWPS-01_FCAW-3G-(E250BR to E250BR-A36)_CSWIP_03.10.2023 (Group-1)_Groove Joints (002)Mohammad AdilNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- 001 WPS Cntim 2023Document10 pages001 WPS Cntim 2023shangyuan1079163.comNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- PQR Sample PrintoutDocument2 pagesPQR Sample PrintoutDhewo Rachmad Yansyah100% (3)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- FORM QW-482 WELDING PROCEDURE SPECIFICATIONDocument2 pagesFORM QW-482 WELDING PROCEDURE SPECIFICATIONsbmmlaNo ratings yet

- Welding Procedure Specifications (WPS) - Qw482Document23 pagesWelding Procedure Specifications (WPS) - Qw482vichu_villamarNo ratings yet

- Ex Wps Train 01Document2 pagesEx Wps Train 01aidil30No ratings yet

- WPS SS316Document4 pagesWPS SS316Budi Setia RahmanNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2Document2 pagesWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2RahmadiNo ratings yet

- Ii. 5 Tes - WPS Rebabbit Bearing Pltu TembilahanDocument4 pagesIi. 5 Tes - WPS Rebabbit Bearing Pltu TembilahanaddinulichsanNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Heat Loss Insulated PipeDocument14 pagesHeat Loss Insulated PipeJonson CaoNo ratings yet

- Rules of Thumb Chapter 8: VesselsDocument4 pagesRules of Thumb Chapter 8: VesselsAri KurniawanNo ratings yet

- 2015 12 Heat-loss-from-Insulated-pipeDocument7 pages2015 12 Heat-loss-from-Insulated-pipeRamu NallathambiNo ratings yet

- Is 3896 2 1985 PDFDocument11 pagesIs 3896 2 1985 PDFRamu NallathambiNo ratings yet

- Solid2 5 PDFDocument1 pageSolid2 5 PDFRamu NallathambiNo ratings yet

- Energy Efficient Steam SystemsDocument46 pagesEnergy Efficient Steam SystemsRamu NallathambiNo ratings yet

- Rules of Thumb Chapter 8: VesselsDocument4 pagesRules of Thumb Chapter 8: VesselsAri KurniawanNo ratings yet

- 2015 12 Heat-loss-from-Insulated-pipeDocument7 pages2015 12 Heat-loss-from-Insulated-pipeRamu NallathambiNo ratings yet

- Solid2 5 PDFDocument1 pageSolid2 5 PDFRamu NallathambiNo ratings yet

- Solid2 5 PDFDocument1 pageSolid2 5 PDFRamu NallathambiNo ratings yet

- Rules of Thumb Chapter 8: VesselsDocument4 pagesRules of Thumb Chapter 8: VesselsAri KurniawanNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Ramu NallathambiNo ratings yet

- Tables HardnessDocument3 pagesTables HardnessRamu NallathambiNo ratings yet

- Rules of Thumb Chapter 8: VesselsDocument4 pagesRules of Thumb Chapter 8: VesselsAri KurniawanNo ratings yet

- Solid2 5 PDFDocument1 pageSolid2 5 PDFRamu NallathambiNo ratings yet

- 2015 12 Heat-loss-from-Insulated-pipeDocument7 pages2015 12 Heat-loss-from-Insulated-pipeRamu NallathambiNo ratings yet

- RADIOGRAPHY PROCEDURE TITLEDocument50 pagesRADIOGRAPHY PROCEDURE TITLERamu Nallathambi100% (3)

- Stainless Steel Cladding and Weld Overlays PDFDocument13 pagesStainless Steel Cladding and Weld Overlays PDFm5416No ratings yet

- Solid2 5 PDFDocument1 pageSolid2 5 PDFRamu NallathambiNo ratings yet

- Resources Pages Steam-Engineering-TuDocument6 pagesResources Pages Steam-Engineering-TuRamu NallathambiNo ratings yet

- Energy Efficient Steam SystemsDocument46 pagesEnergy Efficient Steam SystemsRamu NallathambiNo ratings yet

- Tables HardnessDocument3 pagesTables HardnessRamu NallathambiNo ratings yet

- 2015 12 Heat-loss-from-Insulated-pipeDocument7 pages2015 12 Heat-loss-from-Insulated-pipeRamu NallathambiNo ratings yet

- Tables HardnessDocument3 pagesTables HardnessRamu NallathambiNo ratings yet

- Heat Loss Insulated PipeDocument14 pagesHeat Loss Insulated PipeJonson CaoNo ratings yet

- Display PDFDocument7 pagesDisplay PDFRamu NallathambiNo ratings yet

- Chemistry Stockroom-Reagents LearniDocument2 pagesChemistry Stockroom-Reagents LearniRamu NallathambiNo ratings yet

- Resources Pages Steam-Engineering-TuDocument6 pagesResources Pages Steam-Engineering-TuRamu NallathambiNo ratings yet

- Krytox Typical Properties GPL 227Document2 pagesKrytox Typical Properties GPL 227Ramu NallathambiNo ratings yet

- EZGO Shuttle 6 2010Document2 pagesEZGO Shuttle 6 2010Mohd ZamriNo ratings yet

- Low Cost PCO Billing Meter PDFDocument1 pageLow Cost PCO Billing Meter PDFShrivlsi RamNo ratings yet

- ProWORX32+V2 1+SP2+ReadMeEng PDFDocument12 pagesProWORX32+V2 1+SP2+ReadMeEng PDFRuben LoveraNo ratings yet

- Panasonic TX 29pm11d Chassis Gp2Document32 pagesPanasonic TX 29pm11d Chassis Gp2Jenica RadulescuNo ratings yet

- Raindropz Remix - YouTubeDocument3 pagesRaindropz Remix - YouTubeGary DiazNo ratings yet

- Circuit Diagram: ModelDocument26 pagesCircuit Diagram: ModelOmar LugoNo ratings yet

- DFM GuidelinesDocument58 pagesDFM Guidelinesjav_ra993986No ratings yet

- 1176 PDFDocument169 pages1176 PDFJoshua PalizaNo ratings yet

- Curriculum of Bachelor in Industrial EngineeringDocument138 pagesCurriculum of Bachelor in Industrial EngineeringPratikshya DevkotaNo ratings yet

- Shared Memory ArchitectureDocument39 pagesShared Memory Architectureอภิเษก หงษ์วิทยากรNo ratings yet

- Logarithmic Amplifier: BE o Be Be oDocument1 pageLogarithmic Amplifier: BE o Be Be oJoseGarciaRuizNo ratings yet

- Coke IotDocument18 pagesCoke IotTarunVReddyNo ratings yet

- Ludhiana and Jalandhar CompaniesDocument5 pagesLudhiana and Jalandhar Companiessingh.amardeepNo ratings yet

- Evaluating JFET Transistors for Linear Performance in Active Antenna DesignsDocument9 pagesEvaluating JFET Transistors for Linear Performance in Active Antenna DesignsAlex SanNo ratings yet

- Manual LG Electronics 30FZ1DCDocument2 pagesManual LG Electronics 30FZ1DCEduardo RomeroNo ratings yet

- James HughesDocument2 pagesJames HughesKelly RoseNo ratings yet

- Overview: Brushless DC Motor Driver Circuit Using 555 ICDocument4 pagesOverview: Brushless DC Motor Driver Circuit Using 555 ICJanet Walde100% (1)

- FORM TP 22247: Caribbean Examinat Advanced Proficiency Physics Ions Coun ExaminationDocument19 pagesFORM TP 22247: Caribbean Examinat Advanced Proficiency Physics Ions Coun Examinationpetey78No ratings yet

- Samsung proprietary board information and power sequence timingDocument2 pagesSamsung proprietary board information and power sequence timingHumberto AndujarNo ratings yet

- Electronic Voltage Regulator R100 PDFDocument3 pagesElectronic Voltage Regulator R100 PDFOleg OrnatskyiNo ratings yet

- class-AB Voltage Follower2006Document2 pagesclass-AB Voltage Follower2006tuanka1No ratings yet

- RMLL Kernen Home Brew IPTV v2 OptimisedDocument51 pagesRMLL Kernen Home Brew IPTV v2 Optimisedmario74mNo ratings yet

- Stoeltjes Lift Thyssen Access Flow2Document50 pagesStoeltjes Lift Thyssen Access Flow2Arjan WijnenNo ratings yet

- Name of Project:: 2 X 4.4Mw Rudi Khola HepDocument5 pagesName of Project:: 2 X 4.4Mw Rudi Khola HepapsNo ratings yet

- DFFHMDocument9 pagesDFFHMyaswanthNo ratings yet

- ANSI CodesDocument12 pagesANSI CodesmgkvprNo ratings yet

- Marantz ReceiverDocument2 pagesMarantz ReceiverRolando perez0% (1)

- Lotus Electrical Cooling Tuning 031212 PDFDocument27 pagesLotus Electrical Cooling Tuning 031212 PDFSF FoggNo ratings yet

- Rodo Vibratorio Bomag 172DDocument88 pagesRodo Vibratorio Bomag 172DCarlosFlores100% (7)

- TDA7442Document16 pagesTDA7442gaston30-3@No ratings yet