Professional Documents

Culture Documents

Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135

Uploaded by

Travis WoodCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135

Uploaded by

Travis WoodCopyright:

Available Formats

Karim and Begum, J Material Sci Eng 2014, 3:1

http://dx.doi.org/10.4172/2169-0022.1000135

Material Science & Engineering

Research Article

Research Article Open

OpenAccess

Access

Enhanced Performance of Zinc Oxide Arrester by Simple Modification in

Processing and Design

Karim ANM1 and Shahida Begum2*

1

Department of Manufacturing and Materials Engineering, Faculty of Engineering, International Islamic University Malaysia, Kuala Lumpur, Malaysia

2

Department of Mechanical Engineering, Centre for Advanced Materials, Universiti Tenaga Nasional, Jalan IKRAM-UNITEN, Putrajaya, Malaysia

Abstract

Reliable performance of a Zinc Oxide surge arrester is highly dependent on its energy absorption capability.

This paper presents two simple but promising approaches for enhancement of this property: one with an alternative

sintering orientation and the other with the changed geometry of arrester discs to provide higher surface to

volume (S/V) ratio. Several sintering orientations including the control (or conventional) process were tried and

assessed. Some of these attempts have demonstrated quite superior results which might be linked to lower level

of contamination during sintering. Study conducted to observe the effect of the higher surface to volume (S/V) ratio

through geometrical modification of the discs from cylindrical to hexagonal shape has also demonstrated improved

outcome. Average energy absorption capability for the hexagonal discs was found to increase markedly which

might be attributable to faster heat dissipation aided by higher S/V ratio preventing the discs from premature failure.

Thus by combining the appropriate sintering orientation and the change in geometrical shape for higher (S/V) ratio,

substantial enhancement of the arrester block capability is achievable which would be eventually helpful for improved

protection of electrical system.

Keywords: ZnO arrester block; Energy absorption capability; theoretical density. Pressing is performed by a uniaxial double action

Surface-to-volume ratio; Sintering orientation compaction technique. Sintering of the discs was performed by a

sintering profile with a peak temperature of about 1120C requiring

Introduction a cycle time of about 70 hours. The ceramic body undergoing a liquid

Zinc oxide arresters are electronic ceramic devices, the primary phase sintering process takes the shape of a rigid cylinder with a

function of which is to protect the electrical systems by sensing and theoretical density of more than 95 percent.

limiting transient surges [1]. This metal-oxide varistor technology is Researches in the varistor technology have been primarily aimed

widely applied now-a-days for voltage stabilization or transient surge at improving the fundamental properties. As the performance and

suppression in electronic circuits and electrical power systems [2-5]. reliability of electronic ceramic were thought to depend on the grain

Owing to the improvements of non-ohmic properties and functional and the grain boundary phenomena [7,8], much of the research

reliability, use of ZnO varistors has expanded quite rapidly. Moreover, works are related to the investigation of material composition, micro-

with the advent of advanced manufacturing technology, varistors structure, and the grain and grain boundary [9-15]. Maximum attention

having new designs and configurations are expected to have wider of the research publications is related to the I-V curve characterized

application. by the nonlinear coefficient, . But, reliable performance of arrester

In addition to some finishing operations, varistor manufacture blocks is also largely dependent on their energy absorption capability,

basically follows the route of conventional ceramic processing. considered as the second most important property.

Ceramic materials have been produced and used for centuries. As observed in earlier study [16] the contact zone of a disc remaining

However, compared to the long history of ceramic materials, use of in the vicinity of the liner material during the sintering process is more

electronic ceramic as transient over-voltage suppression device is a susceptible to failure and even after deeper grinding of the bottom

recent development [6]. face, most of the failures were found to originate from this zone. In

Processing of arrester block this respect effect on the change in the orientation of sintering support

on the energy absorption capability would be interesting. Moreover, as

Zinc Oxide varistors produced in the form of cylinder are often reported earlier [17], since in testing the energy absorption capability a

called arrester blocks. These are fundamentally ceramic materials, disc becomes momentarily very hot being subjected to electrical pulses,

processed from a number of metal oxide powders. The basic material

is pulverized and very finely grained ZnO with particle sizes of about

1m, to which as many as 10 or more doping elements are added in

*Corresponding author: Shahida Begum, Department of Mechanical Engineering,

the form of fine oxide powders. Its actual composition differs from Centre for Advanced Materials, Universiti Tenaga Nasional, Jalan IKRAM-UNITEN,

manufacturer to manufacturer. To achieve the required homogeneity Putrajaya, Malaysia, Tel: +6-0196345570; E-mail: Shahida@uniten.edu.my

the powder is treated in several processing steps, after which the ReceivedSeptember 04, 2013; Accepted February 10, 2014; Published February

mixture in the form of slurry has to be spray-dried to obtain the dry 15, 2014

granulates necessary for pressing. Majority of the varistor devices are Citation: Karim ANM, Begum S (2014) Enhanced Performance of Zinc Oxide

processed from this kind of powder. The whole manufacturing process Arrester by Simple Modification in Processing and Design. J Material Sci Eng 3:

relevant to fabrication of arrester blocks is illustrated in a flow diagram 135. doi:10.4172/2169-0022.1000135

as depicted in Figure 1. Copyright: 2014 Karim ANM, et al. This is an open-access article distributed

under the terms of the Creative Commons Attribution License, which permits

Spray dried powder in the form of granulates is compressed unrestricted use, distribution, and reproduction in any medium, provided the

into disc-shaped blocks with approximately 55 to 65 percent of their original author and source are credited.

J Material Sci Eng

ISSN: 2169-0022 JME, an open access journal Volume 3 Issue 1 1000135

Citation: Karim ANM, Begum S (2014) Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design. J Material

Sci Eng 3: 135. doi:10.4172/2169-0022.1000135

Page 2 of 6

Figure 1: Fabrication procedure of the ZnO arrester discs or blocks.

quicker dissipation of heat from the arrester body having greater plane was obtained, the other two adjacent flat surfaces were developed

surface area should be helpful. In this respect a hexagonal disc having at angle of 60 degree. The remaining three flat surfaces were ground one

greater surface to volume ratio is thought to perform better. by one by placing the disc on the conveyor belt making contact with

the already developed flat surfaces. As shown in Figure 5, a cylindrical

Experimental Procedure disc was thus transformed into a hexagonal shape by progressively

Sample preparation of the cylindrical arrester blocks through generating all the six flat surfaces. A 41 mm diameter cylindrical

different sintering orientations and hexagonal shape blocks is disc having a cross-section of 13.2025 cm2 is ground to a hexagonal

described. To minimize the undesirable effect at the bottom, a number disc with cross-section reduced to 10.9184 cm2. Since the disc height

of alternative orientations have been attempted [18] by changing the of 42 mm remained unchanged, the volumes of the cylindrical and

sintering orientation i.e. placing the disc on different kinds of support. hexagonal discs became 55.45 cm3 and 45.86 cm3 respectively with the

The orientation in control process is shown in Figure 2. corresponding surface areas of 80.5032 cm2 and 73.7887 cm2.

Figure 2a shows the positions of discs placed in a sagger. As shown As a result the S/V ratio of hexagonal disc is increased to a value

in Figure 2b, a disc remains in a vertical condition on a liner to separate 1.609 cm-1 compared to that for the cylindrical disc of 1.452 cm-1. Thus

from direct contact of sagger. Modified arrangements for are presented an increase of about 11% in S/V ratio was achieved for the hexagonal

in Figures 3 and 4. discs. To minimize the effect of the process variables the other

necessary operations were conducted in a single run under the same

A fired smaller support system shown in Figure 3a was chosen set conditions.

to keep the edges free from the liner material to ensure good edge

quality. A green support of the same diameter made from the standard Evaluation of energy absorption capability and high current

varistor material as presented in Figure 3b was to aid the bottom edges performance

unaffected from the adverse effects of sliding during the shrinking Energy absorption capability is measured by millisecond

process in sintering. As practiced in control process, the green discs in rectangular pulses whereas high current performance is analyzed

these are kept separated from the direct contact of the supporting liner by high amplitude short duration (HASD) pulses of microseconds

by sparsely spreading ZnO powder. duration. In both the cases highly accurate and reliable impulse test

As illustrated in Figure 4, the Vee-groove support was made from systems (Trigatron type 94 for energy and Impulse current test system

the fired arrester discs. To prevent sticking of the discs in sintering the WO 4924 for high current) were used. This characteristic of a varistor is

supports were made wet by spraying water and covered by sparsely determined by the maximum energy density injected into the ceramic

spreading spinel powder, known to have an inhibiting effect on the body up to which it can sustain without failure for a cycle of three shots,

grain growth. The Vee-groove support could facilitate to keep the edges expressed in terms of Joule.cm-3.

free from any physical contact during the sintering process. Definition of the rectangular impulse current as derived from

Thus these three orientations were anticipated to have enhanced Figure 6a is a 2-millisecond pulse, conventionally termed as long wave.

edge quality. This kind of pulse is usually experienced in switching surges.

The discs are categorized into different cells according to the Energy injected by such a pulse is the integrated value of the product

description given in Table 1 to facilitate to refer in the subsequent of the voltage and current passing through the disc over the pulse

sections. duration. So the amount of energy can be expressed mathematically

with the following relationship:

The shape of hexagonal cross-section was obtained by modifying

the C-surface of the cylindrical discs [19]. A production-line diamond t

grinding wheel rotated along a vertical axis was used. Cylindrical Energy = vidt (1)

0

arrester discs were passed under the flat face of the diamond wheel by

placing them horizontally on the conveyor belt. A small depth of cut However, the instantaneous values of the voltage, v and current,

was used to remove material in one pass. Several passes were needed to i are not practically recorded. To evaluate the integrated energy the

complete one of the six flat sides of the hexagonal discs. After one flat peak values of the clamping voltage and peak current passing through

J Material Sci Eng

ISSN: 2169-0022 JME, an open access journal Volume 3 Issue 1 1000135

Citation: Karim ANM, Begum S (2014) Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design. J Material

Sci Eng 3: 135. doi:10.4172/2169-0022.1000135

Page 3 of 6

Figure 2: Control orientation of arrester blocks on sagger for sintering (CSS).

Figure 3: Circular disc liner intended to improve the bottom edge (modified).

Figure 4: Vee-groove support (VSS) for horizontal sintering orientation.

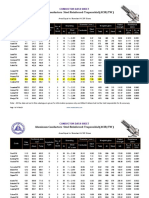

Cell ID Description of the support system

CSS Control Support System (fired ZnO flat liner and spread ZnO powder)

SSS Smaller Sintered Support system (keeping bottom edge free from contact)

TGS Total Green Support System (allowing the bottom to smooth shrinkage)

VSS Vee-groove Support System (keeping both flat surfaces from contact)

Table 1: Identification of four different groups or cells.

the arrester block are used. For a pulse of quasi-rectangular shape as energy absorption cannot be performed in a single step. Testing is

demonstrated in Figure 6a, the relationship can be expressed in terms initiated with a lower charging voltage so that injected energy remains

of the peak voltage, Vpk (KV) and peak current, Ipk (A) for a duration of in the lower range, say, about 200 Joule.cm-3, to minimize the likelihood

time T in millisecond as follows: of failure at the first cycle. The testing by discrete increment of charging

t voltage and cooling of the discs is a tedious process which is continued

Energy = KV pk I pk T

vidt = (2)

until all the discs of the fail at a certain stage.

0

where K is a constant, dependent on the wave-shape. For a pulse as

The High Amplitude Short Duration (HASD) pulses are in the

shown in Figure 6, the value of K is taken as 1.14. Thus the total injected

range of microseconds duration. This is a simulated pulse of the actual

energy by is estimated as 2.28.Vpk Ipk

lightning stroke. Typical short pulse used for evaluating high current

Unlike the measurement of mechanical strength, the test for the performance is 4x10s where the first value (virtual front time) indicates

J Material Sci Eng

ISSN: 2169-0022 JME, an open access journal Volume 3 Issue 1 1000135

Citation: Karim ANM, Begum S (2014) Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design. J Material

Sci Eng 3: 135. doi:10.4172/2169-0022.1000135

Page 4 of 6

Figure 5: Hexagonal shape disc as obtained by grinding a cylindrical arrester block.

Figure 6: (a) Long (ms) pulse for energy absorption and (b) HASD (4x10s) pulse for high current performance.

the rise time from 10% to 90 % of the peak current and the second the first three cells with slightly higher value for SSS category. But, the

value (virtual time to half value) is the duration to reach to 50% of the mean energy absorption capability for the discs sintered on the same

peak during fall. Since this is a destructive test a sample of few discs is size green support (cell TGS) is about 10 percent less compared to the

taken from a lot. Unlike the test for the energy absorption capability, other cells.

only one shot is applied at a time for the high current capability. The

failure mode in this case is predominated by cracking rather than by It may be mentioned here that both the faces of a disc are cleaned

the thermal runaway or puncture as observed in long pulse test. by grinding operation. Regrinding of a disc face is necessary when

defects such as pinhole and chipping of edges are observed by the

A parameter to express the high current performance of a particular visual manual inspection following the initial grinding. In the context

cell can be defined mathematically [16] in the following form: of material, labor, equipment use, and production cycle time of a batch,

regrinding is obviously an undesirable operation. As recorded and

HIgh current performance (%) =

n x i i

(100) (3)

shown in Figure 7b, the category (SSS) looks promising followed by

NX i

(VSS) and (TGS) in the context of the need of minimum regrinding

frequency of the faces.

Where N = initial sample size of discs to be tested According to the level of energy absorption capability and

Xi = rated peak current at the ith pulse regrinding frequency the discs belonging to SSS cell are superior. But

due to the smaller size of the support, placing of discs on top of it

ni = number of discs successfully passing the ith pulse and and subsequent handling of the saggars to position in the furnace for

xi = actual peak current in the ith pulse sintering purpose are to be difficult. Thus this unstable support system

cannot be recommended.

Results and Discussion For high current performance multiple discs from each of the cells

The test for energy also known as the strength test to destruction for sintering orientation were tested. The rated current was selected

is usually conducted on the discs being passed by visual inspection. with an increment of 5 kA for every subsequent shot for every disc.

Reasonably large sample sizes were used. Arrester blocks tested were The starting current was 100 kA and there were no survivor after 115

10, 12, 14 and 16 respectively for the CSS, VSS, SSS and TGS cells. kA shot. Based on the values of high current performance parameter

The results are plotted in Figure 7a with the error bar. In terms of the as defined by equation (4) the relative performance is presented

energy absorption capability there is no significant difference among graphically in Figure 8a. So according to the combined performance

J Material Sci Eng

ISSN: 2169-0022 JME, an open access journal Volume 3 Issue 1 1000135

Citation: Karim ANM, Begum S (2014) Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design. J Material

Sci Eng 3: 135. doi:10.4172/2169-0022.1000135

Page 5 of 6

Figure 7: (a) Mean energy absorption capability of different cells (b) Percentage of discs needing regrinding as change of sintering orientation.

Figure 8: (a) High current performance as affected by sintering orientation (b) Energy absorption capability as influenced by arrester geometry.

on three characteristics such as energy absorption capability, frequency failure mode and the location of damaged marks for each of the discs

of regrinding and high current performance, the choice horizontal were tracked. Pinhole accompanied by a flashover was observed to be

sintering on Vee- groove support (VSS) looks reasonable. the common mode of failure for both categories. In a very few cases

discs failed with crack or fracture alone. Since the hexagonal discs were

To investigate the effect of surface to volume ratio on the energy

absorption capability a total of 20 arrester blocks (10 cylindrical and prepared by grinding the side surface of the cylindrical discs, variation

10 hexagonal) was taken. Figure 8b illustrates the energy absorption in energy absorption capability could likely be linked with the removal

capability for the cylindrical and hexagonal discs by error diagram of the presumably contaminated surface of the cylindrical discs. But

representing the mean and standard deviation. The discs having no such indication was found from the observations of the failure

hexagonal shape exhibited an average of 483 J.cm-3 while the discs patterns and their distribution. So the findings on the influence of S/V

having the cylindrical shape yielded an average of only 357 J.cm-3. ratio in enhancing the energy absorption capability can be taken into

Thus, about 35% increase in the mean energy absorption capability was consideration in designing the geometry of the device for improved

observed for the hexagonal discs. functional reliability.

The energy injected by the electrical pulses only of 2 milliseconds Conclusions

duration may be assumed to follow an adiabatic heating process. But

Through this investigative study on sintering orientation and

the hexagonal discs having higher surface to volume ratio is found to

change of disc geometry leading to higher S/V ratio, some interesting

sustain higher level of energy absorption capability. This phenomenon

results are obtained. Sintering keeping the discs horizontally on Vee-

can be attributable to the effect of increased surface to volume ratio of

groove support is found to be more attractive compared to the current

arrester block refuting the assumption of adiabatic heating.

practice. With the improved edge quality of the sintered discs, there

It may be mentioned here that failure of arrester blocks in the energy is a remarkable reduction in the frequency of regrinding. Moreover,

test is usually dominated by occurrences of pinhole and flashover. The the horizontal sintering technique produces arresters with less density

J Material Sci Eng

ISSN: 2169-0022 JME, an open access journal Volume 3 Issue 1 1000135

Citation: Karim ANM, Begum S (2014) Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design. J Material

Sci Eng 3: 135. doi:10.4172/2169-0022.1000135

Page 6 of 6

gradient and better geometry which could lead to prevent earlier failure. 8. Einzinger R (1980) Grain Boundary Properties in ZnO varistors. Advances in

Ceramics. (Vol 1), Columbus, Ohio, USA.

Additionally, the liners could possibly be used for more cycles as these

are to be minimally affected at the contact zone. So the horizontal 9. Gambino JP, Kingery WD, Pike GE, Philipp HR, Levinson LM (1987) Grain

sintering technique is deemed to be significantly beneficial in terms of boundary electronic states in some simple ZnO varistors. J Appl Phys 61: 2571-

2574.

improved process capability as well as reduced cost for the processing

of arrester blocks. Regarding the design with change in geometry, 10. Gupta TK, Miller AC (1988) Improved stability of the ZnO varistor via donor and

acceptor doping at the grain boundary. J Mater Res 3: 745-754.

higher S/V ratio of the hexagonal disc is found to be more conducive

in transferring heat leading to enhanced life in energy test. With an 11. Yano Y, Takai Y, Morooka H (1994) Interface states in ZnO varistor with Mn,

Co, and Cu impurities. J Mater Res 9: 112-118.

increase of about 11% in S/V ratio, the average energy absorption

capability for the hexagonal discs was found to improve by about 35%. 12. Lee JS, Wiederhorn SM (2004) Effects of Polarity on Grain-Boundary Migration

Since there was no other variation in processing except the geometry in ZnO. J Am Ceram Soc 87: 1319-1323.

of the disc, the significant increase in energy absorption capability can 13. Balzer B, Hagemeister M, Kocher P, Gauckler LJ (2004) Mechanical Strength

be attained with the modification in the design of die for compaction. and Microstructure of Zinc Oxide Varistor Ceramics. J Am Ceram Soc 87: 1932-

1938.

Thus, with simple changes in geometric shape and sintering processing,

surge arresters with enhanced performance are achievable. 14. Nahm CW (2012) Nb2O5 doping effect on electrical properties of ZnO-V2O5-

Mn3O4 varistor ceramics. Ceram Int 38: 5281-5285.

References

15. Yaya A, Dodoo-Arhin D (2012) The influence of Bi2O3 and Sb2O3 doping on the

1. Matsuka M (1971) Nonohmic Properties of Zinc Oxide Ceramics. Jpn J Appl microstructure and electrical properties of sintered Zinc Oxide. ARPN J Eng

Phys 10: 736-746. Appl Sci 7: 834-842.

2. Puyan R (1995) Application and Product Development in Varistor Technology. 16. Karim ANM, Begum S, Hashmi MSJ (1997) Processing of ZnO varistor: sources

J Mater Process Tech 55: 268-277. of defects generation and possible measures for their elimination. Proceedings

of 3rd International Conference on Advanced Methods in Material Processing

3. Eda k (1989) Zinc Oxide Varistors. IEEE Electrical Insulation Magazine 5: 28- Defects (MPD 3), Ecole Normale Superieure de cahan, France.

30.

17. Karim ANM, Begum S, Hashmi MSJ (2005) Electrical performance of zinc oxide

4. Gupta TK (1990) Applications of Zinc Oxide Varistors. J Am Ceram Soc 73: varistor using powders processed by different latex binders. The 9th Japan Int

1817-1840. SAMPE Symposium, Tokyo Big Sight, Tokyo, Japan.

5. (1995) Transient Voltage Suppression Devices. Harris Semiconductor, 18. Karim ANM, Hashmi MSJ (2005) Performance of zinc oxide varistor discs

Melbourne, FL, USA. sintered by alternative orientations. ATCi2005, Conference on Advanced

6. Craner DC (1991) Overview of Technical, Engineering, and Advanced Materials, Putrajaya, Malaysia.

Ceramics. Engineered Materials Handbook: Ceramics and glasses. (Vol 4), 19. Karim ANM, Begum S, Hashmi MSJ (2013) Role of Surface to Volume Ratio of

ASM International, OH, USA. Zinc Oxide Arrester Blocks on the Energy Absorption Capability. IOP Conf Ser:

7. Kingery WD (1981) Grain Boundary Phenomena in Electronic Ceramics: Earth Environ Sci 16: 012008.

Advances in ceramics. (Vol. 1), American Ceramic Society, OH, USA.

Submit your next manuscript and get advantages of OMICS

Group submissions

Unique features:

User friendly/feasible website-translation of your paper to 50 worlds leading languages

Audio Version of published paper

Digital articles to share and explore

Special features:

300 Open Access Journals

25,000 editorial team

21 days rapid review process

Quality and quick editorial, review and publication processing

Indexing at PubMed (partial), Scopus, EBSCO, Index Copernicus and Google Scholar etc

Sharing Option: Social Networking Enabled

Citation: Karim ANM, Begum S (2014) Enhanced Performance of Zinc Oxide Authors, Reviewers and Editors rewarded with online Scientific Credits

Arrester by Simple Modification in Processing and Design. J Material Sci Eng Better discount for your subsequent articles

3: 135. doi:10.4172/2169-0022.1000135 Submit your manuscript at: http://www.omicsgroup.org/journals/submission

J Material Sci Eng

ISSN: 2169-0022 JME, an open access journal Volume 3 Issue 1 1000135

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HRM Assignment Final - Case StudyDocument7 pagesHRM Assignment Final - Case StudyPulkit_Bansal_2818100% (3)

- Aluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Document4 pagesAluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Travis WoodNo ratings yet

- Ehv Disconnectors For Smart GridDocument2 pagesEhv Disconnectors For Smart GridTravis WoodNo ratings yet

- Re Voltage StabilityDocument27 pagesRe Voltage StabilityTravis WoodNo ratings yet

- Anandaram BaruaDocument1 pageAnandaram BaruaTravis WoodNo ratings yet

- Transformer Factory Assembly Area LayoutDocument55 pagesTransformer Factory Assembly Area LayoutTravis Wood100% (2)

- Ceramic Manufacturing PDFDocument41 pagesCeramic Manufacturing PDFTravis WoodNo ratings yet

- Gear Design For Quiet Reduction GearDocument8 pagesGear Design For Quiet Reduction GearTravis WoodNo ratings yet

- April Is The Cruellest MonthDocument1 pageApril Is The Cruellest MonthTravis WoodNo ratings yet

- KSEB Technical SPec PDFDocument279 pagesKSEB Technical SPec PDFTravis WoodNo ratings yet

- Double Sampling-Wha It Means PDFDocument17 pagesDouble Sampling-Wha It Means PDFTravis WoodNo ratings yet

- 1363 Bolts and Nut Standard PDFDocument7 pages1363 Bolts and Nut Standard PDFTravis WoodNo ratings yet

- CT Grounding To Avoid Nuisance TrippingDocument2 pagesCT Grounding To Avoid Nuisance TrippingTravis WoodNo ratings yet

- Analysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceDocument7 pagesAnalysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceTravis WoodNo ratings yet

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended Practicesvjs270385No ratings yet

- Unidirectional Corona RingDocument2 pagesUnidirectional Corona RingTravis WoodNo ratings yet

- Study of Single and Double Sampling PlansDocument14 pagesStudy of Single and Double Sampling PlansTravis WoodNo ratings yet

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodNo ratings yet

- 3 Sec-III-Hardware Fittings & AccessoriesDocument49 pages3 Sec-III-Hardware Fittings & AccessoriesTravis WoodNo ratings yet

- Fretting Fatigue in Overhead ConductorsDocument16 pagesFretting Fatigue in Overhead ConductorsTravis WoodNo ratings yet

- ElectricalDocument34 pagesElectricalTravis WoodNo ratings yet

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 pagesEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosNo ratings yet

- Innovative Adhesive For Sandwich SystemsDocument20 pagesInnovative Adhesive For Sandwich SystemsTravis WoodNo ratings yet

- Spacer Damper IssuesDocument5 pagesSpacer Damper IssuesTravis WoodNo ratings yet

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodNo ratings yet

- Anil Agarwal: Research: Mud As A Traditional Building MaterialDocument10 pagesAnil Agarwal: Research: Mud As A Traditional Building MaterialTravis WoodNo ratings yet

- Mud Architecture: I J I R S E TDocument6 pagesMud Architecture: I J I R S E TJazzNo ratings yet

- An Introduction To Conway's Games and NumbersDocument30 pagesAn Introduction To Conway's Games and NumbersSilentSparrow98No ratings yet

- CB Spec SvenskaDocument44 pagesCB Spec SvenskaTravis WoodNo ratings yet

- Bolt InterlocksDocument5 pagesBolt InterlocksTravis WoodNo ratings yet

- Airframe Exam Review QuestionsDocument23 pagesAirframe Exam Review QuestionsbirukNo ratings yet

- Face To Face Pre-Intermediate B1Document162 pagesFace To Face Pre-Intermediate B1Andra OlariNo ratings yet

- CTM Catalogue 2015-2016Document100 pagesCTM Catalogue 2015-2016Anonymous dXcoknUNo ratings yet

- E Requisition SystemDocument8 pagesE Requisition SystemWaNi AbidNo ratings yet

- Schwarzschild Metric and Black Hole HorizonsDocument39 pagesSchwarzschild Metric and Black Hole Horizonsসায়ন চক্রবর্তীNo ratings yet

- It 7sem Unit Ii IotDocument10 pagesIt 7sem Unit Ii IotMaitrayee SuleNo ratings yet

- Rúbrica de composición escritaDocument2 pagesRúbrica de composición escritafrancisco alonsoNo ratings yet

- Limits, Fits and Tolerances: Prof. S. S. PandeDocument31 pagesLimits, Fits and Tolerances: Prof. S. S. PandeM PankajNo ratings yet

- India An Archaeological History Palaeolithic Beginnings To Early Historic Foundations (Dilip K. Chakrabarti) (Z-Library)Document437 pagesIndia An Archaeological History Palaeolithic Beginnings To Early Historic Foundations (Dilip K. Chakrabarti) (Z-Library)soumadri.2023.1301No ratings yet

- IPA Assignment Analyzes New Public AdministrationDocument8 pagesIPA Assignment Analyzes New Public AdministrationKumaran ViswanathanNo ratings yet

- Sea Cities British English Teacher Ver2Document6 pagesSea Cities British English Teacher Ver2Kati T.No ratings yet

- The Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12Document313 pagesThe Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12justice hayfordNo ratings yet

- NACE CIP Part II - (6) Coatings For Industry - (Qs - As)Document23 pagesNACE CIP Part II - (6) Coatings For Industry - (Qs - As)Almagesto QuenayaNo ratings yet

- VLSI Physical Design: From Graph Partitioning To Timing ClosureDocument30 pagesVLSI Physical Design: From Graph Partitioning To Timing Closurenagabhairu anushaNo ratings yet

- 1993 - Kelvin-Helmholtz Stability Criteria For Stratfied Flow - Viscous Versus Non-Viscous (Inviscid) Approaches PDFDocument11 pages1993 - Kelvin-Helmholtz Stability Criteria For Stratfied Flow - Viscous Versus Non-Viscous (Inviscid) Approaches PDFBonnie JamesNo ratings yet

- J05720020120134026Functions and GraphsDocument14 pagesJ05720020120134026Functions and GraphsmuglersaurusNo ratings yet

- A Sample of Directory or Instruction:: World Temperatures February 16Document1 pageA Sample of Directory or Instruction:: World Temperatures February 16eksaNo ratings yet

- Popular Mechanics 2010-06Document171 pagesPopular Mechanics 2010-06BookshebooksNo ratings yet

- 1136 E01-ML01DP5 Usermanual EN V1.2Document11 pages1136 E01-ML01DP5 Usermanual EN V1.2HectorNo ratings yet

- Usage Instructions - Hengro PoolProtect 1 - 5Document3 pagesUsage Instructions - Hengro PoolProtect 1 - 5Brian VisserNo ratings yet

- Media Effects TheoriesDocument6 pagesMedia Effects TheoriesHavie Joy SiguaNo ratings yet

- Cygnus 4plus Operating ManualDocument141 pagesCygnus 4plus Operating Manualdzul effendiNo ratings yet

- Mayan Calendar End Date Sparks Doomsday SpeculationDocument16 pagesMayan Calendar End Date Sparks Doomsday SpeculationElfen RoxanneNo ratings yet

- Vega Plus 69Document3 pagesVega Plus 69yashNo ratings yet

- Tomas Del Rosario College: Department: EDUCATIONDocument12 pagesTomas Del Rosario College: Department: EDUCATIONveehneeNo ratings yet

- Writing A Spooky Setting DescriptionDocument4 pagesWriting A Spooky Setting DescriptionAayan AnjumNo ratings yet

- Transformer Oil Testing: Dissolved Gas AnalysisDocument18 pagesTransformer Oil Testing: Dissolved Gas AnalysisIkhsan LyNo ratings yet

- Demand Performa For Annual DemandDocument10 pagesDemand Performa For Annual DemandpushpNo ratings yet

- I2E: Embedding Innovation as Organizational StrategyDocument11 pagesI2E: Embedding Innovation as Organizational StrategyDeepak PanditNo ratings yet