Professional Documents

Culture Documents

DS100-30C Centurion Brush Seals

Uploaded by

Tanveer Ahmed0 ratings0% found this document useful (0 votes)

67 views2 pagesCenturion Brush Seals

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCenturion Brush Seals

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

67 views2 pagesDS100-30C Centurion Brush Seals

Uploaded by

Tanveer AhmedCenturion Brush Seals

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Centurion Brush Seal

A Better Alternative To Labyrinth Seals

Eatons Centurion Improved Benefits for using the

Brush Seals are very high Centurion Improved

tip speed, high temperature Brush Seals

seals, usually applied in Better seal, means more

the secondary and tertiary efficiently operating

flow paths in gas turbine motor = improved Mean

engines, capable of surface Time Between Repair

speeds up to 1,100 f/s (MTBR)

(feet per second) and

withstanding temperatures The better seal means

up to 1,200F (648C). fuel efficiency, with up to

a .4% specific fuel cost

As a replacement for savings as indicated by

labyrinth leals, brush seals research (AIAA Mahler

evidence 20% to 40% less and Boyles, 1995)

leakage while their bristles

Far less weight

are in optimal condition.

In addition, Centurion

Capability Ranges

Improved Brush Seals

Labyrinth Seal Improved Centurion weigh far less than labyrinth Operating Pressures:

Brush Seal seals and take less axial 100 psid (690 kPa)

cavity space. per stage

Temperature:

Eatons Patented Design Cryogenic to 1,200F

Increases Bristle Life (650C)

Eatons patented design Surface Speeds:

holds the bristle pack in place, Static to 1,100ft/s

preventing deformation and (335m/s)

stiffening, common problems

affecting the longevity of the Radial Excursions:

traditional brush seal. This Up to 0.030in (0.76mm)

Patent Advanced Brush Seal Design

design allows the seal to Sizes:

last longer at an optimal 2 in. to greater than

sealing performance than 40 in. (.05-1.0 meters);

ordinary brush seals. larger diameters for

segmented seals

Eaton

Aerospace Group

Fluid & Electrical Distribution Division

10 New Road Copyright 2013 Eaton

East Providence RI 02916 All Rights Reserved

Phone: (401) 781-4700 Copying or Editing is Forbidden

Fax: (401) 785 4614 Form No. DS100-30C

www.eaton.com/aerospace October 2013

You might also like

- Fire Protection Engineering Summer 2001Document33 pagesFire Protection Engineering Summer 2001Hany RifaatNo ratings yet

- Water Tank Seat Slab DesignDocument2 pagesWater Tank Seat Slab DesignMesfin Derbew100% (2)

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- The Relevance of YS/UTS RatioDocument21 pagesThe Relevance of YS/UTS RatiocarrespmNo ratings yet

- Ef3602 9Document2 pagesEf3602 9AwanNo ratings yet

- Raychem Shrink SleevesDocument12 pagesRaychem Shrink SleevesislamakthamNo ratings yet

- 14 Bernardo Soustruhy deDocument40 pages14 Bernardo Soustruhy deTanase Constantin0% (1)

- Content Analysis in The Social Sciences From Manual To Automated ApproachesDocument75 pagesContent Analysis in The Social Sciences From Manual To Automated Approachesdiablero999No ratings yet

- Tech Trol Gold Synthetic LubricantDocument2 pagesTech Trol Gold Synthetic LubricantAzhar1109No ratings yet

- Datasheet 9068Document1 pageDatasheet 9068Andrzej KonopkaNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Assault RiflesDocument203 pagesAssault Riflessadfafgdsg100% (1)

- Aries: Underground DrillsDocument3 pagesAries: Underground DrillsEmanuel Nicolas Villarruel100% (1)

- Accounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualDocument26 pagesAccounting Principles Ifrs Version Global 1st Edition Weygandt Solutions ManualKimberlyMendezyptr98% (40)

- Description Features and CharacteristicsDocument2 pagesDescription Features and CharacteristicsPranpath NarupantawartNo ratings yet

- FlexPipe Linepipe HT Product Data SheetDocument2 pagesFlexPipe Linepipe HT Product Data SheetSaidNo ratings yet

- Forest: MasterDocument8 pagesForest: MasterPawan ChaturvediNo ratings yet

- Comparison Bet Stds For Rubber TubesDocument2 pagesComparison Bet Stds For Rubber TubesRam SudheerNo ratings yet

- Brochure Brush-SealsDocument9 pagesBrochure Brush-SealsMohamed ElgendyNo ratings yet

- Metaceram 25010: Aluminum Oxide PowderDocument2 pagesMetaceram 25010: Aluminum Oxide PowderTob NisapakulNo ratings yet

- Sub 155787Document6 pagesSub 155787Ian WilliamsonNo ratings yet

- Strenx 700 Brochure Square ENDocument6 pagesStrenx 700 Brochure Square ENEjang GutNo ratings yet

- Espey WD200: Carbon Floating Ring Seals - Shaft SealsDocument5 pagesEspey WD200: Carbon Floating Ring Seals - Shaft SealsJose Vega VelascoNo ratings yet

- Custom Fiberglass Products - Pas-Gon - Israel ExporterDocument2 pagesCustom Fiberglass Products - Pas-Gon - Israel ExporterIsrael ExporterNo ratings yet

- Eps Pipe Section InsulationDocument1 pageEps Pipe Section InsulationAlankar Nana Ambwade/Infrastructure Solutions-MEP/MUMBAINo ratings yet

- Cop 1032 - 9851 2216 01Document1 pageCop 1032 - 9851 2216 01luis delgadoNo ratings yet

- HCVValve DSDocument4 pagesHCVValve DSPriyam KmNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Coromill® Plura Gannet For Hrsa: Optimized Solid End Mill For Plunging in HrsaDocument4 pagesCoromill® Plura Gannet For Hrsa: Optimized Solid End Mill For Plunging in HrsaazharzebNo ratings yet

- Parflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeDocument2 pagesParflex Fluid Conveyance: Temperature, Flexibility, Abrasion and Length ChangeYazad DoctorrNo ratings yet

- Padn I0006 01 (Glass Wool)Document1 pagePadn I0006 01 (Glass Wool)Melih SENTURKNo ratings yet

- Corena S3R 32Document3 pagesCorena S3R 32HANIF AKBARNo ratings yet

- PEDJ0193-04 FINAL - Low ResDocument16 pagesPEDJ0193-04 FINAL - Low ResCarlos Indigoyen LimaymantaNo ratings yet

- Ramax Hh-Eng P 1604 E6Document8 pagesRamax Hh-Eng P 1604 E6venkithankamNo ratings yet

- Rototherm PDFDocument2 pagesRototherm PDFcnaren67No ratings yet

- Use of Electric Downhole Heaters To Prevent Wax Build-Up, Offshore, West AfricaDocument19 pagesUse of Electric Downhole Heaters To Prevent Wax Build-Up, Offshore, West AfricaEnder HernandezNo ratings yet

- CoiledTubing For Downhole ApplicationsDocument20 pagesCoiledTubing For Downhole ApplicationsCarlos Antonio Padra PerezNo ratings yet

- CT String Design Methodology For Extended Reach ApplicationsDocument25 pagesCT String Design Methodology For Extended Reach ApplicationsPheng Kit WongNo ratings yet

- Gunclean-Toftejorg SSt40TDocument2 pagesGunclean-Toftejorg SSt40Tmoe_htwe_1No ratings yet

- Data Sheets Type 4130 Atmospheric Pressure Relief Valves Anderson Greenwood en en 5197938Document8 pagesData Sheets Type 4130 Atmospheric Pressure Relief Valves Anderson Greenwood en en 5197938CarlosAlbertoBerbeoMurallasNo ratings yet

- Firetex FX5120 PDFDocument2 pagesFiretex FX5120 PDFArturo QuispeNo ratings yet

- MetaCeram-25040.. Castollin EutecticDocument2 pagesMetaCeram-25040.. Castollin EutecticAndrés MolinaNo ratings yet

- Case Study - Explora in AustraliaDocument2 pagesCase Study - Explora in AustraliajorgeNo ratings yet

- Grease Ep 2 Data Sheet tcsl0003Document1 pageGrease Ep 2 Data Sheet tcsl0003Abdulwahed alsafanyNo ratings yet

- Success Made Simple.: The New Standard For Hydraulic Hose and FittingsDocument16 pagesSuccess Made Simple.: The New Standard For Hydraulic Hose and FittingsfrancsanchezNo ratings yet

- Petronas Gear MepDocument3 pagesPetronas Gear MepLetíciaMendesNo ratings yet

- MSDS Denso-LT-TapeDocument2 pagesMSDS Denso-LT-TapeEMPATI LUWU TIMURNo ratings yet

- Bitumastic 50 PDSDocument2 pagesBitumastic 50 PDSscriptd_ozd3nNo ratings yet

- Web ProductSheet DiamondWrap 2018 PDFDocument2 pagesWeb ProductSheet DiamondWrap 2018 PDFRiankwnNo ratings yet

- Clock Spring Diamond Wrap BrochureDocument2 pagesClock Spring Diamond Wrap BrochuremuhammadxpNo ratings yet

- Katalog Booster PumpDocument32 pagesKatalog Booster PumpnorsahiramaslazimNo ratings yet

- CATALOGO-Bombas WarrenDocument4 pagesCATALOGO-Bombas Warrenjlrllfn81No ratings yet

- Válvulas Modelo CTDocument5 pagesVálvulas Modelo CTOdlanier José MendozaNo ratings yet

- DCT Data Sheet - TurboRunner v3Document2 pagesDCT Data Sheet - TurboRunner v3Mahmoud MoustafaNo ratings yet

- Brochure PAS VAR Dewatering Pumps English v06Document20 pagesBrochure PAS VAR Dewatering Pumps English v06Maximo MartinezNo ratings yet

- Shell Corena S4 P 100 (En) TDS v1Document3 pagesShell Corena S4 P 100 (En) TDS v1Anonymous oAbjbl4HNo ratings yet

- P10305 TSA Petrochemical LRDocument2 pagesP10305 TSA Petrochemical LRcelonevesNo ratings yet

- Z3500 Pump: Stationary and Truck ApplicationsDocument2 pagesZ3500 Pump: Stationary and Truck ApplicationsCarlos JavierNo ratings yet

- Interthane 990: Long Term Recoatability With AestheticsDocument2 pagesInterthane 990: Long Term Recoatability With AestheticsAndri AjaNo ratings yet

- Emitterline Lime en LeachingDocument2 pagesEmitterline Lime en LeachingvictorNo ratings yet

- The Barmac Deep Rotor Reduces Cost and Increases Tonnage - It's A Fact!Document6 pagesThe Barmac Deep Rotor Reduces Cost and Increases Tonnage - It's A Fact!NismicNo ratings yet

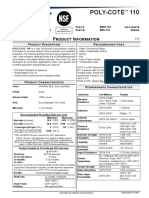

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- P52 - AHP Seals For High PressureDocument2 pagesP52 - AHP Seals For High PressureTrushar GhosalkarNo ratings yet

- Stainless Steel Flow Control Equipment For The Food, Dairy, Beverage, Pharmaceutical, Biotech, Personal CareDocument6 pagesStainless Steel Flow Control Equipment For The Food, Dairy, Beverage, Pharmaceutical, Biotech, Personal CareJuanpablo OXNo ratings yet

- Petronas Disrol 300: Premium Quality 30 TBN Medium Speed Diesel Engine OilsDocument1 pagePetronas Disrol 300: Premium Quality 30 TBN Medium Speed Diesel Engine OilsHazrulnizam HassanNo ratings yet

- K 450 Plus PDFDocument8 pagesK 450 Plus PDFrkssNo ratings yet

- K 450 Plus PDFDocument8 pagesK 450 Plus PDFrkssNo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- 12V 180ah (10hr) : Battery ConstructionDocument2 pages12V 180ah (10hr) : Battery ConstructionTanveer AhmedNo ratings yet

- Blue Dynamic: Order InformationDocument2 pagesBlue Dynamic: Order InformationTanveer AhmedNo ratings yet

- SEP BrochureDocument4 pagesSEP BrochureTanveer AhmedNo ratings yet

- Emergency Lighting: Innovation!Document2 pagesEmergency Lighting: Innovation!Tanveer AhmedNo ratings yet

- Sentry-4412HV: The Sentry-4412HV Is An Industrial Grade Battery Health Monitoring SystemDocument3 pagesSentry-4412HV: The Sentry-4412HV Is An Industrial Grade Battery Health Monitoring SystemTanveer AhmedNo ratings yet

- APC SMART 2200VA SMTiDocument4 pagesAPC SMART 2200VA SMTiTanveer AhmedNo ratings yet

- Invoice SR0012 Narowal Energy Limited (Repair of VFD 150KW)Document2 pagesInvoice SR0012 Narowal Energy Limited (Repair of VFD 150KW)Tanveer AhmedNo ratings yet

- Yuasa SWL 1100Document1 pageYuasa SWL 1100Tanveer AhmedNo ratings yet

- Sentry-4412HV: The Sentry-4412HV Is An Industrial Grade Battery Health Monitoring SystemDocument3 pagesSentry-4412HV: The Sentry-4412HV Is An Industrial Grade Battery Health Monitoring SystemTanveer AhmedNo ratings yet

- Specification: F.V/Time 10MIN 15MIN 30MIN 1HR 2HR 3HR 4HR 5HR 8HR 10HR 20HR 1.60V 1.65V 1.70V 1.75V 1.80V 1.85VDocument2 pagesSpecification: F.V/Time 10MIN 15MIN 30MIN 1HR 2HR 3HR 4HR 5HR 8HR 10HR 20HR 1.60V 1.65V 1.70V 1.75V 1.80V 1.85VTanveer AhmedNo ratings yet

- AppolloDocument2 pagesAppolloTanveer AhmedNo ratings yet

- Specification: F.V/Time 10MIN 15MIN 30MIN 1HR 2HR 3HR 4HR 5HR 8HR 10HR 20HR 1.60V 1.65V 1.70V 1.75V 1.80V 1.85VDocument2 pagesSpecification: F.V/Time 10MIN 15MIN 30MIN 1HR 2HR 3HR 4HR 5HR 8HR 10HR 20HR 1.60V 1.65V 1.70V 1.75V 1.80V 1.85VTanveer AhmedNo ratings yet

- Snap-Action Temperature Controls: 60T SeriesDocument9 pagesSnap-Action Temperature Controls: 60T SeriesTanveer AhmedNo ratings yet

- RA12-120SA: SpecificationDocument2 pagesRA12-120SA: SpecificationTanveer AhmedNo ratings yet

- Kph75 12ne DBDocument2 pagesKph75 12ne DBTanveer AhmedNo ratings yet

- WPL65 12anDocument2 pagesWPL65 12anTanveer AhmedNo ratings yet

- LPX12 100Document2 pagesLPX12 100Tanveer AhmedNo ratings yet

- Inverter Brochure 0924Document1 pageInverter Brochure 0924Tanveer AhmedNo ratings yet

- KPH100 12anDocument2 pagesKPH100 12anTanveer AhmedNo ratings yet

- Kph75 12ne DBDocument2 pagesKph75 12ne DBTanveer AhmedNo ratings yet

- Contactors and Contactor Assemblies: Contactors For Switching Motors SiriusDocument2 pagesContactors and Contactor Assemblies: Contactors For Switching Motors SiriusTanveer AhmedNo ratings yet

- AVR Series Brochure 1257Document1 pageAVR Series Brochure 1257Tanveer AhmedNo ratings yet

- Omron S8JX G BrochDocument4 pagesOmron S8JX G BrochTanveer AhmedNo ratings yet

- Fiamm FLB Battery 2016Document4 pagesFiamm FLB Battery 2016Tanveer AhmedNo ratings yet

- 2V Gel Vrla Battery:Individual Data Sheet Ng2 (Opzv) - 1200: Main Technical Parameters and Environment RequirementsDocument1 page2V Gel Vrla Battery:Individual Data Sheet Ng2 (Opzv) - 1200: Main Technical Parameters and Environment RequirementsTanveer AhmedNo ratings yet

- Active 3000 ChlorideDocument60 pagesActive 3000 ChlorideTanveer AhmedNo ratings yet

- HR 1221W F2: SpecificationDocument2 pagesHR 1221W F2: SpecificationTanveer AhmedNo ratings yet

- BodyTom OnePage Handout 1NL4000-130rev00Document2 pagesBodyTom OnePage Handout 1NL4000-130rev00Tanveer AhmedNo ratings yet

- LP12 24Document2 pagesLP12 24Tanveer AhmedNo ratings yet

- Power Supply Brochure Final - SHDocument4 pagesPower Supply Brochure Final - SHTanveer AhmedNo ratings yet

- Trodat Standard Self Inking Stamp and Accessory Mini CatalogDocument12 pagesTrodat Standard Self Inking Stamp and Accessory Mini CatalogpromotesourceNo ratings yet

- GRT655 GRT655L Product Guide ImperialDocument20 pagesGRT655 GRT655L Product Guide ImperialDanilo UrruchurtoNo ratings yet

- Experience The Latest & Safest in Building Circuit ProtectionDocument28 pagesExperience The Latest & Safest in Building Circuit ProtectionYashwanth KrishnanNo ratings yet

- ORF Issue Brief 309 SpaceLawDocument12 pagesORF Issue Brief 309 SpaceLawNitish KumarNo ratings yet

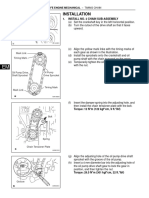

- Sincronizacion de Motor Toyota 2az-FeDocument12 pagesSincronizacion de Motor Toyota 2az-FeWilliams NavasNo ratings yet

- Chapter 5 - Decision Making and LoopingDocument94 pagesChapter 5 - Decision Making and LoopingAcapSuiNo ratings yet

- Homework 1&2 Report EE440Document19 pagesHomework 1&2 Report EE440Võ Hoàng Chương100% (1)

- Workstation-Sub Micro Space PlanDocument21 pagesWorkstation-Sub Micro Space Planarnella_hNo ratings yet

- Commercial Vehicles BrochureDocument20 pagesCommercial Vehicles Brochurebinhtb14No ratings yet

- ECS Florida SOQ - 2018 - FT MyersDocument11 pagesECS Florida SOQ - 2018 - FT MyersPaul BenvieNo ratings yet

- MclogitDocument19 pagesMclogitkyotopinheiroNo ratings yet

- Global Edge Interview ExperienceDocument2 pagesGlobal Edge Interview Experienceshafi hasmaniNo ratings yet

- DE GUZMAN - Module 2 Activity No. 2Document4 pagesDE GUZMAN - Module 2 Activity No. 2Alvin De GuzmanNo ratings yet

- Eco ProductsDocument3 pagesEco Productssreekutty A SNo ratings yet

- Ice Plant TrainerDocument1 pageIce Plant TrainerVirender RanaNo ratings yet

- Memory QVL 3rd Gen AMD Ryzen Processors PDFDocument14 pagesMemory QVL 3rd Gen AMD Ryzen Processors PDFნიკო ქარცივაძეNo ratings yet

- Sand Reclamation - Standard Devices: Shake Out MachinesDocument2 pagesSand Reclamation - Standard Devices: Shake Out MachinesKaarthicNatarajanNo ratings yet

- Emmeskay MIL-SIL TutorialDocument52 pagesEmmeskay MIL-SIL TutorialNeacsu EugenNo ratings yet

- Structural Equation Model : Determinant of Customer Satisfaction and It S Implications On Customer EngagementDocument15 pagesStructural Equation Model : Determinant of Customer Satisfaction and It S Implications On Customer EngagementGSA publishNo ratings yet

- WEdu Abroad - Study Abroad E-GuidebookDocument111 pagesWEdu Abroad - Study Abroad E-GuidebookRithyKhouyNo ratings yet

- Cs9152 DBT Unit IV NotesDocument61 pagesCs9152 DBT Unit IV NotesNivithaNo ratings yet