Professional Documents

Culture Documents

CORE Principles of RCM Compatibility Mode

Uploaded by

freebookman0 ratings0% found this document useful (0 votes)

58 views33 pagesrcm core principles

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentrcm core principles

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

58 views33 pagesCORE Principles of RCM Compatibility Mode

Uploaded by

freebookmanrcm core principles

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 33

CORE Principles of Reliability-

Centered Maintenance

Rich Overman,

Overman CMRP

(904) 655-0787 Cell

Rich@coreprinciplesllc.com

2012 CORE Principles, LLC, all rights reserved 1

Introduction

L

Late

t 1970s

1970 ushered

h d ini a new era off assett

maintenance

United States Department of Defense

published the seminal book entitled

Reliability-Centered Maintenance (RCM)

Entire industries have g

grown from this one

book

Growth brings variability

2012 CORE Principles, LLC, all rights reserved 2

Definition of RCM

a logical discipline for the development of

scheduled maintenance p programs.

g Nolan and

Heap

Reliability-centered

Reliability centered Maintenance: a process used to

determine what must be done to ensure that any

physical asset continues to do what its users wanted

it to do in its present operating context. John

Moubray

2012 CORE Principles, LLC, all rights reserved 3

Definitions of RCM

RCM is the best way to develop a maintenance

improvement program.

program A.M.

A M Smith

RCM uses a cross-functional team to develop a

complete

l t maintenance

i t strategy

t t designed

d i d to t ensure

inherent design reliability for a process or piece of

equipment.

i t Doug

D Pl

Plucknett

k tt

RCM is to identify components whose functional

failures can cause unwanted consequences to ones

plant or facility. Neil Bloom

2012CORE Principles, LLC, all rights reserved 4

Process Variants

Jack Nicholas categorized various RCM

p

processes:

Classical

Variants

Derivatives

Result is RCM has come to mean different

things to different people

2012 CORE Principles, LLC, all rights reserved 5

CORE Principles of RCM

Not presenting:

RCM process

RCM philosophy

Primary or CORE Principles of RCM

Underlying principles upon which all RCM

processes are based.

b d

2012 CORE Principles, LLC, all rights reserved 6

Core Principles of RCM

Components Fail

Operational Impact

Reliability Engineering Solutions

2012 CORE Principles, LLC, all rights reserved 7

Components Fail

Without intervention everything will eventually fail

Each component has failure characteristic

Nolan and Heap identified six failure characteristics

2012 CORE Principles, LLC, all rights reserved 8

Components Fail

Failure characteristic curves basis for all of

the RCM processes

One fundamental principle of RCM is

identification of component failure

characteristic

The

Th goall isi to

t attempt

tt t to

t understand

d t d failure

f il

characteristic to identify appropriate

i t

intervention

ti

2007 CORE Principles, LLC, all rights reserved 9

Failure Characteristics

2012 CORE Principles, LLC, all rights reserved 10

But There is More

It is intuitively obvious that components will fail

It is possible to intervene in some way to try to

pprevent all failures

It is equally intuitively obvious that no company can

afford to try to prevent all failures

The primary purpose of RCM is to identify the

appropriate intervention

Simply recognizing that components fail is not

sufficient

ffi i t

2012 CORE Principles, LLC, all rights reserved 11

Core Principles of RCM

Components Fail

Operational Impact

Reliability Engineering Solutions

2012 CORE Principles, LLC, all rights reserved 12

Operational Impact

Every component failure has some degree of

operational impact

Direct operational impact ranges from shutting

down to none

Indirect operational impact is to drain resources

Every failure requires resources that could be more

efficiently and effectively used to increase company

value

2012 CORE Principles, LLC, all rights reserved 13

Operational Impact

Goal of RCM

evaluate

categorize

Prioritize

understand the operational impact of failure

Identify the appropriate intervention.

intervention

2012 CORE Principles, LLC, all rights reserved 14

But There is More

Components fail

They impact operations

That knowledge, by itself, is not sufficient

to identify appropriate intervention

Need a logical way of organizing and

evaluating

l i information

i f i to make k soundd

intervention decisions

2012 CORE Principles, LLC, all rights reserved 15

Core Principles of RCM

Components Fail

Operational Impact

Reliability Engineering Solutions

2012 CORE Principles, LLC, all rights reserved 16

Reliability Engineering Solutions

Reliability Engineers used analytical

q

techniques for yyears

Failure Modes, Effects, and Criticality Analysis

(

(FMECA) )

Stochastic analyses

Only logical to apply these techniques to the

issue of failure intervention.

2012 CORE Principles, LLC, all rights reserved 17

FMECA

FMECA provides logical method for identifying

failures and evaluating operational impact

Every component failure leads to loss of a function

Loss

oss of

o function

u ct o has

as process

p ocess effect

e ect

FMECA process identifies and documents

Functions

Functional failures

F il

Failure modes

d

Effects of failure at various levels

C i i li analysis

Criticality l i categorizes/prioritizing

i / i i i i failure

f il modes

d

2012 CORE Principles, LLC, all rights reserved 18

FMECA

Importance of FMECA to RCM process cannot be

overstated

Understanding operational impact of failure is

crucial to developing appropriate intervention

a good FMECA will not guarantee a good RCM

analysis but a bad FMECA will guarantee a bad

RCM analysis.

2012 CORE Principles, LLC, all rights reserved 19

Stochastic Analysis

FMECA is great existing Reliability Engineering

tool for understanding operational impact of failures

Not sufficient for developing intervention schemes

FMECA C iss foundation

ou dat o but not

ot eend

d oof RCM

C pprocess

ocess

Stochastic analysis is other Reliability Engineering

tool that needs to be employed

Most common stochastic analysis used in RCM is

Weib l analysis

Weibul anal sis

Weibul analysis can identify failure characteristic

curve applicable

li bl to failure

f il mode

d

2012 CORE Principles, LLC, all rights reserved 20

Relating Failure to Intervention

Failure characteristic defines intervention

Scheduled overhaul/replacement would not work for

infant mortality characteristic

A random

a do failure

a u e characteristic

c a acte st c iss more

o e appropriate

app op ate

for applying a predictive maintenance

A wear out characteristic would benefit from either

a predictive maintenance or overhaul/replacement

intervention

Stochastic techniques provide information to

determine intervention interval

2012 CORE Principles, LLC, all rights reserved 21

Function Preservation

How do I keep

fl id flowing

fluid fl i out

A Classical RCM asks: of tank?

Traditional analysis asks: B

How do I keep the

pump

p p operating?

p g

2012 CORE Principles, LLC, all rights reserved 22

Function Preservation

What are ways to keep How do I keep

fluid flowing out of

fl id flowing

fluid fl i out

A Tank B other than

keeping the pump of tank?

running?

i ?

Bypass valve

Standby pump

B

Keep tank B full enough to

give time to change a failed

pump

With a functional approach

many alternatives are available

2012 CORE Principles, LLC, all rights reserved 23

7 Steps in the RCM Process

1. System Selection

2. Systems Boundary Definitions

3. System Description

4. Identify System Functions &Functional Failures

5. Failure Modes and Effects Analysis (FMEA)

6 Task

6. k Selection

S l i

7. Program Implementation

2012 CORE Principles, LLC, all rights reserved 24

Source: William A. Keeter, MQS and Jack Nicholas

SAE Standard

1. What are the functions, performance standards in the

present operating context? (Function)

2. In what ways does it fail to fulfill its functions? (Functional

failure))

3. What causes each functional failure? (Failure mode)

4. What happens when each failure occurs? (Failure effects)

5. Why does the failure matter (Failure consequences)

6 What can be done to predict or prevent each failure?

6.

7. What should be done if a suitable task cannot be found?

2012 CORE Principles, LLC, all rights reserved 25

Example Analysis Water Jet Machine

Nagging Failures Worn and failed tips

Lots of down time

Cause Dirty Water

Source Versatile Reliability-Centered

Reliability Centered

Maintenance

2012 CORE Principles, LLC, all rights reserved 26

System and Boundaries

2012 CORE Principles, LLC, all rights reserved 27

Water Jet Reclamation System

2012 CORE Principles, LLC, all rights reserved 28

2012 CORE Principles, LLC, all rights reserved 29

2012 CORE Principles, LLC, all rights reserved 30

Water Jet RCM Analysis

7 Functions

14 F

Functional

ti l Failures

F il

47 Failure Modes

8 Inspections

4 Overhaul/discard

1 Failure finding

25 R

Run-to-failure

t f il

Estimated annual savings $334K

2012 CORE Principles, LLC, all rights reserved 31

Conclusion

All RCM processes apply CORE Principles of RCM

Must be applied to identify appropriate failure

intervention

Component failure must be understood

Operational impact assessed

Reliability Engineering tools applied

2012 CORE Principles, LLC, all rights reserved 32

Conclusion

Each RCM process available today applies the CORE

Principles of RCM to varying degree

Degree applied is indicative of overall benefit

If CORE Principles of RCM applied superficially - some

but limited benefit

More rigorous application of the CORE Principles of RCM

- enhanced benefits

Degree to which CORE Principles of RCM are applied

affects

ff cost off analysis

l i

The more a company is willing to invest in RCM the more

b fit they

benefit th can expectt

2012 CORE Principles, LLC, all rights reserved 33

You might also like

- Slides Ch1 PDFDocument45 pagesSlides Ch1 PDFfreebookmanNo ratings yet

- Installation ReadmeDocument14 pagesInstallation ReadmeOmar Buelna GNo ratings yet

- Start-Up and Operating Procedut Execution Plan (PEP)Document5 pagesStart-Up and Operating Procedut Execution Plan (PEP)freebookmanNo ratings yet

- Kendal Optim AdapDocument22 pagesKendal Optim AdapfreebookmanNo ratings yet

- Eula Microsoft Visual StudioDocument3 pagesEula Microsoft Visual StudioqwwerttyyNo ratings yet

- After The Manifold The Fluid Enters The Inlet Separator and Hits An Inlet DiverterDocument3 pagesAfter The Manifold The Fluid Enters The Inlet Separator and Hits An Inlet DiverterfreebookmanNo ratings yet

- Datasheet l298bDocument14 pagesDatasheet l298bgioganNo ratings yet

- Flux Core Arc Welding (FCAW)Document13 pagesFlux Core Arc Welding (FCAW)Ace TobikumaNo ratings yet

- AVR ATMega16Document357 pagesAVR ATMega16orocimaruNo ratings yet

- Read MeDocument6 pagesRead MefreebookmanNo ratings yet

- Transient Response and Steady State ErrorDocument77 pagesTransient Response and Steady State ErrorfreebookmanNo ratings yet

- GameDocument1 pageGamefreebookmanNo ratings yet

- TMMV2UserManual Procurement PDFDocument46 pagesTMMV2UserManual Procurement PDFfreebookmanNo ratings yet

- D3 PrefsDocument1 pageD3 PrefsfreebookmanNo ratings yet

- Simboli Cevovod SD230511-17Document1 pageSimboli Cevovod SD230511-17tekijacNo ratings yet

- Simboli Cevovod SD230511-17Document1 pageSimboli Cevovod SD230511-17tekijacNo ratings yet

- GameDocument1 pageGamefreebookmanNo ratings yet

- LogDocument3 pagesLogichneutaeNo ratings yet

- Listt GameeeDocument1 pageListt GameeefreebookmanNo ratings yet

- ThermodynamicsDocument14 pagesThermodynamicsManoj TiwariNo ratings yet

- AaaDocument1 pageAaafreebookmanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- EN 15232 - BMS For Eficiency of HVAC Buildings PDFDocument87 pagesEN 15232 - BMS For Eficiency of HVAC Buildings PDFStroe George100% (1)

- K1810-13 Sigma A-XT BrochureDocument2 pagesK1810-13 Sigma A-XT BrochureShayan IrevaniNo ratings yet

- A11yprovider LogDocument260 pagesA11yprovider LogAntonella SalasNo ratings yet

- Change 19 Key Essays On How Internet Is Changing Our LivesDocument470 pagesChange 19 Key Essays On How Internet Is Changing Our LivesahcaetanoNo ratings yet

- F5 Training Lab GuideDocument11 pagesF5 Training Lab GuideBrayan Anggita LinuwihNo ratings yet

- Datasheet IC 3771 PDFDocument20 pagesDatasheet IC 3771 PDFekodianirawanto100% (1)

- Bharat Electronics Limited: (A Govt of India Enterprise Under The Ministry of Defence)Document4 pagesBharat Electronics Limited: (A Govt of India Enterprise Under The Ministry of Defence)Sudip MondalNo ratings yet

- Zund Cutter Tutorial - Harvard GSD Fabrication Lab - Harvard WikiDocument13 pagesZund Cutter Tutorial - Harvard GSD Fabrication Lab - Harvard WikiRadoNo ratings yet

- 5G ReadyDocument6 pages5G ReadyRoshan JamesNo ratings yet

- TD100 VDM Installation ManualDocument25 pagesTD100 VDM Installation ManualSumit KumarNo ratings yet

- Industrial Control System (ICS)Document156 pagesIndustrial Control System (ICS)tihitatNo ratings yet

- 2021 UNI-T InstrumentsDocument70 pages2021 UNI-T InstrumentsOdyem SadamNo ratings yet

- Autosar TR SwcmodelingguideDocument57 pagesAutosar TR SwcmodelingguideRadu ButnaruNo ratings yet

- The Ages of Globalization Geography Technology and Institutions by Jeffrey D. SachsDocument316 pagesThe Ages of Globalization Geography Technology and Institutions by Jeffrey D. SachsJesus Rubio50% (2)

- Oracle Reports 10g Ekit PDFDocument760 pagesOracle Reports 10g Ekit PDFykamal7No ratings yet

- Measurement of NPK, Temperature, Moisture, Humidity Using WSNDocument6 pagesMeasurement of NPK, Temperature, Moisture, Humidity Using WSNFajar AnugrahNo ratings yet

- Mixed Signal Electronics IntroductionDocument32 pagesMixed Signal Electronics IntroductionMuhammad Waqas AliNo ratings yet

- FRDM-KE06Z Quick Start Guide (Rev 1.0)Document9 pagesFRDM-KE06Z Quick Start Guide (Rev 1.0)BOLFRANo ratings yet

- World-wide Input Output Power Boost XL120DDocument2 pagesWorld-wide Input Output Power Boost XL120DJavier CastilloNo ratings yet

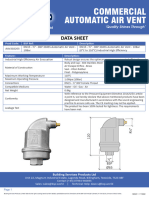

- BSP - Commercial AAV - 10bar - DataSheet - V1.1 - 11-2022Document1 pageBSP - Commercial AAV - 10bar - DataSheet - V1.1 - 11-2022j.iqubalNo ratings yet

- Manual Toshiba 32TL515UDocument102 pagesManual Toshiba 32TL515URené J Izquierdo RNo ratings yet

- Payback2 CHEATus - LuaDocument41 pagesPayback2 CHEATus - LuaDoanh ĐặngNo ratings yet

- Erp KPL Jul16Document192 pagesErp KPL Jul16sriiyer85No ratings yet

- Epp Delivery Format and Personal Provision BRCDocument3 pagesEpp Delivery Format and Personal Provision BRCScribdTranslationsNo ratings yet

- Chris Kapend ResumeDocument3 pagesChris Kapend ResumeChrist KaNo ratings yet

- Ns-Jsra: Risk Type: Risk TypeDocument6 pagesNs-Jsra: Risk Type: Risk TypeMarco MotaNo ratings yet

- Chapter 22 Transport LayerDocument25 pagesChapter 22 Transport LayerAnonymous ey6J2bNo ratings yet

- Resume Amit BhagwatDocument5 pagesResume Amit Bhagwatabh93071046100% (3)

- Cement plant proposalDocument49 pagesCement plant proposalTesfaye Degefa100% (1)

- YOGENDocument1 pageYOGENYogendranNo ratings yet